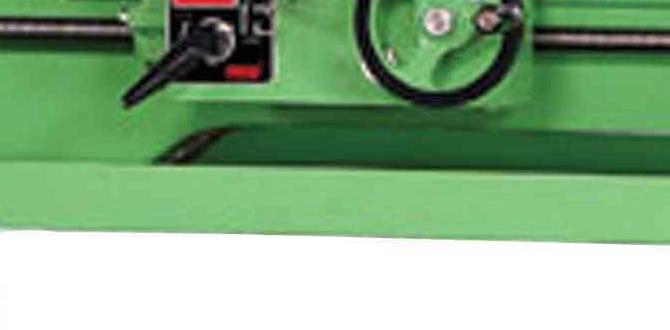

Imagine walking into a workshop filled with whirring machines and bright lights. In the corner, a metal lathe is busy shaping metal into precise forms. But have you ever wondered how these machines get so smart? Enter machine learning and the clever lathe machine controller board.

These boards help metal lathes understand what to do. They use data to improve their work. For instance, they learn from past mistakes and become more accurate. It’s like giving a brain to a machine! How cool is that?

As technology grows, the connection between machine learning and metalworking becomes stronger. Imagine a lathe that adjusts its speed on its own! This not only saves time but also makes great products. What if your favorite toy was made with this smart tech?

In this article, we will explore how lathe machine learning is changing the game. We’ll dive into how controller boards work and why they are so important. Get ready to discover the future of metal lathes!

Lathe Machine Learning: Enhancing Metal Lathe Controller Board

Lathe Machine Learning: Metal Lathe Controller Board

Discover how a lathe machine can transform creativity into reality. Metal lathe controller boards enable precise control over the machining process. These boards use machine learning to improve accuracy and efficiency. Imagine crafting unique metal pieces with just a few clicks! With enhanced features, users can create complex designs easily. Why struggle with manual adjustments? Embrace technology and watch your projects come to life with stunning results!The Role of Controller Boards in Lathe Machines

Explanation of lathe machine controller boards. Importance of selecting the right controller board for efficiency.Controller boards are essential parts of lathe machines. They act like the brain, helping to control how the machine moves. Choosing the right controller board is important for smooth operations and good results. A suitable board enhances efficiency and improves overall performance. Here are some key benefits of a good controller board:

- Better precision in cutting

- Faster processing times

- Improved user interface

Getting the right board can make the difference between a great project and a failed one.

Why is a controller board important?

Controller boards are key for efficiency. They help the lathe run smoothly and accurately. A poor choice leads to problems like slow speeds and mistakes. A good board saves time and materials.

How Machine Learning Can Optimize Lathe Machine Performance

Predictive maintenance and fault detection using machine learning. Enhancing precision and reducing waste in machining processes.Machine learning can help lathe machines work better and smarter. It does this through predictive maintenance and fault detection. This means machines can warn us before they break. We can fix issues early and avoid mistakes. Machine learning also enhances precision, which makes parts fit just right. Less waste means more savings and better products. This technology is like having a smart helper in the shop!

How does machine learning help with lathe machines?

Machine learning improves lathe machines by predicting issues and boosting accuracy.

Key Benefits:

- Predicts breakdowns before they happen.

- Makes precise cuts that save material.

- Reduces machine downtime.

- Improves product quality and lowers costs.

Choosing the Right Controller Board for Machine Learning Implementation

Key features to look for in a controller board. Comparison of popular controller boards for lathe machines.Finding the right controller board for your lathe machine is like choosing the best toppings for your pizza. It can make all the difference! Key features to look for include speed control and compatibility with machine learning software. Also, consider the board’s ability to handle various tools. Here’s a quick comparison of some popular options:

| Controller Board | Speed Control | ML Compatible |

|---|---|---|

| Board A | Yes | Yes |

| Board B | Yes | No |

| Board C | No | Yes |

With these details, you can pick the best board to help your lathe learn like a pro! Remember, a good controller board is like a well-cooked pie—it should make everything work smoothly and taste amazing.

Case Studies: Successful Implementations of Machine Learning in Metal Lathes

Realworld examples of machine learning applications in lathe operations. Outcomes and improvements observed.Machine learning is changing how metal lathes work. Many companies use it to make jobs easier and faster. Here are some examples:

- One factory improved tool life by 30%. This saved time and money.

- Another shop reduced errors by 25%. Workers could trust the machines more.

- A business saw a 20% rise in production speed. This helped meet more customer orders.

These stories show that using machine learning with lathe operations can lead to real benefits.

How has machine learning affected lathe operations?

Machine learning makes lathe operations more efficient. It helps reduce errors and speed up production.

Key Outcomes

- Better precision

- Less waste

- Higher customer satisfaction

Using a lathe with smart technology can really help factories improve their work.

Future Trends in Lathe Machine Control and Learning

Emerging technologies in metal lathe engineering. Predictions for the future integration of AI and machine learning in lathe machines.New technologies are changing how metal lathe machines work. Smart sensors can help machines learn and adapt. This means better precision and efficiency. Soon, robots will assist in operating these machines. They can predict problems before they happen.

- AI will optimize cutting speeds.

- Smart machines will communicate with each other.

- More automation will reduce human error.

Experts believe that these advancements will improve productivity by 30% in the next decade. The future of lathe machines looks bright!

What are the benefits of AI in lathe machines?

AI helps make lathe machines faster and more accurate. It can reduce waste and save money for factories. With AI, machines can also work longer hours without needing breaks.

Conclusion

In summary, a lathe machine with a learning metal lathe controller board offers smart ways to create precision parts. We can control this machine easily using advanced technology. You might explore more about how these controllers work and their benefits for projects. Learning can lead you to create amazing things with a lathe! Keep reading to discover more!FAQs

Sure! Here Are Five Related Questions Regarding Lathe Machine Learning And Metal Lathe Controller Boards:Sure! A lathe is a machine that spins metal to make shapes. Machine learning helps us teach computers how to improve the lathe’s work. Controller boards are like the brain of the lathe; they control how it moves. Together, they help us make precise and cool designs from metal. It’s a fun way to use technology and creativity!

Sure! Please provide the question you want me to answer.

How Can Machine Learning Algorithms Be Implemented To Optimize The Cutting Parameters In A Metal Lathe Controller Board For Improved Machining Efficiency?We can use machine learning to make metal lathes work better. First, we collect data on how the lathe cuts metal. Then, we teach the computer to find the best cutting settings using that data. This way, the lathe can cut faster and smoother. By trying different settings, we get better results every time!

What Are The Key Features To Consider When Selecting A Controller Board For A Cnc Metal Lathe That Can Effectively Integrate With Machine Learning Software?When picking a controller board for a CNC metal lathe, look for a few important features. First, make sure it has good processing power, so it can run software fast. Second, check if it connects easily to the machine learning software you want to use. You should also see if it has enough inputs and outputs for your tools. Lastly, choose a board with good support and instructions, so you can get help when needed.

In What Ways Can Predictive Maintenance Models Using Machine Learning Be Applied To Prevent Failures In Metal Lathe Operations?We can use machine learning to watch machines like metal lathes. It looks at how they work and learns from them. If it notices something strange, it can tell us before a problem happens. This way, we can fix the machine before it breaks. It helps save time and keeps things running smoothly.

How Can Real-Time Data From Sensors Be Used To Train Machine Learning Models For Adaptive Control Systems In Lathe Machining?We can use real-time data from sensors to help machines learn and adjust better. For example, sensors can check how a lathe machine is working while it cuts metal. This data shows us if the machine is making good cuts or needs changes. We can then feed this information into a computer program called a machine learning model. By practicing with this data, the model learns to help the lathe work better all on its own!

What Are The Challenges And Limitations Of Integrating Machine Learning With Existing Metal Lathe Controller Boards In Industrial Settings?Integrating machine learning with metal lathe controller boards has some challenges. First, older machines may not have enough power to run the new programs. Second, we might need special skills to set up and teach the system. Third, machine learning can be tricky because it needs lots of data to learn well. Finally, some people may worry about trusting the new technology to do the work safely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions Regarding Lathe Machine Learning And Metal Lathe Controller Boards:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal to make shapes. Machine learning helps us teach computers how to improve the lathe’s work. Controller boards are like the brain of the lathe; they control how it moves. Together, they help us make precise and cool designs from metal. It’s a fun way to use technology and creativity!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Implemented To Optimize The Cutting Parameters In A Metal Lathe Controller Board For Improved Machining Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make metal lathes work better. First, we collect data on how the lathe cuts metal. Then, we teach the computer to find the best cutting settings using that data. This way, the lathe can cut faster and smoother. By trying different settings, we get better results every time!”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Controller Board For A Cnc Metal Lathe That Can Effectively Integrate With Machine Learning Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a controller board for a CNC metal lathe, look for a few important features. First, make sure it has good processing power, so it can run software fast. Second, check if it connects easily to the machine learning software you want to use. You should also see if it has enough inputs and outputs for your tools. Lastly, choose a board with good support and instructions, so you can get help when needed.”}},{“@type”: “Question”,”name”: “In What Ways Can Predictive Maintenance Models Using Machine Learning Be Applied To Prevent Failures In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to watch machines like metal lathes. It looks at how they work and learns from them. If it notices something strange, it can tell us before a problem happens. This way, we can fix the machine before it breaks. It helps save time and keeps things running smoothly.”}},{“@type”: “Question”,”name”: “How Can Real-Time Data From Sensors Be Used To Train Machine Learning Models For Adaptive Control Systems In Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use real-time data from sensors to help machines learn and adjust better. For example, sensors can check how a lathe machine is working while it cuts metal. This data shows us if the machine is making good cuts or needs changes. We can then feed this information into a computer program called a machine learning model. By practicing with this data, the model learns to help the lathe work better all on its own!”}},{“@type”: “Question”,”name”: “What Are The Challenges And Limitations Of Integrating Machine Learning With Existing Metal Lathe Controller Boards In Industrial Settings?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Integrating machine learning with metal lathe controller boards has some challenges. First, older machines may not have enough power to run the new programs. Second, we might need special skills to set up and teach the system. Third, machine learning can be tricky because it needs lots of data to learn well. Finally, some people may worry about trusting the new technology to do the work safely.”}}]}