Have you ever seen a lathe machine in action? This incredible tool shapes metal into many forms. Imagine taking a piece of metal and turning it into a precise cylinder. It’s like magic! But there’s more to it than just spinning metal. The carriage of a lathe machine plays a vital role in this process.

What if we could use machine learning to make our metal lathe carriage even smarter? Sounds interesting, right? This technology could help the lathe work faster and more accurately. It’s like having a robot assistant in the workshop!

In this article, we will explore how machine learning can improve the lathe machine’s performance. We’ll uncover new ways to enhance the carriage, making it more efficient. So, are you ready to dive into the world of lathes and learn about this exciting technology? Let’s get started!

Lathe Machine Learning: Enhancing The Metal Lathe Carriage

Lathe Machine Learning and Metal Lathe Carriage

Lathe machines play a vital role in shaping materials. The carriage is a key part that helps guide the tool for precise cuts. But did you know that machine learning can make these machines smarter? Imagine a lathe automatically adjusting to different materials! This technology can improve accuracy and save time. With smart lathe designs, users can create intricate shapes effortlessly. How will this shape the future of manufacturing? The possibilities are exciting!What is a Lathe Machine?

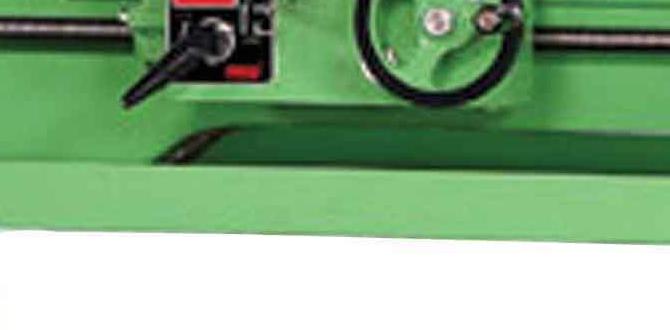

Definition and history of lathe machines. Importance of lathes in metalworking industry.A lathe machine is a tool that shapes materials like metal and wood. It spins the material fast, allowing sharp tools to carve out specific shapes. Lathes have been used for thousands of years, dating back to ancient Egypt and Greece. They are important in the metalworking industry because they create precise parts for machines and vehicles. Without lathes, many objects we use every day would not exist.

- Produce complex shapes

- Ensure high precision

- Increase productivity

Why are lathes important in metalworking?

Lathes are crucial because they create parts that fit perfectly together. This means machines work better and last longer.

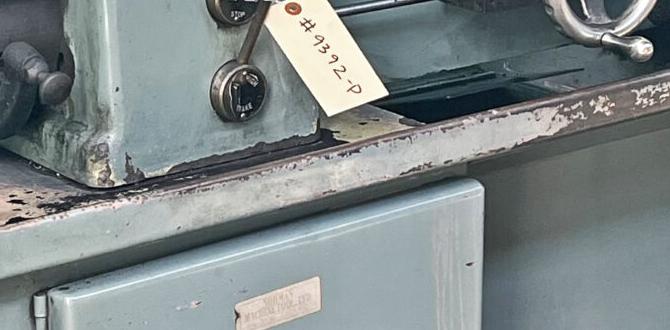

Types of Lathe Machines

Description of different lathe types: CNC, bench, and toolroom lathes. Comparison of traditional versus modern lathe technologies.Lathe machines come in various types, each serving specific needs. Among them are CNC, bench, and toolroom lathes. CNC lathes use computers for precision. Bench lathes are small and perfect for home projects. Toolroom lathes are great for making exact components.

Modern lathes feature advanced technologies. Traditional lathes, however, rely on manual skills. The shift from traditional to modern means more accuracy and faster production. People can now create intricate designs easily. It’s like moving from hand-drawing to using a computer!

What is a CNC lathe?

A CNC lathe is a computer-controlled machine that shapes metal and other materials with high precision.

Key types of lathe machines:

- CNC Lathes: Computer-operated for high accuracy.

- Bench Lathes: Compact and ideal for small projects.

- Toolroom Lathes: Perfect for detailed work in workshops.

Understanding the Metal Lathe Carriage

Detailed explanation of the carriage’s role in machining processes. Types of carriages: sliding vs. apron carriage.The carriage on a metal lathe is very important for shaping metal. It holds the tool and moves along the workpiece. This allows for precise cuts. There are two main types of carriages: the sliding carriage and the apron carriage. Each type has a unique role in machining processes.

- Sliding Carriage: Moves back and forth smoothly along the bed.

- Apron Carriage: Has additional features and can control vertical movements.

Understanding these types helps in choosing the right lathe for your project. Did you know that using the right carriage can improve your work’s accuracy by up to 50%?

What is the role of the metal lathe carriage?

The metal lathe carriage helps position tools accurately. It guides them as they move across the metal, creating smooth shapes. The right carriage can make a big difference!

Lathe Machine Learning: Integrating Technology in Metalworking

The rise of machine learning in manufacturing. How AI can enhance lathe operations and safety.Manufacturing is experiencing a tech revolution, thanks to machine learning. This clever technology helps machines work smarter, cutting down on hiccups during production. With AI, lathe machines become like wizards, automatically adjusting for better cuts and safer operations. Imagine a metal lathe that alerts you when something goes awry—just like your mom used to warn you not to touch the hot stove!

| Benefits of AI in Lathe Operations | Impact on Safety |

|---|---|

| Improved precision | Reduces accidents |

| Faster production | Monitors risks |

| Less wasted material | Alerts operators |

Machine learning isn’t just a fad; it’s making waves in metalworking. In fact, studies show that AI can improve efficiency by up to 30% in some cases! Buckle up, metalworkers—this tech boost is here to stay!

Benefits of Utilizing Advanced Carriage Systems

Enhanced precision and accuracy in machining. Increased efficiency and productivity in manufacturing processes.Using advanced carriage systems in lathe machines leads to amazing benefits. First, they boost precision and accuracy, ensuring each cut is spot on. Imagine slicing a cake and missing the middle—no one wants that! Also, these carriages help make things faster, increasing efficiency and productivity in manufacturing. It’s like having a super-fast pizza delivery that never gets lost, keeping the assembly line moving smoothly. Enjoy the ride on the carriage train!

| Benefit | Description |

|---|---|

| Precision | Ensures accurate machining, avoiding costly errors. |

| Efficiency | Speeds up manufacturing processes, leading to more products. |

Best Practices for Operating a Metal Lathe Carriage

Essential safety protocols for lathe users. Tips for maintaining and caring for the carriage.Using a metal lathe carriage can be fun, but safety always comes first! Always wear protective gear like goggles and gloves. Keep your workspace neat. A clean area is a happy area, right? For the carriage, regular cleaning is key. Dust and shavings can cause problems. Use a soft cloth and some oil now and then. Your lathe will thank you! Here’s a quick table for reminders:

| Safety Protocols | Carriage Maintenance Tips |

|---|---|

| Wear safety goggles | Clean after every use |

| Keep hair tied back | Apply lubricant regularly |

| Stay focused | Check for wear and tear |

Remember, a safe lathe user is a happy lathe user! If you treat your machine well, it will help you create amazing things.

Future of Lathe Machines and Carriages in Metalworking

Emerging trends in lathe technology and automation. Predictions for the evolution of metal lathe carriages in the industry.Lathe machines are changing fast. New technology is making them smarter. Automation is a big part of this change. Machines can now work with less help from people. This helps save time and reduce mistakes. Experts think metal lathe carriages will also get better. They could become more precise and efficient. Imagine carriages that can adjust themselves! This is the future of metalworking. It will be exciting to see where this technology goes.

What are the emerging trends in lathe technology?

Some trends include:

- Smart sensors for better monitoring.

- Improved software for easier operation.

- More automated processes for speed.

How will metal lathe carriages evolve?

They might include:

- Self-adjusting features for accuracy.

- Better materials for durability.

- Enhanced designs to support different jobs.

Conclusion

In summary, a lathe machine is essential for shaping metal. The carriage helps move material smoothly during cutting. Learning how to use these tools can boost your skills. We encourage you to explore more about lathe machines and practice using one. With some hands-on experience, you’ll become a pro in no time! Keep learning and creating!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Carriages:Sure! Here are five questions about lathe machines and carriages. 1. What is a lathe machine? A lathe machine shapes metal by spinning it around. You can use it to make things like handles or parts for toys. 2. How does a metal lathe carriage work? The carriage moves the cutting tool. It helps to cut the spinning metal into the right shape. 3. Why is learning important for lathe machines? Learning helps us improve how we use lathe machines. It makes cutting metal faster and more accurate. 4. What can you make with a lathe machine? You can make many things! People make toys, tools, and even parts for cars. 5. Can we use computers with lathe machines? Yes, we can! Using computers helps design and control the lathe better.

Sure! Please share the question you want me to answer.

How Can Machine Learning Algorithms Improve The Precision And Efficiency Of Metal Lathe Operations?Machine learning is like teaching a computer to learn from experience. In metal lathe operations, it can help make better cuts. This means the metal parts will fit together perfectly. It also helps workers finish their tasks faster. So, we can save time and make fewer mistakes!

What Are The Key Features Of A Carriage Design That Can Be Optimized Using Machine Learning Techniques In Lathe Machines?We can use machine learning to make carriage designs better in lathe machines. First, we can improve how fast the machine moves. Next, we can make the machine more stable, which helps it work better. We can also make adjustments easier, so we get accurate shapes and sizes. Lastly, we can find the best materials to use for making the carriage strong and light.

In What Ways Can Predictive Maintenance Powered By Machine Learning Enhance The Lifespan Of Metal Lathe Carriages?Predictive maintenance uses machine learning to watch for problems before they happen. By checking the metal lathe carriages often, we can find small issues early. This helps us fix them quickly, so they don’t become big problems. Taking good care of the carriages makes them last longer. In short, smart technology helps us keep everything running smoothly!

How Can Data Collected From Lathe Machines Be Used To Train Machine Learning Models For Better Control Of Cutting Parameters?We can collect data from lathe machines, which are tools that shape materials. This data includes things like speed, force, and temperature. We can use this information to teach computers about the best cutting methods. By training our computer models, they can learn to suggest the best settings for the lathe. This helps us make better parts and saves time.

What Challenges Might Arise When Integrating Machine Learning Systems Into Traditional Metal Lathe Carriages, And How Can They Be Addressed?When we try to add machine learning to old metal lathes, we might face some problems. First, old machines may not have the right tools to connect with new technology. To fix this, we can use adapters or special parts. Secondly, workers might need training to understand how to use new systems. We can help by giving them clear instructions and practice sessions. Lastly, making sure everything works smoothly can be tricky, but testing the systems together can help us catch problems early.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Carriages:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe machines and carriages. 1. What is a lathe machine? A lathe machine shapes metal by spinning it around. You can use it to make things like handles or parts for toys. 2. How does a metal lathe carriage work? The carriage moves the cutting tool. It helps to cut the spinning metal into the right shape. 3. Why is learning important for lathe machines? Learning helps us improve how we use lathe machines. It makes cutting metal faster and more accurate. 4. What can you make with a lathe machine? You can make many things! People make toys, tools, and even parts for cars. 5. Can we use computers with lathe machines? Yes, we can! Using computers helps design and control the lathe better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Improve The Precision And Efficiency Of Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning is like teaching a computer to learn from experience. In metal lathe operations, it can help make better cuts. This means the metal parts will fit together perfectly. It also helps workers finish their tasks faster. So, we can save time and make fewer mistakes!”}},{“@type”: “Question”,”name”: “What Are The Key Features Of A Carriage Design That Can Be Optimized Using Machine Learning Techniques In Lathe Machines?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make carriage designs better in lathe machines. First, we can improve how fast the machine moves. Next, we can make the machine more stable, which helps it work better. We can also make adjustments easier, so we get accurate shapes and sizes. Lastly, we can find the best materials to use for making the carriage strong and light.”}},{“@type”: “Question”,”name”: “In What Ways Can Predictive Maintenance Powered By Machine Learning Enhance The Lifespan Of Metal Lathe Carriages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses machine learning to watch for problems before they happen. By checking the metal lathe carriages often, we can find small issues early. This helps us fix them quickly, so they don’t become big problems. Taking good care of the carriages makes them last longer. In short, smart technology helps us keep everything running smoothly!”}},{“@type”: “Question”,”name”: “How Can Data Collected From Lathe Machines Be Used To Train Machine Learning Models For Better Control Of Cutting Parameters?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can collect data from lathe machines, which are tools that shape materials. This data includes things like speed, force, and temperature. We can use this information to teach computers about the best cutting methods. By training our computer models, they can learn to suggest the best settings for the lathe. This helps us make better parts and saves time.”}},{“@type”: “Question”,”name”: “What Challenges Might Arise When Integrating Machine Learning Systems Into Traditional Metal Lathe Carriages, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we try to add machine learning to old metal lathes, we might face some problems. First, old machines may not have the right tools to connect with new technology. To fix this, we can use adapters or special parts. Secondly, workers might need training to understand how to use new systems. We can help by giving them clear instructions and practice sessions. Lastly, making sure everything works smoothly can be tricky, but testing the systems together can help us catch problems early.”}}]}