Have you ever wondered how metal lathes work so smoothly? A big part of that secret lies in proper lathe lubrication. Keeping your lathe well-lubricated can make a huge difference. It helps prevent wear and tear, ensuring your machine runs better and lasts longer.

Imagine a metal lathe you’ve just bought. You want it to perform its best, right? Using the right lubrication keeps everything moving smoothly. Plus, with a quick change tool post, you can switch tools without skipping a beat. This speeds up your work and saves you time.

But, did you know that neglecting lubrication can lead to costly repairs? It’s true! Regular maintenance is as important as choosing high-quality tools. A small effort in lubrication can make a big impact on your projects. So, let’s explore how to keep your lathe and tools in top shape!

Lathe Lubrication: Metal Lathe Quick Change Tool Post Guide

Understanding Lathe Lubrication and Quick Change Tool Post

Lathe lubrication is crucial for keeping a metal lathe running smoothly. Proper lubrication reduces friction and wear on parts. Did you know that using the right oil can extend your tool’s life? A quick change tool post helps you switch tools faster. This saves time and makes your projects more efficient. By learning about these features, you can improve your lathe work. Imagine finishing projects quicker while getting better results!Importance of Lathe Lubrication

Benefits of proper lubrication for machine longevity. Impact on precision and surface finish quality.Keeping your lathe well-lubricated is like giving it a warm hug. A good oil helps it last longer, like a favorite toy that doesn’t get old. Proper lubrication ensures smooth moves, so your metal projects look great. Imagine crafting something shiny and perfect! Without enough oil, machines squeal like a rusty door. Plus, it can mess up precision. Regular lubrication is the secret to success in your workshop!

| Benefits of Lubrication | Impact on Quality |

|---|---|

| Increases machine lifespan | Improves precision |

| Reduces wear and tear | Enhances surface finish |

| Prevents overheating | Boosts overall performance |

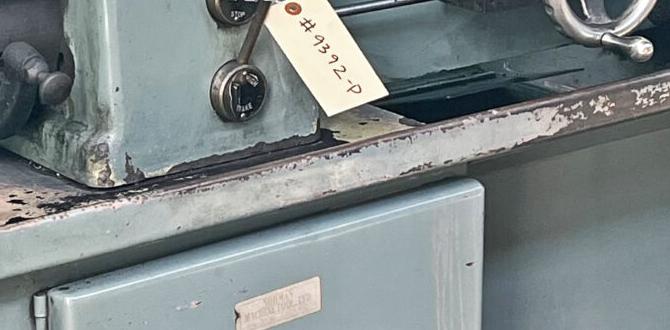

Lubrication Points on a Metal Lathe

Key areas requiring lubrication (spindle, saddle, etc.). Recommended lubrication frequency for each point.Keeping a metal lathe well-lubricated is key for smooth operations. You should focus on a few important spots. First is the spindle, where you should apply lubricant often to keep it running without a hitch. Next is the saddle. A little oil goes a long way here too. And don’t forget the tailstock! Regular lubrication helps to avoid unnecessary hiccups, like squeaks that sound like a cat in a blender.

| Part | Recommended Lubrication Frequency |

|---|---|

| Spindle | Every 8 hours of operation |

| Saddle | Daily |

| Tailstock | After every few uses |

Stick to these points and your lathe will hum along, instead of crying for help! Plus, a well-oiled machine is a happy machine.

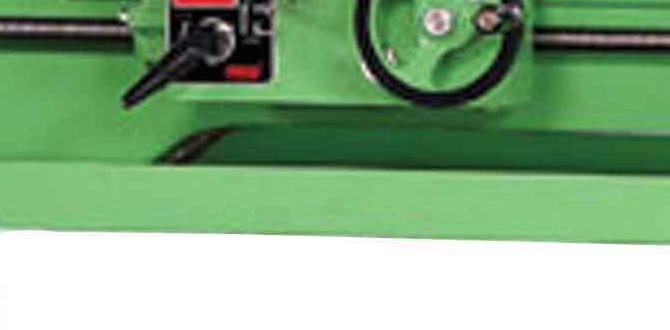

Quick Change Tool Post Mechanics

Explanation of quick change tool post functionality. How lubrication affects tool post performance.A quick change tool post makes switching tools easy on a lathe. You can change tools without losing time, making work faster and smoother. Lubrication is key for a great-performing tool post. It keeps parts moving easily and reduces wear. This helps tools last longer and work better.

- Easy transitions between tools save valuable time.

- Proper lubrication helps keep everything running smoothly.

- Less wear means longer tool life and less replacement.

How does lubrication help the quick change tool post?

Lubrication helps the quick change tool post by reducing friction and heat. This makes tools work better and last longer.

Choosing the Right Lubricant for Your Lathe

Factors to consider when selecting a lubricant. Recommended brands and products for metal lathes.Choosing the right lubricant is key for your lathe’s performance. Think about the type of work you’ll do. Will you be cutting hard metals or softer ones? It’s crucial to select a lubricant that matches your needs. Here are some great options:

- ISO 32 Oil – Good for general use

- Way Oil – Helps prevent rust

- Cutting Oil – Ideal for cutting tasks

Also, consider brands like Mobil, Chevron, and Castrol. These brands offer high-quality products that metalworkers trust.

What should I consider while selecting lubricant?

Check the viscosity, application type, and manufacturer recommendations.What lubricant works best for a metal lathe?

Way Oil and Cutting Oil are usually the best choices.Step-by-Step Lubrication Process

Detailed procedure for lubricating a metal lathe. Tools and equipment needed for effective lubrication.First, gather the right tools for lubricating your metal lathe. You’ll need machine oil, a clean cloth, and an oil can. Now, follow these steps:

- Check the oil level in the lathe.

- Clean any dirt from the lubrication points.

- Apply a small amount of oil to each point.

- Move the machine to spread the oil evenly.

- Wipe away any excess oil.

This routine will help your lathe run smoothly and last longer!

What tools are needed for lathe lubrication?

The main tools you need are machine oil, a clean cloth, and an oil can. These will make lubrication easy and effective.

Maintenance Schedule for Lathe Lubrication

Developing a regular maintenance routine. Recommended intervals for different tasks related to lubrication.Creating a regular maintenance routine for your lathe lubrication is key to keeping it running smoothly. You wouldn’t want your lathe to sound like it’s auditioning for a heavy metal band! Lubrication intervals depend on usage, but a good rule of thumb is to grease it every 8 hours of operation. Daily checks for any leaks or wear are also smart moves. Below is a handy schedule:

| Task | Recommended Interval |

|---|---|

| General Lubrication | Every 8 hours |

| Inspect Oil Levels | Daily |

| Deep Clean Machine | Weekly |

| Full Maintenance Check | Monthly |

Following this schedule keeps your lathe happy and helps avoid unexpected surprises. Remember, a well-lubricated lathe is a happy lathe!

Troubleshooting Lubrication Problems

Identifying signs of inadequate lubrication. Solutions for common lubricationrelated issues.It’s important to spot lubrication issues early. Look for these signs: strange noises, metal shavings, or uneven cuts. These can mean your lathe is not getting enough oil. Ignoring these signs can lead to bigger problems. To fix common lubrication problems, do these things:

- Check oil levels regularly.

- Clean the lubrication ports.

- Use the right lubricant for your machine.

Keeping your metal lathe lubricated helps it run smoothly and lasts longer.

What are common signs of lubrication problems?

Common signs include unusual sounds, poor surface finish, and visible rust.

Solutions for lubrication problems

- Check oil levels frequently.

- Ensure no obstructions in lube channels.

- Use recommended lubricants only.

Conclusion

In summary, proper lathe lubrication is essential for smooth operation and tool longevity. Using a quick change tool post saves time and boosts productivity. Remember to check your lubrication regularly and adjust as needed. For more tips on maintaining your metal lathe, consider reading further or asking experienced users in your workshop. Happy machining!FAQs

What Type Of Lubricants Are Recommended For Maintaining A Metal Lathe’S Quick Change Tool Post?You should use light oil or machine oil for your metal lathe’s quick change tool post. These oils keep the parts moving smoothly. You can also use grease for the bigger pieces. Just be careful not to use too much. Always clean off old lubricant before putting on new oil or grease.

How Often Should You Lubricate The Moving Parts Of A Quick Change Tool Post On A Metal Lathe?You should lubricate the moving parts of a quick change tool post regularly. Do this after every few uses or daily if you work a lot. This helps keep things running smoothly and prevents rust. Just put a little oil on the parts that move.

What Are The Signs That Indicate A Quick Change Tool Post On A Lathe Needs Lubrication?You can tell a quick change tool post on a lathe needs lubrication if it feels sticky or hard to move. If you hear squeaking or grinding sounds when you use it, that’s a sign too. You might also see rust or dirt on the moving parts. If it looks dry or hard to adjust, it’s time to add some oil!

Can Improper Lubrication Of A Metal Lathe’S Quick Change Tool Post Affect Machining Accuracy?Yes, if you don’t put enough oil or grease on the quick change tool post of a metal lathe, it can cause problems. The tool post helps hold the cutting tools in place. Without proper lubrication, it might not move as smoothly. This can make your cuts less precise, leading to mistakes in your work. Always check and add lubrication to keep everything running well!

What Are Some Best Practices For Applying Lubricant To The Tool Post And Other Components Of A Metal Lathe?To keep your metal lathe working well, you should use lubricant carefully. First, clean the tool post and other parts to remove dirt. Then, apply a small amount of lubricant where metal touches metal. Use a cloth or a brush to spread it evenly. Don’t use too much, or it can get messy and attract dust!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Lubricants Are Recommended For Maintaining A Metal Lathe’S Quick Change Tool Post? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use light oil or machine oil for your metal lathe’s quick change tool post. These oils keep the parts moving smoothly. You can also use grease for the bigger pieces. Just be careful not to use too much. Always clean off old lubricant before putting on new oil or grease.”}},{“@type”: “Question”,”name”: “How Often Should You Lubricate The Moving Parts Of A Quick Change Tool Post On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate the moving parts of a quick change tool post regularly. Do this after every few uses or daily if you work a lot. This helps keep things running smoothly and prevents rust. Just put a little oil on the parts that move.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Quick Change Tool Post On A Lathe Needs Lubrication? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a quick change tool post on a lathe needs lubrication if it feels sticky or hard to move. If you hear squeaking or grinding sounds when you use it, that’s a sign too. You might also see rust or dirt on the moving parts. If it looks dry or hard to adjust, it’s time to add some oil!”}},{“@type”: “Question”,”name”: “Can Improper Lubrication Of A Metal Lathe’S Quick Change Tool Post Affect Machining Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, if you don’t put enough oil or grease on the quick change tool post of a metal lathe, it can cause problems. The tool post helps hold the cutting tools in place. Without proper lubrication, it might not move as smoothly. This can make your cuts less precise, leading to mistakes in your work. Always check and add lubrication to keep everything running well!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Applying Lubricant To The Tool Post And Other Components Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well, you should use lubricant carefully. First, clean the tool post and other parts to remove dirt. Then, apply a small amount of lubricant where metal touches metal. Use a cloth or a brush to spread it evenly. Don’t use too much, or it can get messy and attract dust!”}}]}