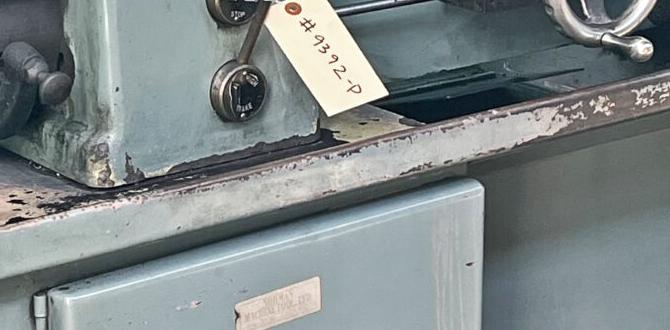

Have you ever watched a metal lathe in action? It’s fascinating to see how metal turns into precise shapes. But there’s more to it than just spinning metal. One important factor often overlooked is lathe lubrication, especially when it comes to keeping a lathe pulley in good shape.

Imagine a car engine without oil. It wouldn’t run very well, right? The same goes for a metal lathe. Without proper lubrication, parts can wear out or break. This can cause a lot of problems during your projects. What if you could avoid those troubles with just a little care?

In this article, we’ll explore why lathe lubrication matters. We’ll discuss how it helps your lathe pulley work smoothly. You’ll learn tips that can make your metal lathe last longer and function better. Are you ready to keep your lathe in top shape?

Essential Lathe Lubrication For Metal Lathe Pulley Performance

Lathe Lubrication for Metal Lathe Pulley

Proper lathe lubrication keeps your metal lathe pulleys in top shape. Imagine your lathe running smoothly, making perfect cuts every time. That’s what good lubrication does! It reduces friction and wear, extending the lathe’s life. Different oils work better for specific machines, so choosing the right one is key. Regularly checking and applying lubrication can prevent expensive repairs. A well-maintained lathe not only saves money but also boosts your projects’ quality. Don’t overlook this easy step for success!Understanding Lathe Lubrication

Importance of lubrication in metalworking machinery. Common types of lubricants used for lathes.Lubrication is vital for metalworking machines. It keeps parts moving smoothly and prevents wear and tear. Imagine trying to run a race while wearing shoes made of glue! That’s how your lathe feels without grease. Common lubricants for lathes include oil and grease. Each type works like magic, reducing friction like butter on toast. Remember, without proper lubrication, your lathe might just decide to take a vacation!

| Type of Lubricant | Purpose |

|---|---|

| Oil | Reduces friction and cools parts. |

| Grease | Offers long-lasting protection. |

Choosing the Right Lubricant

Factors to consider when selecting lubricants for lathe pulleys. Comparison of oils, greases, and synthetic lubricants.Choosing the right lubricant for lathe pulleys is important. Each type of lubricant has its benefits. Consider the following factors:

- Temperature Range: Some oils work better in heat.

- Application Method: Check if it’s easy to apply.

- Compatibility: Ensure it works with your materials.

Oil, grease, and synthetic lubricants all have unique qualities:

- Oil: Great for fluid movement and less friction.

- Grease: Stays in place, ideal for heavy loads.

- Synthetic Lubricants: Offer longer-lasting protection.

Choosing wisely helps keep your lathe running smoothly.

What factors should I consider when selecting lubricants for lathe pulleys?

You should consider the temperature range, application method, and compatibility with materials.

How do oils, greases, and synthetic lubricants compare?

Oils are for fluid movement, greases stay in place, and synthetic lubricants provide long-lasting protection.

Best Practices for Lubrication

Recommended lubrication intervals for optimal performance. Techniques for applying lubricants effectively.To keep your lathe spinning like a top, regular lubrication is a must! Aim to apply lubricant every 20-50 hours of use. Think of it as giving your machine a refreshing drink. The right technique matters too! Use a clean cloth to apply lubricant evenly on moving parts. Avoid dumping it everywhere like you’re pouring syrup on pancakes! Keeping things tidy will help your lathe work better and last longer.

| Lubrication Frequency | Recommended Action |

|---|---|

| Every 20 hours | Check and apply lubricant |

| Every 50 hours | Thorough cleaning and lubrication |

Signs of Insufficient Lubrication

Common issues caused by poor lubrication in lathe systems. How to diagnose lubrication problems early.Noticing signs of poor lubrication is key for keeping a lathe working well. If your machine makes strange noises, it may lack oil. Overheating parts can also mean something is wrong. Look for wear or rust, too. Fixing these issues early saves time and money.

- Strange sounds from the lathe.

- Parts that feel hot to the touch.

- Visible wear or rust on parts.

What to do about lubrication issues?

Act fast! Always check oil levels and refill as needed. Use a good lubricant, as it keeps things running smooth. Regular maintenance will help spot problems before they grow.

Maintenance Tips for Metal Lathe Pulley Systems

Routine maintenance practices to enhance pulley longevity. Tools and equipment needed for effective lubrication.To keep your metal lathe pulley working well, regular maintenance is key. This helps the pulley last longer. Basic practices include checking, cleaning, and lubricating parts. Use the right tools for the job:

- Screwdriver

- Lubricating oil

- Cleaning cloth

- Brush

Make sure to lubricate the pulley regularly. This can prevent future problems and save money on repairs.

What are the best practices for maintaining a metal lathe pulley?

The best practices include regular lubrication, cleaning dust and debris, and checking for wear and tear.

Environmental Considerations in Lathe Lubrication

Ecofriendly lubricant options for metal lathes. Safe disposal practices for used lubricants.Choosing eco-friendly lubricants for metal lathes can help protect our environment. Biodegradable options work well without harming nature. They break down easily, causing less pollution. It’s important to dispose of used lubricants safely. Never pour them down the drain!

- Check local laws for disposal rules.

- Use recycling services for oil.

- Store in sealed containers until disposal.

By making smart choices, everyone can keep our planet clean!

What are eco-friendly lubricant options?

Some good choices include water-based lubricants and plant-based oils. These options reduce harm to the environment and can work just as well as traditional lubricants.

Troubleshooting Lubrication Issues

Common lubricationrelated problems and their solutions. Preventive measures to avoid future lubrication issues.Lubrication issues can be tricky. Common problems include dry gears and noisy pulleys. These can slow down your metal lathe and cause damage. Lubricate regularly to keep everything running smoothly. If you notice strange noises or difficulty in movement, check the oil levels. Always use the right type of lubricant. Here are some tips:

- Use a clean cloth to wipe off old grease.

- Check for leaks in the lubrication system.

- Regularly replace old oil with fresh lubricant.

Taking these small steps can prevent future problems. Keep your lathe working well!

What are common lubricant problems?

Common issues include dry parts and unusual noises. These can lead to bigger issues like damage or breakdowns if ignored.

How can you prevent lubrication problems?

To avoid problems, check oil levels often and use the right lubricant. Clean your lathe regularly. This care keeps everything running smoothly.

Conclusion

In summary, properly lubricating your metal lathe pulley is essential for smooth operation and longevity. Regular lubrication reduces friction and wear, ensuring your lathe works efficiently. Always choose the right lubricant for your machine. To learn more, check your lathe manual or look up guides online. Taking these steps will help keep your lathe in great shape!FAQs

What Are The Recommended Lubricants For Maintaining A Metal Lathe Pulley System?To keep a metal lathe pulley system working well, you should use light machine oil or lithium grease. These lubricants help reduce friction and keep the parts moving smoothly. You can apply the oil with a cloth or a small brush. Always check the manufacturer’s guide for any special recommendations, too!

How Often Should A Metal Lathe Pulley Be Lubricated To Ensure Optimal Performance?You should lubricate a metal lathe pulley every few months. If you use it a lot, do it more often. Check the pulley for any signs of dryness. When it feels smooth and easy to turn, you know it’s working well. Keeping it lubricated helps it last longer and work better.

What Are The Signs Of Improper Lubrication In A Lathe Pulley System?If a lathe pulley system is not lubricated properly, you might notice some signs. First, you could hear squeaking or grinding noises. Next, the pulley might move slowly or get stuck. You may also see wear or damage on the parts. Finally, if you feel heat coming from the pulley, it’s a sign it needs more oil.

Can Using The Wrong Type Of Lubricant Damage The Components Of A Metal Lathe Pulley?Yes, using the wrong lubricant can hurt the metal lathe pulley. It might make the parts stick or wear out faster. This can cause the lathe to work poorly or even break. Always use the right lubricant for your machine to keep it safe.

What Is The Proper Technique For Applying Lubricant To A Metal Lathe Pulley?To apply lubricant to a metal lathe pulley, first, clean the pulley with a cloth. Next, use a small amount of lubricant. You can use a grease or oil made for machines. Spread it evenly over the moving parts. Make sure not to use too much, as it can attract dirt.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Recommended Lubricants For Maintaining A Metal Lathe Pulley System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe pulley system working well, you should use light machine oil or lithium grease. These lubricants help reduce friction and keep the parts moving smoothly. You can apply the oil with a cloth or a small brush. Always check the manufacturer’s guide for any special recommendations, too!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Pulley Be Lubricated To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate a metal lathe pulley every few months. If you use it a lot, do it more often. Check the pulley for any signs of dryness. When it feels smooth and easy to turn, you know it’s working well. Keeping it lubricated helps it last longer and work better.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Improper Lubrication In A Lathe Pulley System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe pulley system is not lubricated properly, you might notice some signs. First, you could hear squeaking or grinding noises. Next, the pulley might move slowly or get stuck. You may also see wear or damage on the parts. Finally, if you feel heat coming from the pulley, it’s a sign it needs more oil.”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Lubricant Damage The Components Of A Metal Lathe Pulley? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong lubricant can hurt the metal lathe pulley. It might make the parts stick or wear out faster. This can cause the lathe to work poorly or even break. Always use the right lubricant for your machine to keep it safe.”}},{“@type”: “Question”,”name”: “What Is The Proper Technique For Applying Lubricant To A Metal Lathe Pulley? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To apply lubricant to a metal lathe pulley, first, clean the pulley with a cloth. Next, use a small amount of lubricant. You can use a grease or oil made for machines. Spread it evenly over the moving parts. Make sure not to use too much, as it can attract dirt.”}}]}