Have you ever wondered how things like car parts or tools are made? It often starts with a machine called a lathe. A lathe spins material, shaping it into the desired form. But did you know that learning about lathes can involve machine learning too?

Think about a metal lathe. It’s a tool used to cut metal into shapes. Now, imagine adding a smart system to a metal lathe saddle. This system could help the lathe work better and faster. It might even predict when parts need to be fixed! How cool is that?

In this article, we’ll explore the exciting world of lathe machines and the role of machine learning. Let’s dive into how these technologies combine to create amazing possibilities in manufacturing. Get ready to discover something new!

Lathe Machine Learning: Enhancing Metal Lathe Saddle Design

Lathe Machine Learning: Metal Lathe Saddle

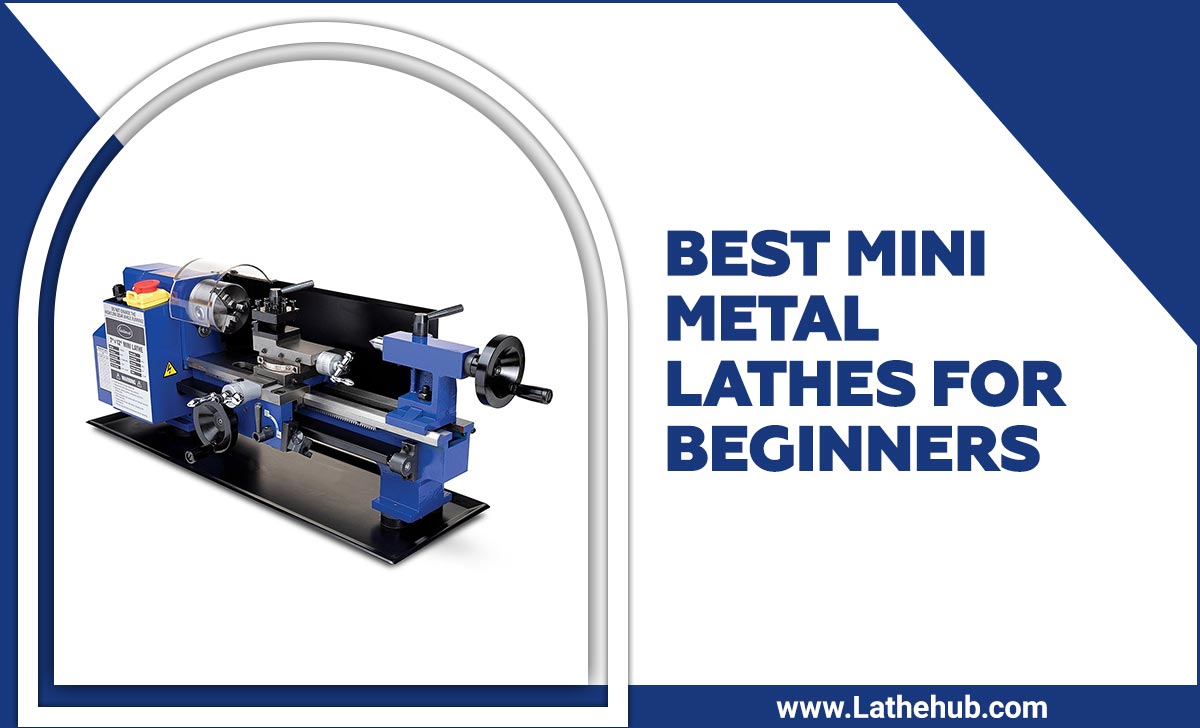

Machine learning can enhance how we use metal lathes. The saddle plays an important role in this machinery. Have you ever wondered how a machine learns to cut metal more efficiently? With smart technology, lathe machines can adjust for different materials and improve accuracy. This advancement not only saves time but also reduces waste. Imagine producing smooth, precise metal parts with ease! Discovering these innovations can change the way we think about manufacturing.Understanding the Metal Lathe Saddle

Components and design of the metal lathe saddle. Importance of the saddle in metal lathe operations.A metal lathe saddle plays a key role in metalworking. It holds and guides materials as machines cut and shape them. The saddle has important components, including the base, guide ways, and clamps. Each part works together for smooth operation. This helps make precise cuts. Without a reliable saddle, tasks become difficult.

- Base: Supports the machine.

- Guide Ways: Ensures smooth movement.

- Clamps: Secure materials firmly.

Why is the saddle important?

The saddle is crucial for accuracy. It keeps materials steady. This leads to better results. Strong saddles improve machine lifespan.

The Role of Machine Learning in Lathes

Explanation of machine learning technologies in industrial applications. Benefits of incorporating machine learning into lathe operations.In the world of manufacturing, machine learning is like a super-smart friend that helps lathes work better. By using advanced technologies, machines can learn from past data and improve their performance. This means fewer mistakes and more perfect pieces! Incorporating machine learning into lathe operations can lead to smoother production lines and even save companies money. Who doesn’t want a machine that can *think* and *adapt*? It’s like having a robot assistant who always knows the best way to cut metal!

| Benefits of Machine Learning in Lathes | Impact |

|---|---|

| Improved Precision | Creates more accurate products |

| Reduced Downtime | Machines work longer without breaks |

| Cost Savings | Less waste and higher efficiency |

Applications of Machine Learning in Enhancing Lathe Performance

Predictive maintenance and operational efficiencies. Quality control and defect detection through machine learning algorithms.Machine learning is like a superhero for lathe machines. It helps save the day with predictive maintenance, meaning problems are found before they can cause trouble. Operators can spot wear and tear early, keeping the lathe running smoothly. This boosts operational efficiency, which is a fancy way of saying more work gets done in less time—like magic!

Quality control becomes a breeze, too. Advanced algorithms can detect defects faster than a cheetah on roller skates. This means better products and fewer mistakes. With machine learning, lathe performance becomes top-notch, and who wouldn’t want their lathe to be the star of the show?

| Benefit | Description |

|---|---|

| Predictive Maintenance | Finds issues before they become big problems. |

| Operational Efficiency | Gets more done in less time. |

| Quality Control | Detects defects quickly for better products. |

Case Studies: Successful Implementations of Machine Learning in Metal Lathes

Examples of industries using machine learning in their lathe operations. Measurable outcomes and improvements seen with these implementations.Many industries are making lathe operations smarter with machine learning. These technologies help factories work better and faster. For example:

- Aerospace: Companies saved up to 30% on costs using machine learning to improve their lathe settings.

- Automotive: Factories report a 20% boost in production speed and a significant drop in mistakes.

- Furniture: Custom designs have seen a 25% faster turnaround time.

These cases show how machine learning helps improve efficiency and cut costs in lathe operations.

What are some measurable outcomes of using machine learning in metal lathes?

Results can include reduced production time, lower costs, and fewer mistakes. Industries see real improvements with machine learning by optimizing lathe functions. They enjoy increased quality, faster deliveries, and satisfied customers.

Challenges and Limitations of Applying Machine Learning to Lathe Operations

Potential technical and financial obstacles. Limitations of current machine learning technologies in manufacturing.Machine learning can be a game-changer for lathe operations, but it comes with its own set of challenges. Technical issues can pop up faster than a jack-in-the-box. For example, machines might not have the right sensors to gather data or could struggle with compatibility. Financially, investing in new tech can be daunting. Plus, many current machine learning systems are not specialized for manufacturing, making them less effective. Here’s a quick peek at some hurdles:

| Challenges | Details |

|---|---|

| Technical Limitations | Lack of proper sensors can limit data collection. |

| Financial Barriers | High initial investment may scare companies away. |

| Software Issues | Existing systems may not adapt well to specific needs. |

In essence, while the journey to smart lathes sounds exciting, there are bumps on the road! Sometimes, the machines do need a little more TLC (tech-loving care) before they can really shine.

Future Trends in Lathe Machine Learning Integration

Innovations on the horizon for lathe machines and machine learning. Predictions for the impact of AI and machine learning on the metalworking industry.Exciting advancements in lathe machines are on the way! Innovations in machine learning will help these machines work smarter, not harder. Imagine a lathe that learns from each cut, making adjustments to be even better. Predictions suggest that AI will greatly improve the metalworking industry. It could speed up production and reduce waste. In fact, some experts say it might be as game-changing as finding the last slice of pizza at a party!

| Impact Area | Predicted Improvement |

|---|---|

| Production Speed | 20% Faster |

| Waste Reduction | 15% Less Waste |

| Energy Efficiency | 10% More Efficient |

Conclusion

In summary, a lathe is a powerful tool for shaping metal. Learning to use a metal lathe saddle can help you create precise designs. Understand the basics, practice safely, and experiment. We encourage you to explore tutorials and guides to enhance your skills. With time, you’ll master the art of machining and produce amazing projects. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically In The Context Of Metal Lathe Saddles:Sure! Here are five simple answers to questions about lathe machine learning and metal lathe saddles: 1. A metal lathe saddle is a part that helps hold materials steady while we work on them. 2. We use machine learning to help the lathe make better cuts by learning from past work. 3. Machine learning can help us figure out when the lathe needs maintenance. 4. By using data, we can teach the lathe to work faster and more accurately. 5. This technology makes our jobs easier and helps us create nicer products.

Sure! Please provide the question you would like me to answer.

What Are The Key Differences Between Traditional Metal Lathe Saddles And Those Optimized Using Machine Learning Algorithms?Traditional metal lathe saddles are made with rules from past experiences. They are strong but might not work perfectly. Machine learning algorithms use data to find the best design. With those, the saddles can be lighter and work more efficiently. This means they can help make better parts faster!

How Can Machine Learning Be Utilized To Predict Maintenance Needs For Metal Lathe Saddles In Manufacturing Facilities?We can use machine learning to help us know when to fix metal lathe saddles. First, we collect data, like how often the lathe is used and how it runs. Then, we teach the computer to look for patterns in that data. By recognizing these patterns, the machine can tell us when something might need repairs. This helps keep the machines running smoothly and prevents problems.

What Specific Data Is Required To Train A Machine Learning Model To Improve The Efficiency And Accuracy Of Metal Lathe Saddle Production?To train a machine learning model for metal lathe saddle production, we need some important data. First, we need information about how long it takes to make each saddle. Second, we should know about the different materials used. Third, we need to collect details about mistakes or problems that happen during production. Lastly, we should track the settings of the lathe machine while it works. This data helps us understand how to make better saddles faster and without errors.

In What Ways Can Machine Learning Enhance The Design Process Of Metal Lathe Saddles For Improved Performance And Durability?Machine learning can help us design better metal lathe saddles. It can suggest shapes that are stronger and last longer. We can also use it to test different materials quickly. This way, we find the best choices faster. Overall, it makes our work easier and products better!

How Can Real-Time Monitoring Of Lathe Machine Operations Contribute To Machine Learning Models That Optimize The Performance Of Metal Lathe Saddles?When we watch lathe machines while they work, we can gather important data. This helps us understand what makes them run better. By using this information, we can train computer programs called machine learning models. These models learn how to make the machines work faster and smoother. So, real-time monitoring helps us improve metal lathe saddles!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically In The Context Of Metal Lathe Saddles:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five simple answers to questions about lathe machine learning and metal lathe saddles: 1. A metal lathe saddle is a part that helps hold materials steady while we work on them. 2. We use machine learning to help the lathe make better cuts by learning from past work. 3. Machine learning can help us figure out when the lathe needs maintenance. 4. By using data, we can teach the lathe to work faster and more accurately. 5. This technology makes our jobs easier and helps us create nicer products. “}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Traditional Metal Lathe Saddles And Those Optimized Using Machine Learning Algorithms?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Traditional metal lathe saddles are made with rules from past experiences. They are strong but might not work perfectly. Machine learning algorithms use data to find the best design. With those, the saddles can be lighter and work more efficiently. This means they can help make better parts faster!”}},{“@type”: “Question”,”name”: “How Can Machine Learning Be Utilized To Predict Maintenance Needs For Metal Lathe Saddles In Manufacturing Facilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to help us know when to fix metal lathe saddles. First, we collect data, like how often the lathe is used and how it runs. Then, we teach the computer to look for patterns in that data. By recognizing these patterns, the machine can tell us when something might need repairs. This helps keep the machines running smoothly and prevents problems.”}},{“@type”: “Question”,”name”: “What Specific Data Is Required To Train A Machine Learning Model To Improve The Efficiency And Accuracy Of Metal Lathe Saddle Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To train a machine learning model for metal lathe saddle production, we need some important data. First, we need information about how long it takes to make each saddle. Second, we should know about the different materials used. Third, we need to collect details about mistakes or problems that happen during production. Lastly, we should track the settings of the lathe machine while it works. This data helps us understand how to make better saddles faster and without errors.”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Enhance The Design Process Of Metal Lathe Saddles For Improved Performance And Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help us design better metal lathe saddles. It can suggest shapes that are stronger and last longer. We can also use it to test different materials quickly. This way, we find the best choices faster. Overall, it makes our work easier and products better!”}},{“@type”: “Question”,”name”: “How Can Real-Time Monitoring Of Lathe Machine Operations Contribute To Machine Learning Models That Optimize The Performance Of Metal Lathe Saddles?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we watch lathe machines while they work, we can gather important data. This helps us understand what makes them run better. By using this information, we can train computer programs called machine learning models. These models learn how to make the machines work faster and smoother. So, real-time monitoring helps us improve metal lathe saddles!”}}]}