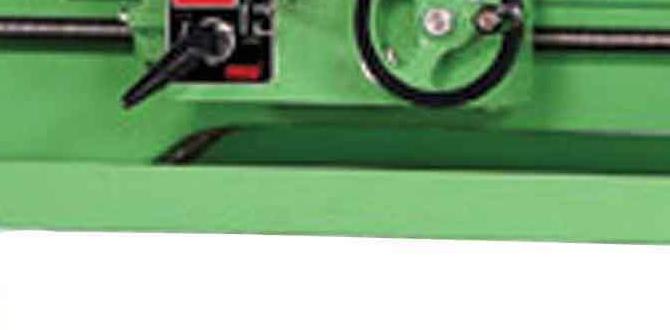

Have you ever wondered why machines work better with a little oil? Lubrication is key, especially for a metal lathe. These tools shape and cut metal with great precision. But without proper lathe lubrication, they can struggle and wear down quickly.

Imagine trying to ride your bike with rusty wheels. It wouldn’t go far, right? Similarly, a metal lathe needs smooth movement to function well. That’s where lathe lubrication comes in. It keeps everything running smoothly and prevents damage.

Now, let’s talk about power feed. This feature helps your lathe work automatically. It saves time and energy. But did you know that even the power feed needs lubrication? It’s true! Whether you’re a beginner or a pro, knowing how to lubricate your lathe can make a big difference.

In this article, we’ll explore the best ways to lubricate your lathe and keep it running like new. Get ready to learn how to make your metal lathe a power tool that works hard for you!

Essential Lathe Lubrication For Metal Lathe Power Feed Maintenance

Lathe Lubrication for Metal Lathe Power Feed

Proper lathe lubrication is crucial for smooth metal lathe operation and power feed efficiency. It reduces friction, extending the machine’s lifespan and improving precision. Did you know that using the right oil can prevent costly repairs? Regularly check lubrication levels and apply oil to moving parts. This simple routine can dramatically enhance performance. Imagine completing your projects faster with fewer interruptions! Keeping your lathe well-lubricated makes a big difference in your workshop.Understanding Lathe Lubrication

Importance of lubrication in metalworking machinery. Types of lubricants used in lathes.Lubrication is vital for metalworking machines like lathes. It keeps parts moving smoothly, preventing wear and tear. Without it, machines can break down, causing accidents and costly repairs. Common lubricants used in lathes include:

- Mineral oil

- Synthetic oil

- Grease

Each type has unique benefits. Proper lubrication helps extend the life of your lathe and improves performance.

Why is lubrication important for lathes?

Lubrication prevents friction, which can cause damage to the machine. It ensures that all moving parts work together smoothly. Regular lubrication saves time and money.

Types of Lubricants for Metal Lathes

Oilbased vs. greasebased lubricants. Synthetic lubricants: benefits and drawbacks.Choosing the right lubricant for metal lathes can feel like picking the perfect pizza topping. Let’s break it down! There are oil-based and grease-based lubricants. Oil-based lubricants flow easily, great for quick jobs. Grease-based ones stick around longer, perfect for heavy-duty tasks. Then, we have synthetic lubricants. They can be super slick but may cause some issues if not chosen wisely. Here’s a quick comparison:

| Type | Benefits | Drawbacks |

|---|---|---|

| Oil-based | Flows easily | Needs frequent application |

| Grease-based | Lasts longer | Can get messy |

| Synthetic | High performance | Can be pricey |

So, whether you need to keep it slick or sticky, there’s a lubricant for every lathe job!

Proper Lubrication Techniques for Power Feeds

Recommended lubrication points on a power feed. Frequency and amount of lubrication needed.Keeping your power feed running smoothly is like giving your lathe a nice spa day! The main lubrication spots include the lead screw and the bearings. It’s best to check and oil them every 50 hours of operation. As for how much, a little goes a long way—think of it like putting on butter on toast, not a whole stick! Overdoing it can lead to a slippery mess.

| Lubrication Point | Frequency | Amount |

|---|---|---|

| Lead Screw | Every 50 hours | Small amount |

| Bearings | Every 50 hours | Pinch of grease |

Remember, regular care means a happy lathe, and happy lathes make cool projects! So, grab that oil can and let’s keep things moving smoothly.

Common Mistakes in Lathe Lubrication

Overlubrication and its effects on performance. Choosing the wrong lubricant for your lathe.Lubrication is key for keeping your lathe running smoothly. However, too much oil can cause a slippery mess. Overlubrication makes chips stick to the machine, which can harm performance. Imagine trying to run a race in shoes filled with jelly! Choosing the wrong lubricant is another big oops. Every type of lathe needs the right oil. The wrong choice can lead to damage and results that are less than stellar. Think of it like putting ketchup on ice cream—just doesn’t fit!

| Mistake | Effect |

|---|---|

| Overlubrication | Causes chips to stick and performance drops |

| Wrong lubricant | Leads to damage and poor results |

Signs of Insufficient Lubrication

Indicators that your lathe requires more lubrication. Maintenance schedules and checklists.Have you noticed your lathe acting a bit sluggish? That could mean it’s time for a little oil! Here are some signs to look for. First, watch for unusual noises, like a cat trying to sing. This could mean it needs more lube. Secondly, if the machine feels stiff, it’s like trying to ride a bicycle with square wheels—definitely not ideal! Check your maintenance schedule. Regular checklists can save the day. Think of them as your lathe’s favorite snack! They help ensure everything runs smoothly.

| Signs of Insufficient Lubrication | Action Needed |

|---|---|

| Unusual Noises | Add lubrication |

| Stiff Movements | Check oil levels |

| Increased Heat | Lubricate parts |

Keep an eye out for these signs. A well-lubricated lathe is a happy lathe!

Best Practices for Lathe Maintenance and Lubrication

Routine checks and proactive maintenance strategies. How lubrication impacts tool lifespan and productivity.Taking care of your lathe is like giving your puppy a bath—necessary, but not always fun! Regular checks help you spot issues early. Try checking the fluids and belts every week. This simple habit avoids big problems later.

Lubrication isn’t just for preventing rust; it makes your tools happy! A well-lubricated lathe can double its lifespan. Yes, you read that right—double! A happy lathe also works faster, boosting your productivity.

| Routine Maintenance Tips | Benefits |

|---|---|

| Weekly Lubrication | Extends tool life |

| Check Belts Regularly | Avoid breakdowns |

| Clean Dust and Debris | Enhances performance |

Remember, a little effort goes a long way. Your lathe will thank you with smooth operations and happy projects!

FAQs about Lathe Lubrication

Common queries related to lubrication and its impact on metal lathe performance. Expert advice on troubleshooting lubrication issues.Many people ask about lathe lubrication and how it helps a metal lathe. Proper lubrication keeps the lathe running smoothly. Without it, parts can wear out quickly. Are you facing issues? Here are some common problems with solutions:

- Oil is leaking: Check for loose fittings.

- No oil flow: Clean the oil lines.

- Unusual sounds: Add more lubricant or check for blockages.

Experts agree that routine checks can prevent these issues. Keeping your lathe well-oiled can make it last longer and work better.

Conclusion

In conclusion, proper lathe lubrication is essential for smooth operation and longevity of your metal lathe’s power feed. You should regularly check and apply the right lubricant to keep everything running efficiently. Remember, well-lubricated machines perform better and last longer. For more tips on maintenance, consider exploring guides or videos to enhance your skills. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication For Metal Lathes, Specifically Focusing On Power Feeds:Sure! Keeping your metal lathe lubricated is important for smooth operation. You need to use the right oil for the power feed. This helps the moving parts work well and prevents rust. Check the oil level and change it regularly to keep everything running nicely. Don’t forget to follow the instructions in the manual!

Sure! Please ask your question, and I’ll give you a short answer that’s easy to understand.

What Are The Best Types Of Lubricants To Use For The Power Feed Mechanism On A Metal Lathe?For the power feed mechanism on a metal lathe, you should use light machine oil or lithium grease. Light machine oil helps parts move smoothly. Lithium grease sticks well and lasts longer. Always make sure to apply just enough, so it doesn’t get messy. Regular lubrication keeps your lathe happy and working well!

How Often Should The Power Feed System On A Metal Lathe Be Lubricated To Ensure Optimal Performance?You should lubricate the power feed system on a metal lathe every few weeks. If you use it a lot, do this more often. Check the machine’s instructions for specific advice. This helps keep everything working smoothly. Regular oiling makes sure your lathe lasts longer.

What Are The Signs That A Power Feed On A Metal Lathe Is Not Adequately Lubricated?If the power feed on a metal lathe isn’t getting enough oil, you might notice a few things. First, it can make strange noises when it moves. You might also see parts getting rusty or worn out. The machine could move more slowly than usual, too. These signs show it needs more lubrication to work well.

Can Improper Lubrication Of The Power Feed Lead To Damage Or Wear In A Metal Lathe?Yes, if you don’t lubricate the power feed properly, it can hurt the metal lathe. The machine parts may grind against each other. This can cause them to wear out faster. You should always check and use the right oil. Keeping it well-lubricated helps everything run smoothly.

Are There Specific Lubrication Maintenance Tips For Power Feeds On Older Metal Lathes Compared To Newer Models?Yes, older metal lathes often need more careful lubrication. You should check the oil level regularly. Use the right oil type for your machine. Newer lathes usually have better seals, so they hold oil better. Always clean out old oil before adding new oil.