Have you ever faced issues with your lathe? Does it frustrate you when your cutting isn’t as precise as it should be? One common problem is leadscrew backlash. This term might sound technical, but it simply means there’s a little wiggle in the parts that help your lathe move. This can make your projects messy and frustrating.

Imagine trying to carve a smooth piece of wood, only to find your tool slipping. Sounds annoying, right? The good news is, there is a fix for lathe leadscrew backlash. Taking the time to learn about this can save you a lot of headaches.

Did you know many skilled woodworkers have faced this issue? They found ways to fix it, and so can you! Understanding and addressing leadscrew backlash can improve your work. It’s like giving your lathe a magic boost. So, let’s dive into how you can fix that pesky backlash and make your lathe work better.

Lathe Leadscrew Backlash Fix: Effective Solutions Explained

Lathe Leadscrew Backlash Fix

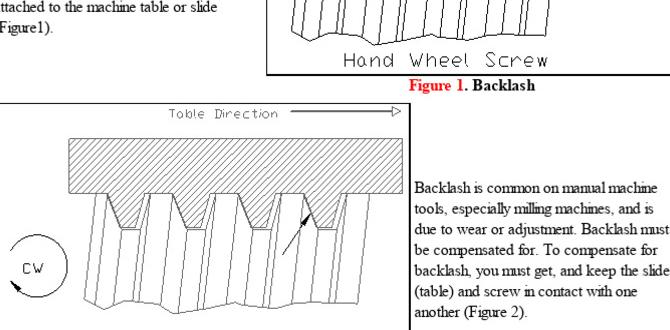

Fixing lathe leadscrew backlash can greatly improve your machining precision. Backlash happens when there’s space between the parts that move. This can lead to inaccuracies in your work. By adjusting the leadscrew and ensuring tight fittings, you can lessen this issue. Did you know small adjustments can make a big difference? Regular maintenance and proper setup are key. A well-tuned lathe enhances your projects, making them smoother and more enjoyable.Understanding Leadscrew Backlash

Definition of backlash in lathe leadscrews. Causes of leadscrew backlash in machining.Backlash in lathe leadscrews is a sneaky problem. It occurs when there is some play or looseness between the leadscrew and the nut. This can cause machines to be less accurate, making your cuts look like a toddler drew them! Common causes include wear and tear, poor installation, or degraded parts. Think of it like trying to drive a car with a flat tire. It just won’t work well!

| Cause | Description |

|---|---|

| Wear and Tear | Over time, parts can wear down. |

| Poor Installation | Improper setup can lead to issues. |

| Degraded Parts | Old or damaged components can create gaps. |

Signs of Backlash in Your Lathe

Common symptoms indicating backlash issues. How to measure leadscrew backlash accurately.Backlash in your lathe can show in different ways. You might notice a fuzzy or wobbly finish on your parts. Another sign is a skipping motion when cutting. You may also experience uneven depth cuts. To check for backlash:

- Move the carriage to the left, then right.

- Measure the play or movement back and forth.

- Use a dial indicator for more accuracy.

These steps help you find any issues. Fixing backlash early can save time and effort!

What are common symptoms of backlash?

Symptoms include poor cut quality, uneven shaping, and skipping movements.

Importance of Fixing Backlash

Impact on precision and accuracy of machining. Consequences of ignoring leadscrew backlash.Keeping your lathe in top shape is like ensuring your favorite snack stays fresh—nobody wants a soggy cookie! A proper fix for backlash boosts your machining precision, making your cuts sharp and accurate. If ignored, leadscrew backlash can turn smooth operations into a wobbly dance. You’ll find yourself second-guessing every measurement. Remember, no one wants their masterpiece to look like it was made by a toddler armed with a crayon.

| Issue | Impact |

|---|---|

| Backlash | Decreased accuracy |

| Ignored leadscrew | Poor machining results |

So fix that backlash! You’ll be glad you did when your lathe performs like a pro instead of a confused puppy chasing its tail.

Tools and Materials Needed for Backlash Fix

Essential tools for the repair process. Recommended materials for effective fixes.Getting ready to fix that pesky backlash? You’ll need a few trusty tools and materials. First, grab a wrench and some screwdrivers. They’re the superheroes of this mission! A measuring tape is also key; even heroes need measurements, right? You might want some lubricant to keep everything moving smoothly. Here’s a quick table to keep things organized:

| Tools | Materials |

|---|---|

| Wrench | Lubricant |

| Screwdrivers | Cleaning Cloth |

| Measuring Tape | Replacement Screws |

Don’t forget a cleaning cloth to wipe away any dust and grease. A clean work area helps your fix go smoother. With these tools and materials, you’re all set! Remember, even the best superheroes need the right gadgets for their adventures!

Step-by-Step Guide to Fixing Backlash

Detailed instructions for adjusting leadscrew tension. How to replace wornout components to eliminate backlash.Fixing backlash on a lathe is like fixing a wobbly chair; it just needs a bit of adjustment! First, check the leadscrew tension. Loosen the lock nuts and turn the adjusting screw until it’s snug, but not too tight. If your leadscrew feels more like a rubber band, replace worn-out components like nuts and bearings. It’s a bit like changing a tire. Here’s a simple table to guide you:

| Part | Action |

|---|---|

| Leadscrew Nut | Adjust tension |

| Bearing | Replace if worn |

Following these steps will help reduce backlash. It’s like giving your lathe a spa day! Now, it can work smoothly and accurately, just like you!

Preventive Measures to Avoid Backlash

Maintenance tips for prolonging leadscrew life. Best practices to minimize the onset of backlash.To keep your lathe leadscrew in good shape, follow some easy maintenance tips. Regular cleaning is important. Dirt can cause problems. Lubrication reduces friction, which helps the leadscrew last longer. Check for wear and tear often. Fixing issues early prevents bigger problems. Here are some best practices:

- Clean the leadscrew regularly.

- Use proper lubrication.

- Inspect for damage.

- Align components carefully.

These steps help minimize backlash and ensure smooth operation.

How can I maintain my lathe leadscrew?

You can keep your lathe leadscrew in great shape by cleaning and lubricating it regularly. Check it for any signs of wear. This will help avoid issues like backlash.

Troubleshooting Persistent Backlash Issues

Common challenges during the fixing process. Strategies for diagnosing hardtofix leadscrew backlash.Fixing backlash can feel like trying to catch a slippery fish! One common challenge is finding where the problem hides. It may be in the leadscrew, the nut, or even the bearings. Diagnosing this can be tricky. To start, check for loose components. Tighten those screws like they’re running for the gold! The right strategy is to measure the backlash with a dial indicator. This tool is a game-changer. Here’s a quick overview of challenges and fixes:

| Challenge | Solution |

|---|---|

| Loose Leadscrew | Tighten the leadscrew and check alignment. |

| Worn Nut | Replace the nut to reduce play. |

| Improper Lubrication | Ensure proper maintenance and lubrication. |

With patience and a little humor, tackling these issues can be less daunting. Remember, every error is a step closer to perfection!

Professional Help and Resources

When to seek professional repair services. Recommended resources and communities for further assistance.Sometimes, fixing leadscrew backlash can feel like trying to untangle a knotted shoelace—it’s tricky! If you find yourself stuck, it might be time to call in a pro. Seek help if repairs go beyond your skill or tools. Don’t worry; teams out there have experience navigating this mechanical maze.

| Recommended Resources | Communities |

|---|---|

| Local Machine Shops | Online Forums like Reddit |

| Lathe Repair Services | Facebook Groups on Machining |

Getting advice can save you time and effort. Why wrestle with your lathe alone? Plus, sharing your troubles with others can lighten the load—just don’t forget to bring laughter along for the ride!

Conclusion

In conclusion, fixing lathe leadscrew backlash is essential for precision work. You can reduce or eliminate backlash by adjusting the nuts or replacing worn parts. Check your lathe’s manual for specific tips. Remember, taking these small steps can improve your lathe’s performance. For more details, consider exploring tutorials online or joining a woodworking community. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Leadscrew Backlash Fix:Backlash is the tiny space where parts don’t touch. It happens in a lathe when you move things. To fix it, we can tighten the parts. We might also add a spring or a special shim. These changes help the lathe work better and make smooth cuts.

Sure! Please share the question you’d like me to answer, and I’ll be happy to help!

What Are The Common Causes Of Backlash In A Lathe Leadscrew And How Can They Be Identified?Backlash in a lathe leadscrew happens when there’s too much space between parts. Common causes include worn gears or loose parts. You can identify it by seeing if the tool moves a bit without cutting. If you turn the handle and it feels wobbly or loose, that’s a sign. Regular checks can help catch these problems early.

What Tools And Materials Are Needed To Effectively Adjust Or Eliminate Backlash In A Lathe Leadscrew?To adjust or fix backlash in a lathe leadscrew, you need a few tools. You’ll want a wrench to tighten or loosen screws. A screwdriver is also important for adjusting small parts. Some people use a dial indicator to measure the movement accurately. Don’t forget some lubricant to keep things smooth!

How Can The Adjustment Of The Gibs And Nuts On A Lathe Leadscrew Help Reduce Backlash?Adjusting the gibs and nuts on a lathe helps make it tighter. When things are tight, there’s less wiggle or play in the machine. This means the tool stays where you put it. Less movement helps make better cuts. So, adjusting these parts helps the lathe work more accurately.

What Are The Differences Between Mechanical And Electronic Methods For Compensating For Lathe Leadscrew Backlash?Mechanical methods use simple parts like springs or gears to help reduce backlash, which is the small gap between moving parts. You can feel this gap when using a lathe, which is a machine that shapes materials. Electronic methods use sensors and computer controls to adjust movements automatically. These electronic systems can be more precise and quick than mechanical ones. So, mechanical is hands-on, while electronic is techy!

How Can Regular Maintenance Practices Prevent The Development Of Backlash In A Lathe Leadscrew?Regularly checking the lathe helps keep it working well. You should clean the leadscrew to remove dirt and grime. Lubricating the leadscrew makes it move smoothly and reduces wear. When everything is tight and clean, there’s less chance of backlash, which is when the machine moves back a little after you stop. So, taking care of your lathe means better performance!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Leadscrew Backlash Fix:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Backlash is the tiny space where parts don’t touch. It happens in a lathe when you move things. To fix it, we can tighten the parts. We might also add a spring or a special shim. These changes help the lathe work better and make smooth cuts. “}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Backlash In A Lathe Leadscrew And How Can They Be Identified?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Backlash in a lathe leadscrew happens when there’s too much space between parts. Common causes include worn gears or loose parts. You can identify it by seeing if the tool moves a bit without cutting. If you turn the handle and it feels wobbly or loose, that’s a sign. Regular checks can help catch these problems early.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Needed To Effectively Adjust Or Eliminate Backlash In A Lathe Leadscrew?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust or fix backlash in a lathe leadscrew, you need a few tools. You’ll want a wrench to tighten or loosen screws. A screwdriver is also important for adjusting small parts. Some people use a dial indicator to measure the movement accurately. Don’t forget some lubricant to keep things smooth!”}},{“@type”: “Question”,”name”: “How Can The Adjustment Of The Gibs And Nuts On A Lathe Leadscrew Help Reduce Backlash?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting the gibs and nuts on a lathe helps make it tighter. When things are tight, there’s less wiggle or play in the machine. This means the tool stays where you put it. Less movement helps make better cuts. So, adjusting these parts helps the lathe work more accurately.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Mechanical And Electronic Methods For Compensating For Lathe Leadscrew Backlash?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Mechanical methods use simple parts like springs or gears to help reduce backlash, which is the small gap between moving parts. You can feel this gap when using a lathe, which is a machine that shapes materials. Electronic methods use sensors and computer controls to adjust movements automatically. These electronic systems can be more precise and quick than mechanical ones. So, mechanical is hands-on, while electronic is techy!”}},{“@type”: “Question”,”name”: “How Can Regular Maintenance Practices Prevent The Development Of Backlash In A Lathe Leadscrew?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regularly checking the lathe helps keep it working well. You should clean the leadscrew to remove dirt and grime. Lubricating the leadscrew makes it move smoothly and reduces wear. When everything is tight and clean, there’s less chance of backlash, which is when the machine moves back a little after you stop. So, taking care of your lathe means better performance!”}}]}