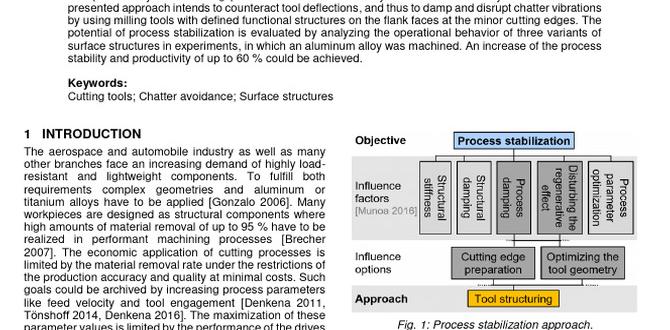

Have you ever wondered how a small amount of oil can make a big difference? In metalworking, especially with machines like a lathe, proper lubrication is essential. The quill on a metal lathe plays a crucial role. It holds and moves the cutting tools. But did you know that without the right lathe lubrication, the quill can wear out quickly?

Imagine your favorite toy that needs batteries to run. Without them, it just won’t work. That’s similar to how a lathe needs lubrication to function smoothly. Keep the quill well-oiled, and your lathe will work better and last longer!

In this article, we will explore the importance of lathe lubrication for the metal lathe quill. We’ll uncover tips and tricks for keeping your lathe in top shape. You might even be surprised by how much a little oil can improve your projects!

Lathe Lubrication: Essential Tips For Metal Lathe Quill

Understanding Lathe Lubrication for Your Metal Lathe Quill

Maintaining your metal lathe quill is crucial for smooth operation. Proper lathe lubrication reduces friction, leading to better performance. But did you know that neglecting lubrication can cause costly damage? It’s true! Regularly oiling the quill ensures accuracy and extends tool life. A fun fact: Did you know some lathes have automatic lubrication systems? These systems help keep your quill in top shape, saving you time and effort! Prioritize lubrication for a reliable machining experience.Understanding Lathe Lubrication

Definition and importance of lubrication in lathe operations. Types of lubricants suitable for metal lathes.Lubrication in lathe operations is like giving your metal friend a nice oil bath. It helps reduce friction and wear, ensuring smooth cuts and a longer life for both the lathe and the tools. Choose the right lubricant to keep everything running smoothly. Common options for metal lathes include oil and grease, each with its perks. Remember, a well-lubricated lathe is a happy lathe—kind of like a cat after a good meal!

| Type of Lubricant | Best For |

|---|---|

| Oil | High-speed operations |

| Grease | Longevity and low-speed tasks |

Remember, proper lubrication can improve your lathe’s performance by up to 30%! So, don’t skip this step, or your lathe might remind you in the most cringe-worthy ways: metal squeaks! 😂

Components of a Metal Lathe Quill

Description of the quill and its function in metal lathes. Other essential components that require lubrication.The quill of a metal lathe is like the magic wand of the workshop. It holds and controls the cutting tool, helping shape the metal into wonderful designs. Proper lubrication keeps it moving smoothly, preventing wear and tear. Other parts that need some love include the spindle and the tailstock, which also crave lubrication to work their best.

| Component | Function | Lubrication Need |

|---|---|---|

| Quill | Holds the cutting tool | Yes |

| Spindle | Rotates the workpiece | Yes |

| Tailstock | Supports tools and workpieces | Yes |

Remember, a well-lubricated lathe is a happy lathe! Neglecting to grease these areas is like forgetting to feed your pet—bad news all around!

Choosing the Right Lubricant for Metal Lathe Quill

Factors to consider when selecting lubricants. Popular lubricant options and their properties.Choosing the right lubricant for your metal lathe quill is like picking the best ice cream flavor—everyone has their favorite! First, think about viscosity, which affects how easily it spreads. Then, consider the operating temperature and the load capacity you need. Here are some popular options:

| Lubricant Type | Properties |

|---|---|

| Mineral Oil | Good for general use, affordable. |

| Synthetic Oil | Lasts longer, works in extreme temps! |

| Graphite | Great for high-pressure areas. |

Remember, using the right lubricant helps your lathe shine and work like a superstar! If you’re unsure, don’t hesitate to ask a pro—after all, even superheroes call for backup sometimes!

Recommended Lubrication Schedule

Frequency of lubrication for different materials and applications. Signs indicating the need for lubrication.Keeping your lathe well lubricated is important. It helps your machine run smoothly and lasts longer. A good schedule depends on what you’re working with. Here are some tips:

- For soft metals, lubricate every 30 minutes.

- For hard metals, check every hour.

- Plastic materials need lubrication every 45 minutes.

Watch for signs. If you hear squeaking, see rust, or notice poor performance, it’s time to add more oil.

When Should You Lubricate a Lathe?

Lubricate your lathe when you notice noise, stalling, or a rough finish on your workpiece.

Common Mistakes in Lathe Lubrication

Errors to avoid when lubricating the lathe quill. Consequences of improper lubrication.Many folks make simple mistakes with lathe lubrication. One big blunder is not using enough oil on the quill. Imagine trying to run a marathon with tight shoes! Similarly, a dry quill can cause serious wear and tear. Another error is using the wrong type of lubricant. It’s like putting pickle juice in a chocolate cake; not a good idea! Over-lubrication can also create a mess and attract dirt, turning your workspace into a sticky pickle jar!

| Error | Consequence |

|---|---|

| Insufficient lubrication | Increased wear and tear |

| Wrong lubricant | Possible damage |

| Over-lubrication | Messy workspace |

To keep your lathe quill happy, remember to apply the right amount of good lubricant. Your tools will thank you, and you’ll avoid those sticky situations!

Maintenance Tips for Prolonging Quill Life

Routine maintenance practices alongside lubrication. Best practices to enhance the lifespan of the quill.To keep your quill in great shape, regular maintenance is essential. A few simple habits can make a big difference. First, clean the quill and its surroundings often. This prevents dust from causing wear. Next, check the lubrication regularly. Applying the right oil helps the quill move smoothly. Here are some tips:

- Wipe down the quill after use.

- Use high-quality oil for lubrication.

- Inspect for any wear or damage each week.

- Keep the area around the lathe clean.

The quill lifespan can improve with these practices. A well-maintained quill can last for many years, saving time and money. Remember, just a little care goes a long way!

How often should I lubricate my lathe quill?

You should lubricate your lathe quill at least once a month or more frequently if you use it often. Regular lubrication keeps it functioning smoothly and extends its life.

FAQs About Lathe Lubrication

Answers to common questions regarding lathe quill lubrication. Troubleshooting issues related to lubrication in metal lathes.Lubrication is key for a metal lathe to run smoothly. Many folks wonder how often they should lubricate the quill. Short answer: often! This keeps the machine happy and problem-free. If your lathe makes strange noises or has sticky movement, it might need a little love in the lubrication department. Here’s a quick guide to help:

| Problem | Solution |

|---|---|

| Strange Noises | Add more lubricant to the quill. |

| Sticky Movement | Check for dirt and clean before lubricating. |

| Inconsistent Cuts | Ensure proper lubrication in all parts. |

Regular maintenance is like a superhero cape for your lathe! Keep it oiled up and ready to go. Who knew metal machines could be so high maintenance?

Conclusion

In summary, using the right lubrication for your metal lathe quill keeps it running smoothly. It reduces wear and tear, helping your machine last longer. Always check your manual for lubrication needs and use high-quality oil. You can improve performance and get better results with proper care. For more tips, consider reading guides on lathe maintenance!FAQs

Sure! Here Are Five Questions Related To Lathe Lubrication And The Quill Of A Metal Lathe:Sure! Here are some answers to questions about lathe lubrication and the quill. 1. Why do we need to lubricate a lathe? We need to lubricate a lathe to keep it running smoothly. Lubrication reduces friction, which helps prevent wear and tear. 2. How do you lubricate the quill? To lubricate the quill, you can use a special oil. Just apply a few drops to the moving parts. 3. What happens if a lathe isn’t lubricated? If a lathe isn’t lubricated, it can get very hot and may break. This can make it harder to work with. 4. How often should we lubricate the lathe? You should lubricate the lathe regularly. Doing it every time you use it is a good idea. 5. Can you use any oil for a lathe? No, we shouldn’t use just any oil. It’s best to use the oil meant for lathes to protect it well.

Sure! Please share the question you’d like me to answer.

What Types Of Lubricants Are Recommended For The Quill Of A Metal Lathe, And How Do They Differ In Effectiveness?For the quill of a metal lathe, we can use oil or grease. Oil is thinner and flows easily, helping to keep things cool. Grease is thicker and sticks better, so it lasts longer. Each type works well, but oil is better for high-speed jobs, while grease is great for slower tasks.

How Often Should The Quill Of A Metal Lathe Be Lubricated To Ensure Optimal Performance And Longevity?You should lubricate the quill of a metal lathe every time you use it. This helps it work smoothly and last longer. If you use the lathe a lot, check the quill for oil more often. A little oil goes a long way in keeping things running well!

What Are The Signs That The Quill On A Metal Lathe May Be Under-Lubricated Or In Need Of Maintenance?If the quill on a metal lathe is under-lubricated or needs maintenance, you might notice some signs. First, it may make strange noises when you use it. Second, the quill could feel sticky or hard to move. Third, you might see metal shavings getting stuck. Lastly, the machine might start to vibrate more than usual.

How Does Proper Lubrication Of The Quill Affect The Accuracy And Precision Of Machining Operations On A Metal Lathe?Lubricating the quill keeps it moving smoothly. This helps the machine cut metal more accurately. When everything works well together, you get better results. If it’s not lubricated, the quill can stick or move unevenly. That can make your cuts less precise and mess up your project.

What Are The Best Practices For Applying Lubricant To The Quill And Other Moving Parts Of A Metal Lathe?To keep your metal lathe working well, apply lubricant carefully. First, turn off the machine to stay safe. Use a clean cloth to wipe dust off the quill and parts. Then, put a small amount of lubricant on a cloth or directly on the parts. Move the quill up and down to spread the lubricant evenly. This helps everything move smoothly and last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Lubrication And The Quill Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers to questions about lathe lubrication and the quill. 1. Why do we need to lubricate a lathe? We need to lubricate a lathe to keep it running smoothly. Lubrication reduces friction, which helps prevent wear and tear. 2. How do you lubricate the quill? To lubricate the quill, you can use a special oil. Just apply a few drops to the moving parts. 3. What happens if a lathe isn’t lubricated? If a lathe isn’t lubricated, it can get very hot and may break. This can make it harder to work with. 4. How often should we lubricate the lathe? You should lubricate the lathe regularly. Doing it every time you use it is a good idea. 5. Can you use any oil for a lathe? No, we shouldn’t use just any oil. It’s best to use the oil meant for lathes to protect it well.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Lubricants Are Recommended For The Quill Of A Metal Lathe, And How Do They Differ In Effectiveness?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For the quill of a metal lathe, we can use oil or grease. Oil is thinner and flows easily, helping to keep things cool. Grease is thicker and sticks better, so it lasts longer. Each type works well, but oil is better for high-speed jobs, while grease is great for slower tasks.”}},{“@type”: “Question”,”name”: “How Often Should The Quill Of A Metal Lathe Be Lubricated To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate the quill of a metal lathe every time you use it. This helps it work smoothly and last longer. If you use the lathe a lot, check the quill for oil more often. A little oil goes a long way in keeping things running well!”}},{“@type”: “Question”,”name”: “What Are The Signs That The Quill On A Metal Lathe May Be Under-Lubricated Or In Need Of Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the quill on a metal lathe is under-lubricated or needs maintenance, you might notice some signs. First, it may make strange noises when you use it. Second, the quill could feel sticky or hard to move. Third, you might see metal shavings getting stuck. Lastly, the machine might start to vibrate more than usual.”}},{“@type”: “Question”,”name”: “How Does Proper Lubrication Of The Quill Affect The Accuracy And Precision Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubricating the quill keeps it moving smoothly. This helps the machine cut metal more accurately. When everything works well together, you get better results. If it’s not lubricated, the quill can stick or move unevenly. That can make your cuts less precise and mess up your project.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Applying Lubricant To The Quill And Other Moving Parts Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well, apply lubricant carefully. First, turn off the machine to stay safe. Use a clean cloth to wipe dust off the quill and parts. Then, put a small amount of lubricant on a cloth or directly on the parts. Move the quill up and down to spread the lubricant evenly. This helps everything move smoothly and last longer!”}}]}