Have you ever wondered how intricate metal parts are made? The answer often involves a lathe machine. This clever tool helps shape metal into precise designs, like gears and shafts. But did you know that a lathe machine can also learn? Yes, that’s right!

Imagine a lathe machine using learning techniques to improve its work. This is where machine learning steps in. With advanced technology, the metal lathe motor can adapt and create better results. It’s a game changer for industries!

Picture a factory where each turn of the lathe is faster and more accurate. Less waste means a better environment. Plus, the factory can make more products in less time. How cool is that?

In this article, we’ll dive into how lathe machine learning is reshaping manufacturing. You’ll see the amazing benefits of using a smart metal lathe motor. Get ready to be amazed by the world of modern machining!

Lathe Machine Learning: Enhancing Metal Lathe Motor Efficiency

Lathe Machine Learning and Metal Lathe Motors

Lathe machines reshape metal with precision. Have you ever wondered how these powerful tools work? They spin and cut materials to create parts for various machines. With modern technology, machine learning helps improve lathe operations. It predicts the right settings for different tasks, making work faster and safer. Imagine being able to optimize every cut! This blend of traditional metalworking and advanced technology opens exciting possibilities in manufacturing and engineering.Understanding Lathe Machines

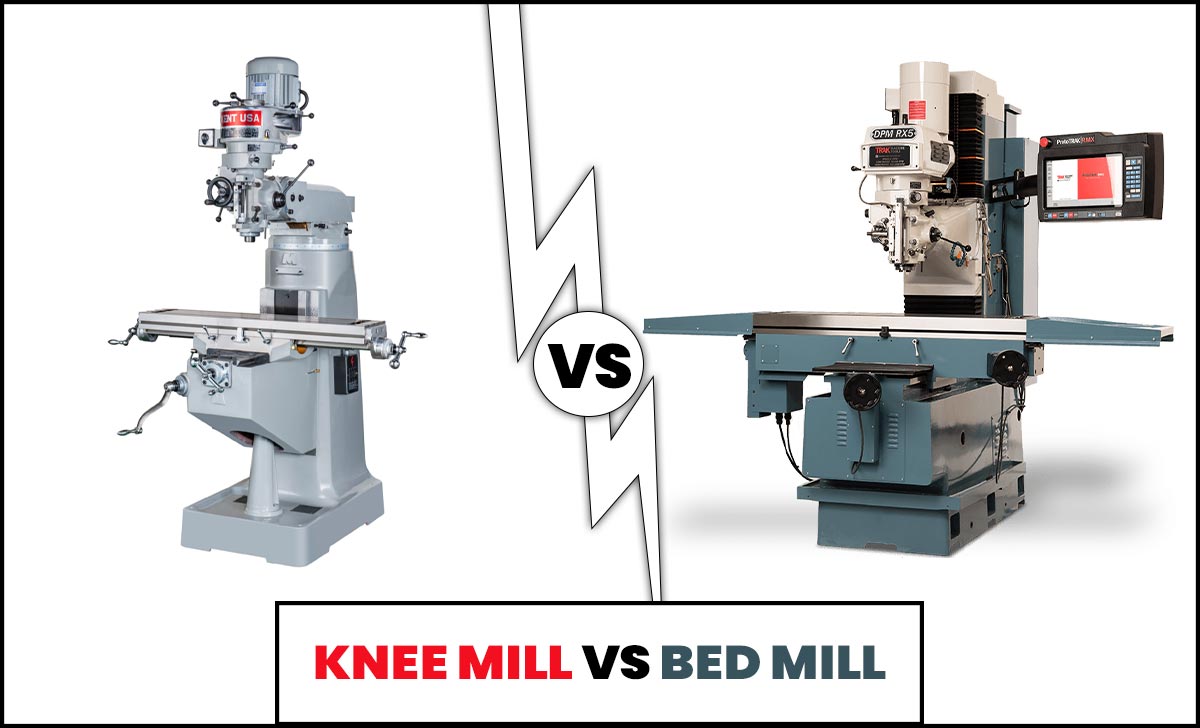

Definition and purpose of lathe machines in manufacturing.. Different types of lathe machines and their applications..Lathe machines are like magic wands for manufacturers! They shape materials, making cylinders, cones, and more from metals and woods. This process is called turning. There are different types of lathes, each with its special job. For example, a production lathe is fast and great for making lots of pieces, while a bench lathe is perfect for small projects. Here’s a quick overview:

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General-purpose turning |

| Turret Lathe | Making multiple identical parts |

| Toolroom Lathe | Precision work |

| Wood Lathe | Shaping wood into various forms |

Next time you see a perfectly round object, remember the handy lathe machine and its abilities! It’s pretty cool how a simple machine helps create amazing things in our world!

Applications of Machine Learning in Lathe Operations

Predictive maintenance and its impact on lathe machine efficiency.. Optimization of cutting parameters for enhanced precision and performance..Machine learning makes lathe operations smarter! For example, predictive maintenance helps find problems before they happen. This keeps the lathe running smoothly, making it more efficient and less grumpy. Imagine a lathe that tells you, “Hey, change my oil before I throw a tantrum!”

Also, machine learning optimizes cutting parameters. It fine-tunes speed and feed rates to get perfect cuts every time. This level of precision means fewer mistakes. In fact, it can reduce waste by up to 30%! Who knew a lathe could be so resourceful and humorous?

| Benefit | Impact |

|---|---|

| Predictive Maintenance | Increases Efficiency |

| Optimized Cutting | Enhances Precision |

Integrating Machine Learning with Lathe Motors

How machine learning algorithms can improve motor performance.. Case studies of successful implementations in the industry..Machine learning helps lathe motors work better and smarter. These algorithms can predict problems before they happen. They also help the motors run more efficiently, saving energy. When companies use machine learning, they often see great results. For example:

- An auto parts maker improved output by 30%.

- A factory reduced downtime by 50% using smart diagnostics.

These examples show how technology can help in everyday tasks. Improving lathe motors means better quality for everyone!

How can machine learning improve motor performance?

Machine learning can boost motor performance by predicting issues, saving energy, and increasing efficiency.

Advantages of Using Machine Learning in Lathe Operations

Increased production efficiency and reduced downtime.. Enhanced product quality and consistency through datadriven insights..Using machine learning in lathe operations brings many benefits. First, it boosts production speed. Machines work faster with less waiting time. Second, it leads to better product quality. Data helps makers create items that look the same every time. This reduces errors and waste, making everyone happy. The combination of speed and quality is a win-win for businesses.

- Increased production efficiency

- Reduced downtime

- Enhanced product consistency

- Data-driven insights

What are the benefits of using machine learning in lathe operations?

Machine learning improves speed, reduces errors, and enhances product quality. It helps factories make items faster and better, saving time and money.

Challenges and Considerations in Implementing Machine Learning

Common obstacles faced in adopting machine learning technologies.. Strategies for overcoming these challenges in metalworking environments..Implementing machine learning in metalworking can be tough. Some common challenges include lack of data, high costs, and resistance to change. Workers may worry about new technology replacing their jobs. To overcome these hurdles, companies can:

- Start with small projects to build confidence.

- Offer training sessions for employees.

- Show how machine learning improves their work.

By addressing these issues, businesses can successfully embrace the power of machine learning.

What are the common obstacles in adopting machine learning?

Common obstacles include lack of skilled workers, high implementation costs, and cultural resistance within the workplace.

How can companies overcome these challenges?

Companies can overcome challenges by providing training, starting with pilot programs, and showing the benefits of machine learning.

The Future of Lathe Machines with Machine Learning

Emerging trends and innovations in lathe technologies.. Predictions on the evolution of machine learning in metalworking..Lathe machines are getting a tech upgrade! Imagine your trusty old lathe learning new tricks. With machine learning, these machines can now spot patterns and improve their work. For example, they can predict when parts might break and adjust before it happens—talk about being ahead of the game! Emerging trends show lathes becoming smarter and faster. Soon, we might see robots chatting with metal lathes, or maybe we’ll have lathes that can do the tango! Let’s take a peek at some exciting changes.

| Innovation | Description |

|---|---|

| Smart Sensors | Help lathe machines gather real-time data to prevent errors. |

| AI Integration | Allows machines to learn from past mistakes and improve. |

| Remote Control | Operators can manage lathes from anywhere. Who needs to wear steel-toed boots at the shop? |

Experts predict that machine learning will take over many tasks in metalworking. Machines will not only cut metal but also think for themselves. Who knew lathes would be the new thinking machines? Keep an eye on these innovations. The future looks bright—perhaps even shiny!

Conclusion

In conclusion, a lathe machine is crucial for shaping metal. Learning about lathe motors can help you improve your skills. You can create precise designs easier with the right knowledge. We encourage you to explore more about lathe machines and practice using them. This hands-on experience will boost your confidence and abilities in metalworking. Keep learning and creating!FAQs

Sure! Here Are Five Questions Related To The Topic Of Lathe Machine Learning, Metal Lathe, And Motors:Sure! Here are the questions and their answers: 1. What is a lathe machine? A lathe machine is a tool that helps you shape metal or wood. It spins the material to make it round or smooth. 2. How does a lathe machine work? The lathe machine spins a piece of metal. Then, it uses sharp tools to cut and shape it into different forms. 3. What is machine learning? Machine learning is when computers learn from data. They get better at tasks without being told what to do. 4. Can machines make parts for lathes? Yes, machines can create parts for lathes. They use careful measurements to make everything fit perfectly. 5. What is a motor? A motor is a device that makes things move. It uses electricity to spin or run other machines, like lathes.

Sure! Please provide the question you would like me to answer.

How Can Machine Learning Be Integrated Into The Operational Processes Of A Metal Lathe To Improve Precision And Reduce Waste?We can use machine learning to make metal lathes work better. First, we can teach the machine how to understand the right measurements. It learns from past mistakes and gets better at making the right cuts. This way, we waste less metal and produce better parts. By using machine learning, we can save time and make our work more precise.

What Types Of Motors Are Commonly Used In Modern Metal Lathes, And How Can Their Performance Be Optimized Through Machine Learning Algorithms?Modern metal lathes usually use two types of motors: AC motors and DC motors. AC motors are good for steady speed, while DC motors can change speed easily. We can make these motors work better by using machine learning. This technology learns from how the lathe performs and helps us make smart choices to improve its speed and efficiency.

In What Ways Can Predictive Maintenance Powered By Machine Learning Enhance The Longevity And Efficiency Of Metal Lathe Motors?Predictive maintenance uses machine learning to help us take care of metal lathe motors. It watches how the motors work every day. If it sees problems starting, it tells us early. This way, we can fix things before they break. By doing this, the motors last longer and run better!

What Data Should Be Collected From A Lathe Machine To Train A Machine Learning Model For Tasks Such As Fault Detection Or Process Optimization?To help a machine learn about a lathe machine, we should collect different types of data. We can look at how fast it runs and how hot it gets. We should also check the sounds it makes. Finally, we can note any mistakes or problems that happen during work. This information will help us find faults and make things better!

How Can Computer Vision And Machine Learning Be Utilized In Conjunction With Metal Lathes To Achieve Better Quality Control And Real-Time Monitoring During Machining Processes?We can use computer vision and machine learning with metal lathes to watch how they work. Computer vision helps cameras see what’s happening during machining. If something goes wrong, the system can quickly tell us. Machine learning helps the system learn from mistakes, so it gets better over time. This way, we can make sure the parts are always good quality and fix problems fast.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of Lathe Machine Learning, Metal Lathe, And Motors:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are the questions and their answers: 1. What is a lathe machine? A lathe machine is a tool that helps you shape metal or wood. It spins the material to make it round or smooth. 2. How does a lathe machine work? The lathe machine spins a piece of metal. Then, it uses sharp tools to cut and shape it into different forms. 3. What is machine learning? Machine learning is when computers learn from data. They get better at tasks without being told what to do. 4. Can machines make parts for lathes? Yes, machines can create parts for lathes. They use careful measurements to make everything fit perfectly. 5. What is a motor? A motor is a device that makes things move. It uses electricity to spin or run other machines, like lathes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Be Integrated Into The Operational Processes Of A Metal Lathe To Improve Precision And Reduce Waste?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make metal lathes work better. First, we can teach the machine how to understand the right measurements. It learns from past mistakes and gets better at making the right cuts. This way, we waste less metal and produce better parts. By using machine learning, we can save time and make our work more precise.”}},{“@type”: “Question”,”name”: “What Types Of Motors Are Commonly Used In Modern Metal Lathes, And How Can Their Performance Be Optimized Through Machine Learning Algorithms?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern metal lathes usually use two types of motors: AC motors and DC motors. AC motors are good for steady speed, while DC motors can change speed easily. We can make these motors work better by using machine learning. This technology learns from how the lathe performs and helps us make smart choices to improve its speed and efficiency.”}},{“@type”: “Question”,”name”: “In What Ways Can Predictive Maintenance Powered By Machine Learning Enhance The Longevity And Efficiency Of Metal Lathe Motors?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses machine learning to help us take care of metal lathe motors. It watches how the motors work every day. If it sees problems starting, it tells us early. This way, we can fix things before they break. By doing this, the motors last longer and run better!”}},{“@type”: “Question”,”name”: “What Data Should Be Collected From A Lathe Machine To Train A Machine Learning Model For Tasks Such As Fault Detection Or Process Optimization?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help a machine learn about a lathe machine, we should collect different types of data. We can look at how fast it runs and how hot it gets. We should also check the sounds it makes. Finally, we can note any mistakes or problems that happen during work. This information will help us find faults and make things better!”}},{“@type”: “Question”,”name”: “How Can Computer Vision And Machine Learning Be Utilized In Conjunction With Metal Lathes To Achieve Better Quality Control And Real-Time Monitoring During Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use computer vision and machine learning with metal lathes to watch how they work. Computer vision helps cameras see what’s happening during machining. If something goes wrong, the system can quickly tell us. Machine learning helps the system learn from mistakes, so it gets better over time. This way, we can make sure the parts are always good quality and fix problems fast.”}}]}