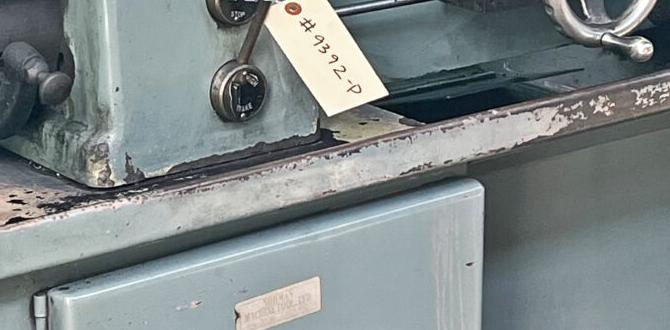

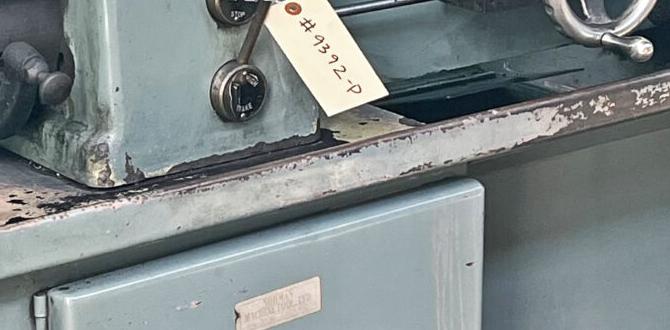

Have you ever wondered how a lathe works? It’s a fascinating tool that can shape and cut metal. But did you know that the headstock bearing is a key part? Proper alignment of the metal lathe tailstock can make all the difference. It helps you create accurate and smooth pieces.

Imagine trying to carve a beautiful statue out of wood. If the tools are not right, the statue might look funny or even break. The same goes for metalworking with a lathe. If the tailstock is misaligned, your work will suffer.

In this article, we’ll explore how to check and fix the alignment of your metal lathe’s tailstock. You’ll learn tips and tricks that can save you time and make your projects easier. Let’s dive into the world of lathes and uncover the secrets to perfect alignment!

Lathe Headstock Bearing: Metal Lathe Tailstock Alignment Guide

Understanding Lathe Headstock Bearing and Tailstock Alignment

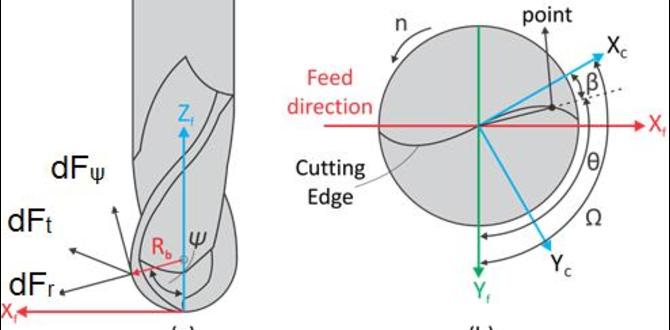

Lathe headstock bearing plays a crucial role in metal lathes. Proper alignment of the tailstock is essential for precision. Imagine trying to cut a straight line but your tool keeps wobbling. Frustrating, right? It’s vital to check these components regularly. Misalignment can lead to poor work quality. Did you know that even a tiny misalignment can ruin a project? Keeping the lathe well-adjusted ensures smooth operation and great results every time.What is a Lathe Headstock Bearing?

Definition and role in lathe performance. Types of bearings used in metal lathes.A lathe headstock bearing is a key part of a lathe machine. It’s the unsung hero that helps keep everything running smoothly. Without it, your projects might go “wobble” instead of “wow”! There are several types of bearings used in metal lathes, including ball bearings and roller bearings, which help support the spinning spindle and ensure precise movements. Here’s a quick rundown:

| Type of Bearing | Role |

|---|---|

| Ball Bearings | Provide smooth rotation |

| Roller Bearings | Handle heavy loads |

These bearings play a huge role in lathe performance. Choosing the right one is like picking the best pizza topping; it makes a big difference!

Common Issues with Headstock Bearings

Symptoms of bearing wear or misalignment. Impact on machining quality.Worn or misaligned headstock bearings can create noticeable problems. Common signs include unusual sounds, uneven movement, and poor finish on your workpiece. These issues can affect machining quality by leading to inaccurate cuts and reduced tool life. Addressing bearing issues quickly can save time and effort.

What are the signs of bearing wear or misalignment?

Symptoms include:

- Noisy operation

- Vibration during use

- Difficulty in movement

How does bearing wear impact machining quality?

Poor bearing condition can lead to:

- Inaccurate cuts

- Poor surface finish

- Shorter tool life

Tailstock Alignment Challenges

Reasons for misalignment in tailstock. Signs that indicate an alignment issue.Misalignment in the tailstock can happen for a few reasons. One common issue is wear and tear from regular use. Another reason might be improper setup when first aligning it. If you notice uneven cuts or difficulty while machining, these could signal an alignment problem. Also, check for:

- Loose bolts

- Worn bearings

- Damaged parts

Keeping an eye on these signs can help you maintain your lathe properly.

What are the signs of tailstock misalignment?

Signs of tailstock misalignment include poor cut quality and increased vibration during operation. These issues often mean it’s time to realign your tailstock.

Steps to Check Tailstock Alignment

Tools and instruments required for alignment check. Stepbystep guide to assess tailstock alignment.To check your tailstock alignment, gather a few key tools. You will need a dial indicator, a straight edge, and a wrench. First, set the dial indicator on the tailstock and align it with the spindle. Next, use the straight edge against the bed. Check the reading on the dial indicator. Adjust the tailstock if needed, and repeat until you get a perfectly aligned reading. This ensures smooth operation for your lathe.

What tools do you need for tailstock alignment?

You need a few essential tools: dial indicator, straight edge, and wrench. These tools help you measure and adjust accurately.

Steps for checking tailstock alignment:

- Set the dial indicator on the tailstock.

- Align it with the spindle.

- Use the straight edge against the bed.

- Check the dial reading.

- Adjust accordingly and repeat.

Adjusting Tailstock Alignment

Techniques for correcting alignment issues. Importance of regular maintenance and adjustment.Alignment issues with your tailstock can cause problems. Luckily, there are techniques to fix these problems. First, check the alignment by using a test bar or dial indicator. Make small adjustments until it’s just right. Regular maintenance is important, too. Check the bearings and adjust frequently.

- Use a dial gauge for precise measurements.

- Inspect and clean the tailstock frequently.

- Lubricate parts to keep them moving smoothly.

By taking care of your metal lathe, you can ensure it runs well and lasts longer.

What should I check for tailstock alignment?

Check if the tailstock is perpendicular to the bed. Ensure the center height matches the spindle center. A level tailstock helps improve accuracy.

How often should I adjust my tailstock?

It’s best to check alignment every week during regular use. Regular checks keep your lathe performing well.

The Relationship Between Headstock Bearings and Tailstock Alignment

How bearing stability affects tailstock precision. Interdependence of headstock and tailstock components.The headstock bearings play a vital role in keeping everything stable. If they’re too loose or worn out, the tailstock can go a bit wobbly. This wobble means precision goes out the window. Picture trying to balance a spoon on your nose – not easy, right? The headstock and tailstock work like a dance team. If one partner stumbles, the other feels it too. Thus, keeping those bearings in tip-top shape is key!

| Component | Effect on Tailstock |

|---|---|

| Headstock Bearings | Affects stability |

| Tailstock | Requires precision |

Best Practices for Maintenance and Alignment

Routine checks and preventative measures. Recommended maintenance schedules and tips.To keep your lathe running smoothly, perform routine checks often. Look for wear and tear, and ensure everything is aligned properly. Remember, an ounce of prevention is worth a pound of cure! It helps to have a maintenance schedule. Aim for tasks like cleaning and lubrication every month. Also, consider checking the tailstock alignment regularly to avoid pesky issues later. After all, a happy lathe means a happy user!

| Maintenance Task | Frequency |

|---|---|

| Clean Lathe | Weekly |

| Lubricate Moving Parts | Monthly |

| Tailstock Alignment Check | Every 3 Months |

Conclusion

In conclusion, proper alignment of your lathe headstock and tailstock is crucial for accurate machining. Check the bearings regularly for wear and tear. You can achieve better results by ensuring everything is aligned correctly. Take time to learn about your lathe’s setup. For more help, look for guides or videos online. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Tailstock Alignment:Sure! Here are some answers to the topic about a lathe. 1. The headstock is the part of the lathe that holds the motor and tool. Its bearing helps it spin smoothly. 2. A metal lathe helps shape metal into different forms. You can make parts for machines or tools with it. 3. The tailstock helps hold items in place on the lathe. It’s important to line it up so everything cuts evenly. 4. You can check if the tailstock is aligned by using a ruler. Make sure it matches up with the headstock for good results. 5. Regularly checking the bearings in the headstock is important. It helps your lathe work better and last longer.

Sure! Just let me know the question you want me to answer.

What Are The Key Indicators That Suggest Misalignment Between The Lathe Headstock And Tailstock?If the lathe headstock and tailstock are not aligned, you might see wobbly pieces when they spin. You may also notice uneven cuts or marks on the wood. If your tools are harder to use or don’t fit well, that’s another sign. Finally, listen for strange sounds, like grinding or rubbing, while the lathe is on. These signs mean something is wrong with the alignment.

How Can You Accurately Measure And Adjust The Alignment Of The Tailstock On A Metal Lathe?To check the tailstock on a metal lathe, we can use a test bar. First, put the test bar in the tailstock and make it spin. Then, watch how much it wobbles. If it wobbles too much, we can adjust the tailstock by loosening a few screws and moving it until it spins straight. Finally, tighten the screws again to keep it in place.

What Role Do Headstock Bearings Play In Ensuring The Precision And Stability Of A Metal Lathe During Operation?Headstock bearings help the metal lathe spin smoothly and stay stable. They support the part that holds the cutting tool. When the bearings work well, you get better cuts and more precise shapes. If they wear out, the lathe can vibrate and make uneven shapes. So, good bearings are important for making things accurately!

What Common Issues Can Arise From Improper Alignment Between The Headstock And Tailstock, And How Can They Impact The Machining Process?When the headstock and tailstock are not lined up, it can cause problems. Your tool might cut unevenly, making surfaces rough. This can also lead to parts getting stuck or breaking. You may end up wasting time fixing mistakes instead of making good parts. So, proper alignment is really important for smooth machining.

What Maintenance Practices Can Be Implemented To Ensure The Longevity And Accuracy Of Headstock Bearings On A Metal Lathe?To keep the headstock bearings on a metal lathe working well, we should check them often. Make sure they are clean and free of dirt. You can use oil to keep them moving smoothly. If you notice any sounds or issues, fix them right away. Regularly tightening any loose parts also helps them last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers to the topic about a lathe. 1. The headstock is the part of the lathe that holds the motor and tool. Its bearing helps it spin smoothly. 2. A metal lathe helps shape metal into different forms. You can make parts for machines or tools with it. 3. The tailstock helps hold items in place on the lathe. It’s important to line it up so everything cuts evenly. 4. You can check if the tailstock is aligned by using a ruler. Make sure it matches up with the headstock for good results. 5. Regularly checking the bearings in the headstock is important. It helps your lathe work better and last longer. “}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Indicators That Suggest Misalignment Between The Lathe Headstock And Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe headstock and tailstock are not aligned, you might see wobbly pieces when they spin. You may also notice uneven cuts or marks on the wood. If your tools are harder to use or don’t fit well, that’s another sign. Finally, listen for strange sounds, like grinding or rubbing, while the lathe is on. These signs mean something is wrong with the alignment.”}},{“@type”: “Question”,”name”: “How Can You Accurately Measure And Adjust The Alignment Of The Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the tailstock on a metal lathe, we can use a test bar. First, put the test bar in the tailstock and make it spin. Then, watch how much it wobbles. If it wobbles too much, we can adjust the tailstock by loosening a few screws and moving it until it spins straight. Finally, tighten the screws again to keep it in place.”}},{“@type”: “Question”,”name”: “What Role Do Headstock Bearings Play In Ensuring The Precision And Stability Of A Metal Lathe During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Headstock bearings help the metal lathe spin smoothly and stay stable. They support the part that holds the cutting tool. When the bearings work well, you get better cuts and more precise shapes. If they wear out, the lathe can vibrate and make uneven shapes. So, good bearings are important for making things accurately!”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise From Improper Alignment Between The Headstock And Tailstock, And How Can They Impact The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the headstock and tailstock are not lined up, it can cause problems. Your tool might cut unevenly, making surfaces rough. This can also lead to parts getting stuck or breaking. You may end up wasting time fixing mistakes instead of making good parts. So, proper alignment is really important for smooth machining.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Ensure The Longevity And Accuracy Of Headstock Bearings On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the headstock bearings on a metal lathe working well, we should check them often. Make sure they are clean and free of dirt. You can use oil to keep them moving smoothly. If you notice any sounds or issues, fix them right away. Regularly tightening any loose parts also helps them last longer.”}}]}