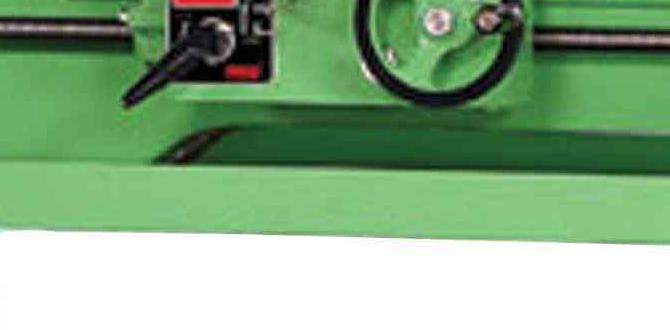

Have you ever wondered how a metal lathe works? Imagine a machine that spins metal to shape it, just like a potter shapes clay. At the heart of this powerful tool is something called the lathe headstock. This part holds the spindle and helps it turn smoothly.

But there’s more! The lathe headstock has bearings that play a huge role in its performance. These bearings help manage the torque, which is the twist or turning power. If the bearings aren’t working right, the lathe can wobble and make poor cuts.

Did you know that a well-maintained lathe headstock bearing can make your projects easier and more precise? Imagine finishing your work twice as fast just by keeping the bearings in top shape. That’s pretty cool, right? Keep reading to learn how to care for your lathe’s headstock and keep the torque just right!

Lathe Headstock Bearing: Essential For Metal Lathe Torque

Lathe Headstock Bearing and Torque Insights

The lathe headstock bearing plays a crucial role in the performance of a metal lathe. Understanding how it works can improve your projects. Did you know that proper torque management can prevent wear and tear? With the right setup, you’ll achieve smoother turns and better accuracy. Explore how adjusting torque enhances control and prolongs the life of your lathe. This knowledge can lead to amazing results in your metalworking adventures!What is a Lathe Headstock Bearing?

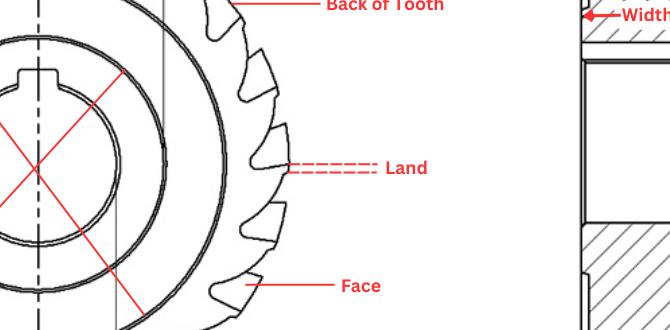

Definition and function of the headstock bearing in a lathe.. Types of headstock bearings used in metal lathes..A lathe headstock bearing is a key part of a lathe machine. It helps support the spindle and allows it to spin smoothly. This part keeps everything stable while the lathe works. There are two common types of headstock bearings.

- Ball Bearings: These allow for smooth rotation and are great for precision.

- Plain Bearings: These provide strength and are easy to maintain.

Choosing the right bearing can affect the lathe headstock bearing metal lathe torque. It’s essential for cutting materials well.

What is the function of a headstock bearing?

The function of a headstock bearing is to support the spindle. It keeps it centered and allows it to rotate. This helps in achieving precise cuts and smooth operation.

Importance of Headstock Bearings in Metal Lathes

Role in ensuring precision and stability during machining.. Impact on tool performance and longevity of the lathe..Headstock bearings are like the trusty sidekicks of metal lathes. They keep everything running smoothly, ensuring precision and stability during machining. When these bearings are in top shape, tools work better and last longer. Imagine trying to cut wood with dull scissors – not fun, right? Good bearings help avoid that chaos! A well-functioning bearing means less wobble and more wow!

| Benefit | Impact |

|---|---|

| Precision | Improved accuracy in cuts |

| Stability | Less vibration leads to better results |

| Longevity | Extends tool and lathe life |

Keep an eye on your headstock bearings. They’re the unsung heroes! After all, nobody wants to turn their metalworking dreams into a wobbly mess!

Types of Bearings in Metal Lathe Headstocks

Comparison between ball bearings and roller bearings.. Advantages and disadvantages of each type..There are two main types of bearings in metal lathe headstocks: ball bearings and roller bearings. Ball bearings roll smoothly and support heavy loads. They are great for high speeds but can wear out faster under too much pressure. On the other hand, roller bearings handle heavier weights better and last longer but can be a bit noisy. Choosing the right one is like picking your favorite ice cream flavor: it depends on the job!

| Type | Advantages | Disadvantages |

|---|---|---|

| Ball Bearings | Smoother operation | Can wear out easily |

| Roller Bearings | Handles heavier loads | A bit noisy |

Whether it’s for speed or strength, knowing the differences can save you from a spinning disaster. Think of it like picking a trusty sidekick—each type has its own strengths, and you’ll want to choose wisely!

Calculating Torque Requirements for Lathe Operations

Formula to calculate the required torque for different machining tasks.. Practical examples of torque calculations in various materials..Torque is key for operating lathes. To calculate it, you can use the formula: Torque (T) = Power (P) / Angular Velocity (ω). This helps you know how much twist your machine needs. For example, if you’re cutting wood, you might need less torque than cutting metal. Let’s say a wood lathe needs 50 Nm, while a metal lathe requires 70 Nm to do the job well. Here’s a quick look:

| Material | Required Torque (Nm) |

|---|---|

| Wood | 50 |

| Aluminum | 65 |

| Steel | 70 |

Remember, the tougher the material, the more torque you need. So, if your lathe isn’t twisting enough, it might be saying, “No thanks!” to hard materials. Keep this in mind, and your lathe will be happy to help!

Common Issues with Headstock Bearings and Torque

Typical problems encountered in lathe headstock bearings.. Effects of improper torque settings on lathe performance..Headstock bearings can occasionally act like grumpy cats. They might wear out or get damaged, leading to increased friction. This can cause uneven turning and create unwanted noise. Improper torque settings as if your lathe is on a diet, can also mess things up. Too tight might strain the bearings, while too loose can throw everything off balance. Keep an eye on these issues to keep your lathe purring smoothly!

| Issue | Effect |

|---|---|

| Worn Bearings | Increased friction and noise |

| Improper Torque Settings | Strain and imbalance |

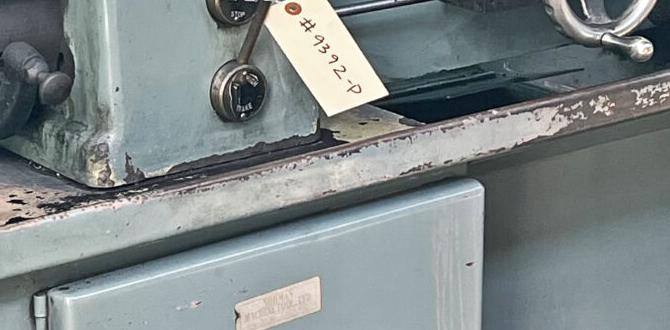

Maintenance Tips for Headstock Bearings

Best practices for lubricating and maintaining bearings.. Recommended intervals for checks and replacements..Keeping your headstock bearings in tip-top shape isn’t rocket science! Start by giving them a squirt of the right lubricant. It’s like giving them a refreshing drink. Aim to check them every month, and don’t be afraid to replace them if they start making weird sounds—those sounds aren’t your friends! Regular checks help your lathe run smoothly and keep it happy.

| Check Interval | Action |

|---|---|

| Monthly | Lubricate bearings |

| Quarterly | Inspect for wear |

| Annually | Replace if necessary |

Choosing the Right Bearing for Your Metal Lathe

Key factors to consider when selecting headstock bearings.. Recommendations based on specific lathe models or applications..Selecting the right bearing for your metal lathe can feel like choosing a favorite ice cream flavor—there are many options! Key factors include load capacity, speed rating, and material type. For example, if you have a high-speed lathe, you’ll want a bearing that can handle extra torque without melting down like ice cream on a hot day.

Here’s a quick reference for popular models:

| Lathe Model | Recommended Bearing Type | Load Capacity (lbs) |

|---|---|---|

| Model A | Ball Bearing | 200 |

| Model B | Roller Bearing | 350 |

| Model C | Magnetic Bearing | 500 |

Always check your lathe specifications and choose wisely. After all, no one wants their lathe dancing out of control!

Conclusion

In summary, the lathe headstock bearing is crucial for smooth operation and stability. It helps control torque, ensuring your metal lathe works efficiently. You should regularly check and maintain this part for better performance. For more tips on lathe care, consider reading guides or watching videos. You’ll improve your skills and keep your lathe in great shape!FAQs

What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe, And How Do They Affect Torque Transmission?Metal lathes often use plain bearings or roller bearings in their headstock. Plain bearings are smooth and support the spinning parts. Roller bearings have small cylinders that help them turn easily. Both types help the lathe transmit torque, which is the force that makes it spin. Good bearings mean less friction, so we can work faster and better!

How Does The Quality Of Headstock Bearings Influence The Overall Performance And Precision Of A Metal Lathe?The headstock bearings hold the spindle in place as it spins. Good quality bearings help the spindle turn smoothly and straight. When the spindle moves well, it makes better cuts on the metal. This means your projects will be more precise and look nicer. If the bearings are not good, you might end up with a wobbly or uneven cut.

What Are The Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can This Impact Torque Delivery During Machining?You can notice worn-out lathe headstock bearings by listening for strange noises. If the machine vibrates a lot, that’s a sign too. You might also see uneven cuts on your workpiece. When bearings fail, they can make it hard for the machine to deliver consistent power. This affects how well you can shape your materials.

How Do Different Bearing Materials, Such As Bronze Or Ball Bearings, Affect The Torque Capacity And Load-Bearing Characteristics Of A Lathe Headstock?Different bearing materials can change how strong a lathe headstock is. Bronze bearings are smooth and strong but may wear out faster. Ball bearings roll, making them great for carrying heavy loads. With better bearings, you can use more power without problems. This keeps your lathe running smoothly when you work on projects.

What Techniques Can Be Used To Properly Adjust And Maintain Headstock Bearings In Order To Optimize Torque And Reduce Friction In A Metal Lathe?To adjust and maintain headstock bearings, you should first clean them regularly to remove dirt. You can check the tightness of the bearings; they shouldn’t be too loose or too tight. Use the right amount of oil or grease to keep everything running smoothly. Make sure to check for signs of wear and replace parts when needed. By doing these steps, you help the lathe work better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe, And How Do They Affect Torque Transmission? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes often use plain bearings or roller bearings in their headstock. Plain bearings are smooth and support the spinning parts. Roller bearings have small cylinders that help them turn easily. Both types help the lathe transmit torque, which is the force that makes it spin. Good bearings mean less friction, so we can work faster and better!”}},{“@type”: “Question”,”name”: “How Does The Quality Of Headstock Bearings Influence The Overall Performance And Precision Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock bearings hold the spindle in place as it spins. Good quality bearings help the spindle turn smoothly and straight. When the spindle moves well, it makes better cuts on the metal. This means your projects will be more precise and look nicer. If the bearings are not good, you might end up with a wobbly or uneven cut.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can This Impact Torque Delivery During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can notice worn-out lathe headstock bearings by listening for strange noises. If the machine vibrates a lot, that’s a sign too. You might also see uneven cuts on your workpiece. When bearings fail, they can make it hard for the machine to deliver consistent power. This affects how well you can shape your materials.”}},{“@type”: “Question”,”name”: “How Do Different Bearing Materials, Such As Bronze Or Ball Bearings, Affect The Torque Capacity And Load-Bearing Characteristics Of A Lathe Headstock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different bearing materials can change how strong a lathe headstock is. Bronze bearings are smooth and strong but may wear out faster. Ball bearings roll, making them great for carrying heavy loads. With better bearings, you can use more power without problems. This keeps your lathe running smoothly when you work on projects.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Properly Adjust And Maintain Headstock Bearings In Order To Optimize Torque And Reduce Friction In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust and maintain headstock bearings, you should first clean them regularly to remove dirt. You can check the tightness of the bearings; they shouldn’t be too loose or too tight. Use the right amount of oil or grease to keep everything running smoothly. Make sure to check for signs of wear and replace parts when needed. By doing these steps, you help the lathe work better and last longer.”}}]}