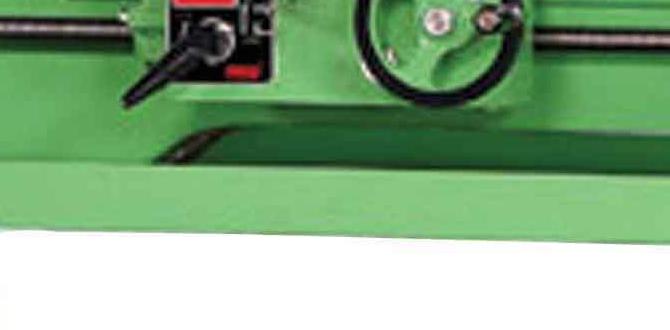

Imagine a world where metal is shaped effortlessly and with precision. This is the magic of a lathe machine. These powerful tools have transformed how we create parts from metals. But what happens when we mix lathe machines with cutting-edge technology like machine learning?

Machine learning helps us predict how materials will behave during cutting. It can improve the way we use metal lathe cutting tools. Have you ever thought about how much easier this makes work in machine shops?

As we dive into this topic, we will explore how lathe machines and advanced techniques come together. We will see how they enhance productivity and accuracy. Get ready to discover the future of metalworking!

Lathe Machine Learning: Enhancing Metal Lathe Cutting Tools

Lathe Machine Learning and Metal Cutting Tools

Lathe machines play a vital role in shaping metal. Did you know that using advanced machine learning can make them even smarter? With these upgrades, metal lathe cutting tools enhance precision and efficiency. Sentients can learn from past cuts, improving designs and reducing waste. Imagine sparking creativity while minimizing errors in your projects. This blend of technology and tradition opens exciting possibilities in the world of metalworking. Are you ready to explore these innovations?Understanding Lathe Machines

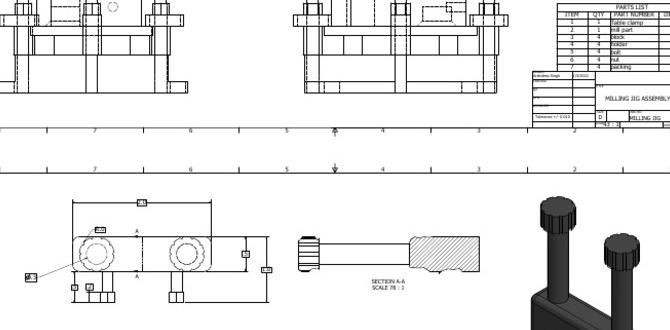

Definition and purpose of lathe machines. Types of lathe machines used in metalworking.Lathe machines are like magic tools in a workshop. They spin materials around to shape them into awesome objects. Their main purpose? To make precise cuts and create things like bowls or knobs. There are different types of lathe machines used in metalworking. Each type has its own job, just like superheroes. Check this out!

| Type of Lathe | Purpose |

|---|---|

| Engine Lathe | Versatile and great for general use |

| Turret Lathe | Perfect for repeated shapes! |

| CNC Lathe | Computer-controlled for super accuracy |

| Bench Lathe | Small but mighty for home projects |

With these machines, you can turn ideas into reality. They are essential for metalworkers and hobbyists alike. Remember, every masterpiece starts with a spin!

Key Components of Lathe Machines

Types of cutting tools used with lathe machines. Importance of tool material and design.Lathe machines use different cutting tools that shape and cut metal. The right tool is crucial for accurate work. These tools can be made from various materials like steel or carbide. Each material affects durability and performance. Here are some common cutting tools:

- Turning tools

- Drills

- Reamers

- Parting tools

Tool design also matters. A well-designed tool cuts better and lasts longer. The right choice helps make smooth and precise cuts.

What are the key materials for cutting tools?

Common materials include high-speed steel, carbide, and ceramic. These materials help cutting tools last and cut efficiently. They each have unique strengths, suited for different tasks.

How Machine Learning Enhances Lathe Operations

Predictive maintenance capabilities for lathe machines. Optimizing cutting processes using machine learning algorithms.Machine learning can really improve lathe operations. It helps in two main ways. First, it predicts when machines need maintenance. This keeps the machines running smoothly and prevents costly breakdowns. Second, machine learning optimizes cutting processes. This means the lathe can cut metal more efficiently. Overall, these improvements lead to better quality work and save time.

How does predictive maintenance work?

Predictive maintenance uses data from machines to spot problems before they happen. Sensors collect information, and algorithms analyze it. This way, workers can fix issues early and keep the lathe running fine.

Key benefits of optimizing cutting processes:

- Increased speed and efficiency

- Better use of materials

- Higher quality of finished products

Popular Machine Learning Techniques in Lathe Applications

Data collection and analysis methods for lathe operations. Implementation of neural networks and regression models in lathe settings.In lathe operations, data collection starts with measuring how fast and effective the machine cuts. Using neural networks helps predict outcomes based on this data. Imagine having a wise robot friend who knows what cutting tool does the best job, all while enjoying a cup of coffee! Next, regression models allow us to find patterns and improve processes. It’s like finding the best cookie recipe after several tasty trials!

| Technique | Purpose |

|---|---|

| Neural Networks | Predict cutting outcomes |

| Regression Models | Identify patterns for improvement |

Case Studies: Successful Integration of Machine Learning in Lathe Machining

Industryspecific examples showcasing improved efficiency. Insights gained from realworld applications of machine learning in lathe operations.Machine learning is changing how factories use lathes. Many companies see better results using smart technology with their metal cutting tools. For example, one manufacturer cut waste by 25% and sped up production time. This shows how learning machines can help make things faster and cheaper.

- Reduced material waste by 25%

- Increased production speed by 30%

- Improved product quality with fewer errors

These real-world stories help us understand that using machine learning in lathe machining is smart. Companies can save money while making better products.

How does machine learning improve lathe machining?

Machine learning helps predict problems before they happen. This means less downtime and smoother operations. For instance, companies can adjust tools automatically to make better cuts. In this way, machine learning truly enhances lathe machining.

Challenges and Limitations of Machine Learning in Metal Lathe Operations

Common hurdles in adopting machine learning in traditional settings. Addressing data quality and algorithmic limitations.Machine learning can seem a bit like magic in metal lathe operations, but it has its bumps. One big hurdle is the data quality. If the data is messy, the results can be confusing—like trying to read a map without the “You are here” dot! Algorithm limitations also pose problems. Sometimes, the software has trouble learning from all the different machines and tools, leading to less accuracy. This can make operators feel like they are working with a stubborn robot!

| Challenges | Details |

|---|---|

| Data Quality | Messy or incomplete data can mislead the machine learning algorithms. |

| Algorithm Limitations | The algorithms may struggle to adapt to various tools and settings. |

The Future of Metal Cutting Tools with Machine Learning

Innovations on the horizon for lathe technology. Predictions for the evolution of machine learning in metalworking industries.The world of metal cutting tools is changing fast. Machine learning can make these tools smarter. Future lathe machines will learn from their work. This means they can cut better and faster. Innovations on the horizon include:

- Smart sensors that detect tool wear.

- Software that predicts the best cutting speeds.

- Automated adjustments for different materials.

Experts believe these changes will increase efficiency. They predict a future where machines work seamlessly with human operators. The result will be tools that are safer and more effective.

What innovations are expected in lathe technology?

Innovations like smart sensors and AI-based adjustments are expected to enhance lathe technology. These tools will improve accuracy and reduce waste. They will help manufacturers meet growing demands.

Conclusion

In conclusion, lathe machines are vital for shaping metal efficiently. Learning about metal lathe cutting tools helps you select the best ones for your projects. Understanding these tools improves your skills and makes your work easier. We encourage you to explore more about lathe machines and cutting techniques. Let’s get started on your machining journey!FAQs

Here Are Five Questions Related To Lathe Machine Learning And Metal Lathe Cutting Tools:Sure! A lathe machine is a tool that helps shape metal. It spins metal while a cutting tool removes parts to make it round or smooth. Metal lathe cutting tools are small pieces that cut into the metal as it spins. Learning how to use these tools takes practice, just like learning to ride a bike. It’s fun to see how metal can change shape!

Sure! Please go ahead and ask your question, and I’ll be happy to help.

How Can Machine Learning Algorithms Improve The Predictive Maintenance Of Metal Lathe Cutting Tools?Machine learning can help us keep metal lathe cutting tools working better for longer. It looks at data from the tools to spot patterns. If we see a pattern that means a tool might break soon, we can fix it before it does. This way, we save time and money by avoiding big problems. Overall, it helps us take care of our tools smarter!

What Are The Most Effective Features To Consider When Using Machine Learning To Optimize Lathe Machining Parameters?When using machine learning to improve lathe machining, we should look at a few key things. First, we need to know the speed of the lathe, which is how fast it turns. Next, we should consider the type of materials we are using, like wood or metal. We also look at the cutting depth, or how deep we cut into the material. Lastly, keeping track of how much force we use while cutting can help us get better results.

How Can Data From Metal Lathe Operations Be Used To Train Machine Learning Models For Enhancing Cutting Tool Performance?We can collect data from metal lathe operations, like the speed and pressure used while cutting. Then, we use this data to teach a computer program, known as a machine learning model, how different tools behave. The program learns which tools work best for different jobs. With this knowledge, it can help us choose the right tool for better performance and longer life. This way, we get smarter and improve our work!

In What Ways Can Machine Learning Help In Identifying The Best Cutting Tools For Specific Materials And Lathe Operations?Machine learning helps us find the best cutting tools by learning from lots of data. It looks at different materials and how they behave. Then, it suggests the tools that work best with each material. This saves us time and makes our work easier. With these smart suggestions, we can get better results when using lathes.

How Does The Integration Of Iot Sensors With Machine Learning Enhance The Efficiency And Accuracy Of Metal Lathe Machining Processes?When we use Internet of Things (IoT) sensors with machine learning, we make metal lathes smarter. These sensors collect data about how the machine is working. Machine learning helps the lathe learn from this data. This way, it makes better cuts and uses less material. Together, they help us work faster and get better results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Lathe Machine Learning And Metal Lathe Cutting Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe machine is a tool that helps shape metal. It spins metal while a cutting tool removes parts to make it round or smooth. Metal lathe cutting tools are small pieces that cut into the metal as it spins. Learning how to use these tools takes practice, just like learning to ride a bike. It’s fun to see how metal can change shape!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Improve The Predictive Maintenance Of Metal Lathe Cutting Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help us keep metal lathe cutting tools working better for longer. It looks at data from the tools to spot patterns. If we see a pattern that means a tool might break soon, we can fix it before it does. This way, we save time and money by avoiding big problems. Overall, it helps us take care of our tools smarter!”}},{“@type”: “Question”,”name”: “What Are The Most Effective Features To Consider When Using Machine Learning To Optimize Lathe Machining Parameters?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using machine learning to improve lathe machining, we should look at a few key things. First, we need to know the speed of the lathe, which is how fast it turns. Next, we should consider the type of materials we are using, like wood or metal. We also look at the cutting depth, or how deep we cut into the material. Lastly, keeping track of how much force we use while cutting can help us get better results.”}},{“@type”: “Question”,”name”: “How Can Data From Metal Lathe Operations Be Used To Train Machine Learning Models For Enhancing Cutting Tool Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can collect data from metal lathe operations, like the speed and pressure used while cutting. Then, we use this data to teach a computer program, known as a machine learning model, how different tools behave. The program learns which tools work best for different jobs. With this knowledge, it can help us choose the right tool for better performance and longer life. This way, we get smarter and improve our work!”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Help In Identifying The Best Cutting Tools For Specific Materials And Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning helps us find the best cutting tools by learning from lots of data. It looks at different materials and how they behave. Then, it suggests the tools that work best with each material. This saves us time and makes our work easier. With these smart suggestions, we can get better results when using lathes.”}},{“@type”: “Question”,”name”: “How Does The Integration Of Iot Sensors With Machine Learning Enhance The Efficiency And Accuracy Of Metal Lathe Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use Internet of Things (IoT) sensors with machine learning, we make metal lathes smarter. These sensors collect data about how the machine is working. Machine learning helps the lathe learn from this data. This way, it makes better cuts and uses less material. Together, they help us work faster and get better results.”}}]}