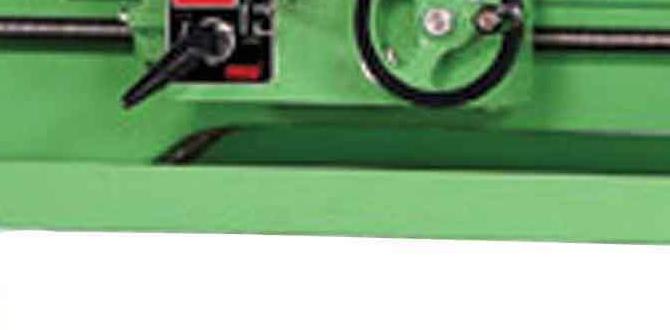

Have you ever wondered how metal lathes work? These machines shape metal into amazing designs. A big part of their success comes from a special piece called the lathe headstock bearing. But what does it do? Think about it like the wheels on your bike. When they roll smoothly, you can ride fast and enjoy the ride. In the same way, the lathe headstock bearing helps the machine move smoothly.

The power feed feature is another cool aspect of metal lathes. It lets the machine work automatically. This means you can focus on other things while it cuts metal. Imagine setting it up and just watching the magic happen!

Did you know that choosing the right lathe headstock bearing can affect what you create? A good bearing leads to better results. It’s like having the right tools for a school project. The right tools make everything easier!

In this article, we will explore how these elements connect. We will dive into the world of metal lathes, their parts, and how they work together. Let’s get started!

Lathe Headstock Bearing: Metal Lathe Power Feed Explained

Understanding Lathe Headstock Bearing and Power Feed

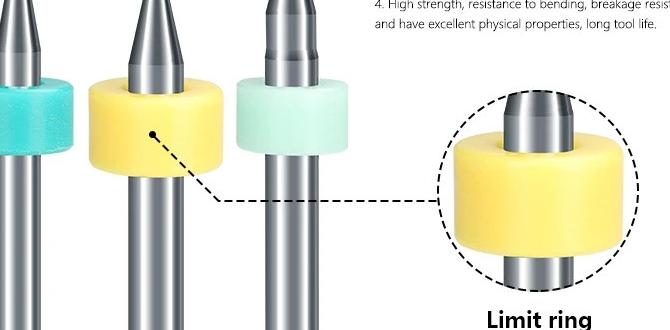

Lathe headstock bearings are crucial for smooth operation on a metal lathe. They support the spindle, allowing it to turn freely at high speeds. Did you know a well-maintained bearing can extend the life of your lathe? Power feed systems enhance your control when working on projects. They enable consistent feeding into the workpiece, improving precision. This combination of bearing quality and power feed functions can elevate your metalworking skills significantly.What is a Lathe Headstock Bearing?

Definition and function of headstock bearing.. Importance in the operation of metal lathes..A lathe headstock bearing is a key part of a metal lathe. It holds the spindle and allows it to turn smoothly. This part is crucial because it affects how well the lathe operates. If the bearing is worn out, it can cause problems like vibrations and uneven cuts.

- It supports the weight of the spindle.

- It keeps the spindle aligned.

- It ensures smooth rotation for better precision.

In short, good headstock bearings are important for a successful lathe operation.

What is the function of a headstock bearing?

The function is to support and stabilize the spindle during rotation.

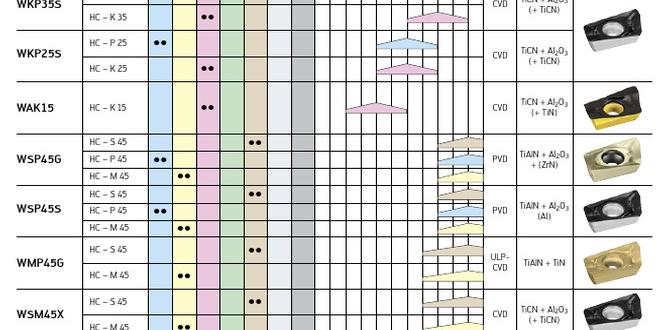

Construction and Design of Headstock Bearing

Key components and materials used in manufacturing bearings.. Design considerations for durability and performance..The headstock bearing is a vital part of a lathe. Its job is to support the spindle, allowing smooth rotation. Key components include inner and outer races, rolling elements, and cages. These are often made from tough materials like steel or ceramics to withstand wear. Designing them for durability means they must handle heavy loads and intense movement. If they fail, your lathe might not work, or worse, it could throw a tantrum! The right design keeps everything spinning safely and efficiently.

| Component | Material |

|---|---|

| Inner Race | Steel |

| Outer Race | Ceramic |

| Rolling Elements | Chrome Steel |

| Cage | Plastic |

How Power Feed Mechanism Works

Explanation of power feed and its role in lathe operation.. Integration of power feed with headstock bearing..The power feed mechanism acts like a little helper for the lathe, making machining easier and faster. It allows the tool to move automatically along the workpiece, saving muscle power and keeping fingers safe. With this nifty setup, the lathe keeps spinning, while the tool does its job. The headstock bearing plays a big role here. It supports the spindle and helps the power feed work smoothly. It’s like a dance party for metal, and everyone needs to do their part!

| Component | Role |

|---|---|

| Power Feed | Automates tool movement |

| Headstock Bearing | Supports spindle rotation |

In a nutshell, when the lathe says, “Let’s groove!” the power feed and headstock bearings work together to keep the show going. Think of it as teamwork—without the right partners, the dance floor might just turn into a big mess!

Common Issues with Lathe Headstock Bearings

Typical problems faced by users (e.g., wear, noise).. Signs of failure and when to consider replacement..Lathe headstock bearings can face problems over time. Users often notice wear, causing changes in performance. Noise is a common sign of trouble. If you hear grinding or unusual sounds, it may be time for a check-up. Watch for these signs:

- Excessive play in the spindle

- Vibration during operation

- Inconsistent speed while cutting

When these issues arise, consider replacement. Ignoring them can lead to bigger problems and more costly repairs.

What are signs of failing lathe headstock bearings?

Signs include increased noise, vibration, and inconsistent performance. Pay attention to changes in how your lathe works.

Maintenance Tips for Lathe Headstock Bearings

Best practices for lubricating and maintaining bearings.. Tips for prolonging the lifespan of bearings in metal lathes..To keep lathe headstock bearings running well, regular lubrication is key. Use high-quality oil to reduce friction. Apply it every few weeks, or more often with heavy use. Clean the bearings regularly to remove dirt and dust. This helps them last longer. Here are some tips for better maintenance:

- Check for wear and tear often.

- Keep parts dry and free from rust.

- Use protectors or covers when not in use.

Following these simple steps will help ensure your bearings work efficiently and last longer.

How often should I lubricate lathe headstock bearings?

You should lubricate lathe headstock bearings every few weeks to keep them in good shape. If you use them a lot, check more often and add oil as needed.

Choosing the Right Headstock Bearing for Your Lathe

Factors to consider when selecting a bearing (size, load capacity).. Recommendations for popular bearing brands/models..Choosing a headstock bearing can feel like picking the right flavor of ice cream. You need to consider the size and load capacity first. The right size ensures it fits your lathe, while load capacity tells you how much weight it can handle without crying out for help. Brands like Timken and SKF have great models to check out. these brands are like the superheroes of the bearing world—tough and reliable!

| Brand | Model | Features |

|---|---|---|

| Timken | HM218210 | High load capacity |

| SKF | 6206-2RS1 | Excellent sealing |

Upgrading Your Metal Lathe’s Headstock Bearing

When and why to consider an upgrade.. Steps to successfully replace or upgrade bearings in a lathe..Upgrading the headstock bearing of your metal lathe can be a game-changer. When you notice signs like noise or vibration, it’s time to consider an upgrade. A smooth lathe makes for smooth projects! To replace the bearings, start by safely removing the headstock. Next, take out the old bearings and clean the area. Finally, fit in new bearings and reassemble your lathe. Voila! Your lathe is ready to spin without those pesky wobbles.

| Signs You Need an Upgrade | Steps to Replace Bearings |

|---|---|

| Noisy operation | 1. Remove the headstock |

| Vibration | 2. Take out old bearings |

| Inconsistent feed | 3. Clean the area |

| 4. Fit in new bearings | |

| 5. Reassemble the lathe |

FAQs about Lathe Headstock Bearings and Power Feed

Commonly asked questions and detailed answers.. Clarifications on misconceptions related to lathe bearings and operation..Many people have questions about lathe headstock bearings and power feeds. Here are some common queries and clear answers to help you understand better.

What is a lathe headstock bearing?

A lathe headstock bearing supports the spindle. It allows smooth rotation and handling of the material being worked on. This part is crucial for accuracy.

How do you know if the bearing is worn out?

If you hear noise or feel vibration during use, it might be time for a check-up. Worn bearings can affect your work and your machine’s performance.

Can bearings be replaced easily?

- Yes, but it requires some skill.

- You need to follow the instructions from your lathe’s manual.

- Using proper tools makes it simpler and safer.

Does a power feed improve performance?

A power feed allows for consistent and even movement. This makes it easier to control cuts and helps achieve better results.

Understanding lathe headstock bearings and power feeds can help you use your lathe more effectively. Keep these tips in mind next time you work on a project!

Conclusion

In summary, the lathe headstock bearing is crucial for smooth power feed. It supports movement and keeps the lathe running well. Understanding its function helps you maintain your equipment better. We recommend checking your lathe’s bearings regularly. For more information, explore online resources or manuals that explain maintenance tips. Keeping your lathe in top shape will improve your projects!FAQs

Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Power Feed:Sure! The lathe headstock is the part of a metal lathe that holds the spinning piece of metal. It helps keep things straight and makes it easier to cut shapes. The bearings in the headstock support the spinning parts and help them move smoothly. Power feed is a feature that automatically moves the cutting tool, making it easier for you to work. This saves you time and helps you make better cuts!

Sure! Please provide the question, and I’ll be happy to help with a short answer.

What Are The Common Types Of Bearings Used In Lathe Headstocks And How Do They Affect The Performance Of The Lathe?Common types of bearings in lathe headstocks are ball bearings and roller bearings. Ball bearings allow smooth spinning and reduce friction. Roller bearings can handle heavier loads without getting too hot. Using good bearings helps the lathe work better and last longer. When bearings are strong, you can make better and more precise cuts in your projects.

How Does The Design Of A Lathe Headstock Influence The Accuracy And Precision Of Machining Operations?The headstock on a lathe holds the part you are working on. Its design helps keep everything steady and in place. When it is strong and well-made, you get better cuts and shapes. This means your work is more accurate and precise. A good headstock helps make sure everything turns smoothly.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Optimal Performance Of Headstock Bearings In A Metal Lathe?To keep headstock bearings in a metal lathe working well, you should do a few key things. First, always check the oil level and add more if it looks low. Next, clean the bearings and remove any dirt or shavings. Also, listen for strange noises when the lathe runs; this can mean a problem. Finally, handle the lathe gently and avoid overloading it to help it last longer.

How Does The Power Feed Mechanism Work In A Metal Lathe, And What Are The Benefits Of Using It Compared To Manual Feeding?The power feed mechanism in a metal lathe uses a motor to move the tools automatically. You set it to control how fast the tool moves. This way, you don’t have to push or pull the tool yourself. Using power feed helps make smoother cuts and keeps the tool steady. It saves you energy and makes your work easier.

What Are The Signs That Indicate A Failure Or Wear Of The Headstock Bearings In A Lathe, And How Can These Issues Be Addressed?You might notice some signs that your lathe’s headstock bearings are not working well. It could make strange noises, feel rough, or vibrate a lot. You may also see uneven marks on the pieces you are making. To fix this, you should stop using the lathe and check the bearings. If they are worn out, it’s best to replace them or ask an adult for help.