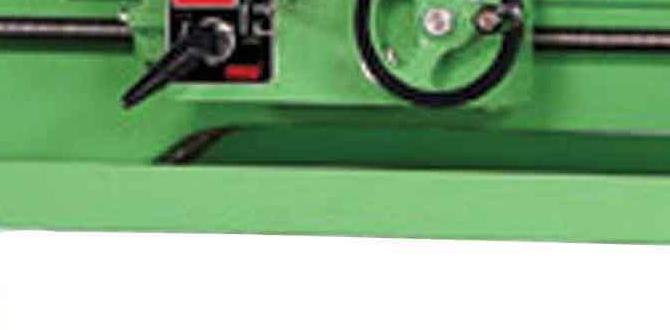

Have you ever wondered how metal lathes work so smoothly? One key part of this magic is the lathe headstock bearing. These bearings play a crucial role in guiding the spindle with precision. Without them, a lathe would struggle to spin properly.

Imagine trying to carve a beautiful design out of metal, but the machine is shaky. That’s where the headstock bearing comes in. It keeps the lathe steady and accurate. But that’s not all. The lead screw also contributes to its smooth operation.

A surprising fact is that these components are often overlooked, yet they are essential. The lead screw allows you to move the cutting tool with ease. Together, the lathe headstock bearing and the lead screw create magic. They help makers turn raw materials into amazing creations.

So, why does this matter to you? Whether you’re a novice or a seasoned pro, understanding these parts can enhance your metalworking journey. Let’s dive deeper into the world of lathe headstock bearings and lead screws!

Lathe Headstock Bearing: Essential For Metal Lathe Lead Screw Functionality When It Comes To Precision Machining, Understanding The Components Of A Metal Lathe Is Crucial. Among These Components, The Lathe Headstock Bearing Plays A Vital Role In Ensuring The Smooth Operation Of The Lead Screw. This Article Will Delve Into The Significance Of The Lathe Headstock Bearing And How It Affects The Performance Of The Metal Lathe Lead Screw, Ensuring Optimal Functionality And Longevity Of Your Equipment. Understanding The Lathe Headstock Bearing The Lathe Headstock Bearing Is A Critical Part Of The Machine That Supports The Spindle And Allows For Smooth Rotation. Proper Function Of The Bearing Is Essential As It Directly Impacts The Performance Of The Lathe. A Well-Maintained Bearing Reduces Friction, Promotes Accuracy In Cutting, And Extends The Service Life Of The Lathe. The Role Of Bearings In Metal Lathe In Metal Lathes, Bearings Can Be Of Various Types, Including Ball Bearings And Roller Bearings. Each Type Offers Different Levels Of Load Capacity And Friction. The Choice Of Bearing Will Depend On The Specific Requirements Of The Machining Task And The Load That The Lathe Will Frequently Endure. How It Affects The Lead Screw The Lead Screw Is Another Fundamental Component In The Operation Of A Metal Lathe, Responsible For Translating The Rotational Movement Of The Headstock Into Linear Movement Along The Axis. If The Lathe Headstock Bearing Is Worn Or Improperly Installed, It Can Lead To Issues Like Backlash Or Play, Which Directly Affects The Precision Of The Lead Screw. Maintaining Optimal Performance To Ensure Your Lathe Headstock Bearing Is Working Efficiently, Regular Maintenance Is Important. This Includes Lubricating The Bearings, Checking For Wear, And Replacing Them When Necessary. Keeping Your Lead Screw Clean And Free From Debris Will Also Contribute To The Overall Performance Of The Lathe. Conclusion In Summary, The Lathe Headstock Bearing Is Crucial For The Effective Operation Of A Metal Lathe Lead Screw. Regular Checks And Maintenance Will Help Maintain The Quality Of Your Machining Projects And Prolong The Lifespan Of Your Equipment. By Understanding The Relationship Between These Components, You Can Ensure Your Lathe Operates At Its Best, Delivering Accurate And Precise Results In Your Machining Tasks.

Understanding Lathe Headstock Bearing and Lead Screw

Lathe headstock bearings provide support and stability for the spindle. This is crucial for smooth operation. Did you know that the lead screw on a metal lathe plays a key role in moving the carriage? This allows for precise cutting of materials. Proper maintenance of these parts is vital. A well-maintained lathe can last for years, helping both hobbyists and professionals achieve amazing results. Curious about how to keep your lathe in top shape?What is a Lathe Headstock Bearing?

Definition and purpose of a lathe headstock bearing. Importance in the overall functioning of a metal lathe.A lathe headstock bearing is a special part of a metal lathe. It helps the spindle spin smoothly. This is important because it supports the weight and movement of the lathe. Without a good bearing, the machine can have problems.

- Definition: A part that supports the spindle.

- Purpose: Ensures smooth spinning and accuracy.

- Importance: Key to the lathe’s overall performance.

When the bearing is strong, it makes work easier and creates better results. Think about trying to ride a bike with a flat tire. It’s tough, right? A good bearing is like a full tire for a lathe.

Why is the lathe headstock bearing important?

The lathe headstock bearing is crucial for smooth operation. It prevents wear and tear on the machine. Better bearings lead to better work!

Types of Lathe Headstock Bearings

Description of different bearing types (e.g., plain, roller). Pros and cons of each type for metal lathes.When it comes to lathe headstock bearings, there are mainly two types: plain and roller bearings. Plain bearings are simple and easy to maintain, but they can wear out faster. On the other hand, roller bearings provide smoother movement and can handle heavier loads but might also cost a bit more. Choosing the right type can make or break your metal lathe experience! Here’s a quick look:

| Type | Pros | Cons |

|---|---|---|

| Plain | Easy maintenance | Wears out faster |

| Roller | Smoother movement | Higher cost |

Think of it like a donut: plain bearings are the classic kind, while roller bearings are like filled ones—better but a bit pricier! Choose wisely!

How Lathe Headstock Bearings Work

Explanation of the mechanics behind headstock bearings. Interaction with other components of the lathe, especially the lead screw.Headstock bearings are special parts of a lathe. They let the spindle turn smoothly. This helps create precise shapes in metal. The bearings reduce friction, making it easier for the lathe to work. The lead screw interacts closely with these bearings. This connection moves the cutting tool along the workpiece. Together, they help the lathe shape metal properly.

- Headstock bearings support the spindle.

- They reduce friction for smoother movement.

- The lead screw aids in tool positioning.

How do headstock bearings affect performance?

Good bearings help the lathe run better. They allow faster and more precise cutting. This is important for quality metalwork.

Common Issues with Lathe Headstock Bearings

Identification of frequent problems encountered. Signs that headstock bearings require maintenance or replacement.Lathe headstock bearings can sometimes throw a wrench in your plans. Common problems include strange noises like grinding or whining, which can sound like a singing cat—unpleasant and not quite right. You might also notice uneven cutting or excessive vibration, like riding a roller coaster blindfolded! To keep things running smoothly, watch for signs like heat buildup or slippage in the lead screw. If your lathe starts misbehaving, it’s time for maintenance or possibly a replacement.

| Problem | Signs | Action Needed |

|---|---|---|

| Noisy Bearings | Grinding or whining sounds | Check and lubricate |

| Vibration | Uneven cutting results | Inspect bearings |

| Heat Build-up | Overheating during use | Replace if necessary |

Maintenance Tips for Lathe Headstock Bearings

Best practices for ensuring longevity and performance. Recommended lubricants and cleaning methods.Keep your lathe headstock bearings in top shape with regular care! First, always use the right lubricants; they keep the bearings smooth and happy. Great oils include mineral oil and lithium grease! Clean them often to remove dirt and grime. A clean lathe is a happy lathe, after all! You can easily wipe away dirt with a soft cloth. Make it a habit, and your lathe will reward you with long-lasting performance.

| Lubricants | Cleaning Methods |

|---|---|

| Mineral Oil | Soft Cloth |

| Lithium Grease | Non-Abrasive Cleaners |

Remember, giving your lathe some love keeps it running like a champ! Always check for wear and replace parts when needed. How long does this take? A few minutes each month! That’s a small price to pay for smooth operations and happy bearings!

Choosing the Right Lead Screw for Your Lathe

Factors to consider when selecting a lead screw. Compatibility with specific headstock bearings.Choosing the right lead screw for your lathe is like picking the perfect ice cream flavor — it matters! You need to think about how the lead screw fits with your lathe’s headstock bearings. Not every screw is created equal! Compatibility is key, or you could end up with a wobbly mess. Make sure you check the size and threading before you dive in. It’s like finding the right puzzle piece; everything should click together smoothly.

| Factor | Details |

|---|---|

| Size | Ensure it matches your lathe’s specifications. |

| Thread Type | Choose a compatible threading pattern. |

| Material | Select one durable enough for your needs. |

Upgrading Your Lathe Headstock Bearings

Reasons for upgrading and what to look for in new bearings. Stepbystep guide to the upgrade process.Upgrading your lathe headstock bearings can work wonders. Worn-out bearings can cause vibrations, leading to uneven cuts. A smooth upgrade brings better performance and precision. Look for bearings made of quality materials and ensure they fit your lathe perfectly. Here’s how to do it:

| Step | Description |

|---|---|

| 1 | Gather tools: You’ll need a wrench, lubricant, and new bearings. |

| 2 | Remove the old bearings: Carefully take them out without damaging the lathe. |

| 3 | Clean the area: Dust and grime don’t play well with new parts! |

| 4 | Install new bearings: Slide them in and add some grease for smooth sailing. |

| 5 | Check alignment: Make sure everything is level before turning it on. |

Smoother operation means fewer headaches. Just think, with great bearings, you’re the Captain of Precision Seas! Smooth sailing ahead!

Impact of Bearing Quality on Machining Precision

How bearing selection influences machining accuracy. Case studies or examples of performance differences.The quality of bearings greatly affects how accurately machines can work. Better bearings allow machines to run smoother. This leads to more precise cuts and shapes. Imagine trying to draw a straight line with a wobbly pencil. It won’t turn out well!

- High-quality bearings support the lead screw better.

- They reduce vibrations during machining.

- This helps keep measurements correct.

In one case, a shop switched to premium bearings. They saw a 20% increase in accuracy. Choosing quality materials truly makes a difference!

Why is bearing selection important for machining accuracy?

Good bearings improve machine stability and precision. This is vital for achieving better overall results.

Factors to consider in bearing selection:

- Material strength

- Load capacity

- Environmental conditions

Frequently Asked Questions (FAQs) about Lathe Headstocks and Lead Screws

Common queries regarding lathe maintenance and performance. Expert answers to enhance reader understanding.Got questions about lathe headstocks and lead screws? You’re not alone! Many folks wonder how to keep their lathes running smoothly. One common question is, “How often should I check my lathe bearings?” The expert advice? Do it every month! Regular checks can save you from big problems later on. Another popular question is, “What should I do if my lead screw is sticking?” Well, a little oiling usually does the trick. If it still sticks, you might need to check for dirt or damage.

| Question | Answer |

|---|---|

| How often to check bearings? | Every month! |

| What if the lead screw sticks? | Try oiling it! |

Conclusion

In conclusion, the lathe headstock bearing and lead screw are vital parts of a metal lathe. They help the machine work smoothly and accurately. Understanding these components improves your skills and projects. If you’re keen on machining, explore more about lathe maintenance. This knowledge will make you a better user and enhance your creations! Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Lead Screw:Sure! A lathe is a machine that cuts metal. The headstock holds important parts, like the bearing. The bearing helps the parts spin smoothly. A lead screw helps move the tool up and down. Together, they help us make precise shapes in metal.

Sure! Please share the question you want me to answer.

What Are The Common Types Of Bearings Used In The Headstock Of A Metal Lathe, And How Do They Affect Machining Precision?In a metal lathe, we often use plain bearings and ball bearings. Plain bearings let the spindle turn smoothly. Ball bearings have little balls inside that help reduce friction. Both types help the machine be more precise, making sure the cuts are smooth and accurate. When the bearings work well, your projects turn out better!

How Can Wear And Tear On The Lead Screw Of A Metal Lathe Impact The Accuracy Of Dimensions In Machined Parts?When the lead screw wears out, it can cause problems. You see, the lead screw helps move the tools on the lathe. If it isn’t smooth, the tools might not cut where we want them to. This means the parts could be the wrong size. So, worn lead screws can make our work less accurate.

What Maintenance Practices Should Be Followed To Ensure Optimal Performance Of The Headstock Bearings In A Metal Lathe?To keep the headstock bearings in a metal lathe working well, you should regularly check the oil level. Make sure you add the right type of oil when it’s low. You should also clean the area often to remove dust and chips. Finally, listen for any unusual sounds, as they can mean something needs fixing. Taking these steps helps your lathe run smoothly!

How Do You Diagnose Common Issues Related To The Lead Screw And Headstock Bearings In A Lathe Setup?To find problems with the lead screw and headstock bearings on a lathe, we can do a few things. First, check if the lead screw turns smoothly. If it feels rough, there might be dirt or damage. Next, listen for any strange noises when you use the lathe. That could mean the bearings are breaking down. Finally, look for any loose parts or vibrations while the machine runs. If you notice anything unusual, it’s time to make repairs.

What Role Does The Lubrication Of Headstock Bearings And Lead Screws Play In The Longevity And Efficiency Of A Metal Lathe?Lubricating headstock bearings and lead screws helps a metal lathe work better and last longer. The lubrication reduces friction, which means parts can move easily. When parts move smoothly, they wear down less over time. This means you can use your lathe for a long time without problems. Keeping things lubricated is important for good performance!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Lead Screw:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that cuts metal. The headstock holds important parts, like the bearing. The bearing helps the parts spin smoothly. A lead screw helps move the tool up and down. Together, they help us make precise shapes in metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Bearings Used In The Headstock Of A Metal Lathe, And How Do They Affect Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe, we often use plain bearings and ball bearings. Plain bearings let the spindle turn smoothly. Ball bearings have little balls inside that help reduce friction. Both types help the machine be more precise, making sure the cuts are smooth and accurate. When the bearings work well, your projects turn out better!”}},{“@type”: “Question”,”name”: “How Can Wear And Tear On The Lead Screw Of A Metal Lathe Impact The Accuracy Of Dimensions In Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the lead screw wears out, it can cause problems. You see, the lead screw helps move the tools on the lathe. If it isn’t smooth, the tools might not cut where we want them to. This means the parts could be the wrong size. So, worn lead screws can make our work less accurate.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure Optimal Performance Of The Headstock Bearings In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the headstock bearings in a metal lathe working well, you should regularly check the oil level. Make sure you add the right type of oil when it’s low. You should also clean the area often to remove dust and chips. Finally, listen for any unusual sounds, as they can mean something needs fixing. Taking these steps helps your lathe run smoothly!”}},{“@type”: “Question”,”name”: “How Do You Diagnose Common Issues Related To The Lead Screw And Headstock Bearings In A Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find problems with the lead screw and headstock bearings on a lathe, we can do a few things. First, check if the lead screw turns smoothly. If it feels rough, there might be dirt or damage. Next, listen for any strange noises when you use the lathe. That could mean the bearings are breaking down. Finally, look for any loose parts or vibrations while the machine runs. If you notice anything unusual, it’s time to make repairs.”}},{“@type”: “Question”,”name”: “What Role Does The Lubrication Of Headstock Bearings And Lead Screws Play In The Longevity And Efficiency Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubricating headstock bearings and lead screws helps a metal lathe work better and last longer. The lubrication reduces friction, which means parts can move easily. When parts move smoothly, they wear down less over time. This means you can use your lathe for a long time without problems. Keeping things lubricated is important for good performance!”}}]}