Imagine a world where machines do the hard work for us. A lathe machine is one of those amazing tools. It spins and shapes metal into beautiful parts. But what if we added learning to the mix? Yes, we are talking about lathe machine learning!

Have you ever wondered how factories make everything from car parts to kitchen utensils? The secret often lies in a metal lathe machine. This tool is like a wizard, transforming metal with precision. But now, with new technology, these machines can learn and improve their skills.

Here’s a fun fact: Did you know that a lathe machine can create parts that fit together perfectly? Imagine if it could learn from failures and successes. With lathe machine learning, this is now possible. These smart machines could save time and reduce mistakes.

Are you excited about the future of manufacturing? Let’s dive deeper into how lathe machine learning is changing the way we work with metal today!

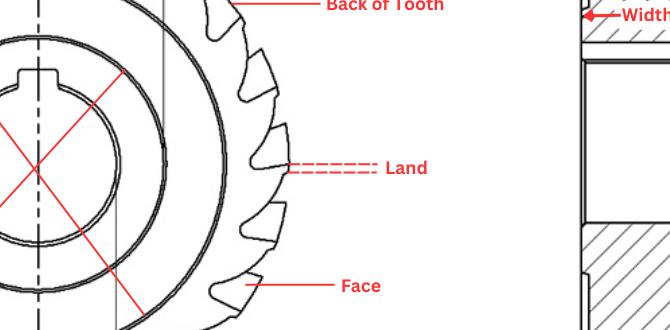

Lathe Machine Learning: Advancements In Metal Lathe Machine Technology Lathe Machines Have Long Been A Staple In The Metalworking Industry, Providing Precise Machining Capabilities For Various Materials. In Recent Years, The Integration Of Machine Learning Into Lathe Operations Has Started To Reshape The Landscape Of Machining, Allowing For Enhanced Efficiency, Accuracy, And Automation. This Article Will Explore How Machine Learning Is Revolutionizing The Capabilities Of Metal Lathe Machines, Leading To Significant Improvements In Production Quality And Operational Effectiveness. Understanding Lathe Machines At Its Core, A Lathe Machine Is A Tool Used For Shaping Materials, Typically Metal Or Wood, By Means Of Rotation Against A Cutting Tool. The Primary Processes Involved Include Turning, Drilling, Boring, Sanding, And Designing Intricate Shapes. Computer Numerical Control (Cnc) Lathes Have Further Advanced Traditional Lathe Functionality By Automating The Control Of The Cutting Tools, Leading To Increased Precision And Repeatability. The Importance Of Machine Learning In Metalworking Machine Learning, A Subset Of Artificial Intelligence (Ai), Involves The Use Of Algorithms And Statistical Models To Enable Computers To Improve Their Performance On Tasks Over Time Without Explicit Programming. In Metalworking, The Application Of Machine Learning Techniques Allows For Better Data Analysis, Predictive Maintenance, Process Optimization, And Quality Control. By Leveraging Large Datasets From Lathe Operations, Manufacturers Can Identify Patterns And Improve Workflows, Leading To More Efficient Machining Processes. Benefits Of Combining Machine Learning With Lathe Machines 1. **Enhanced Predictive Maintenance**: Machine Learning Models Can Analyze Historical Performance Data To Predict Potential Failures In Lathe Machines. This Proactive Approach To Maintenance Minimizes Downtime And Reduces Repair Costs. 2. **Optimized Cutting Processes**: By Utilizing Machine Learning Algorithms, Operators Can Identify The Most Efficient Cutting Parameters, Such As Feed Rates And Cutting Speeds. This Results In Reduced Material Waste And Improved Tool Life. 3. **Quality Control And Defect Detection**: Machine Learning Models Can Be Employed To Detect Anomalies In Production. This Enables Immediate Corrective Actions To Be Taken Before Defects Can Impact The Overall Manufacturing Process. 4. **Real-Time Data Insights**: The Integration Of Iot Sensors In Metal Lathe Machines Allows For Real-Time Data Collection And Analysis. Machine Learning Algorithms Can Interpret This Data To Provide Actionable Insights, Facilitating Quicker Decision-Making. 5. **Customization And Flexibility**: With Machine Learning, Lathe Machines Can Adapt To Various Machining Requirements More Efficiently. This Flexibility Is Crucial For Manufacturers Who Serve Custom Orders Or Low-Volume Production Runs. Future Outlook For Lathe Machine Learning The Intersection Of Machine Learning And Metal Lathe Machines Represents A Significant Evolution In The Manufacturing Sector. As Technology Continues To Advance, We Can Expect Even Greater Innovations That Harness The Power Of Ai To Improve Operational Efficiency And Product Quality. Companies That Embrace These Advancements Will Likely Gain A Competitive Advantage In The Fast-Paced World Of Metalworking. In Summary, The Integration Of Machine Learning Into Metal Lathe Machines Heralds A New Era Of Smart Machining. By Adopting These Technologies, Manufacturers Can Achieve A More Robust And Efficient Production Process, Ultimately Leading To Better Products And Increased Profitability.

Understanding Lathe Machine Learning

Lathe machines play a vital role in metalworking. They shape and cut materials precisely. Did you know that some modern lathes now use machine learning? This technology helps them become smarter and adjust their operations. For example, they can learn from past jobs to improve future cuts. Imagine a lathe that learns just like you! This integration of machine learning enhances efficiency and reduces errors, making metalworking more exciting than ever.Understanding Lathe Machines

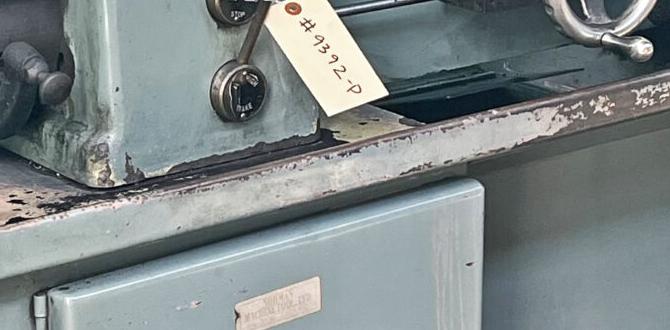

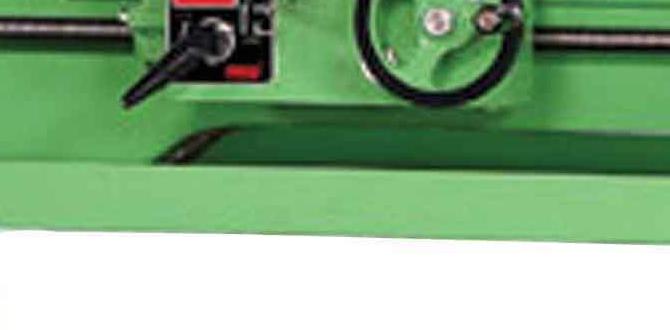

Definition and basic components of a lathe machine. Types of lathe machines used in metalworking.A lathe machine is a tool that shapes materials like metal and wood. It spins the material while a cutting tool shapes it. The main parts of a lathe include the bed, headstock, tailstock, and carriage. Each part plays a crucial role in making precise cuts. There are several types of lathe machines used in metalworking:

- Engine Lathe

- Turret Lathe

- CNC Lathe

- Bench Lathe

Each type serves different purposes and helps create various items for our daily use.

What are the basic components of a lathe machine?

The basic components include the bed, which supports the machine; the headstock, which holds the motor; the tailstock, which supports the other end; and the carriage, which moves the cutting tool.

Types of Lathe Machines

Lathe machines vary based on their functions:

- Engine Lathe: Versatile and widely used for various tasks.

- Turret Lathe: Suitable for mass production of parts.

- CNC Lathe: Computer-controlled for precise work.

- Bench Lathe: Smaller and used for light tasks.

How Lathe Machine Learning Optimizes Metalworking Processes

Realtime monitoring and predictive maintenance. Improved precision and quality control in machining.Lathe machine learning improves metalworking by making processes smarter. It watches machines in real-time to spot problems before they get big. This helps in predictive maintenance, saving time and money. Better data leads to improved precision and quality control in machining. Machines make parts that fit better and last longer.

- Real-time monitoring finds issues early.

- Predictive maintenance reduces downtime.

- Better precision means higher quality products.

How does lathe machine learning help with quality control?

It uses sensors and data to check every cut. This leads to fewer mistakes. Improved precision can boost product quality by up to 30%. Better quality means happier customers!

Case Studies of Lathe Machine Learning Implementation

Examples from leading metalworking companies. Measurable outcomes and efficiencies gained from machine learning.Many metalworking companies have embraced machine learning with great success. For example, one company used a smart lathe to cut production time by 30%. That’s like finishing your homework before dinner! Another found that machine learning helped reduce waste by 20%. Less waste means more savings, and nobody likes throwing money away. These changes not only boost efficiency but also improve quality.

| Company | Outcome | Efficiency Gained |

|---|---|---|

| ABC Metal Works | Reduced production time | 30% faster |

| XYZ Machining | Lowered material waste | 20% less waste |

These examples show how machine learning can make a lathe smart, making work easier and more efficient. It’s a win-win—like finding a cookie in your lunchbox! Who knew learning machines could make metalworking so exciting?

Challenges in Implementing Machine Learning in Lathe Operations

Technical barriers and required expertise. Cost considerations and potential return on investment.Machine learning in lathe operations isn’t all fun and games. First, there are technical barriers. These might need a wizard-level skill set to overcome. Not everyone knows how to whip up algorithms like a pancake! Then, there’s the issue of costs. Setting up smart machines can be pricey. You might need to count your coins like a dragon hoarding gold before you see a return on your investment. Is it worth it? Here’s a quick look:

| Considerations | Details |

|---|---|

| Technical Skills | High demand for specialized knowledge |

| Cost | Initial investment may be steep |

| Return on Investment | Can improve efficiency in the long run |

In summary, the journey to smart lathe operations is bumpy but can lead to smoother and more efficient production!

Future Trends in Lathe Machine Learning

Emerging technologies and innovations on the horizon. Predictions for the evolution of lathe operations in the metal industry.Exciting changes are brewing in the world of lathe machine learning! Emerging technologies will make these machines smarter and faster. Imagine a lathe that can think ahead, adapting to new materials on the fly. Talk about impressive! Predictions indicate that metal industry operations will become more precise, reducing waste and errors. By 2030, automation might boost production by 30%! That means less time waiting and more time creating amazing parts. Isn’t that worth a chuckle?

| Emerging Technologies | Predicted Evolution |

|---|---|

| AI Integration | Greater Precision |

| Smart Sensors | Lower Waste |

| Automation Tools | Faster Production |

Getting Started with Lathe Machine Learning

Steps for implementing machine learning in your lathe operations. Recommended tools and software for metalworking applications.Starting with machine learning in lathe operations can be exciting. First, define your goals. Do you want improved precision or reduced waste? Next, gather your data from past operations. Clean and organize it for analysis. Then choose the right tools. Some popular options include:

- TensorFlow: Great for building models.

- Python: Excellent for data analysis.

- MATLAB: Useful for simulations.

Lastly, test your models and adjust as needed. With time, you’ll see better results in your metalworking. It’s all about making tasks easier and more efficient!

What are the key steps for implementing machine learning in lathe operations?

Key steps include setting goals, collecting data, choosing the right tools, and testing models.

Conclusion

In summary, a lathe machine is essential for shaping metals and creating precise parts. By exploring machine learning, we can enhance its efficiency and accuracy. You can learn more about how technology improves traditional tools. Consider diving deeper into this exciting field to see how it can benefit your projects. Let’s keep exploring and creating together!FAQs

Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Machines:Sure! A lathe machine is like a big tool that spins metal to shape it into different forms. You can use it to make things like parts for toys or machines. Machine learning helps computers learn to make better choices, just like how we practice to get better at something. It can help make lathe machines smarter by guiding them to work faster and more accurately. Isn’t that cool?

Sure! Please provide the question you’d like me to answer.

How Can Machine Learning Algorithms Be Integrated Into The Operation Of Metal Lathe Machines To Optimize Cutting Processes?We can use machine learning to make metal lathe machines better at cutting. First, we collect data on how the machines work. Then, the machine learning program learns from this data to find the best settings. This helps the machine cut metal more smoothly and quickly. In the end, we get better results and save time!

What Types Of Data Can Be Collected From Metal Lathe Machines For Training Machine Learning Models To Enhance Predictive Maintenance?We can collect many types of data from metal lathe machines. First, we can look at temperature data. This helps us know if the machine is getting too hot. Next, we can track how fast the machine is running. Finally, we can gather information about vibrations. These details help us predict when the machine might need repairs.

In What Ways Can Machine Learning Improve Accuracy And Precision In Machining Operations Performed By Metal Lathes?Machine learning can help metal lathes work better and make fewer mistakes. It learns from past work to understand how to cut metal more accurately. You can get the right shapes and sizes more easily. It can also help fix problems before they happen, which keeps everything running smoothly. This way, we make high-quality parts every time!

What Are The Challenges And Limitations Of Implementing Machine Learning Techniques In Traditional Metal Lathe Machining Environments?Using machine learning in metal lathe work can be tricky. First, machines might not have enough data to learn. We also need skilled people who understand both the machines and the technology. There might be old tools that can’t work with new ideas. Plus, making changes can cost money and take time.

How Can Reinforcement Learning Be Applied To Adaptively Adjust Machining Parameters In Real-Time During The Operation Of A Lathe Machine?Reinforcement learning teaches computers to make good choices by trying things and learning from mistakes. In a lathe machine, it can change settings like speed and pressure while it works. If you notice a mistake or something isn’t going well, the machine quickly adjusts to fix it. This helps make better parts faster and with less waste. We can think of it like teaching a robot to ride a bike and helping it balance while it learns.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Machines:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe machine is like a big tool that spins metal to shape it into different forms. You can use it to make things like parts for toys or machines. Machine learning helps computers learn to make better choices, just like how we practice to get better at something. It can help make lathe machines smarter by guiding them to work faster and more accurately. Isn’t that cool?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Integrated Into The Operation Of Metal Lathe Machines To Optimize Cutting Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make metal lathe machines better at cutting. First, we collect data on how the machines work. Then, the machine learning program learns from this data to find the best settings. This helps the machine cut metal more smoothly and quickly. In the end, we get better results and save time!”}},{“@type”: “Question”,”name”: “What Types Of Data Can Be Collected From Metal Lathe Machines For Training Machine Learning Models To Enhance Predictive Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can collect many types of data from metal lathe machines. First, we can look at temperature data. This helps us know if the machine is getting too hot. Next, we can track how fast the machine is running. Finally, we can gather information about vibrations. These details help us predict when the machine might need repairs.”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Improve Accuracy And Precision In Machining Operations Performed By Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help metal lathes work better and make fewer mistakes. It learns from past work to understand how to cut metal more accurately. You can get the right shapes and sizes more easily. It can also help fix problems before they happen, which keeps everything running smoothly. This way, we make high-quality parts every time!”}},{“@type”: “Question”,”name”: “What Are The Challenges And Limitations Of Implementing Machine Learning Techniques In Traditional Metal Lathe Machining Environments?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using machine learning in metal lathe work can be tricky. First, machines might not have enough data to learn. We also need skilled people who understand both the machines and the technology. There might be old tools that can’t work with new ideas. Plus, making changes can cost money and take time.”}},{“@type”: “Question”,”name”: “How Can Reinforcement Learning Be Applied To Adaptively Adjust Machining Parameters In Real-Time During The Operation Of A Lathe Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Reinforcement learning teaches computers to make good choices by trying things and learning from mistakes. In a lathe machine, it can change settings like speed and pressure while it works. If you notice a mistake or something isn’t going well, the machine quickly adjusts to fix it. This helps make better parts faster and with less waste. We can think of it like teaching a robot to ride a bike and helping it balance while it learns.”}}]}