Have you ever watched a metal lathe in action? It’s amazing to see how it transforms blocks of metal into precise parts. But did you know that the lathe headstock bearing plays a crucial role in this process? This small part helps the lathe spin smoothly. Without it, everything could come to a halt.

Many makers and hobbyists want their lathes to work like new. They often look into a CNC retrofit. Retrofitting upgrades the machine with newer technology. This can improve accuracy and speed. It’s like giving your old bike a brand new engine!

Imagine creating complex shapes with ease. With a good lathe headstock bearing, you can! Let’s explore how these tiny parts make a big difference in metalworking. You’ll discover why they are essential for any lathe. Get ready to unlock new possibilities for your projects!

Lathe Headstock Bearing: Cnc Retrofit For Metal Lathes

Understanding Lathe Headstock Bearing in CNC Retrofit

Lathe headstock bearings play a crucial role in the metal lathe’s performance. They support the spindle and allow smooth rotation, essential for precision work. Retrofitting a CNC lathe can enhance this performance. It improves accuracy and efficiency, making it easier to create detailed projects. Have you ever thought about how a small part can make such a big difference? Upgrading your lathe isn’t just a change; it’s an investment in your craft.Understanding Lathe Headstocks

Components of a lathe headstock. Importance of headstock in lathe operations.The lathe headstock is key to how the machine works. It holds important parts that help shape materials. Here are its main components:

- **Spindle**: The part that spins the workpiece.

- **Bearing**: Reduces friction and supports the spindle.

- **Motor**: Powers the spindle to create movement.

- **Gearbox**: Changes the speed of the spindle.

The headstock helps make smooth cuts and precise designs. Without it, turning metal or wood would be hard. A strong headstock ensures better results in every project.

What is a lathe headstock?

A lathe headstock is the machine part that drives the workpiece and tools. It is crucial for keeping everything stable during operations.

Signs of Worn Headstock Bearings

Common symptoms indicating bearing wear. Impact of worn bearings on machining accuracy.Worn headstock bearings can show clear signs of trouble. Look out for these key symptoms:

- Unusual noise during operation

- Vibrations that were not there before

- Rough movement in the spindle

- Inaccurate cuts or measurements

These issues can lead to poor machining accuracy. When bearings wear, tool performance suffers. You’ll notice uneven surfaces and misaligned pieces. Remember, early detection makes fixing easier!

What are signs of worn headstock bearings?

Common signs include noises, vibrations, and rough movement. These indicate the bearings may need replacement.

Signs of Worn Bearings:

- Noise during machining

- Inconsistent measurements

- Rough operation

Benefits of CNC Retrofit for Lathe Machines

Increased precision and efficiency. Enhanced functionalities and automation features.Upgrading to a CNC retrofit for lathe machines offers many advantages. First, precision sees a significant boost. You can create parts that fit perfectly every time. This increase in efficiency helps machines finish jobs faster. Also, with the CNC upgrade, you gain powerful automation features. These tools make it easier to operate the machine and reduce human error. Overall, CNC retrofits help improve productivity and quality.

What are the main benefits of CNC retrofits?

The main benefits include increased precision, faster production times, and enhanced automation.

Key Advantages:

- Better precision for accurate parts

- Faster machine operation

- Advanced automation features

Choosing the Right Bearings for CNC Retrofit

Factors to consider when selecting bearings. Comparison of different bearing materials and types.Choosing bearings for a CNC retrofit can be tricky. You need to think about a few things. First, check the size and fit. Next, consider materials like steel or ceramic, as they offer different strengths. Also, think about how much weight they can handle. Here are some factors to keep in mind:

- Size: Bearings must fit properly in the lathe.

- Material: Steel is strong, while ceramic is lighter and can resist heat.

- Load capacity: Ensure they can support your project needs.

Different types of bearings serve various functions. Some last longer, while others provide better speed. Picking the right one can make your CNC retrofit smoother and more efficient!

What should I consider when choosing CNC retrofit bearings?

Consider size, material, and load capacity when choosing bearings. Size ensures a good fit. Material affects strength and weight. Load capacity helps them support your project efficiently.

Common Challenges in Retrofitting

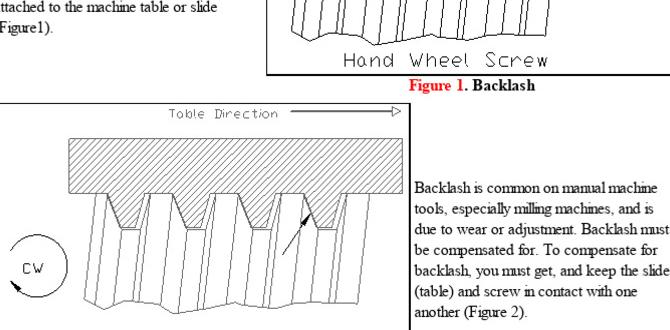

Potential pitfalls and how to avoid them. Tips for troubleshooting issues during retrofit.Retrofitting your metal lathe can feel like assembling a puzzle without the picture. Common challenges pop up, like misaligned parts or incorrect settings. To tackle these bumps, start by checking your measurements twice. It’s always wiser to measure than to guess—“Measure twice, cut once,” right? Trust me, your future self will thank you! If an issue arises, don’t panic. Break the problem down into smaller parts, just like dividing cookies among friends. Here’s a handy troubleshooting guide:

| Issue | Solution |

|---|---|

| Parts won’t fit | Double-check your specs |

| Noise during operation | Lubricate bearings |

| Inaccurate readings | Calibrate tools |

Following these tips can save a lot of time and headaches. Remember, every challenge is just a chance to learn and laugh a little along the way!

Maintenance Tips for Retrofitted Lathe Bearings

Recommended maintenance practices for longevity. Frequency of inspections and servicing.Keeping lathe bearings happy is like giving them a spa day! Regular checks help catch issues early. Aim for inspections every month. Check for dirt, loose parts, and wear. Lubrication is key—think of it as the oil for your favorite frying pan. A clean, well-lubricated bearing can last years, while a neglected one might throw a tantrum. Remember, an ounce of prevention is worth a pound of cure!

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect bearings | Monthly | Look for dirt and damage. |

| Lubricate bearings | Bi-weekly | Add oil like a delicious dressing! |

| Check alignment | Every 3 months | Ensure everything is in line! |

Case Studies: Successful Lathe CNC Retrofits

Examples of lathe upgrades for improved performance. Analysis of results from retrofitted machines.Upgrading a lathe can make a big difference. Many people have succeeded with CNC retrofits. Here are some examples of the upgrades and the results:

- Faster cutting speed with new motors

- More precise designs using advanced software

- Improved efficiency with better bearings

The results often show clear improvements. Machines run smoother and last longer. Many users report up to a 30% increase in output after retrofitting. This not only saves time but also boosts profits.

What are the benefits of upgrading a lathe?

Upgrading a lathe can lead to better performance. It allows for finer details in work. Users can also enjoy reduced noise and better accuracy.

Future Trends in Lathe Technology

Innovations in lathe design and bearing technology. Potential advancements in CNC retrofitting techniques.Lathe technology keeps getting cooler! New designs are popping up, and bearing tech is advancing. Imagine a lathe that runs smoother than a penguin on ice. Companies are exploring CNC retrofitting tricks that will turn your old lathe into a high-tech marvel. Picture this: a lathe that talks back and helps you make stuff like a pro. Exciting times are ahead!

| Innovation Type | Description |

|---|---|

| Design Improvements | New shapes and materials make lathes faster and stronger. |

| Bearing Technology | Better bearings reduce friction and enhance performance. |

| CNC Advancements | New retrofitting options make old machines smart! |

Conclusion

In conclusion, upgrading your lathe with a new headstock bearing can improve performance. A CNC retrofit makes your metal lathe easier to use and more precise. We recommend researching your specific lathe model for the best options. You can also explore guides online for step-by-step instructions. Enjoy enhanced machining and better results with these upgrades!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Cnc Retrofit:A lathe headstock bearing helps the metal lathe spin smoothly. It holds the main part of the lathe, where we attach tools. Upgrading to CNC, which means Computer Numerical Control, makes the lathe even better. It allows for precise cuts without much effort. With these upgrades, our work can be faster and more accurate!

Sure! Please provide the question you would like me to answer.

What Are The Key Considerations When Selecting Bearings For A Lathe Headstock During A Cnc Retrofit?When you pick bearings for a lathe headstock during a CNC retrofit, think about a few important things. First, consider the size of the bearings to make sure they fit correctly. Next, check the load capacity, so they can handle the weight and pressure. You also want to look at the speed rating, because the lathe needs to turn fast. Finally, think about how long the bearings will last, so you don’t have to replace them often.

How Does The Type Of Bearing Used In A Lathe Headstock Affect The Precision And Performance Of Cnc Machining Operations?The type of bearing in a lathe headstock is very important. Bearings help the lathe spindle turn smoothly. When they work well, the lathe can cut materials very precisely. If the bearings are not good, the cuts might be rough or uneven. This means the machine won’t perform as well.

What Steps Are Involved In Retrofitting A Traditional Metal Lathe With Cnc Technology, Particularly In Relation To The Headstock Assembly?To retrofit a traditional metal lathe with CNC, we start by removing the old headstock. This is the part that holds the spinning tool. Next, we install a new headstock with a motor that can be controlled by a computer. We then connect wires from the motor to the computer. Finally, we test everything to make sure it works correctly.

How Can One Identify Signs Of Wear Or Failure In Lathe Headstock Bearings, And What Maintenance Practices Can Extend Their Lifespan?You can look for signs of wear in lathe headstock bearings by listening for unusual noises, like grinding or squeaking. You might also feel vibrations or notice if the lathe isn’t moving smoothly. To keep the bearings working longer, you should clean them regularly and add fresh oil. Check for loose parts and make sure everything is tight. These steps will help the lathe run better and last longer.

What Are The Benefits And Challenges Of Using Upgraded Bearing Materials, Such As Ceramic Or Hybrid Bearings, In A Cnc-Retrofitted Metal Lathe?Upgraded bearing materials, like ceramic or hybrid bearings, can be great for a CNC metal lathe. They help machines run smoother and last longer. This means less time fixing things and more time making cool projects. But they can also be more expensive and harder to find. You might need special tools to replace them too.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Cnc Retrofit:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe headstock bearing helps the metal lathe spin smoothly. It holds the main part of the lathe, where we attach tools. Upgrading to CNC, which means Computer Numerical Control, makes the lathe even better. It allows for precise cuts without much effort. With these upgrades, our work can be faster and more accurate!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations When Selecting Bearings For A Lathe Headstock During A Cnc Retrofit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you pick bearings for a lathe headstock during a CNC retrofit, think about a few important things. First, consider the size of the bearings to make sure they fit correctly. Next, check the load capacity, so they can handle the weight and pressure. You also want to look at the speed rating, because the lathe needs to turn fast. Finally, think about how long the bearings will last, so you don’t have to replace them often.”}},{“@type”: “Question”,”name”: “How Does The Type Of Bearing Used In A Lathe Headstock Affect The Precision And Performance Of Cnc Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of bearing in a lathe headstock is very important. Bearings help the lathe spindle turn smoothly. When they work well, the lathe can cut materials very precisely. If the bearings are not good, the cuts might be rough or uneven. This means the machine won’t perform as well.”}},{“@type”: “Question”,”name”: “What Steps Are Involved In Retrofitting A Traditional Metal Lathe With Cnc Technology, Particularly In Relation To The Headstock Assembly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To retrofit a traditional metal lathe with CNC, we start by removing the old headstock. This is the part that holds the spinning tool. Next, we install a new headstock with a motor that can be controlled by a computer. We then connect wires from the motor to the computer. Finally, we test everything to make sure it works correctly.”}},{“@type”: “Question”,”name”: “How Can One Identify Signs Of Wear Or Failure In Lathe Headstock Bearings, And What Maintenance Practices Can Extend Their Lifespan?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can look for signs of wear in lathe headstock bearings by listening for unusual noises, like grinding or squeaking. You might also feel vibrations or notice if the lathe isn’t moving smoothly. To keep the bearings working longer, you should clean them regularly and add fresh oil. Check for loose parts and make sure everything is tight. These steps will help the lathe run better and last longer.”}},{“@type”: “Question”,”name”: “What Are The Benefits And Challenges Of Using Upgraded Bearing Materials, Such As Ceramic Or Hybrid Bearings, In A Cnc-Retrofitted Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgraded bearing materials, like ceramic or hybrid bearings, can be great for a CNC metal lathe. They help machines run smoother and last longer. This means less time fixing things and more time making cool projects. But they can also be more expensive and harder to find. You might need special tools to replace them too.”}}]}