Have you ever watched a metal lathe in action? It’s fascinating! The whirring sounds and shiny pieces of metal can capture anyone’s attention.

The lathe headstock is a key part of this amazing machine. It holds and spins the workpiece, allowing for precise shaping. But did you know that the headstock needs proper care? One important aspect is the bearing. Without good bearings, your lathe might not work smoothly.

Coolant also plays a vital role here. It keeps the metal cool while cutting. It can prevent damage to both the lathe and the metal you are working with. Imagine trying to cut a hot piece of metal! That would be tough, right?

In this article, we will explore the connection between lathe headstock bearing, metal lathe, and coolant. You’ll learn tips on maintaining your lathe to enhance its performance. Let’s dive into this exciting world of metalworking together!

Lathe Headstock Bearing: Optimal Metal Lathe Coolant Tips

Lathe Headstock Bearing Metal Lathe Coolant

Lathe headstock bearings play a vital role in smoothly operating a metal lathe. Properly lubricated bearings reduce friction and increase the machine’s lifespan. Using coolant is key; it keeps the lathe cool during heavy use, preventing overheating. Did you know that using the right kind of coolant can also improve the finish of your workpiece? Always choose high-quality coolant to enhance performance and achieve better results. Keep your lathe in top shape for flawless machining!What is a Lathe Headstock?

Definition and purpose of the headstock in a lathe.. Key components and their functions within the headstock..A lathe headstock is a key part of a lathe. It holds the motor and other important tools. The headstock spins the workpiece and helps shape it. Some main parts are:

- Spindle: This part holds the workpiece and spins it.

- Drive mechanism: This provides power to the spindle.

- Bearing: These allow smooth spinning and reduce friction.

- Gear system: This changes the speed of the spindle.

By using these parts, the headstock ensures precise work when using a lathe.

Why is the headstock important?

The headstock is important because it helps control the speed and stability of the machine. This leads to better quality work.

The Importance of Bearings in Lathe Headstocks

Types of bearings commonly used in lathe headstocks.. Impact of bearing quality on lathe performance and longevity..Bearings are key components in lathe headstocks. They help the lathe spin smoothly. The quality of these bearings affects how well the lathe works and how long it lasts. Here are some common types of bearings used:

- Ball Bearings

- Roller Bearings

- Plain Bearings

High-quality bearings can make a big difference. They reduce friction and wear. This means a smoother operation and a longer lifespan for your lathe. Investing in the right bearings can save you time and money.

What types of bearings are best for lathe headstocks?

Ball and roller bearings are often the best choices. They provide high efficiency and durability. Plain bearings work too, but may need more maintenance.

Choosing the Right Bearing for Your Metal Lathe

Factors to consider when selecting bearings for lathe headstocks.. Comparison of different bearing materials and designs..Picking the right bearing for your metal lathe can make a big difference. Think about these important factors:

- Load Capacity: Make sure the bearing can handle the weight and force.

- Speed: Some bearings work better at high speeds than others.

- Material: Different materials affect strength and durability.

Here’s a quick look at common bearing materials:

- Steel: Strong and tough, great for heavy use.

- Bronze: Good for low friction, but not as robust.

- Plastic: Lightweight and resistant to rust, but weaker.

Choosing wisely helps your lathe run smoothly and last longer.

What should I consider when selecting a bearing?

Consider load capacity, speed, and material. Each factor affects how well the bearing performs and lasts. Always match the bearing to your specific lathe needs for the best results.

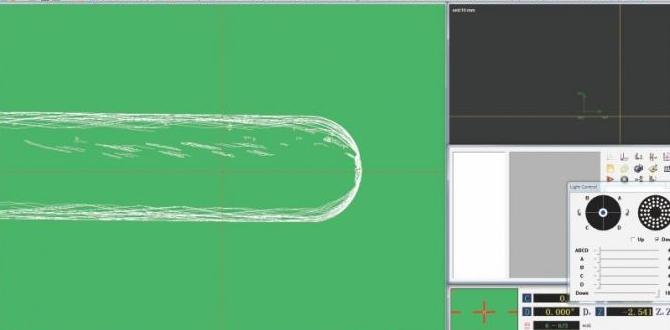

Understanding Metal Lathe Coolant Systems

Explanation of how coolant systems work in metal lathes.. Importance of coolant in the machining process for material properties..Coolant systems play a vital role in metal lathes. They keep tools and materials cool during machining. This helps prevent damage and improves accuracy. Without them, things could get as hot as a sunbather in July! Coolant also helps wash away chips and debris, making work smoother. In short, these systems keep everything cool, clean, and ready to roll!

| Coolant Benefits | Description |

|---|---|

| Temperature Control | Prevents overheating of the tool and workpiece. |

| Chip Removal | Washes away metal shavings and debris. |

| Surface Finish | Improves the quality of the finished product. |

Maintaining Lathe Headstock Bearings and Coolant Systems

Regular maintenance tips for prolonging the life of bearings and coolant systems.. Common issues and troubleshooting tips for bearings and coolantrelated problems..Proper care keeps your lathe running smoothly. Regular maintenance of lathe headstock bearings and coolant systems is crucial. Here are some quick tips:

- Check bearings for wear and tear regularly.

- Replace worn bearings immediately to avoid bigger issues.

- Keep coolant clean and at the right level.

- Flush the coolant system to remove debris.

Common problems can arise in these systems. If you notice unusual noises, it may mean the bearings need attention. Leaking coolant could indicate a blocked line. Always address these issues early to prolong the machine’s life.

What are signs of bearing problems?

Signs of bearing problems include strange noises, excessive heat, and vibration. Checking these signs early can save on repairs.

Upgrading Your Lathe: Bearings and Coolant Enhancements

Benefits of upgrading to highperformance bearings and advanced coolant systems.. Case studies or examples of successful upgrades in metal lathes..Upgrading your bearings and coolant system can feel like giving your lathe a spa day. High-performance bearings keep everything smooth, allowing for better precision and less wear. With advanced coolant systems, your metal lathe stays cool and happy, just like a popsicle on a sunny day. Look at some shops that switched and saw impressive results—like a 30% boost in efficiency. A little upgrade goes a long way!

| Upgrade Component | Benefits |

|---|---|

| High-Performance Bearings | Smoother operation and improved accuracy |

| Advanced Coolant Systems | Better heat management and longer tool life |

Conclusion

In summary, lathe headstock bearings are essential for smooth operation. Using the right coolant keeps your metal lathe running better. It helps reduce heat and wear. Make sure to check your bearings regularly. This simple step can extend the life of your lathe. For more tips, explore online resources or ask experienced users. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Coolant:Sure! A lathe is a machine that shapes metal. It has a part called the headstock. The headstock holds the spinning part and uses bearings to help it spin smoothly. Coolant is a special liquid that keeps things cool and helps the machine work better. You should use it to prevent heat when cutting metal.

Sure! Just let me know the question you want me to answer.

What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe, And How Do They Impact Performance?In the headstock of a metal lathe, we commonly use three types of bearings: plain bearings, ball bearings, and roller bearings. Plain bearings are smooth and simple, helping things spin nicely. Ball bearings use small balls to reduce friction, making them fast and easy to turn. Roller bearings can carry heavy loads better, so they help the lathe work without shaking. All these bearings help the lathe cut metal more smoothly and accurately.

How Does The Choice Of Coolant Affect The Longevity And Maintenance Of Headstock Bearings In Metal Lathes?The type of coolant you use can change how long headstock bearings last. Some coolants keep the parts cool and clean, which helps them work better. Others might create gunk that can harm the bearings. Choosing the right coolant makes it easier to keep your lathe working well and can save you money on repairs. So, always pick a good coolant to help your machine last longer.

What Are The Signs That Headstock Bearings Need Lubrication Or Replacement In A Metal Lathe?You can tell headstock bearings need help if you hear a grinding noise when the lathe runs. If the lathe vibrates more than usual, that’s another sign. You might also notice that it feels harder to turn the machine. If you see any oil leaks, it’s time to check them. Regularly checking these signs keeps your lathe working well!

How Can Improper Coolant Application Lead To Damage In The Headstock Bearings Of A Metal Lathe?Using coolant the wrong way can harm the headstock bearings in a metal lathe. If there’s too much coolant, it can wash away important oil. Without oil, the bearings can get very hot and wear out fast. This can cause the lathe to break or not work well. So, it’s important to use just the right amount of coolant.

What Preventive Measures Can Be Taken To Ensure The Optimal Performance Of Headstock Bearings While Using Coolant In A Metal Lathe?To keep headstock bearings working well with coolant in a metal lathe, you can do a few things. First, make sure to keep the coolant clean. Dirty coolant can harm the bearings. Second, check the levels of the coolant regularly to ensure there’s enough. Finally, use the right type of coolant for your machine, as this helps protect the bearings.