Have you ever wondered how a lathe works smoothly? It’s often about the little things, like caring for the leadscrew. Proper lubrication keeps everything running well. But, how often should you lubricate the leadscrew?

It might surprise you to learn that many people neglect this simple task. When we think of machines, we picture gears and motors. Yet, a lathe’s performance hinges on its leadscrew too.

Imagine a busy workshop where every minute counts. If the leadscrew is dry, it can cause problems. This can slow you down and even lead to bigger repairs. Regular lubrication can help avoid these issues and keep your lathe in top shape.

In this article, we’ll explore the best intervals for lathe leadscrew lubrication. You’ll discover tips to ensure your lathe runs smoothly. Let’s dive in and keep that machine happy!

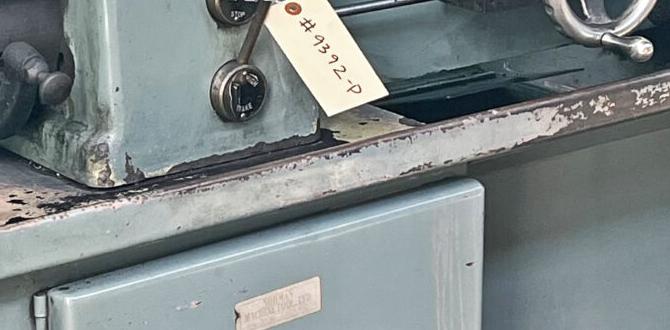

Lathe Leadscrew Lubrication Interval: Essential Guide

Lathe Leadscrew Lubrication Interval

Keeping your lathe leadscrew well-lubricated is vital for smooth operation. Did you know that many experts suggest lubricating it every 8 to 12 hours of use? Regular lubrication not only extends the life of your lathe but also ensures precise cuts. Remember, a well-oiled leadscrew works like a happy machine, making your projects easier and more enjoyable. Don’t let neglect lead to wear and tear—stay on top of your lubrication schedule!The Importance of Leadscrew Lubrication

Explanation of leadscrew function in lathe operations. Impact of lubrication on machine performance and longevity.In a lathe, the leadscrew helps move the tool across the workpiece. This is important for making precise cuts. Without proper lubrication, the leadscrew can wear down quickly. Lubrication keeps it running smoothly and extends its life. When you oil it regularly, you’ll notice better machine performance.

- Improves accuracy: Smooth movement leads to cleaner cuts.

- Reduces wear: Less friction means longer-lasting parts.

- Less heat: Lubrication helps cool down the machinery.

How does lubrication affect lathe operations?

Lubrication keeps the leadscrew running smoothly, enhancing machine efficiency and accuracy. It prevents wear and tear, ensuring the lathe lasts longer. Regular lubrication is vital for optimal performance.

Factors Influencing Lubrication Interval

Discussion of operational environment (temperature, dust, etc.). Usage frequency and its effect on lubrication needs.Lubrication intervals for your lathe may change based on a few key factors. First up is the operational environment. If you’re working in a hot garage or a dusty workshop, those conditions can affect how often you need to lubricate. Heat can make oil break down faster, while dust can cause wear and tear. Next is usage frequency. If you use your lathe every day, it’ll need more love. Think of it like a pet: the more you use it, the more care it needs!

| Factor | Influence on Lubrication |

|---|---|

| Temperature | High temps cause oil to degrade quickly. |

| Dust | More dust means more wear, needing more oil! |

| Usage Frequency | Daily use = more frequent lubrication. |

Remember, keeping your lathe happy can save you from big repairs later!

Recommended Lubrication Intervals

General guidelines for various lathe models and usage styles. Signs that indicate the need for lubrication.Regularly checking your lathe is key for smooth operation. Different models may need different lubrication schedules. As a general rule, lubricate every 100 hours of use. If you see signs like squeaking sounds or rough movements, it’s time to add more oil. Here are some helpful guidelines:

- For heavy usage: Lubricate once a week.

- For occasional use: Check once a month.

- For light-duty models: Every few months should be enough.

How do I know if my lathe needs lubrication?

Watch for signs like noise or sticky movement. These mean oil is needed. Keeping your lathe well-lubed helps it work better and last longer.

Methods for Applying Lubrication

Stepbystep guide on proper lubrication techniques. Common mistakes to avoid during the lubrication process.Lubricating your lathe leadscrew correctly is vital for smooth operation. First, gather your tools: the right lubricant and a clean cloth. Apply the lubricant evenly along the leadscrew. Avoid overdoing it; too much is just as bad as too little! Wipe off excess to prevent dust from sticking. Common mistakes? Don’t forget to clean the leadscrew first. A dirty screw can turn into a sticky situation. Instead of a smooth glide, you might get a squeak! Be sure to check your owner’s manual for specific guidelines.

| Step | Action |

|---|---|

| 1 | Gather tools |

| 2 | Clean the leadscrew |

| 3 | Apply lubricate evenly |

| 4 | Wipe away excess |

Preventive Maintenance Practices

Additional maintenance tasks to perform alongside lubrication. Scheduling regular inspections to optimize lathe performance.To keep your lathe running well, follow some extra maintenance steps. Lubrication is just the start. You should also:

- Check for worn parts regularly

- Clean the machine to avoid dust buildup

- Inspect belts and gears for signs of wear

Scheduling these tasks helps keep everything smooth. Regular checks can prevent bigger problems down the line. A small effort now can save time and money later.

How does regular inspection help my lathe?

Regular inspections ensure your lathe operates at its best. They help find issues before they become costly repairs.

Consequences of Neglecting Leadscrew Lubrication

Potential mechanical issues resulting from inadequate lubrication. Longterm effects on machining accuracy and machine lifespan.If you skip lubricating the leadscrew, serious problems can arise. Lack of lubrication can cause wear and tear on the machine. This makes it harder for parts to move smoothly. In the long run, it may hurt how precise your machining is. It can also shorten the life of your machine.

- Increased friction and heat can damage components.

- Reduced machining accuracy leads to poor results.

- Machine lifespan may decrease significantly.

What happens if you don’t lubricate your lathe leadscrew?

Neglecting lubrication can lead to costly repairs and reduced performance. Your machine may not work well, and you might need to replace it sooner than expected.

Expert Tips for Effective Leadscrew Maintenance

Industry insights and best practices from experienced machinists. Tools and resources to assist in maintaining lubrication intervals.Taking care of your lathe leadscrew is like giving your pet a bath—neglect it, and things can get messy. Experienced machinists suggest keeping a close eye on lubrication intervals. It’s vital to use the right tools, such as a high-quality grease gun. Moreover, having a simple schedule helps. Check once every 50 hours of use or weekly, whichever comes first. You want it smooth, not squeaky! Here’s a quick reference table:

| Maintenance Task | Frequency |

|---|---|

| Lubrication Check | Every 50 hours |

| Cleaning | Weekly |

Following these tips keeps your leadscrew happy and working well, saving you a headache later. Remember, as they say, “A well-oiled machine is a happy machine!”

Conclusion

In summary, keeping your lathe leadscrew properly lubricated is crucial for smooth operation. Regular lubrication prevents wear and tear, ensuring your machine runs efficiently. Aim to check and lubricate your leadscrew every few weeks. This simple action can boost your lathe’s performance. For more details, consider reading your lathe’s manual or seeking advice from experienced users.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Leadscrew Lubrication Interval:Sure! Here are five questions about how often to lubricate a lathe’s leadscrew. 1. **What is a leadscrew?** A leadscrew helps move the lathe tool back and forth. It’s important for making precise cuts. 2. **Why do we need to lubricate it?** We lubricate the leadscrew to keep it running smoothly. This helps prevent rust and wear. 3. **How often should we oil the leadscrew?** You should oil the leadscrew every few hours of use. Regular oiling keeps it in good shape. 4. **What happens if we forget to lubricate?** If you forget to lubricate, the leadscrew can get stuck. This can damage the lathe and make it harder to use. 5. **What kind of oil should we use?** You should use a light machine oil. It helps keep everything moving without getting sticky.

Sure! Please ask your question, and I’ll be happy to help you with a clear and simple answer.

What Factors Influence The Recommended Lubrication Interval For A Lathe Leadscrew?The lubrication interval for a lathe leadscrew depends on a few important things. First, how much you use the lathe affects how often you need to lubricate. The type of work you do matters too; tougher jobs need more lubrication. Also, the type of oil or grease you use can change how often you should apply it. Finally, the environment, like dust or heat, can impact the lubrication needs.

How Can Improper Lubrication Of A Lathe Leadscrew Affect The Machine’S Performance And Accuracy?If we don’t put enough oil on the lathe leadscrew, it can get stuck. This makes the machine harder to move. When the lathe doesn’t move smoothly, it can make mistakes, like cutting uneven shapes. Good lubrication keeps everything running well and helps make accurate cuts. So, always check and add oil when needed!

What Type Of Lubrication Is Typically Best For Lathe Leadscrews: Grease, Oil, Or Other Alternatives?For lathe leadscrews, a light oil is usually the best choice. It spreads easily and helps keep everything moving smoothly. Grease can be too thick and might trap dirt. So, using oil is a smart way to keep your lathe working well.

How Can Operators Effectively Monitor The Condition Of The Leadscrew To Determine If It Needs Lubrication Sooner Than The Recommended Interval?You can check the leadscrew by feeling it with your hand. If it feels rough or makes strange noises, it might need oil. You can also look for wear or rust. Regularly cleaning it helps you see any problems. This way, you can keep it working well between oiling times.

Are There Specific Maintenance Practices That Should Be Followed In Conjunction With Regular Lubrication Of A Lathe Leadscrew To Ensure Optimal Performance?Yes, we should keep the lathe clean. Dust and dirt can mess up how it works. You should check for any loose parts and fix them. It’s also good to look for wear and tear on the leadscrew. This way, we keep everything running smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Leadscrew Lubrication Interval:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about how often to lubricate a lathe’s leadscrew. 1. **What is a leadscrew?** A leadscrew helps move the lathe tool back and forth. It’s important for making precise cuts. 2. **Why do we need to lubricate it?** We lubricate the leadscrew to keep it running smoothly. This helps prevent rust and wear. 3. **How often should we oil the leadscrew?** You should oil the leadscrew every few hours of use. Regular oiling keeps it in good shape. 4. **What happens if we forget to lubricate?** If you forget to lubricate, the leadscrew can get stuck. This can damage the lathe and make it harder to use. 5. **What kind of oil should we use?** You should use a light machine oil. It helps keep everything moving without getting sticky.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Recommended Lubrication Interval For A Lathe Leadscrew?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lubrication interval for a lathe leadscrew depends on a few important things. First, how much you use the lathe affects how often you need to lubricate. The type of work you do matters too; tougher jobs need more lubrication. Also, the type of oil or grease you use can change how often you should apply it. Finally, the environment, like dust or heat, can impact the lubrication needs.”}},{“@type”: “Question”,”name”: “How Can Improper Lubrication Of A Lathe Leadscrew Affect The Machine’S Performance And Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If we don’t put enough oil on the lathe leadscrew, it can get stuck. This makes the machine harder to move. When the lathe doesn’t move smoothly, it can make mistakes, like cutting uneven shapes. Good lubrication keeps everything running well and helps make accurate cuts. So, always check and add oil when needed!”}},{“@type”: “Question”,”name”: “What Type Of Lubrication Is Typically Best For Lathe Leadscrews: Grease, Oil, Or Other Alternatives?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For lathe leadscrews, a light oil is usually the best choice. It spreads easily and helps keep everything moving smoothly. Grease can be too thick and might trap dirt. So, using oil is a smart way to keep your lathe working well.”}},{“@type”: “Question”,”name”: “How Can Operators Effectively Monitor The Condition Of The Leadscrew To Determine If It Needs Lubrication Sooner Than The Recommended Interval?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can check the leadscrew by feeling it with your hand. If it feels rough or makes strange noises, it might need oil. You can also look for wear or rust. Regularly cleaning it helps you see any problems. This way, you can keep it working well between oiling times.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Practices That Should Be Followed In Conjunction With Regular Lubrication Of A Lathe Leadscrew To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we should keep the lathe clean. Dust and dirt can mess up how it works. You should check for any loose parts and fix them. It’s also good to look for wear and tear on the leadscrew. This way, we keep everything running smoothly!”}}]}