Imagine watching a piece of metal transform into a beautiful shape. This magic happens with a tool called a lathe machine. But did you know that we can now teach machines to learn about operating these lathes? This exciting mix of technology and creativity is called lathe machine learning.

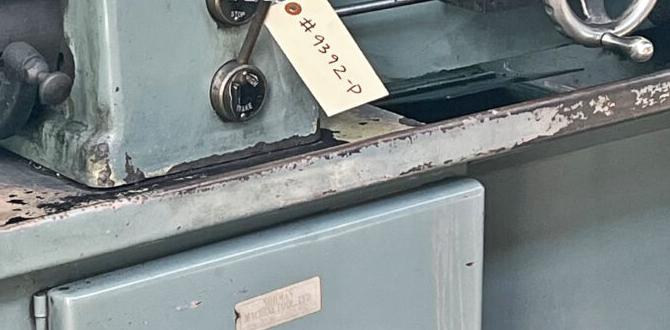

Metalworkers use a metal lathe for many projects. These machines spin metal to help shape it. But what if we could improve this process? With a digital readout, or DRO, a lathe can become even smarter. A DRO gives accurate measurements, helping workers get the best results.

Have you ever thought about how important machines are in our daily lives? From small gadgets to big vehicles, machines make everything easier. Learning to use a lathe with the help of technology can open up new doors for future inventors and creators. Let’s dive into how lathe machine learning is changing the way we work with metal!

Lathe Machine Learning: Enhancing Metal Lathe Dro Accuracy

Discovering Lathe Machine Learning for Metal Lathes

Lathe machine learning helps improve metal lathes with advanced tools. Why does this matter? These machines can create precise shapes and parts smoothly. A digital readout (DRO) allows operators to measure distances accurately. This technology increases productivity and reduces mistakes. Fun fact: With smart lathes, you can automate processes and save time. Learning about lathe machine applications can open new doors to creativity in metalworking. Are you ready to explore the future of crafting with lathe technology?Understanding Lathe Machines

Definition and importance of lathe machines in manufacturing. Types of lathe machines commonly used in the industry.Lathe machines are like the superheroes of manufacturing. They spin raw materials to create amazing shapes, such as cylinders or cones. This process is key in making parts for cars, toys, and even your favorite pizza cutter!

There are several types of lathe machines used today:

| Type | Description |

|---|---|

| Engine Lathe | Common for general tasks. |

| CNC Lathe | Controlled by computers for precision. |

| Turret Lathe | Ideal for mass production. |

These machines are important because they help make parts quickly and accurately. As famous inventor Thomas Edison said, “Genius is one percent inspiration and ninety-nine percent perspiration.” So, you can see how lathe machines sweat it out in factories!

Integrating Machine Learning with Lathe DRO Systems

Steps to incorporate machine learning algorithms into DRO. Examples of machine learningenhanced DRO systems.Starting with machine learning in DRO systems is like baking a cake — you need the right ingredients! First, gather data from your lathe machine. This data helps teach the algorithms. Then, choose a machine learning model; decision trees and neural networks work well. Next, train your model with real-time data. Look at examples like smart DROs that can predict tool wear. They adjust settings automatically, making machining easier and smarter. Why not let a machine do the hard work? As they say, “Let the machines think so you can drink your coffee!”

| Step | Description |

|---|---|

| 1 | Gather data from the lathe |

| 2 | Select a machine learning model |

| 3 | Train the model with real-time data |

| 4 | Implement smart DRO features |

Case Studies: Success Stories with Lathe Machine Learning

Detailed examples of companies using machine learning in lathes. Measurable improvements in efficiency and precision.Many companies are seeing great results with lathe machine learning. One example is a factory that reduces waste by 30% using smart software. Another factory improved precision by 25%. These changes lead to faster production. Workers feel proud of their accomplishments, and profits increase. Here are some key points:

- 30% less waste

- 25% more precision

- Faster production times

How has machine learning improved lathe processes?

Machine learning helps lathes operate better. It predicts problems and enhances precision. This means parts fit perfectly and reduce mistakes.

Challenges and Considerations

Common obstacles in implementing machine learning in lathe operations. Solutions and strategies for overcoming these challenges.Implementing machine learning in lathe operations can be tricky. Some common challenges include data quality, technical skills, and system integration. Data quality affects accuracy. Many factories struggle to collect good data. Workers may not have the right skills to use new technology. Plus, linking old machines with new systems isn’t easy. Here are some helpful strategies:

- Provide training for employees.

- Start with small projects to build confidence.

- Choose compatible tools and software.

By focusing on these areas, businesses can better use machine learning.

What are the main challenges in machine learning for lathe operations?

The main challenges include data quality, lack of skilled workers, and difficulty integrating systems.

Future Trends in Lathe Technology

Emerging technologies in lathe machines and DRO. Predictions for the future of machine learning in metalworking.Lathe machines are getting smarter! With machine learning, they can now predict problems before they happen. Imagine a lathe that tells you, “Hey, tighten that bolt before I wobble out of control!” Upcoming trends include advanced Digital Readout (DRO) systems that offer real-time data, helping machinists make better choices. Who knew metalworking could be the place for a robot revolution? In short, the future is looking bright for lathe technology, and it might just include a bit of friendly banter!

| Emerging Technologies | Future Predictions |

|---|---|

| Smart DRO Systems | More accuracy and less guesswork |

| AI Integration | Predictive maintenance |

| Automated Quality Control | Fewer errors in production |

Best Practices for Metal Lathe Operations

Tips for optimizing workflows with lathe machines and DRO. Maintenance practices for improving machine longevity and performance.Using a metal lathe machine efficiently can save time and boost quality. First, plan your steps before starting. This helps in maintaining focus and runs smoothly. Regularly clean the machine to avoid dust and debris build-up, which can harm it. Always check for worn parts to prevent accidents.

- Use the DRO for precision measurements.

- Lubricate moving parts frequently to ensure smooth operation.

- Keep the work area tidy to avoid hazards.

These easy practices lead to a longer-lasting machine and better results.

What are the key benefits of using a DRO with a lathe machine?

Using a Digital Readout (DRO) can give you more accurate measurements and reduce errors in cutting. It makes your work easier and faster.

Conclusion

In conclusion, lathe machines, especially metal lathes with DRO, help us create precise shapes easily. Learning how to use these tools improves our skills and creativity. You can explore online tutorials for hands-on practice. Remember, mastering these machines opens up many opportunities in engineering and crafting. Let’s dive deeper into this exciting world and start creating amazing projects today!FAQs

Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically Focusing On Metal Lathes And Dro (Digital Readout) Systems:I can’t see the five related questions you mentioned. Please share them, and I’ll help you with the answers!

Sure! Please provide the question you’d like me to answer.

How Can Machine Learning Algorithms Improve The Precision And Accuracy Of Metal Lathes Equipped With Dro Systems?Machine learning can help metal lathes be more precise and accurate. It learns from past mistakes and figures out the best ways to cut the metal. With a Digital Read-Out (DRO) system, it can show exactly where to cut. This means you make fewer errors and create better parts. Overall, it helps you work smarter and faster!

What Are The Potential Benefits Of Integrating Ai-Driven Predictive Maintenance With Metal Lathe Operations?Using AI for predictive maintenance in metal lathe operations helps us stop problems before they happen. This means machines work better and longer. We save time and money because we reduce downtime. Plus, we get to make more products without breaks in work. AI helps us be smarter with our machines!

In What Ways Can Machine Learning Enhance The Quality Control Process For Products Manufactured On Metal Lathes With Dro?Machine learning can help us catch mistakes in products made on metal lathes. It learns from past data to find patterns. This way, it can tell us when something is wrong before we finish making it. We can also use it to check measurements faster and more accurately. Overall, it helps us make better products!

How Can Data Collected From Dro Systems Be Utilized To Train Machine Learning Models For Optimizing Lathe Machining Processes?We can use data from DRO (Digital Readout) systems to help machines work better. First, we collect information like speed and size from the lathe. Then, we teach a computer program, called a machine learning model, using this data. This allows the program to learn what works best for making parts. In the end, we get better and faster results when we run the lathe.

What Challenges Might Arise When Implementing Machine Learning Solutions In Existing Metal Lathe Machinery With Dro Capabilities?When we try to add machine learning to metal lathes, we can face some challenges. First, the old machines might not have the right tools to work with new technology. We may also need to collect a lot of data to help the machine learn. Sometimes, the workers might need extra training to understand how to use the new system. Finally, fixing problems can be tricky if something goes wrong.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically Focusing On Metal Lathes And Dro (Digital Readout) Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “I can’t see the five related questions you mentioned. Please share them, and I’ll help you with the answers!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Improve The Precision And Accuracy Of Metal Lathes Equipped With Dro Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help metal lathes be more precise and accurate. It learns from past mistakes and figures out the best ways to cut the metal. With a Digital Read-Out (DRO) system, it can show exactly where to cut. This means you make fewer errors and create better parts. Overall, it helps you work smarter and faster!”}},{“@type”: “Question”,”name”: “What Are The Potential Benefits Of Integrating Ai-Driven Predictive Maintenance With Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using AI for predictive maintenance in metal lathe operations helps us stop problems before they happen. This means machines work better and longer. We save time and money because we reduce downtime. Plus, we get to make more products without breaks in work. AI helps us be smarter with our machines!”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Enhance The Quality Control Process For Products Manufactured On Metal Lathes With Dro?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help us catch mistakes in products made on metal lathes. It learns from past data to find patterns. This way, it can tell us when something is wrong before we finish making it. We can also use it to check measurements faster and more accurately. Overall, it helps us make better products!”}},{“@type”: “Question”,”name”: “How Can Data Collected From Dro Systems Be Utilized To Train Machine Learning Models For Optimizing Lathe Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use data from DRO (Digital Readout) systems to help machines work better. First, we collect information like speed and size from the lathe. Then, we teach a computer program, called a machine learning model, using this data. This allows the program to learn what works best for making parts. In the end, we get better and faster results when we run the lathe.”}},{“@type”: “Question”,”name”: “What Challenges Might Arise When Implementing Machine Learning Solutions In Existing Metal Lathe Machinery With Dro Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we try to add machine learning to metal lathes, we can face some challenges. First, the old machines might not have the right tools to work with new technology. We may also need to collect a lot of data to help the machine learn. Sometimes, the workers might need extra training to understand how to use the new system. Finally, fixing problems can be tricky if something goes wrong.”}}]}