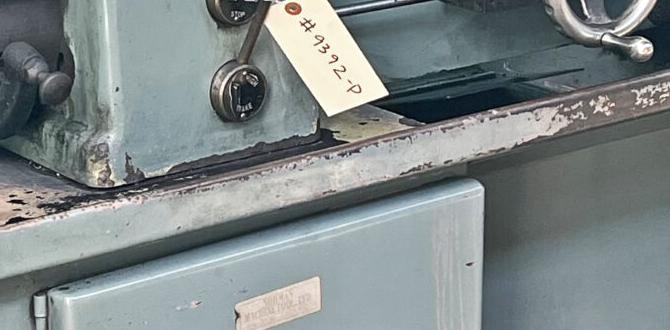

Have you ever watched a lathe in action? It’s fascinating to see how metal transforms under the spinning tool. But did you know that proper lathe lubrication is key to keeping those machines running smoothly? Without the right lubrication, even the best metal lathe can jam or wear out quickly.

Imagine creating a perfect CAD design for your project. You work hard on every detail, but then the lathe gets stuck. Frustrating, right? That’s why understanding how to properly lubricate your lathe can save you time and effort. It allows your creativity to flow without interruptions.

Many people don’t realize that lubrication isn’t just about oil. It’s about choosing the right kind for your specific machine. Each metal lathe has unique needs. So, knowing what works best can make all the difference.

So, let’s dive into how proper lathe lubrication can elevate your metalworking game. With the right tips in mind, you’ll be well on your way to crafting amazing designs with ease.

Effective Lathe Lubrication For Metal Lathe Cad Design

Lathe Lubrication for Metal Lathe CAD Design

Lathe lubrication plays a crucial role in metal lathe operations. Proper lubrication reduces friction, prevents wear, and ensures smooth movement. Did you know that using the right oil can extend the life of your machine? CAD design tools help plan effective lubrication systems. They show precise locations for oiling points, making maintenance easier. With the right strategy, you can keep your lathe running efficiently and enhance overall performance. Wouldn’t you want that for your workshop?Understanding Lathe Lubrication

Importance of lubrication in metal lathes. Common types of lubricants used in machining.Lubrication is the unsung hero of metal lathes. It keeps your machine running smoothly and prevents nasty wear and tear. Without it, things could get as messy as a toddler with spaghetti! Common lubricants used in machining include oil, grease, and even specialty fluids designed for heavy-duty tasks. Each type has its own benefits, so choose wisely! Here’s a quick look:

| Type of Lubricant | Use |

|---|---|

| Oil | General lubrication and easy flow |

| Grease | Heavy-duty tasks where staying power is needed |

| Specialty Fluids | High-pressure and high-temperature applications |

Choosing the right lubricant can turn your lathe from a grumpy machine to a happy worker! Take care of your tools, and they’ll take care of you!

Principles of CAD Design for Metal Lathes

Key features to incorporate in CAD models. How CAD design impacts lubrication efficiency.Good CAD design for metal lathes includes key features. First, models must represent realistic shapes. These shapes improve lubrication efficiency. Second, include lubrication paths. This helps oil reach the right spots. Third, materials should be specified clearly. Proper materials ensure durability. Effective CAD designs boost performance. They help machines run smoothly and last longer. In fact, great designs can delay machine wear!

What features should be in CAD models for metal lathes?

Key features include realistic shapes, lubrication paths, and proper material specifications.

Benefits of good CAD design:

- Improved lubrication flow

- Reduced friction

- Extended machine lifespan

Choosing the Right Lubricant for Your Metal Lathe

Factors to consider when selecting a lubricant. Comparative analysis of oils, greases, and synthetic options.Finding the right lubricant for your metal lathe can make your work smoother. Consider these factors:

- Viscosity: Thicker oils may protect better, but thinner ones flow easier.

- Temperature: Some lubes perform well in heat, while others stay effective in cold.

- Type of work: Different tasks might need different lubricants.

You can choose from oils, greases, or synthetic options. Oils can spread quickly, while greases offer longer protection. Synthetics may last even longer and resist temperature changes.

How do I know which lubricant to choose?

Many factors matter. Choose based on what feels right for your lathe and the job at hand.

Effective Lubrication Techniques for Metal Lathes

Strategies for manual lubrication. Automation options for lubrication in CNC lathes.Keeping metal lathes happy is all about effective lubrication. For manual lubricating, grab a grease gun and give those parts a squeeze. Think of it as a spa day for your machine! But if your CNC lathe is feeling fancy, consider automating the process. Automatic systems can sprinkle oil like confetti during a parade. Below is a simple comparison of methods:

| Lubrication Type | Benefit |

|---|---|

| Manual | Cost-effective and allows for personal touch! |

| Automated | Consistency! No more skipping lunch to oil your lathe! |

Remember, a well-lubricated lathe is a happy lathe, and happiness leads to quality work!

Common Mistakes in Lathe Lubrication

Overlubrication vs. underlubrication consequences. Misapplication of lubricants in CAD designs.Many makers face big issues with lathe lubrication. Overlubrication can create messes and attract dirt. This leads to machine breakdowns. On the other hand, underlubrication increases friction, causing parts to wear out quickly. It’s like running without water! Also, using the wrong lubricant in CAD designs can mess up your projects. Always choose the right type for each part. Keeping it simple helps machines run smoother.

What happens if I over or under lubricate my lathe?

Overlubrication can clog parts, while underlubrication can cause wear and tear. Both can lead to big repair costs.

Key Mistakes to Avoid:

- Not checking lubricant types.

- Overusing lubricants.

- Ignoring CAD specifications.

Maintenance Practices for Optimal Lubrication

Regular inspection routines for lubrication systems. Tips for maintaining CAD designs to improve lubrication setup.Regular checks on lubrication systems are like giving your lathe a quick spa day. Schedule weekly inspections to make sure everything is flowing smoothly. Look for leaks or clogs, and keep those pesky dust bunnies away! For CAD designs, tweak your setup to match real-life needs. Use clear visuals and annotations to show lubrication points. This will make installation a breeze. Remember, a happy lathe leads to shiny metal while avoiding cranky machine tantrums!

| Inspection Task | Frequency |

|---|---|

| Check Oil Levels | Weekly |

| Inspect Lubrication Lines | Bi-Weekly |

| Clean Dust Filters | Monthly |

Impact of Lubrication on Longevity and Performance of Metal Lathes

Correlation between proper lubrication and machinery lifespan. Performance metrics affected by effective lubrication strategies.Lubrication is like a superhero for metal lathes. It helps them run smoothly and live longer. Without proper lubrication, machines can wear out faster than a toddler’s favorite toy. The right oil keeps everything moving and improves the lathe’s performance. Good lubrication decreases friction and heat, making your work precise and shiny!

| Benefits of Lubrication | Impact on Longevity |

|---|---|

| Reduced wear | Increases lifespan |

| Less heat | Prevents breakdowns |

| Smoother operation | Enhances accuracy |

So remember, treat your lathe well; oil it up, and it will return the favor!

Conclusion

In summary, lathe lubrication is crucial for keeping your metal lathe running smoothly. Proper lubrication extends the lathe’s life and improves accuracy. Understanding CAD design can help you create better projects. We encourage you to explore more about lubrication techniques and CAD software. This knowledge will make your metalworking experience even more enjoyable and effective. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication, Metal Lathe Design, And Cad:Sure! Here’s a brief answer about lathe lubrication. Lathe lubrication helps machines work better. It keeps parts from getting too hot and breaking. When we add oil, it makes everything smooth. This lets us cut metal shapes easily and safely.

Sure! Please provide the question you would like me to answer.

What Are The Best Lubrication Methods For Different Types Of Metal Lathes, And How Do They Impact Machine Performance?Using the right lubrication for metal lathes helps them run smoothly. For example, oil works well for moving parts, keeping them safe from wear. Grease is great for places that don’t move a lot, as it sticks better. Good lubrication keeps machines cool and helps them last longer. When we care for our lathes, they work better and make our jobs easier!

How Can Cad Software Be Utilized To Design An Effective Lubrication System For A Metal Lathe, Considering Factors Like Ease Of Access And Oil Distribution?You can use CAD (Computer-Aided Design) software to create a plan for a lubrication system on a metal lathe. First, design the layout to make it easy to reach all parts. Then, you can show where the oil will go, so every part gets enough. Make sure the oil lines are clear and not too crowded. Finally, you can test your design in the software before you build it!

What Are The Common Materials And Components Required For Creating A Custom Lubrication System In A Cad Design For A Metal Lathe?To create a custom lubrication system for a metal lathe using CAD (Computer-Aided Design), you need some basic materials and parts. First, you will need tubes to carry the oil. You also need a pump to move the oil where it’s needed. Don’t forget oil reservoirs to hold the oil. Lastly, you’ll need fittings to connect everything together. Make sure to choose materials that can handle oil well!

How Does The Choice Of Lubricant Affect The Longevity And Maintenance Of A Metal Lathe, And How Can This Be Incorporated Into The Cad Design Process?The right lubricant helps a metal lathe work smoothly. It reduces wear and tear, which means it lasts longer. If we choose the best lubricant, we spend less time fixing it. In the Computer-Aided Design (CAD) process, we can include notes about using special lubricants. This way, everyone remembers to keep the lathe running well.

What Are The Key Design Features In A Metal Lathe That Facilitate Optimal Lubrication And Minimize Wear During Operation?A metal lathe has special spots for oil that help it stay smooth. These spots allow the oil to flow easily, keeping the moving parts from rubbing too much. The lathe’s parts often fit together tightly to help keep dirt out, which also helps it last longer. Some lathes even have a way to automatically add oil while you work. These designs help keep everything working well and reduce wear.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication, Metal Lathe Design, And Cad:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a brief answer about lathe lubrication. Lathe lubrication helps machines work better. It keeps parts from getting too hot and breaking. When we add oil, it makes everything smooth. This lets us cut metal shapes easily and safely.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Lubrication Methods For Different Types Of Metal Lathes, And How Do They Impact Machine Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the right lubrication for metal lathes helps them run smoothly. For example, oil works well for moving parts, keeping them safe from wear. Grease is great for places that don’t move a lot, as it sticks better. Good lubrication keeps machines cool and helps them last longer. When we care for our lathes, they work better and make our jobs easier!”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design An Effective Lubrication System For A Metal Lathe, Considering Factors Like Ease Of Access And Oil Distribution?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD (Computer-Aided Design) software to create a plan for a lubrication system on a metal lathe. First, design the layout to make it easy to reach all parts. Then, you can show where the oil will go, so every part gets enough. Make sure the oil lines are clear and not too crowded. Finally, you can test your design in the software before you build it!”}},{“@type”: “Question”,”name”: “What Are The Common Materials And Components Required For Creating A Custom Lubrication System In A Cad Design For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a custom lubrication system for a metal lathe using CAD (Computer-Aided Design), you need some basic materials and parts. First, you will need tubes to carry the oil. You also need a pump to move the oil where it’s needed. Don’t forget oil reservoirs to hold the oil. Lastly, you’ll need fittings to connect everything together. Make sure to choose materials that can handle oil well!”}},{“@type”: “Question”,”name”: “How Does The Choice Of Lubricant Affect The Longevity And Maintenance Of A Metal Lathe, And How Can This Be Incorporated Into The Cad Design Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The right lubricant helps a metal lathe work smoothly. It reduces wear and tear, which means it lasts longer. If we choose the best lubricant, we spend less time fixing it. In the Computer-Aided Design (CAD) process, we can include notes about using special lubricants. This way, everyone remembers to keep the lathe running well.”}},{“@type”: “Question”,”name”: “What Are The Key Design Features In A Metal Lathe That Facilitate Optimal Lubrication And Minimize Wear During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has special spots for oil that help it stay smooth. These spots allow the oil to flow easily, keeping the moving parts from rubbing too much. The lathe’s parts often fit together tightly to help keep dirt out, which also helps it last longer. Some lathes even have a way to automatically add oil while you work. These designs help keep everything working well and reduce wear.”}}]}