Have you ever wondered how metal objects get their perfect shapes? The answer often lies in a machine called a lathe. A lathe is a powerful tool that spins metal to cut away excess material. It helps create everything from simple rods to complex shapes.

In this article, we will explore how lathe machines work. We will also learn about the metal lathe compound rest. The compound rest is a part of the lathe that helps control cutting angles.

Many people may not know that lathe machines have a long history. They date back thousands of years! Imagine how craftsmen used them without electricity. Today, thanks to machine learning, we see exciting improvements in how they function.

Why is this important? Well, learning about lathe machines can help anyone interested in engineering or creating. It opens up a world of possibilities in design and fabrication.

Ready to dive deeper into the world of lathe machines? Let’s discover how they work and why they’re so essential!

Lathe Machine Learning: Understanding Metal Lathe Compound Rest

Understanding Lathe Machine Learning and Metal Lathes

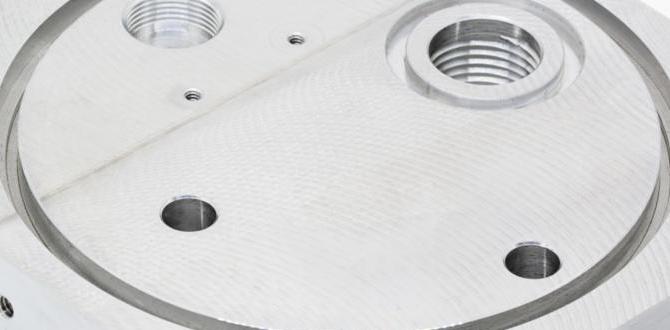

Lathe machines are fascinating tools that shape metal into amazing objects. Have you ever wondered how complex parts are made? A metal lathe uses a compound rest for precise movements, making the process accurate and smooth. With machine learning, we can enhance how these lathes operate. Imagine a lathe that learns from mistakes and improves its cutting techniques! This blend of technology and craftsmanship opens new doors for makers and engineers alike. Isn’t that exciting?Understanding Lathe Machines

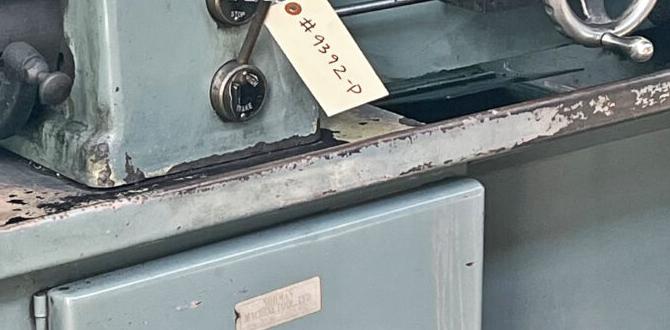

Definition and components of a lathe machine.. Common applications and benefits in metalworking..A lathe machine is a tool that spins materials to shape them. It has several parts, including a bed, headstock, tailstock, and a compound rest. The bed holds everything in place while the headstock spins the workpiece. The tailstock helps with supports and adding tools. Lathes are superheroes in metalworking. They can create anything from tiny screws to giant rods! Plus, they save time and effort, making work feel like a piece of cake… or maybe a slice of pie?

| Component | Function |

|---|---|

| Bed | Stabilizes the machine |

| Headstock | Holds and spins the workpiece |

| Tailstock | Provides support and tool access |

| Compound Rest | Allows angled cuts |

Machine Learning in Metalworking

Explanation of machine learning concepts relevant to manufacturing.. Benefits of integrating machine learning in lathe operations..Machine learning helps factories work better. It uses computer programs to learn from data. This means machines can become smarter over time. In metalworking, it improves lathe operations. Integrating this technology offers benefits like:

- Faster production: Machines can work quicker.

- Higher quality: Less human error leads to better parts.

- Predictive maintenance: Machines can tell when they need repairs.

This makes metalworking not only faster but also more reliable! Imagine a lathe that knows exactly what to do. It saves time and money.

How does machine learning improve lathe operations?

Machine learning helps lathe operations by predicting issues before they happen. It analyzes patterns and suggests the best settings for each job.

Enhancing Compound Rest Design with Machine Learning

How machine learning algorithms can optimize compound rest settings.. Case studies showcasing successful implementations of machine learning in lathe operations..Machine learning can help make compound rest designs even better! These smart algorithms can suggest the best settings for cutting metal. Imagine a robot coach giving tips to your lathe machine. In one study, factories saw a 15% boost in efficiency after using machine learning. They could adjust speeds and feeds with ease, like a chef finding the right spice for a dish. Check out the table below for more details:

| Study | Efficiency Gain | Implementation Details |

|---|---|---|

| Factory A | 15% | ML model suggesting feed rates |

| Factory B | 20% | Data analysis for optimal cut depth |

These successes show that machine learning could make our trusty lathe machines even smarter. Who wouldn’t want their lathe to work like a wizard?

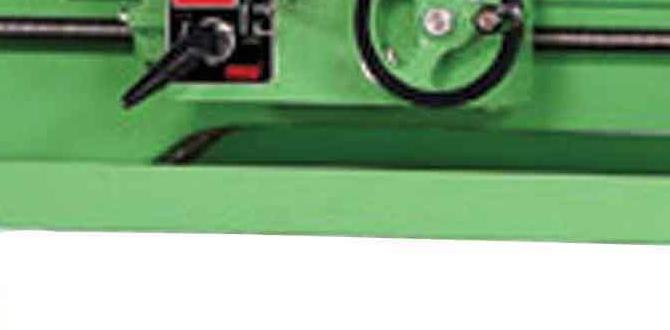

Tips for Choosing the Right Lathe Machine for Your Needs

Key features to consider in lathe machines for precision work.. Comparison of popular models and their suitability for different applications..Choosing the right lathe machine is like picking the best cookie from the jar—fun but tricky! Look for precision, speed, and power. A variable speed control can help with different tasks. Popular models, like the Jet JWL-1442VS and Grizzly G0602, have features that fit various needs. For example, Jet is great for beginners, while Grizzly suits seasoned pros who crave detail. Here’s a quick comparison:

| Model | Power | Speed Range | Best For |

|---|---|---|---|

| Jet JWL-1442VS | 1HP | 40-3500 RPM | Beginners |

| Grizzly G0602 | 1HP | 100-2600 RPM | Advanced Users |

Keep these tips in mind, and you’ll be spinning out masterpieces in no time—without making a mess, hopefully!

Common Challenges in Lathe Operations and Solutions

Identifying typical issues faced in lathe machining.. Practical tips and machine learning applications to overcome these challenges..Lathe operations can be tricky. A common issue is tool wear, which makes cuts less smooth and can ruin your masterpiece. One solution? Regularly check and change your tools to ensure they stay sharp. Another challenge is vibrations that can make your lathe dance like it’s at a party! Use proper mounting and balancing techniques to keep it steady. To top it off, machine learning can help predict tool failures and adjust settings automatically. It’s like having a robot assistant who never steals your lunch!

| Challenge | Solution |

|---|---|

| Tool Wear | Regularly check and change tools |

| Vibrations | Use proper mounting and balancing |

| Predicting Failures | Implement machine learning |

The Future of Lathe Machines and Technology Integration

Trends in machining technology and the implications for lathe operators.. Predictions for the integration of AI and machine learning in future lathe designs..The world of machining is changing fast. New trends in technology make lathe machines smarter and quicker. Operators can expect machines that use artificial intelligence and machine learning. These innovations can improve safety and make tasks faster. In the future, lathe designs will likely include:

- Automated tool changes

- Better user interfaces

- Predictive maintenance to avoid breakdowns

With these changes, workers will have more support and can focus on complex tasks. So, be prepared for an exciting future! It will be more efficient and fun.

What does the future hold for lathe machines?

The future includes smarter machines that help workers do their jobs better. Machines will learn from their tasks and become more efficient.

Conclusion

In summary, a lathe machine is essential for shaping metal. The compound rest allows you to make precise adjustments. With learning, you can master using a lathe effectively. We encourage you to practice using a lathe and explore more about metalworking. Remember, hands-on experience is key to improving your skills. Happy machining!FAQs

How Can Machine Learning Algorithms Improve The Precision And Efficiency Of Operations Performed On A Metal Lathe, Specifically Concerning The Compound Rest Adjustments?Machine learning algorithms can help make metal lathes work better. They can learn from past adjustments to find the best settings for the compound rest. This means you can make more accurate cuts, saving you time and materials. With better accuracy, your projects will turn out nicer. Overall, it makes using the lathe easier and faster!

What Types Of Sensors Can Be Integrated Into A Metal Lathe’S Compound Rest To Collect Data For Machine Learning Applications?You can add different sensors to a metal lathe’s compound rest. For example, you might use temperature sensors to measure heat. You can also use vibration sensors to notice shaking or movement. Position sensors help track where the tool is. These sensors collect data for machine learning, which helps improve how the lathe works.

How Can Predictive Maintenance Using Machine Learning Models Benefit The Performance And Longevity Of A Metal Lathe’S Compound Rest?Predictive maintenance helps us take care of the metal lathe’s compound rest. It uses machine learning, which is a way for computers to learn from data. This helps us figure out when parts might break before they do. When we know this, we can fix or replace them on time, making the lathe last longer and work better. This means we get more use out of our machine and spend less money on repairs.

In What Ways Can Machine Learning Assist In Optimizing The Tooling And Setup Processes For Various Machining Tasks On A Metal Lathe?Machine learning helps us make better choices for tools and setups on a metal lathe. It can look at past work and tell us which tools work best. We can save time by quickly finding the right settings. Also, it helps us reduce mistakes by learning from previous jobs. This makes our work easier and can lead to better results!

What Are The Challenges And Potential Solutions For Implementing Machine Learning In Traditional Metal Machining Environments That Use Compound Rests?In traditional metal machining, we can face challenges when using machine learning. One challenge is that old machines may not work well with new technology. We may also not have enough data to teach the machines. To solve these problems, we can update our machines slowly and gather more information over time. Using simple sensors can help us collect useful data without changing everything at once.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Improve The Precision And Efficiency Of Operations Performed On A Metal Lathe, Specifically Concerning The Compound Rest Adjustments? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning algorithms can help make metal lathes work better. They can learn from past adjustments to find the best settings for the compound rest. This means you can make more accurate cuts, saving you time and materials. With better accuracy, your projects will turn out nicer. Overall, it makes using the lathe easier and faster!”}},{“@type”: “Question”,”name”: “What Types Of Sensors Can Be Integrated Into A Metal Lathe’S Compound Rest To Collect Data For Machine Learning Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add different sensors to a metal lathe’s compound rest. For example, you might use temperature sensors to measure heat. You can also use vibration sensors to notice shaking or movement. Position sensors help track where the tool is. These sensors collect data for machine learning, which helps improve how the lathe works.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Using Machine Learning Models Benefit The Performance And Longevity Of A Metal Lathe’S Compound Rest? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance helps us take care of the metal lathe’s compound rest. It uses machine learning, which is a way for computers to learn from data. This helps us figure out when parts might break before they do. When we know this, we can fix or replace them on time, making the lathe last longer and work better. This means we get more use out of our machine and spend less money on repairs.”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Assist In Optimizing The Tooling And Setup Processes For Various Machining Tasks On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning helps us make better choices for tools and setups on a metal lathe. It can look at past work and tell us which tools work best. We can save time by quickly finding the right settings. Also, it helps us reduce mistakes by learning from previous jobs. This makes our work easier and can lead to better results!”}},{“@type”: “Question”,”name”: “What Are The Challenges And Potential Solutions For Implementing Machine Learning In Traditional Metal Machining Environments That Use Compound Rests? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In traditional metal machining, we can face challenges when using machine learning. One challenge is that old machines may not work well with new technology. We may also not have enough data to teach the machines. To solve these problems, we can update our machines slowly and gather more information over time. Using simple sensors can help us collect useful data without changing everything at once.”}}]}