Have you ever felt frustrated when your lathe handwheel doesn’t move smoothly? You’re not alone! Many hobbyists and professionals face the same annoying problem called backlash. This occurs when the handwheel has extra play in the gears, making it hard to get accurate cuts. Imagine trying to shape a piece of wood, only to have your tool drift unexpectedly.

But don’t worry! Fixing lathe handwheel backlash is easier than you think. With some simple steps, you can make your lathe work better. Did you know that a small adjustment can improve accuracy right away? It’s true! People often overlook this quick fix but, once you do it, you’ll notice a huge difference.

In this article, we’ll explore effective methods to minimize that pesky backlash. Whether you’re using a vintage lathe or a modern model, these tips will help you. So, let’s dive in and make your lathe experience smooth and enjoyable!

Lathe Handwheel Backlash Fix: Effective Solutions Explained

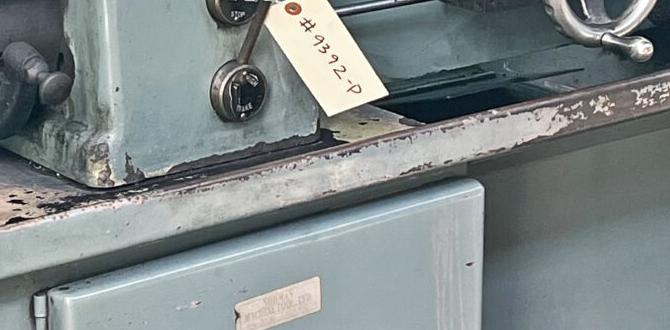

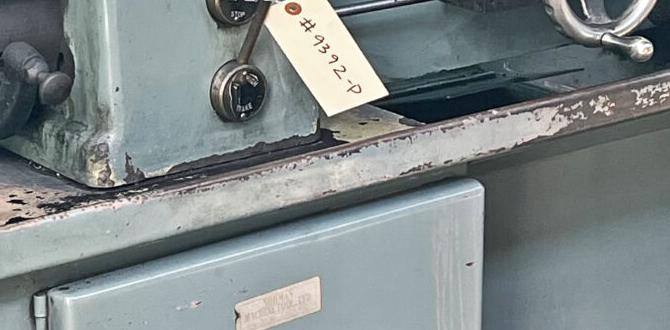

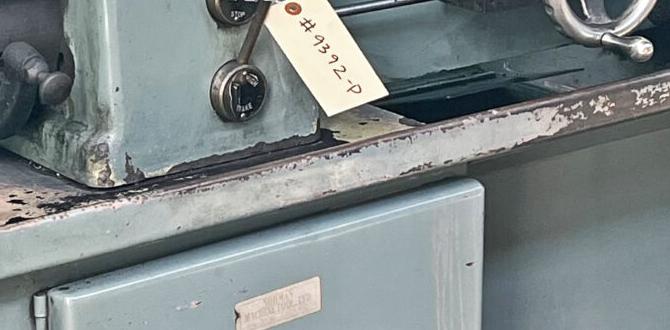

Lathe Handwheel Backlash Fix

Many hobbyists love using lathes, but backlash can be a real problem. It makes precision difficult. Fixing the handwheel’s backlash helps improve accuracy. Try adjusting the bearing or adding shims. You can even use a tension spring for a better grip. Did you know that even small tweaks can greatly enhance your project outcomes? Making these adjustments can make your lathe feel brand new. Enjoy turning with confidence!Understanding Lathe Backlash

Definition of backlash in lathe operations. Causes of backlash in handwheel mechanisms.Backlash in lathe operations is the slight movement that happens when changing direction. It can cause your machine to misalign, leading to mistakes. The handwheel is often the main culprit here. Below are some common causes of backlash:

- Wear and tear on gears

- Loose connections

- Improper installation

These issues can make it hard to get accurate results. Knowing about backlash helps you fix problems faster.

What is the effect of backlash on lathe machines?

Backlash reduces accuracy in cuts and can create uneven surfaces. Users may notice sloppy movements in the machine.How can one reduce backlash?

- Regular maintenance of the lathe

- Adjusting the handwheel mechanisms

- Using anti-backlash devices

Identifying Backlash Issues

Signs of backlash in your lathe. Methods to measure backlash accurately.Backlash can feel like a sneaky gremlin in your lathe. You might notice strange movements in your tool, like it’s doing a little dance instead of cutting smoothly. Common signs include uneven cuts or a delayed response when changing directions. Measuring backlash is as easy as pie—or should I say lathe pie? Use a dial indicator for precision. Place it on the tool holder, then move the handwheel back and forth. The reading will show you how much play exists. Ready to tackle it?

| Signs of Backlash | Measurement Method |

|---|---|

| Uneven cuts | Use a dial indicator |

| Delayed tool response | Move handwheel back and forth |

Common Causes of Handwheel Backlash

Wear and tear of components. Incorrect adjustments and settings.Handwheel backlash can come from several common issues. Wear and tear of components is a big factor. As parts age, they become loose, causing gaps. Also, incorrect adjustments and settings can lead to problems. If the handwheel is not set right, it might move too much or not enough. Regular maintenance and checks can help avoid these issues.

What causes handwheel backlash?

Wear and tear of parts and wrong settings cause handwheel backlash.

- Old or worn-out components can create gaps.

- Wrong adjustments can lead to improper movement.

Tools Needed for Backlash Fix

Essential tools for lathe maintenance. Recommended software or gadgets for diagnostic purposes.To fix lathe handwheel backlash, you need the right tools. Start with some basic items. Here’s a quick list:

- Wrenches

- Screwdrivers

- Calipers

- Dials for measurement

For smart fixes, you may want to use software. This helps check your lathe’s performance and find issues quickly. Some popular options include diagnostics apps that make checking easier.

What tools are best for lathe maintenance?

Essential tools include wrenches, screwdrivers, and calipers. These help keep your lathe in top shape.

Step-by-Step Backlash Adjustment

Procedures for tightening the handwheel mechanism. How to align and calibrate the lathe properly.Tightening the handwheel is key to fixing backlash. Start by locating the adjusting screw on the handwheel. Use a tool to wiggle the handwheel gently. Then, turn the screw clockwise until snug but not too tight. You want it to sing, not squeal! Now, align your lathe by checking the level and adjusting it if needed. A straight lathe equals smooth cuts. Voila! You’re ready to get back to making neat shapes and maybe even a spaghetti holder!

| Step | Action |

|---|---|

| 1 | Locate adjusting screw |

| 2 | Tighten clockwise until snug |

| 3 | Check lathe alignment |

| 4 | Adjust level if necessary |

Preventative Maintenance Tips

Regular inspection schedules. Lubrication techniques to reduce future backlash.Keeping your lathe machine in top shape is important. Regular inspections help spot problems early. Check the handwheel often to see if it moves smoothly. Lubrication can help reduce future backlash. Proper techniques keep parts moving easily. Try these tips:

- Use a light oil for the handwheel.

- Apply grease to other moving parts.

- Clean the machine before lubricating it.

What should I check during regular inspections?

Look for wear and tear on parts, listen for unusual sounds, and test moving parts for smoothness.

Upgrading Lathe Components

When to consider component upgrades. Recommended products for better performance.Upgrading parts of your lathe can improve its performance. It’s wise to consider upgrades if you notice wear and tear. You might also upgrade to increase precision or power. Some recommended products are:

- New Handwheels – They provide better control.

- Improved Bearings – They reduce friction.

- Better Drive Belts – They enhance speed and power.

These upgrades can make your lathe work faster and smoother.

When should you upgrade lathe components?

Consider upgrading when you face issues like vibration and precision loss. Regular maintenance checks help identify these problems early.

Key Signs to Upgrade:

- Inconsistent Cuts – This shows a need for better parts.

- Excessive Noise – Noisy machinery often indicates wear.

- Frequent Breakdowns – If repairs are too common, upgrades help.

Expert Tips and Tricks

Industry secrets for optimal lathe operation. How to manage user expectations regarding backlash.Finding the best ways to run a lathe can be tricky. Here are some expert tips for smooth operation:

- Check your lathe for any loose parts. Tighten them regularly.

- Keep the tool clean. It helps to avoid unexpected problems.

- Lubricate moving parts for better performance.

Managing expectations is key. Backlash might happen; it’s normal. Let users know that precision takes practice. Keeping these points in mind will help everyone enjoy the lathe experience!

How can you reduce backlash on a lathe?

To reduce backlash, regularly adjust the gibs. Tightening them can help lessen play in the handwheel. Also, using a backlash eliminator might be beneficial. Following these steps helps ensure better accuracy.

Frequently Asked Questions

Common queries regarding lathe maintenance. Troubleshooting tips for persistent backlash issues.Many people have questions about taking care of lathes. Here are some common ones:

What is backlash in a lathe?

Backlash is the small gap between gears or parts. This gap can cause the tool to move slightly when you turn the handwheel.

How can I fix lathe backlash?

To reduce backlash, check the following:

- Adjust the handwheel tightly.

- Lubricate moving parts.

- Replace worn gears if needed.

What maintenance helps prevent backlash?

Regular cleaning and lubrication keep your lathe in good shape. This allows smooth movement without much backlash.

Conclusion

In summary, fixing lathe handwheel backlash improves accuracy and makes your work easier. To reduce backlash, you can adjust the handwheel or replace worn parts. Regular maintenance helps keep your lathe in top shape. Try these tips and see the difference it makes! For more details, check out guides or videos on lathe care. Happy lathe working!FAQs

Here Are Five Related Questions On The Topic Of Lathe Handwheel Backlash Fix:To fix the backlash in a lathe handwheel, first, check if the handwheel is loose. If it is, you can tighten the nuts or screws holding it in place. Sometimes, adding a small spacer can help too. It’s also a good idea to clean any dirt or grime around the handwheel. This can help the handwheel move better without any delays.

Of course! Please provide me with the question you’d like answered.

What Are The Common Causes Of Backlash In A Lathe Handwheel, And How Can I Identify Them?Backlash in a lathe handwheel happens when there’s a gap in the parts. Common causes include loose parts, worn gears, or dirty areas. You can identify these problems by feeling for extra movement when you turn the handwheel. If it feels wobbly or moves without changing the tool position, check for tightness and clean dusty spots.

What Methods Can Be Used To Adjust Or Minimize Backlash In A Lathe Handwheel?To reduce backlash in a lathe handwheel, you can tighten the adjusting screws. Start by finding the screws near the handwheel. Then, turn them carefully until the wheel feels snug. You can also add a washer to help fill any gaps. Always test it after making changes to make sure it feels right.

Are There Any Specific Tools Or Materials Recommended For Fixing Backlash In A Lathe Handwheel?To fix backlash in a lathe handwheel, you can use a few tools and materials. A wrench helps to tighten loose parts. You might also need some lubricant to make everything move smoothly. Sometimes, adding small shims can reduce the space that causes backlash. Always have a clean cloth nearby to wipe away any extra grease.

How Can I Determine If My Lathe’S Backlash Is Within Acceptable Limits For Precision Machining?To check your lathe’s backlash, first, move the tool in one direction and then back. Notice how much the tool moves when you change direction. If it moves too much, there might be too much backlash. You can also compare it to the machine’s guidelines to see if it’s okay. If you’re unsure, ask someone experienced for help.

What Maintenance Practices Can Help Prevent Backlash From Developing In A Lathe Handwheel Over Time?To prevent backlash in a lathe handwheel, you should keep it clean. Dust and dirt can make it harder to move. You also need to check the screws and tighten them if they’re loose. Always use the right oil to keep parts smooth. Regularly inspect the handwheel for any damage too.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Handwheel Backlash Fix:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix the backlash in a lathe handwheel, first, check if the handwheel is loose. If it is, you can tighten the nuts or screws holding it in place. Sometimes, adding a small spacer can help too. It’s also a good idea to clean any dirt or grime around the handwheel. This can help the handwheel move better without any delays.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide me with the question you’d like answered.”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Backlash In A Lathe Handwheel, And How Can I Identify Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Backlash in a lathe handwheel happens when there’s a gap in the parts. Common causes include loose parts, worn gears, or dirty areas. You can identify these problems by feeling for extra movement when you turn the handwheel. If it feels wobbly or moves without changing the tool position, check for tightness and clean dusty spots.”}},{“@type”: “Question”,”name”: “What Methods Can Be Used To Adjust Or Minimize Backlash In A Lathe Handwheel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce backlash in a lathe handwheel, you can tighten the adjusting screws. Start by finding the screws near the handwheel. Then, turn them carefully until the wheel feels snug. You can also add a washer to help fill any gaps. Always test it after making changes to make sure it feels right.”}},{“@type”: “Question”,”name”: “Are There Any Specific Tools Or Materials Recommended For Fixing Backlash In A Lathe Handwheel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix backlash in a lathe handwheel, you can use a few tools and materials. A wrench helps to tighten loose parts. You might also need some lubricant to make everything move smoothly. Sometimes, adding small shims can reduce the space that causes backlash. Always have a clean cloth nearby to wipe away any extra grease.”}},{“@type”: “Question”,”name”: “How Can I Determine If My Lathe’S Backlash Is Within Acceptable Limits For Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check your lathe’s backlash, first, move the tool in one direction and then back. Notice how much the tool moves when you change direction. If it moves too much, there might be too much backlash. You can also compare it to the machine’s guidelines to see if it’s okay. If you’re unsure, ask someone experienced for help.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Prevent Backlash From Developing In A Lathe Handwheel Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent backlash in a lathe handwheel, you should keep it clean. Dust and dirt can make it harder to move. You also need to check the screws and tighten them if they’re loose. Always use the right oil to keep parts smooth. Regularly inspect the handwheel for any damage too.”}}]}