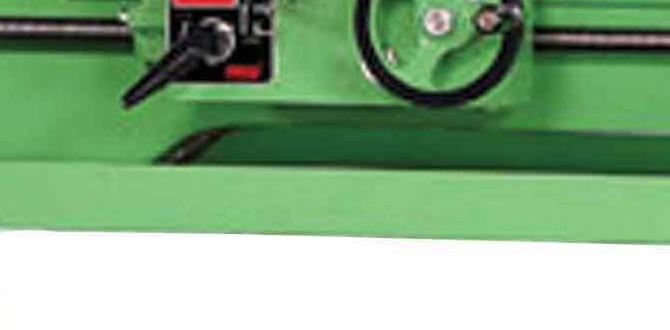

Have you ever wondered how metal lathe tools work? Many people find them fascinating. One of the key parts of these amazing machines is the lathe headstock bearing.

The headstock is like the brain of the lathe. It holds the spindle and lets it spin smoothly. Without good bearings, this spinning would be rough and noisy. They help the tools cut metal cleanly and precisely.

It’s surprising how such a small part makes a big difference. Imagine trying to ride a bike with a wobbly wheel. It would be hard to steer! Similarly, bad bearings can ruin your projects.

In this article, we will explore how lathe headstock bearings work. We will also discuss the best metal lathe tools you can use. Get ready to dive into the world of metalworking!

Lathe Headstock Bearing: Essential Metal Lathe Tools Explained

Lathe Headstock Bearing Metal Lathe Tools

Understanding lathe headstock bearings is crucial for anyone using metal lathe tools. These bearings support the spindle, ensuring smooth rotation. A well-maintained bearing improves precision and extends the lathe’s life. Did you know that worn bearings can lead to costly repairs? Regular checks can save time and money. Proper lubrication is key as it reduces friction. Explore the different types of bearings to find what suits your needs best!What is a Lathe Headstock Bearing?

Definition and purpose of headstock bearings in metal lathes. Different types of bearings used in lathe headstocks.A lathe headstock bearing is a key part of metal lathes. It supports the spindle, letting it spin smoothly. This helps create precise shapes in metal. Without the bearing, your lathe would be like a car with square wheels—not going anywhere fast!

There are different types of bearings used in lathe headstocks. Ball bearings are popular for their high speed and low friction. Roller bearings handle heavy loads but can be a bit clunky. Each type has its own job, just like superheroes in a comic book!

| Type of Bearing | Advantages |

|---|---|

| Ball Bearings | High speed, smooth operation |

| Roller Bearings | Great for heavy loads |

Choosing the right bearing can make all the difference. Happy turning!

Importance of Quality Bearings in Metal Lathes

Impact of headstock bearing quality on precision and accuracy. Role of bearings in vibration reduction and tool longevity.Quality bearings are like the secret sauce for your metal lathe. They can make a big difference in how well your tools work. Good headstock bearings improve precision and accuracy. They help keep everything steady while you turn metal, slicing and dicing like a pro chef with a sharp knife. Vibration reduction is another bonus. Less shake means longer-lasting tools. Remember, happy bearings lead to happy lathes!

| Bearing Quality | Impact on Lathe Performance |

|---|---|

| High Quality | Improves precision and reduces vibration |

| Low Quality | Causes inaccuracies and premature wear |

Signs of Worn or Damaged Headstock Bearings

Identifying symptoms of wear in lathe headstock bearings. Consequences of prolonged use of compromised bearings.Do you hear weird noises from your lathe? That’s a red flag! Worn or damaged headstock bearings can cause major trouble. Look for signs like vibrations, rough operation, or uneven cuts. If those bearings are not in tip-top shape, your projects may turn out like pancakes instead of masterpieces! Prolonged use can lead to expensive repairs and broken tools. In short, don’t ignore those little grumbling sounds; they might just be your lathe begging for help!

| Sign | Possible Consequence |

|---|---|

| Unusual noises | Tool failure |

| Vibrations | Poor precision |

| Rough operation | Increased wear |

How to Replace Lathe Headstock Bearings

Stepbystep guide on disassembly and replacement. Tools and equipment required for bearing replacement.Replacing lathe headstock bearings may sound tricky, but it’s easier than making a sandwich! Start by gathering your tools: a wrench, screwdriver, and bearing puller. First, unplug your lathe—safety first! Next, take off the headstock cover. Carefully remove the old bearings using your bearing puller. Slip in the new ones, making sure they fit snugly. Put everything back together, and voilà! You’ve done it! Remember to check for smooth movement before you start turning metal again.

| Tools Needed | Purpose |

|---|---|

| Wrench | To loosen bolts |

| Screwdriver | To remove screws |

| Bearing Puller | To remove old bearings |

Maintenance Tips for Lathe Headstock Bearings

Best practices for lubrication and maintenance. Recommended frequency of maintenance checks.Taking care of your lathe headstock bearings is easy-peasy if you follow a few simple steps. First, keep them slick by applying lubrication regularly – think of it like giving your bearings a spa day! Check them every 3 to 6 months to keep things running smoothly. If you hear strange noises, it might be time for a check-up. Remember, well-maintained bearings last longer and can save you money in the end. Here’s a quick table to help you keep track:

| Maintenance Task | Frequency |

|---|---|

| Lubricate Bearings | Every 3 months |

| Check for Wear | Every 3-6 months |

| Clean Debris | Monthly |

By following these tips, your lathe will be smooth like butter on warm toast. Now, that’s a win-win!

Choosing the Right Headstock Bearing for Your Metal Lathe

Factors to consider when selecting bearings. Top brands and recommendations for quality bearings.Choosing the right headstock bearing is key for your metal lathe. Consider these factors:

- Size: Make sure it fits your lathe.

- Material: Look for durability and low friction.

- Type: Ball bearings are popular for smooth operation.

Top brands include:

- Timken: Known for strong, reliable bearings.

- NSK: Offers quality and long-lasting performance.

- SKF: Great for precision and efficiency.

Usually, investing in well-known brands ensures better quality and longer-lasting tools.

What should I look for in lathe bearings?

Focus on size, material, and type. These aspects directly affect your lathe’s performance.

Upgrading Headstock Bearings: When and Why

Reasons to consider upgrading bearings for enhanced performance. Costbenefit analysis of upgrading bearings in metal lathes.Every metal lathe owner knows that a smooth ride is key to great projects. Upgrading your headstock bearings can do just that. Better bearings can reduce vibration and improve accuracy, making cutting easier. Over time, worn bearings may lead to more repairs and headaches. Investing in upgrades could actually save you money in the long run by improving performance and extending the lifespan of your tools.

| Item | Cost | Lifetime Value |

|---|---|---|

| Old Bearings | $50 | 1 Year |

| Upgraded Bearings | $80 | 3 Years |

Think of the upgrade like a fancy bicycle for your lathe! It might cost more upfront but saves you from future repairs. Plus, smoother bearings mean more fun and less frustration!

Conclusion

In conclusion, lathe headstock bearings are crucial for smooth metal lathe operation. They support the spindle and help reduce friction. By choosing the right bearing, you improve your tool’s performance. Remember to maintain your lathe regularly for the best results. If you’re curious, explore more about lathe tools and their components to enhance your skills even further!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Metal Lathe Tools:Sure! Here are some questions about lathe headstock bearings for metal lathes. 1. **What does a lathe headstock do?** The headstock is the part of the lathe that holds the motor and the spindle. It spins the material we want to shape. 2. **What are bearings?** Bearings are round parts that help something spin smoothly. They reduce friction and make moving easier. 3. **Why are bearings important?** They help the spindle spin without getting stuck. Good bearings make our job easier and our work better. 4. **How do you know if a bearing is bad?** If a bearing makes loud noises or feels rough when you touch it, it might be damaged. 5. **Can you replace a bad bearing?** Yes, you can swap out a bad bearing for a new one. This fix helps the lathe work well again!

Sure! Please give me the question you’d like me to answer.

What Are The Different Types Of Bearings Used In Lathe Headstocks, And How Do They Affect Machining Performance?In lathe headstocks, we mostly find two types of bearings: plain bearings and ball bearings. Plain bearings are simple and cheap, but they can wear out faster. Ball bearings help machines move smoothly and last longer. When we use better bearings, we get better performance, making our work easier and more precise.

How Do You Properly Maintain And Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Functionality?To keep the bearings in your lathe headstock working well, you should check them often. First, clean the area to remove dirt. Then, add the right kind of oil to the bearings. Make sure to use enough, but not too much. Regular checks will help your lathe work smoothly for a long time!

What Signs Indicate That The Headstock Bearings In A Metal Lathe May Need To Be Replaced?You might need to replace the headstock bearings if you hear strange noises while the lathe is running. If the machine vibrates a lot, that’s another sign. You may also notice that the spindle, which holds the tools, doesn’t turn smoothly. Lastly, if you feel heat coming from the headstock, it could mean something is wrong.

How Do The Materials Used In Headstock Bearings Impact The Overall Durability And Precision Of A Lathe?The headstock bearings in a lathe help it spin smoothly. If we use strong materials, the bearings last longer and won’t wear out easily. This means the lathe can work better and be more precise when cutting. If the materials are weak, the lathe might shake or break down, making it harder to get a good result. So, good materials make a big difference in how well the lathe works.

What Are The Common Causes Of Bearing Failure In Lathe Headstocks, And How Can They Be Prevented?Common causes of bearing failure in lathe headstocks include dirt, lack of oil, and too much heat. To prevent this, keep the lathe clean. Regularly check and add oil to the bearings. Also, let the lathe cool down if it gets too hot. By doing these simple things, we can help the bearings last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about lathe headstock bearings for metal lathes. 1. **What does a lathe headstock do?** The headstock is the part of the lathe that holds the motor and the spindle. It spins the material we want to shape. 2. **What are bearings?** Bearings are round parts that help something spin smoothly. They reduce friction and make moving easier. 3. **Why are bearings important?** They help the spindle spin without getting stuck. Good bearings make our job easier and our work better. 4. **How do you know if a bearing is bad?** If a bearing makes loud noises or feels rough when you touch it, it might be damaged. 5. **Can you replace a bad bearing?** Yes, you can swap out a bad bearing for a new one. This fix helps the lathe work well again!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Bearings Used In Lathe Headstocks, And How Do They Affect Machining Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In lathe headstocks, we mostly find two types of bearings: plain bearings and ball bearings. Plain bearings are simple and cheap, but they can wear out faster. Ball bearings help machines move smoothly and last longer. When we use better bearings, we get better performance, making our work easier and more precise.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the bearings in your lathe headstock working well, you should check them often. First, clean the area to remove dirt. Then, add the right kind of oil to the bearings. Make sure to use enough, but not too much. Regular checks will help your lathe work smoothly for a long time!”}},{“@type”: “Question”,”name”: “What Signs Indicate That The Headstock Bearings In A Metal Lathe May Need To Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to replace the headstock bearings if you hear strange noises while the lathe is running. If the machine vibrates a lot, that’s another sign. You may also notice that the spindle, which holds the tools, doesn’t turn smoothly. Lastly, if you feel heat coming from the headstock, it could mean something is wrong.”}},{“@type”: “Question”,”name”: “How Do The Materials Used In Headstock Bearings Impact The Overall Durability And Precision Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock bearings in a lathe help it spin smoothly. If we use strong materials, the bearings last longer and won’t wear out easily. This means the lathe can work better and be more precise when cutting. If the materials are weak, the lathe might shake or break down, making it harder to get a good result. So, good materials make a big difference in how well the lathe works.”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Bearing Failure In Lathe Headstocks, And How Can They Be Prevented?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common causes of bearing failure in lathe headstocks include dirt, lack of oil, and too much heat. To prevent this, keep the lathe clean. Regularly check and add oil to the bearings. Also, let the lathe cool down if it gets too hot. By doing these simple things, we can help the bearings last longer.”}}]}