Have you ever wondered how a lathe works smoothly? A properly lubricated metal lathe runs like clockwork. Good lathe lubrication keeps your machine in top shape. It’s amazing how a little oil can make a big difference!

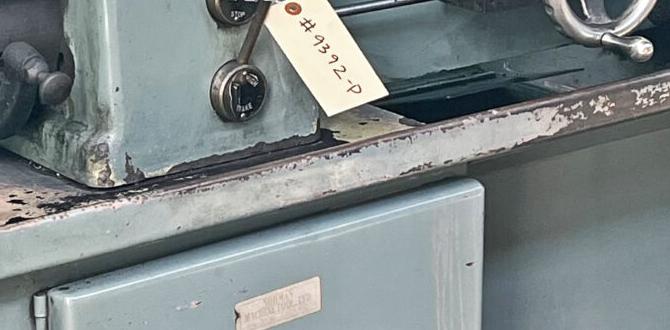

If you’re new to lathe machines, you might feel overwhelmed. The different parts and wiring can seem confusing. But don’t worry! Understanding the metal lathe wiring diagram can help you use your lathe safely and effectively. Imagine creating perfect parts with ease.

Did you know that skipping lubrication can lead to wear and tear? This can break your lathe or slow down your work. Keeping the moving parts oiled helps you avoid frustrating problems. Knowing when and how to lubricate makes all the difference.

In this article, we’ll explore the best practices for lathe lubrication. You’ll learn how to read a metal lathe wiring diagram too. By the end, you’ll feel confident in using your lathe. So, let’s dive in and discover how to keep your lathe running smoothly!

Lathe Lubrication And Metal Lathe Wiring Diagram Guide

Lathe Lubrication and Metal Lathe Wiring Diagram

Lathe lubrication is vital for smooth operation and extended tool life. Proper oiling reduces friction and wear on a metal lathe. Imagine your lathe moving with ease, thanks to just the right amount of grease! A wiring diagram is like a roadmap that guides the electrical setup of your tool. Understanding this wiring helps ensure safety and efficiency. Knowing both lubrication and wiring can turn a good project into a great one!Understanding Lathe Lubrication

Importance of lubrication in lathe operations. Common types of lubricants used for lathes.Lubrication is vital for smooth lathe operation. It helps reduce friction and wear on parts. This can lead to longer tool life and better surface finishes. Without it, machines can overheat or break. Common lubricants used include oil, grease, and special cutting fluids. Here’s a quick overview:

- Oil: Thin and flows easily, perfect for reducing friction.

- Grease: Thick and stays in place, good for heavy loads.

- Cutting fluids: Special mixtures that cool and lubricate during cutting.

Why is lubrication important for lathes?

Lubrication keeps lathe parts working well and prevents damage. It ensures efficient operation and increases the lifespan of the machine.

Types of Lathes and Their Lubrication Needs

Distinguishing between metal and wooden lathes. Specific lubrication requirements for different lathe types.Lathes come in different types, mainly metal and wooden. Metal lathes need special care because they work with hard materials. In contrast, wooden lathes handle softer wood. Each type requires a unique way to keep them running smoothly.

- Metal Lathes: Use cutting oil for parts that move. This helps reduce friction.

- Wooden Lathes: Can use light grease. It keeps the tools safe and working well.

Understanding these needs helps improve the lathe’s life and your work quality.

What lubrication do metal lathes need?

Metal lathes need cutting oil and grease for their moving parts. This keeps them from wearing out quickly and makes them work better.

Do wooden lathes require lubrication?

Yes, wooden lathes benefit from light grease. This helps protect them and keeps them running smoothly.

Best Practices for Lathe Lubrication

Stepbystep guide on how to lubricate a metal lathe. Common mistakes to avoid when lubricating a lathe.Lubricating a metal lathe is key to keeping it running smooth. Start by cleaning old oil. Next, apply fresh oil to moving parts. Here’s a quick guide:

- Use the right lubricant as per the manual.

- Don’t forget to oil the gears and spindle.

- Check for any leaks after lubrication.

Avoid common mistakes like skipping parts or using too much oil. Too much can attract dirt. Always follow the schedule for lubrication. This helps your lathe last longer and work better.

What are the best tips for lathe lubrication?

Some tips include using the right oil, avoiding over-lubrication, and maintaining a regular schedule.Important points for lubrication:

- Use lubrication specified in the lathe manual.

- Apply oil regularly, based on usage frequency.

- Inspect the lathe for wear and tear during lubrication.

Tools and Products for Lathe Lubrication

Recommended lubricants and tools for effective lubrication. Where to purchase quality lubricants for lathes.To keep your lathe running smoothly, using the right lubricants is key. Super slippery oils and greases can make all the difference! Some top choices include way oil and machine oil, which help protect your machine parts. You can grab these high-quality lubricants at local hardware stores or online retailers like Amazon. Also, remember to stock up on brushes and cloths to help apply your lubricants. Below is a table of recommended lubricants:

| Lubricant Type | Best For | Where to Buy |

|---|---|---|

| Way Oil | Improving slide movement | Local Hardware Store, Amazon |

| Machine Oil | General lubrication | Online, Home Depot |

| Grease | Protecting gears | Grainger, Lowe’s |

Remember, a happy lathe equals a happy craftsman! Keeping up with lubrication will save you headaches later. Trust me, your lathe will thank you!

Creating Your Own Metal Lathe Wiring Diagram

Tools and software for designing wiring diagrams. Tips for customizing a wiring diagram for your specific lathe.Designing a wiring diagram for your metal lathe can be fun and helpful! You can use tools like Microsoft Visio or free software like Fritzing. These help you organize your ideas. Keep it simple and clear. Also, remember to customize your diagram according to your lathe model. Add colors and labels to make it pop! A messy diagram is harder to follow, like a spaghetti noodle fight! Here’s a quick table for helpful tips:

| Tool/Software | Feature |

|---|---|

| Microsoft Visio | Professional layouts and symbols. |

| Fritzing | Easy drag-and-drop interface. |

| Lucidchart | Collaboration features for team work. |

To beat those confusing diagrams, keep your wiring organized and clear. You’ll be assembling like a pro in no time!

Troubleshooting Wiring Issues in Metal Lathes

Common electrical issues in metal lathes. How to diagnose and fix wiring problems.Metal lathes can sometimes have electrical problems. These issues often cause machines to stop. Here are some common electrical issues:

- No power to the machine.

- Overheating motors.

- Faulty wiring connections.

To diagnose and fix these problems:

- Check for loose wires or connections.

- Look for burnt or damaged parts.

- Make sure the power supply is working.

Addressing these issues quickly can save time and money. Keeping your lathe lubricated may also help keep it running smoothly.

What Are the Most Common Electrical Problems with Metal Lathes?

Common issues include no power, overheating, and faulty wiring. It’s essential to identify these concerns to ensure safe machine operations.

Safety Considerations When Working With Lathes

Essential safety measures for lathe operation and maintenance. How proper lubrication impacts safety and performance.Using a lathe can be fun but also risky without safety measures. Always wear proper gear like goggles and gloves. Keep the area clean and organized. This helps prevent accidents. Lubricating your lathe correctly is important, too. It not only keeps the machine running smoothly but also reduces the chance of injury. Well-lubricated tools work better, making your projects easier and safer to complete.

Why is lubrication important for lathe safety?

Lubrication helps prevent overheating. A well-lubricated lathe reduces friction and wear, which keeps the machine safe and effective.

Conclusion

In summary, proper lathe lubrication keeps your metal lathe running smoothly. Understanding a wiring diagram helps you set it up safely. You can prolong your lathe’s life with regular maintenance. Next steps include checking your lathe’s lubrication system and reviewing the wiring diagram. Explore more resources to enhance your skills and knowledge about lathe operation!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Wiring Diagrams:Sure! Here are five questions you might ask about lathe lubrication and wiring diagrams. You can ask how to lubricate a lathe, what oil to use, or what a wiring diagram helps you understand. You could also ask why lubrication is important for the lathe or how to read a wiring diagram. Each question helps us learn more about keeping the lathe in good shape!

Sure! Please provide the question you’d like me to answer.

What Are The Common Types Of Lubricants Recommended For Different Components Of A Metal Lathe?For a metal lathe, we use different kinds of lubricants for its parts. You can use oil for the moving parts, like the gears and the spindle. Grease works well for the ways, which help the lathe slide smoothly. We also use way oil for even better smoothness on the ways. Each lubricant helps the lathe work better and last longer.

How Do You Create A Wiring Diagram For A Metal Lathe, And What Are The Essential Components To Include?To create a wiring diagram for a metal lathe, you start with a blank sheet. First, draw the power source, like a plug. Next, add the motor, which makes the lathe move. Don’t forget to include switches for turning the lathe on and off. Make sure to connect these parts with lines that show how the electricity flows between them.

What Maintenance Practices Should Be Performed To Ensure Proper Lubrication Of A Metal Lathe?To keep a metal lathe working well, you should regularly check its oil levels. You can add machine oil to moving parts to help them slide smoothly. Clean off any dirt or old oil on the lathe. Make sure to follow the instructions from the maker about how often to do this. Keeping your lathe clean and properly oiled will help it last longer.

How Can Improper Wiring Affect The Operation And Lubrication System Of A Metal Lathe?Improper wiring can cause a metal lathe to stop working. If the electricity is wrong, the lathe might not turn on. This can make it hard for the machine to pump oil for lubrication. Without enough oil, parts can get stuck and break. Always check the wiring to keep the lathe working well.

What Are The Signs That A Metal Lathe Is Not Being Lubricated Properly, And How Can These Issues Be Resolved?If a metal lathe is not getting enough oil, you might see rust or hear strange noises. You could also notice rough movement or hot parts. To fix this, you should check and add oil regularly. Make sure to clean the lathe parts too. This way, the lathe will work smoothly and last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about lathe lubrication and wiring diagrams. You can ask how to lubricate a lathe, what oil to use, or what a wiring diagram helps you understand. You could also ask why lubrication is important for the lathe or how to read a wiring diagram. Each question helps us learn more about keeping the lathe in good shape!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Lubricants Recommended For Different Components Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, we use different kinds of lubricants for its parts. You can use oil for the moving parts, like the gears and the spindle. Grease works well for the ways, which help the lathe slide smoothly. We also use way oil for even better smoothness on the ways. Each lubricant helps the lathe work better and last longer.”}},{“@type”: “Question”,”name”: “How Do You Create A Wiring Diagram For A Metal Lathe, And What Are The Essential Components To Include?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a wiring diagram for a metal lathe, you start with a blank sheet. First, draw the power source, like a plug. Next, add the motor, which makes the lathe move. Don’t forget to include switches for turning the lathe on and off. Make sure to connect these parts with lines that show how the electricity flows between them.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Performed To Ensure Proper Lubrication Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you should regularly check its oil levels. You can add machine oil to moving parts to help them slide smoothly. Clean off any dirt or old oil on the lathe. Make sure to follow the instructions from the maker about how often to do this. Keeping your lathe clean and properly oiled will help it last longer.”}},{“@type”: “Question”,”name”: “How Can Improper Wiring Affect The Operation And Lubrication System Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper wiring can cause a metal lathe to stop working. If the electricity is wrong, the lathe might not turn on. This can make it hard for the machine to pump oil for lubrication. Without enough oil, parts can get stuck and break. Always check the wiring to keep the lathe working well.”}},{“@type”: “Question”,”name”: “What Are The Signs That A Metal Lathe Is Not Being Lubricated Properly, And How Can These Issues Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is not getting enough oil, you might see rust or hear strange noises. You could also notice rough movement or hot parts. To fix this, you should check and add oil regularly. Make sure to clean the lathe parts too. This way, the lathe will work smoothly and last longer!”}}]}