Have you ever wondered how a lathe works so smoothly? One key to its performance lies in something called gibs. Adjusting the lathe gibs can make a big difference in how well your lathe operates. It might sound complicated, but with the right steps, anyone can learn this essential procedure!

Imagine trying to piece together a puzzle. If the pieces fit perfectly, it’s much easier, right? This is similar to how gibs help align the parts of a lathe. When they’re adjusted correctly, your tools can move freely and smoothly. It’s all about precision!

Did you know that regular gibs adjustment can extend the life of your lathe? It’s true! Taking the time to understand this process can save you money and improve your work. So, are you ready to dive into the lathe gibs adjustment procedure?

Lathe Gibbs Adjustment Procedure: A Step-By-Step Guide

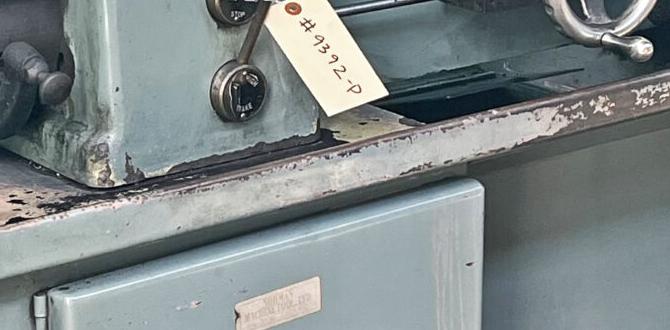

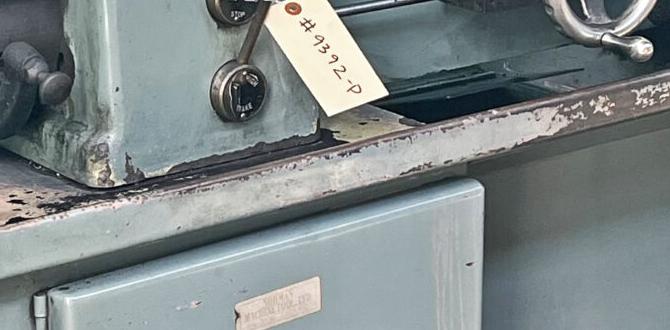

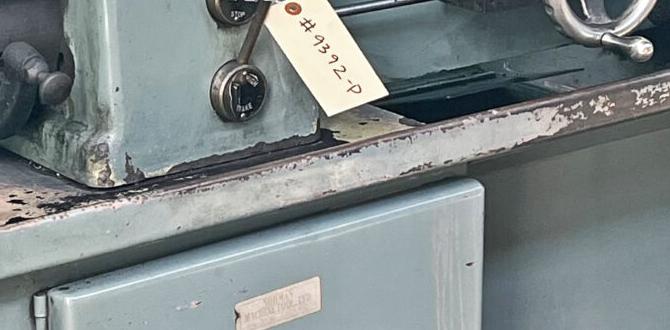

Lathe Gibs Adjustment Procedure

Adjusting lathe gibs is vital for smooth machine operation. Proper alignment helps prevent wear and tear. Start by identifying the gib screws. Loosen them slightly, then move the tool slide. This should ensure it can’t move side to side. Retighten the screws carefully. Did you know that even a small misalignment can cause big problems? Regular adjustments keep your lathe in top shape, enhancing your woodworking or metalwork projects. Happy crafting!Understanding Lathe Gibbs

Definition and purpose of gibs in lathe machinery. Types of gibs used in lathes and their functions.Gibs are like the reliable sidekicks in lathe machinery. They hold key parts in place while letting them move smoothly. Think of gibs as the best friends of your lathe, helping it work its magic without losing balance. There are different types of gibs, and each has a special job. For example, some help adjust tightness, while others keep parts aligned.

| Type of Gib | Function |

|---|---|

| Bearing Gibs | Support and reduce wear |

| Adjustment Gibs | Control movement tightness |

| Compound Gibs | Allow for complex movements |

Knowing about gibs is essential for a well-functioning lathe. So remember, without them, the lathe would wobble around like a penguin on a tightrope!

Importance of Gibs Adjustment

Impact of proper gib adjustment on machining accuracy. Consequences of improper gib settings on lathe operation.Adjusting the gibs is like tuning a musical instrument; it helps the lathe sing in perfect harmony. When the gibs are just right, your machining accuracy improves, leading to smooth and precise cuts. It’s the difference between shaping butter and trying to slice a rock! On the flip side, if the gibs are off, you might face wobbling or uneven cuts that will make you question your skills. Let’s face it; nobody wants a lathe that dances more than works!

| Proper Gib Adjustment | Improper Gib Adjustment |

|---|---|

| Increases machining accuracy | Causes uneven cuts |

| Ensures smooth operation | Leads to machine wobble |

| Extends tool life | Causes tool wear |

Tools Required for Gib Adjustment

Essential tools for performing gib adjustments. Recommended tool brands and models for best results.To adjust the gibs on your lathe, you’ll need some trusty tools. Here’s a simple list: a screwdriver for loosening screws, a wrench to tighten things up, and a feeler gauge to check the gap. Brands like Snap-on and Craftsman make reliable tools that won’t let you down. Now, aren’t tool names fun? They’re like superheroes for your machine! Check the table below for some top tool picks:

| Tool | Recommended Brand | Model |

|---|---|---|

| Screwdriver | Craftsman | 10164 |

| Wrench | Snap-on | F80 |

| Feeler Gauge | Mitutoyo | 182-101 |

Having the right tools makes the job easier. Plus, less chance of losing your sanity – or tools under the lathe! Ready to get adjusting?

Step-by-Step Gib Adjustment Procedure

Detailed steps for adjusting crossslide gibs. Procedures for adjusting carriage gibs. Tips for ensuring consistent adjustments.Adjusting the crossslide gibs helps your lathe run smoothly. First, loosen the screws on the gibs. Next, gently slide the crossslide back and forth. If it feels too loose or tight, adjust the gibs until it glides like a chit-chatting penguin on ice!

For carriage gibs, repeat the process. Start by easing the screws and testing the movement. Remember, the goal is to achieve that sweet spot – just snug enough but not grumpy!

To keep adjustments consistent, use a feeler gauge. It’s like a magic wand that helps you measure gaps. And don’t forget to check yourself like a mirror – adjustments can change over time!

| Adjustment Step | Tip |

|---|---|

| Loosen Screws | Use even pressure! |

| Test Movement | Feel for smoothness! |

| Use a Feeler Gauge | Measure twice, adjust once! |

Common Issues and Troubleshooting

Identifying signs of gib wear or misalignment. Troubleshooting common gibrelated problems during operation.Gibs can wear out or get misaligned, causing problems during lathe operation. You might notice odd sounds, vibrations, or the tool not moving smoothly. These signs can make you think, “Is my lathe part-time job hiding its skills?” Identifying these issues early can save time and energy. Regular checks can help you spot troubles. Here’s a quick table to help you troubleshoot:

| Issue | Possible Cause |

|---|---|

| Tool sticking | Worn gibs or misalignment |

| Strange noises | Loose parts or poor lubrication |

| Poor finish on workpiece | Gib wear or incorrect tension |

Fixing these problems might feel like solving a puzzle. With some patience and knowledge, you can bring that lathe back to its best! Remember, a happy lathe means happy projects!

Maintenance Tips for Lathe Gibbs

Best practices for maintaining gibs to prolong their lifespan. Regular inspection schedules to ensure optimal performance.Taking care of lathe gibs is important for their long life. Here are some tips to help you maintain them:

- Check the gibs often for wear and tear.

- Clean the gibs regularly to remove dust or debris.

- Lubricate the gibs to keep them moving smoothly.

Setting a regular inspection schedule can keep your lathe in good shape. A little care goes a long way!

How often should I check my lathe gibs?

Check your lathe gibs at least once a month. Regular checks can catch small problems before they become big issues.

Advanced Adjustment Techniques

Techniques for finetuning gib adjustments for enhanced precision. Utilizing digital tools for more accurate adjustments.Fine-tuning your lathe gibs can transform your machine’s precision from “meh” to “wow!” One great technique is using digital tools. These gadgets help you measure adjustments with laser-like accuracy. Imagine using an app to get your machine settings just right! You might think, “Why not use a magic wand?” The truth is, digital tools can feel like magic! With just a few tweaks, you can ensure smooth operations and avoid hiccups during your projects.

| Adjustment Technique | Benefit |

|---|---|

| Digital Calipers | Ensures precise measurements |

| Torque Wrench | Prevents over-tightening |

| Software Calibration | Automates adjustment process |

FAQs on Lathe Gibbs Adjustment

Commonly asked questions related to gib adjustments. Expert answers to clarify doubts and improve understanding.Many people have questions about adjusting lathe gibs. Here are some common ones along with their answers:

What are lathe gibs?

Lathe gibs are parts that help keep the machine’s moving parts snug and aligned. They control how tight or loose these movements are.

Why is adjusting gibs important?

Proper adjustments help the lathe work smoothly and safely. If gibs are too tight, it can cause wear and tear. If too loose, it can lead to inaccurate work.

How often should I check my gibs?

You should check them regularly, especially before starting big projects. This ensures everything runs well and safely.

Conclusion

In conclusion, adjusting lathe gibs keeps your machine running smoothly. Follow the steps carefully for the best results. Tighten gibs to eliminate play and loosen them for better movement. Remember, regular checks help maintain accuracy. We encourage you to practice this procedure, and check out more resources for expert tips. Happy machining!FAQs

What Are Lathe Gibs, And What Role Do They Play In The Operation Of A Lathe Machine?Lathe gibs are small parts that help hold other parts tight on a lathe machine. They keep everything steady while we work. This is important because it helps us make smooth and accurate shapes with metal or wood. By adjusting the gibs, we can make the machine work better and last longer.

How Do You Identify When The Gibs On A Lathe Need Adjustment?You can tell the gibs on a lathe need adjustment if the machine feels loose or wobbly while you work. If the tool or part slips out of place easily, that’s another sign. You might also see gaps between the parts or hear strange noises. If you notice these things, it’s time to check the gibs and adjust them.

What Tools And Materials Are Required For Adjusting The Gibs On A Lathe?To adjust the gibs on a lathe, you need a few tools. First, get a wrench to turn the screws. A screwdriver helps too. You might also want some clean cloths to wipe off dust. Lastly, a flashlight can help you see better while you work.

Can Improper Gib Adjustment Affect The Accuracy And Quality Of The Workpiece Produced On A Lathe?Yes, if the gib adjustment is not done right, it can make your work on a lathe messy. The gib helps keep parts tight so they don’t wiggle. If it’s loose, the piece you are making might not be the right shape or size. This means you may have to fix it or start over, which takes more time. So, proper gib adjustment is important for good work.

What Are The Common Techniques Or Methods For Adjusting Lathe Gibs Effectively?To adjust lathe gibs, you can use a few simple methods. First, check for loose screws or bolts and tighten them. Next, you can move the gibs closer to the slide by turning the adjustment screws. Always be careful not to make them too tight. Finally, test the movement to make sure it’s smooth and not too tight or wobbly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are Lathe Gibs, And What Role Do They Play In The Operation Of A Lathe Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe gibs are small parts that help hold other parts tight on a lathe machine. They keep everything steady while we work. This is important because it helps us make smooth and accurate shapes with metal or wood. By adjusting the gibs, we can make the machine work better and last longer.”}},{“@type”: “Question”,”name”: “How Do You Identify When The Gibs On A Lathe Need Adjustment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell the gibs on a lathe need adjustment if the machine feels loose or wobbly while you work. If the tool or part slips out of place easily, that’s another sign. You might also see gaps between the parts or hear strange noises. If you notice these things, it’s time to check the gibs and adjust them.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Required For Adjusting The Gibs On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the gibs on a lathe, you need a few tools. First, get a wrench to turn the screws. A screwdriver helps too. You might also want some clean cloths to wipe off dust. Lastly, a flashlight can help you see better while you work.”}},{“@type”: “Question”,”name”: “Can Improper Gib Adjustment Affect The Accuracy And Quality Of The Workpiece Produced On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, if the gib adjustment is not done right, it can make your work on a lathe messy. The gib helps keep parts tight so they don’t wiggle. If it’s loose, the piece you are making might not be the right shape or size. This means you may have to fix it or start over, which takes more time. So, proper gib adjustment is important for good work.”}},{“@type”: “Question”,”name”: “What Are The Common Techniques Or Methods For Adjusting Lathe Gibs Effectively? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust lathe gibs, you can use a few simple methods. First, check for loose screws or bolts and tighten them. Next, you can move the gibs closer to the slide by turning the adjustment screws. Always be careful not to make them too tight. Finally, test the movement to make sure it’s smooth and not too tight or wobbly.”}}]}