Have you ever thought about how metal shapes and parts are made? One amazing tool that helps with this is the lathe machine. It spins materials to create specific shapes. But now, things are getting even cooler!

Imagine taking a regular metal lathe and giving it a brain. That’s what CNC retrofit does! It turns standard lathes into smart machines. They can make precise cuts and shapes, all by following a computer program.

This technology also involves machine learning. What’s that? It’s when a computer learns from its work. Over time, it gets better and better! This means your lathe can become more accurate and efficient.

How can this change the way we work with metal? Many people are curious about it, and for a good reason! Enhanced lathes offer faster production times and less waste. Isn’t it exciting to think about how these tools will shape our future?

Lathe Machine Learning: Metal Lathe Cnc Retrofit Insights

Lathe Machine Learning in CNC Retrofit

Do you know how a lathe machine changes the game for metalworking? With CNC retrofit, old lathes can become smart machines. They use machine learning to enhance accuracy and efficiency. Imagine transforming a simple metal lathe into a high-tech tool. This upgrade saves time and reduces waste. Plus, it opens new possibilities for creativity in crafting metal parts. Isn’t it exciting to think how technology can revamp classic tools?Understanding Lathe Machines

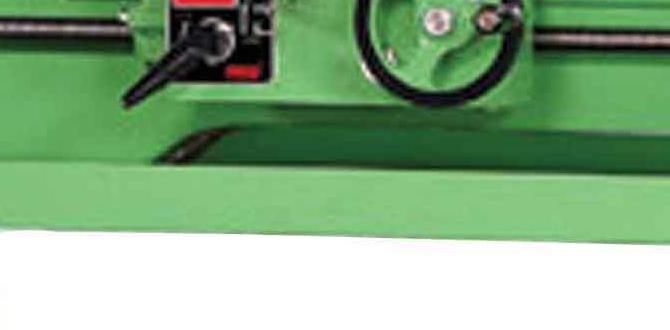

Definition and types of lathe machines. Historical evolution and significance in manufacturing.A lathe machine is a tool that shapes materials, mostly metal or wood. It spins the material while a cutting tool carves it into a desired shape. There are different types of lathes, like:

- Engine lathes: Common for general work.

- CNC lathes: Use computer controls for precision.

- Turret lathes: Allow quick changes between tasks.

Historically, lathes date back to ancient Egypt. They changed how items were made. Lathes made manufacturing faster and more accurate. In fact, they played a key role during the Industrial Revolution, helping factories grow. Today, lathe machine learning and cnc retrofit help improve their efficiency even more.

What is the significance of lathe machines in modern manufacturing?

Lathe machines are crucial in modern manufacturing. They ensure precision and speed in producing parts. Statistics show that nearly 40% of all machine tools used in factories are lathes. This highlights their importance in the manufacturing process.

Benefits of Retrofitting Metal Lathes with CNC

Enhanced precision and accuracy in machining. Increased productivity and efficiency.Retrofitting metal lathes with CNC technology offers many advantages. First, it boosts precision and accuracy in machining. This means parts are made exactly as needed. Second, productivity and efficiency see a rise as machines work faster and with less waste.

- Better precision means fewer mistakes.

- Machines can run longer without stopping.

- Less time is spent changing tools.

- More work can be completed in a day.

Overall, these changes help businesses save money and grow.

Why retrofit a metal lathe?

Retrofitting enhances performance, reduces operation costs, and extends the machine’s lifespan. It’s a smart move for any workshop.

Key Components of CNC Retrofit for Lathe Machines

Essential hardware required for retrofitting. Software solutions and their importance.Retrofitting a lathe machine is like giving it a shiny new toy! You’ll need some key parts to make it work. First, you’ll need hardware like stepper motors and controllers. These help your machine move smoothly. Then comes the software. Think of it as your lathe’s brain. It tells the machine what to do, making your projects easier and faster. Without these components, your lathe might feel as confused as a cat at a dog show!

| Component | Purpose |

|---|---|

| Stepper Motors | Control movement accurately. |

| Controllers | Manage motor operations. |

| Software | Provide instructions and control. |

Step-by-Step CNC Retrofit Process for Lathes

Preparation: Assessing existing equipment. Installation: Hardware setup. Calibration: Ensuring accuracy and machine functionality.Get ready for a fun journey! First, assess your lathe. Is it still in good shape? Check for wear and tear before moving on. Next, it’s time for installation. Set up the new hardware carefully. Each piece must fit just right. Finally, calibrate the machine to ensure it runs accurately. You want perfect measurements! It’s like tuning a musical instrument. A well-calibrated lathe means great results.

What is the CNC retrofit process?

The CNC retrofit process upgrades an old lathe. It’s a blend of new tech with existing tools. This upgrade boosts efficiency and precision. You can make an old machine feel like new.

Key Steps in CNC Retrofit:

- Assess equipment

- Install new hardware

- Calibrate for accuracy

Challenges in CNC Retrofitting of Lathe Machines

Technical difficulties and troubleshooting. Cost considerations and return on investment.CNC retrofitting of lathe machines can be tricky. First, you face technical difficulties. Setting up the software can take time, and finding the right parts might be confusing. If something breaks, troubleshooting can feel overwhelming. Next, think about cost considerations. Retrofits can be expensive, making it hard to see a profit right away. It’s important to calculate the return on investment before starting. Investing wisely can lead to better performance and savings in the long run.

What are some common issues in CNC retrofitting?

Technical issues may include software setup and hardware compatibility. Remember, it may take time to fix problems. Cost can add up quickly, so check your budget.

- Software setup may be complex.

- Finding parts can be hard.

- Repairs can be costly.

Future Trends in CNC Retrofits and Machine Learning

Innovations on the horizon for lathe machines. The role of predictive maintenance in manufacturing.Exciting things are happening in the world of lathe machines! New ideas are popping up, making it easier to work with metal. One big trend is predictive maintenance. This means machines can tell us when they need help, like a robot crying for a battery! It saves time and keeps everything running smoothly. In the near future, we might even see machines that learn and adapt. Imagine a lathe machine that cooks you lunch while you work!

| Innovation | Description |

|---|---|

| Smart Sensors | These help monitor machines, predicting when they need repairs. |

| AI Integration | Machines that learn and improve their operations over time. |

Case Studies: Successful CNC Retrofits of Metal Lathes

Examples of companies that benefited from retrofitting. Analysis of improvements seen postretrofit.Many companies have found great success after retrofitting their metal lathes. For example, a small machining business reported a 35% increase in production speed after updating its equipment. Another company improved its accuracy by 25%, helping them reduce waste. These improvements show that retrofitting is a smart choice for businesses aiming to stay competitive.

- Increased production speed

- Higher accuracy

- Reduced operational costs

Companies are seeing clear benefits and better performance with modern technology. It’s not just an upgrade; it’s a pathway to growth and efficiency.

How does retrofitting benefit companies?

Retrofitting helps companies save money, increase speed, and improve product quality. This means happier customers and more business in the long run!

Conclusion

In conclusion, retrofitting a metal lathe with CNC features enhances precision and control. Learning about machine learning can improve your projects further. We can explore many options together, so consider researching retrofits and CNC techniques. By doing this, you’ll upgrade your skills and machines. Let’s dive deeper and transform how we work with lathes!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Metal Lathe Cnc Retrofitting:Sure! Here are some questions we can think about for lathe machine learning and retrofitting. 1. What is a lathe machine? A lathe machine helps shape metal or wood by spinning it and cutting it into different shapes. 2. What is metal lathe CNC retrofitting? This means upgrading an older lathe machine to make it smart like a computer. 3. Why would we want to retrofit a lathe machine? We want to make it faster and more accurate so we can make better products. 4. How can machine learning help with lathe machines? Machine learning helps them learn from past work, making them smarter and more efficient over time. 5. What can we do with a CNC lathe? With a CNC lathe, we can make parts for cars, toys, and many other things quickly and accurately.

Sure! Just tell me what question you want me to answer.

What Are The Key Benefits Of Retrofitting A Traditional Metal Lathe With Cnc Capabilities Using Machine Learning Algorithms?Retrofitting a traditional metal lathe with CNC (Computer Numerical Control) makes it smarter. You can get better shapes and sizes more easily. Machine learning helps the lathe learn from mistakes, so it gets better every time you use it. This saves time and gives you better results, making your work easier and more fun!

How Can Machine Learning Enhance The Precision And Efficiency Of Cnc Operations In Retrofitted Metal Lathes?Machine learning can make CNC (Computer Numerical Control) operations better and faster on retrofitted metal lathes. By learning from past work, it helps machines understand how to cut metal more accurately. This means we can make parts that fit perfectly every time. It also saves time by showing us the best way to do the job. In the end, we can produce high-quality items more easily!

What Factors Should Be Considered When Selecting Machine Learning Models For Optimizing Machining Processes In A Cnc-Retrofitted Lathe?When choosing machine learning models for a CNC-retrofitted lathe, you should think about the type of data you have. Make sure the model can learn from that data well. You also need to consider how fast the model can make decisions. Lastly, check if the model is easy to use and understand. These factors will help you get better results in your machining tasks.

How Can Data From Sensors And Machine Learning Be Utilized To Predict Maintenance Needs And Reduce Downtime In Cnc Lathe Operations?We can use sensors on CNC lathes to gather information about how they work. Machine learning helps us find patterns in this data. By checking these patterns, we can know when the machine needs care before problems start. This way, we can fix things quickly and keep the machines running smoothly. Less downtime means we can make more products!

What Are The Common Challenges Faced When Integrating Machine Learning Technologies Into Existing Cnc Metal Lathe Systems, And How Can They Be Addressed?When we try to add machine learning to CNC metal lathes, we face some challenges. First, these machines may not have enough data to learn from. We can fix this by collecting more data over time. Second, it can be hard to mix new software with old machines. We can solve this by making sure both work well together. Finally, workers may need training to use the new technology. We can help them by offering workshops and classes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Metal Lathe Cnc Retrofitting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions we can think about for lathe machine learning and retrofitting. 1. What is a lathe machine? A lathe machine helps shape metal or wood by spinning it and cutting it into different shapes. 2. What is metal lathe CNC retrofitting? This means upgrading an older lathe machine to make it smart like a computer. 3. Why would we want to retrofit a lathe machine? We want to make it faster and more accurate so we can make better products. 4. How can machine learning help with lathe machines? Machine learning helps them learn from past work, making them smarter and more efficient over time. 5. What can we do with a CNC lathe? With a CNC lathe, we can make parts for cars, toys, and many other things quickly and accurately.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just tell me what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Benefits Of Retrofitting A Traditional Metal Lathe With Cnc Capabilities Using Machine Learning Algorithms?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting a traditional metal lathe with CNC (Computer Numerical Control) makes it smarter. You can get better shapes and sizes more easily. Machine learning helps the lathe learn from mistakes, so it gets better every time you use it. This saves time and gives you better results, making your work easier and more fun!”}},{“@type”: “Question”,”name”: “How Can Machine Learning Enhance The Precision And Efficiency Of Cnc Operations In Retrofitted Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can make CNC (Computer Numerical Control) operations better and faster on retrofitted metal lathes. By learning from past work, it helps machines understand how to cut metal more accurately. This means we can make parts that fit perfectly every time. It also saves time by showing us the best way to do the job. In the end, we can produce high-quality items more easily!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting Machine Learning Models For Optimizing Machining Processes In A Cnc-Retrofitted Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing machine learning models for a CNC-retrofitted lathe, you should think about the type of data you have. Make sure the model can learn from that data well. You also need to consider how fast the model can make decisions. Lastly, check if the model is easy to use and understand. These factors will help you get better results in your machining tasks.”}},{“@type”: “Question”,”name”: “How Can Data From Sensors And Machine Learning Be Utilized To Predict Maintenance Needs And Reduce Downtime In Cnc Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use sensors on CNC lathes to gather information about how they work. Machine learning helps us find patterns in this data. By checking these patterns, we can know when the machine needs care before problems start. This way, we can fix things quickly and keep the machines running smoothly. Less downtime means we can make more products!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced When Integrating Machine Learning Technologies Into Existing Cnc Metal Lathe Systems, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we try to add machine learning to CNC metal lathes, we face some challenges. First, these machines may not have enough data to learn from. We can fix this by collecting more data over time. Second, it can be hard to mix new software with old machines. We can solve this by making sure both work well together. Finally, workers may need training to use the new technology. We can help them by offering workshops and classes.”}}]}