Have you ever seen a lathe machine at work? It’s a fascinating tool that shapes metal with precision. Picture a hefty piece of metal spinning slowly. A sharp tool cuts away pieces, creating beautiful shapes. It’s almost like magic!

But what happens when we add modern technology to this old tool? That’s where lathe machine learning comes in. By using advanced algorithms, we can make metal lathes smarter. Imagine a lathe that can predict problems before they happen. Wouldn’t that save time and effort?

Also, consider the importance of the lathe belt in this process. The belt connects the motor to the lathe, powering the machine. If it slips or breaks, everything stops. We rely on that simple piece of equipment to keep the metal spinning.

In this article, we will explore these ideas further. Get ready to dive into the world of lathe machines, learning how technology is reshaping metalwork!

Lathe Machine Learning: Optimizing Metal Lathe Belt Usage

Understanding Lathe Machine Learning with Metal Lathes

Lathe machines shape metals with incredible precision. Have you seen how they spin? Imagine a simple belt driving the whole process! Learning about metal lathes involves understanding various parts and their functions. Metal lathes are tools used by engineers to create parts for machines and cars. They help in crafting items smoothly and accurately. Using machine learning, there are new ways to enhance lathe efficiency every day. Isn’t it fascinating how technology improves traditional tools?What is a Lathe Machine?

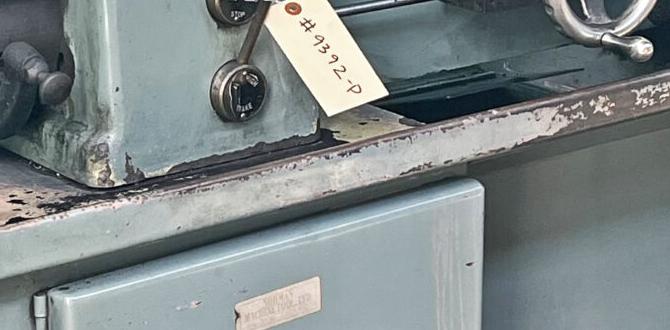

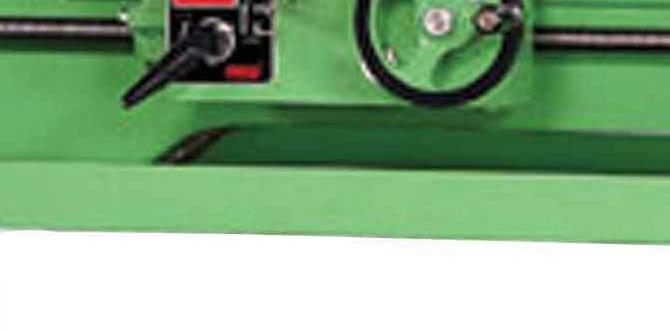

Definition and basic function of a lathe machine. Different types of lathes used in metalworking.A lathe is a machine that spins metal to shape it. It helps create smooth and precise parts for tools and machines. This tool removes material to form items like rods and discs. There are different types of lathes used in metalworking, including:

- Engine Lathe: Common and versatile for many tasks.

- CNC Lathe: Computer-controlled for high precision.

- Turret Lathe: Allows for quick changes of tools.

- Bench Lathe: Portable for small projects.

Each type has its own special use based on the work needed.

What can lathes create?

With a lathe, you can make things like cylinders, gears, and decorative items. They are essential in factories and workshops for countless products.

Components of a Metal Lathe

Explanation of major components (headstock, tailstock, bed, etc.). Role of the belt drive system in lathe functionality.A metal lathe has key parts that work together like a well-rehearsed band. The headstock holds the motor and controls the spindle speed, while the tailstock helps support the workpiece during shaping. The bed is like the stage where all the magic happens, keeping everything stable. Don’t forget the belt drive system—it’s the unsung hero, transferring power from the motor to the spindle. Without it, the lathe would be as useful as a bicycle with square wheels!

| Component | Description |

|---|---|

| Headstock | Contains the motor and controls spindle speeds. |

| Tailstock | Supports the workpiece for precision cutting. |

| Bed | The sturdy base that holds the lathe together. |

| Belt Drive System | Transfers power from the motor to the spindle. |

Machine Learning Applications in Lathe Operations

Predictive maintenance using data analytics. Optimization of cutting processes for efficiency and quality.Machine learning helps make lathe operations smarter. Predictive maintenance uses data to predict when machines will need repairs. This means less downtime! When machines run smoothly, work gets done faster. Optimization of cutting processes improves efficiency. It helps cut materials faster while keeping quality high. Workers save time and get better products. Here are some benefits of using machine learning:

- Improves machine lifespan

- Reduces costs

- Enhances safety

How does machine learning help in lathe operations?

Machine learning streamlines operations by predicting issues and optimizing processes. This leads to higher productivity and better product quality.

Choosing the Right Belt for Your Metal Lathe

Types of belts used in metal lathes and their purposes. Factors to consider when selecting a lathe belt.Choosing the right belt for your metal lathe is key for smooth operation. Different belts serve unique purposes. You can find rubber, leather, or poly-v belts. Rubber belts are flexible. Leather belts are strong but can wear out. Poly-v belts offer great grip and last long. Consider these factors when selecting:

- Size: The belt must fit your lathe.

- Material: Choose based on durability and flexibility.

- Stretch: Some belts stretch after use.

Picking the right belt helps improve your lathe’s performance.

What types of belts are commonly used in metal lathes?

Common belt types include rubber, leather, and poly-v belts. Each type has its strengths, affecting your lathe’s efficiency.

What factors should you consider when buying a lathe belt?

Important factors include size, material, and stretch. These details ensure you get the best fit for your lathe’s needs.

Implementing Machine Learning in Your Lathe Operations

Steps to integrate machine learning solutions with existing lathes. Challenges and solutions in the adoption of machine learning in metalworking.To blend machine learning into your lathe operations, follow these steps. Start by assessing your current setup. Check what sensors and data are available. Next, choose software that suits your needs. You might face challenges like cost or skill gaps. To overcome these, consider training options and gradual investments. Regular monitoring can help too. Remember, small steps lead to big changes!

What are the key challenges of adopting machine learning in metalworking?

Challenges include high costs, lack of skilled workers, and resistance to change.Possible Solutions:

- Offer training programs for staff.

- Start with smaller projects to test effectiveness.

- Invest gradually in technology.

Case Studies: Successful Application of Machine Learning in Metal Lathes

Examples of companies benefiting from machinelearningenhanced metal lathes. Analysis of the outcomes and improvements observed.Many companies are seeing big improvements by using machine learning with their metal lathes. For instance, a factory increased its production speed by 20% after using smart lathes. Another company made fewer mistakes, reducing errors by 30%. Here are some key benefits:

- Increased efficiency

- Lowered waste

- Better quality products

These success stories show how tech can boost business success.

How do metal lathes use machine learning?

Metal lathes use machine learning to analyze data and improve their processes. They make decisions that help in producing parts faster and with better accuracy.

Future Trends in Lathe Machines and Machine Learning

Predictions on how technology will evolve in the metalworking industry. Potential innovations in lathe machinery driven by AI and machine learning.The future of lathe machines looks exciting! Technology is changing fast, especially in the metalworking sector. We can expect new tools that use artificial intelligence (AI) to help operators. These projects can work faster and make fewer mistakes. Imagine a lathe that learns from its tasks and improves over time!

- Predictive maintenance to prevent breakdowns

- Smart sensors for better precision

- User-friendly interfaces for easier operation

- Increased automation for efficiency

These innovations can boost productivity and cut costs. AI and machine learning are becoming essential in making lathe machines smarter. Get ready for a more advanced future!

What is a potential impact of AI on lathe machines?

AI can help make lathe machines more efficient, reducing errors and saving time.

Key Innovations in Lathe Technology:

- Better accuracy with less human intervention

- Learning algorithms for skill improvement

- Data analysis for informed decision-making

As we look ahead, lathe machines will likely be more intelligent and helpful. This shift will lead to exciting changes in how we work with metal and create new products.

Conclusion

In summary, lathe machines are essential tools in metalworking. Learning about their operation, including the use of belts, helps you improve your skills. We encourage you to explore more about lathe machine techniques online or in books. With practice, you can become proficient and create amazing metal projects. Keep experimenting and have fun with your learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Belt:Sure! A lathe machine is a tool that helps shape metal and wood. Machine learning uses computers to learn from data and make decisions. A metal lathe belt connects parts of the machine to help it work. It moves the metal piece so we can shape it better. Both lathe machines and machine learning help us create cool things!

Sure! Please provide the question you’d like me to answer.

What Machine Learning Techniques Can Be Applied To Optimize The Performance Of Metal Lathes In A Manufacturing Environment?To make metal lathes work better, we can use a few smart techniques. One is called “predictive maintenance,” where we guess when a machine might break, so we can fix it before it stops. Another technique is “quality control,” which checks if the parts made are perfect, so we can catch mistakes early. We can also use “data analysis” to look at how the machines are running, helping us find ways to improve them. These methods help make sure everything runs smoothly.

How Can Predictive Maintenance Powered By Machine Learning Improve The Longevity And Efficiency Of Metal Lathe Belts?Predictive maintenance is like having a magic crystal ball. It helps us see when metal lathe belts might break or wear out. By using machine learning, we gather data from the belts while they work. This data helps us know when to fix or replace them before a big problem happens. So, we can keep the belts working longer and make sure they run smoothly!

In What Ways Can Data Analytics Enhance The Process Of Selecting The Appropriate Belt For Different Metal Lathe Applications?Data analytics can help us choose the right belt for metal lathes by looking at important facts. We can see which belts work best with different metals. By comparing performance data, we find out which belt lasts longer and does a better job. This way, we make smarter choices and save time and money. Overall, it helps us pick the perfect belt for each task.

What Are The Challenges Of Integrating Machine Learning Algorithms With Traditional Metal Lathe Operations?Integrating machine learning with metal lathe operations can be hard. First, we need data to train the machines, but that data might be messy. Then, workers must learn how to use this new technology, which can take time. Also, machines and old tools may not always work well together. Finally, safety is very important, so we need to ensure nothing goes wrong when mixing old and new methods.

How Can Real-Time Monitoring Of Lathe Belt Conditions Using Iot And Machine Learning Contribute To Reducing Downtime In Machining Processes?Real-time monitoring means checking something all the time. By using smart tools called IoT (Internet of Things) and machine learning, we can look at lathe belt conditions. These tools can find problems early, like when a belt is worn out or about to break. If we know about a problem quickly, we can fix it before it stops work. This helps us keep machines running smoothly and reduces downtime, so we can make more things.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Belt:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe machine is a tool that helps shape metal and wood. Machine learning uses computers to learn from data and make decisions. A metal lathe belt connects parts of the machine to help it work. It moves the metal piece so we can shape it better. Both lathe machines and machine learning help us create cool things!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Machine Learning Techniques Can Be Applied To Optimize The Performance Of Metal Lathes In A Manufacturing Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make metal lathes work better, we can use a few smart techniques. One is called predictive maintenance, where we guess when a machine might break, so we can fix it before it stops. Another technique is quality control, which checks if the parts made are perfect, so we can catch mistakes early. We can also use data analysis to look at how the machines are running, helping us find ways to improve them. These methods help make sure everything runs smoothly.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Powered By Machine Learning Improve The Longevity And Efficiency Of Metal Lathe Belts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance is like having a magic crystal ball. It helps us see when metal lathe belts might break or wear out. By using machine learning, we gather data from the belts while they work. This data helps us know when to fix or replace them before a big problem happens. So, we can keep the belts working longer and make sure they run smoothly!”}},{“@type”: “Question”,”name”: “In What Ways Can Data Analytics Enhance The Process Of Selecting The Appropriate Belt For Different Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Data analytics can help us choose the right belt for metal lathes by looking at important facts. We can see which belts work best with different metals. By comparing performance data, we find out which belt lasts longer and does a better job. This way, we make smarter choices and save time and money. Overall, it helps us pick the perfect belt for each task.”}},{“@type”: “Question”,”name”: “What Are The Challenges Of Integrating Machine Learning Algorithms With Traditional Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Integrating machine learning with metal lathe operations can be hard. First, we need data to train the machines, but that data might be messy. Then, workers must learn how to use this new technology, which can take time. Also, machines and old tools may not always work well together. Finally, safety is very important, so we need to ensure nothing goes wrong when mixing old and new methods.”}},{“@type”: “Question”,”name”: “How Can Real-Time Monitoring Of Lathe Belt Conditions Using Iot And Machine Learning Contribute To Reducing Downtime In Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Real-time monitoring means checking something all the time. By using smart tools called IoT (Internet of Things) and machine learning, we can look at lathe belt conditions. These tools can find problems early, like when a belt is worn out or about to break. If we know about a problem quickly, we can fix it before it stops work. This helps us keep machines running smoothly and reduces downtime, so we can make more things.”}}]}