If you love working with machines, you probably know about lathes. They are amazing tools that shape metal into different forms. But have you ever thought about what makes a lathe work smoothly? It’s all about the lathe headstock bearing!

The headstock is a vital part of a lathe. It holds the spindle and helps it spin. The bearing inside helps it move freely. Without a good bearing, your metal lathe setup won’t perform well. Imagine trying to ride a bike with a flat tire. It just wouldn’t work right.

Here’s a fun fact: a well-set bearing can make your projects much easier. You can enjoy sharper cuts and cleaner finishes. Have you ever struggled with a project because of a shaky lathe? It’s frustrating, right?

In this article, we will explore how to set up your lathe headstock bearing. You’ll learn tips and tricks that make your setup smoother and more effective. So, let’s dive into the world of lathe headstock bearings and discover how they can improve your metal lathe experience!

Lathe Headstock Bearing: Metal Lathe Setup Essentials

Lathe Headstock Bearing Metal Lathe Setup

Setting up a metal lathe involves understanding its headstock and bearings. The headstock holds the spindle, allowing it to rotate. Proper bearing maintenance is crucial for a smooth operation. Did you know the accuracy of your cuts relies heavily on this setup? Without it, your projects may suffer. Always check alignment and tighten loose parts before starting. A well-maintained lathe can last for years, helping you create amazing projects with ease!Understanding Lathe Headstock Bearings

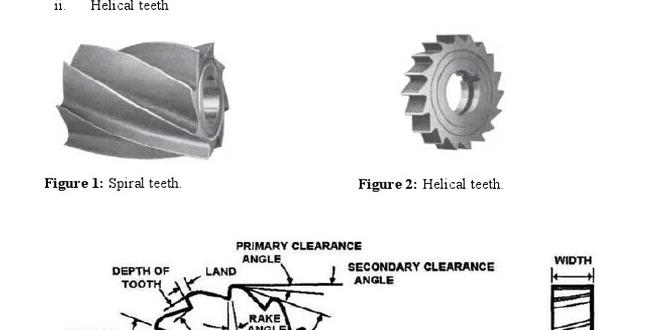

Definition and purpose of headstock bearings in a metal lathe. Types of bearings used in lathe headstocks.Headstock bearings are key players in a metal lathe setup. They help keep the spindle spinning smoothly. Without them, it would be like dancing without any rhythm! There are a few types of bearings used here: plain bearings and ball bearings. Plain bearings are simple and reliable, while ball bearings are speed demons, reducing friction. Choose your fighter wisely!

| Type of Bearing | Characteristics |

|---|---|

| Plain Bearings | Simple construction, low friction. |

| Ball Bearings | High-speed performance, less wear. |

Components of a Lathe Headstock

Key parts of the headstock assembly. Importance of each component in the setup.A lathe headstock has key parts that make the machine work smoothly. The main components include the spindle, the bearings, and the gearbox. The spindle spins the material, while the bearings help it turn without wobbling. Think of them as the best buddies keeping everything aligned. The gearbox controls the speed, allowing you to work on different projects—like turning a block of wood into a fancy snail! Each part is important for a successful setup. If one goes haywire, your lathe might just throw a tantrum!

| Component | Function |

|---|---|

| Spindle | Holds and rotates the workpiece |

| Bearings | Support spindle for smooth movement |

| Gearbox | Controls speed for various tasks |

Selecting the Right Bearings for Your Metal Lathe

Factors to consider when choosing lathe bearings. Popular brands and types of bearings for metal lathes.Choosing the right bearings is important for your metal lathe. It affects how smooth and accurate your work will be. Here are some key things to think about:

- Size: Bearings must fit perfectly in the lathe.

- Material: Look for strong metals like steel.

- Brand: Popular brands include Timken and SKF.

- Type: You can choose between ball bearings and roller bearings.

Different types may perform better for certain jobs, so pick carefully!

What are the best bearing brands for metal lathes?

Some of the top brands for metal lathe bearings are Timken, SKF, and NTN. They are known for strength and reliability. Picking a good brand can make your lathe work smoother and last longer.

Preparing for Metal Lathe Setup

Tools and materials needed for setup. Safety precautions to follow during setup.Setting up your metal lathe is like preparing for a fun adventure. First, gather your tools—like wrenches, screwdrivers, and oil. You’ll also need safety glasses to protect your eyes from flying metal bits. Always wear gloves to keep your hands safe. Remember, safety is key! No one wants to become a human piñata with sharp tools!

| Tools | Safety Gear |

|---|---|

| Wrenches | Safety Glasses |

| Screwdrivers | Gloves |

| Oil | Ear Protection |

Following these steps will make sure your setup goes smoothly and safely. Happy turning!

Step-by-Step Guide to Setting Up a Lathe Headstock Bearing

Detailed instructions for disassembling the headstock. Guidelines for installing and adjusting the bearings.To set up your lathe headstock bearing, start by disassembling the headstock carefully. First, turn off the machine and unplug it. Next, remove any screws or bolts holding the headstock in place. Gently lift it off and set it aside.

Now, for installing and adjusting the bearings:

- Check the old bearings for wear.

- Clean the bearing area well.

- Place new bearings evenly.

- Tighten the screws gently without over-tightening.

- Spin the spindle to check for smoothness.

With these steps, you are on your way to a great setup!

How do I know when to change my lathe bearings?

You should change your lathe bearings when you hear loud noises, feel vibrations, or notice uneven spinning. Regular checks can save you trouble later!

Troubleshooting Common Issues with Lathe Headstock Bearings

Identifying symptoms of bearing issues. Solutions and preventive maintenance tips.When your lathe starts acting up, it’s time to play detective. Common signs of bearing issues include strange noises, vibrations, or overheating. Think of it like your lathe catching a cold—it needs some TLC! To solve these problems, first, check the lubrication and clean the bearings. Regular maintenance is key. Remember, a happy lathe makes for a smoother workspace.

| Symptom | Possible Issue | Solution |

|---|---|---|

| Strange noises | Worn bearings | Lubricate or replace |

| Excessive vibration | Misalignment | Realign or adjust |

| Overheating | Poor lubrication | Check oil levels |

Keep your lathe happy with regular checks. Change the oil and watch for any worn parts. Just like our bodies need exercise, your lathe needs some love, too!

Maintaining Lathe Headstock Bearings for Longevity

Best practices for cleaning and lubricating bearings. Recommended maintenance schedule for optimal performance.To keep your lathe headstock bearings in top shape, regular cleaning and lubrication are key. Clean the bearings with a soft cloth to remove dirt. Use a good lubricant to keep them running smoothly. A good schedule for maintenance is once every month. This helps to prevent wear and tear. Don’t forget to check them often for any unusual noises, which could mean trouble!

How often should I maintain my lathe headstock bearings?

It’s good to check and maintain your bearings every month for the best performance. Performing regular maintenance helps to avoid big problems later.

Best practices include:

- Cleaning bearings with a soft cloth.

- Using quality lubricant for smooth operation.

- Checking for unusual sounds.

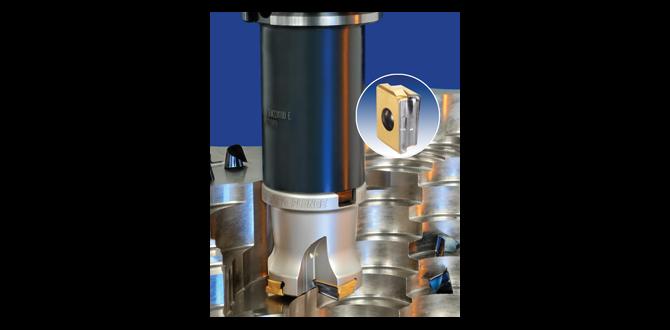

Upgrading Your Lathe Headstock for Improved Performance

Advantages of upgrading bearings or headstock components. How to choose compatible upgrades for your metal lathe.Upgrading your lathe’s headstock can be a game-changer. New bearings can boost precision and reduce vibrations. Who doesn’t want smoother cuts? When selecting parts, consider size and compatibility. A mismatched bearing is about as useful as a chocolate teapot! Check your lathe’s manual or consult online forums for advice. Investing in quality components can lead to better performance and longevity for your metal lathe.

| Upgrade Component | Advantages |

|---|---|

| High-Quality Bearings | Reduce wear and increase accuracy |

| Stronger Headstock | Improves stability during operation |

| Lubrication System | Extends lifespan of components |

Conclusion

In conclusion, the lathe headstock bearing is essential for a smooth metal lathe setup. It supports the spindle and keeps everything aligned. You should regularly check and maintain these bearings for best results. If you’re interested in learning more, consider reading tutorials or watching videos on lathe maintenance. Happy machining—let’s create something amazing!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Setups In Metal Lathes:Sure! A lathe is a tool that helps shape metal. It has parts called headstocks and bearings. Headstocks hold the spinning part, and bearings help it spin smoothly. You need to keep them clean and well-oiled, so everything works right. Taking care of these parts makes your lathe last longer and work better!

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Types Of Bearings Are Commonly Used In Lathe Headstocks, And How Do They Affect Precision And Performance?Lathe headstocks often use plain bearings or ball bearings. Plain bearings are simple and smooth, while ball bearings use tiny balls to reduce friction. Both types help the lathe spin quickly and accurately. When bearings work well, they make your projects more precise and the lathe lasts longer. Choosing the right bearing makes a big difference in how well the lathe performs.

How Do You Properly Align The Headstock Bearings During The Setup Process For Optimal Machining Results?To align the headstock bearings, first, check that they are clean and free of dust. Next, you can gently adjust the bearings until they fit snugly but can still move a little. Use a dial gauge to measure the alignment; it should be very close to zero. Finally, tighten the screws while holding the bearings in place. This helps the machine work better and makes smoother cuts.

What Are The Signs Of Worn Or Damaged Headstock Bearings In A Lathe, And How Can They Be Replaced?You can tell headstock bearings are worn if you hear strange noises or feel roughness when turning the lathe. You might also see extra movement in the spinning parts. To replace them, first, unplug the lathe for safety. Then, take off the headstock cover and carefully remove the old bearings. Finally, put in new bearings and reassemble the lathe.

How Does The Lubrication Of The Headstock Bearings Influence The Overall Operation And Longevity Of The Metal Lathe?Lubricating the headstock bearings keeps them running smoothly. This helps the lathe work better and makes it last longer. When you add oil, it reduces friction, which prevents wear and tear. A well-oiled lathe can make cleaner cuts and help you complete projects faster. So, taking care of the bearings is important for what you build!

What Adjustments Or Modifications Can Be Made To The Lathe Headstock Bearing Setup To Improve Stability And Reduce Vibration During Machining?To make the lathe headstock bearings better, you can tighten them. This helps them hold everything firmly in place. You can also add damping materials, like rubber, to absorb shaking. Keeping the lathe clean and lubricated will also help it run smoothly. These steps will make your work more stable and reduce vibrations.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Setups In Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that helps shape metal. It has parts called headstocks and bearings. Headstocks hold the spinning part, and bearings help it spin smoothly. You need to keep them clean and well-oiled, so everything works right. Taking care of these parts makes your lathe last longer and work better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In Lathe Headstocks, And How Do They Affect Precision And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe headstocks often use plain bearings or ball bearings. Plain bearings are simple and smooth, while ball bearings use tiny balls to reduce friction. Both types help the lathe spin quickly and accurately. When bearings work well, they make your projects more precise and the lathe lasts longer. Choosing the right bearing makes a big difference in how well the lathe performs.”}},{“@type”: “Question”,”name”: “How Do You Properly Align The Headstock Bearings During The Setup Process For Optimal Machining Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the headstock bearings, first, check that they are clean and free of dust. Next, you can gently adjust the bearings until they fit snugly but can still move a little. Use a dial gauge to measure the alignment; it should be very close to zero. Finally, tighten the screws while holding the bearings in place. This helps the machine work better and makes smoother cuts.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Worn Or Damaged Headstock Bearings In A Lathe, And How Can They Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell headstock bearings are worn if you hear strange noises or feel roughness when turning the lathe. You might also see extra movement in the spinning parts. To replace them, first, unplug the lathe for safety. Then, take off the headstock cover and carefully remove the old bearings. Finally, put in new bearings and reassemble the lathe.”}},{“@type”: “Question”,”name”: “How Does The Lubrication Of The Headstock Bearings Influence The Overall Operation And Longevity Of The Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubricating the headstock bearings keeps them running smoothly. This helps the lathe work better and makes it last longer. When you add oil, it reduces friction, which prevents wear and tear. A well-oiled lathe can make cleaner cuts and help you complete projects faster. So, taking care of the bearings is important for what you build!”}},{“@type”: “Question”,”name”: “What Adjustments Or Modifications Can Be Made To The Lathe Headstock Bearing Setup To Improve Stability And Reduce Vibration During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the lathe headstock bearings better, you can tighten them. This helps them hold everything firmly in place. You can also add damping materials, like rubber, to absorb shaking. Keeping the lathe clean and lubricated will also help it run smoothly. These steps will make your work more stable and reduce vibrations.”}}]}