Have you ever watched a lathe machine in action? It’s like magic. The machine slowly spins metal, shaping it into something special. But did you know that modern technology is helping these machines become smarter? That’s where metal lathe machine learning comes in. Imagine a metal lathe that learns from its past tasks. It can improve its work over time!

Many people love creating things with lathes. They might build furniture or craft tools. But have you thought about how important the lathe stand is? A sturdy stand keeps everything steady while you work. If the stand is weak, the whole project can go wrong.

In this article, we’ll explore how lathe machine learning works and why having a strong metal lathe stand matters. Plus, we’ll share some tips for setting up your lathe at home. Are you ready to dive into the world of metal lathes and their exciting future? Let’s get started!

Lathe Machine Learning: Metal Lathe Stand Innovations

Understanding Lathe Machines and Their Stands

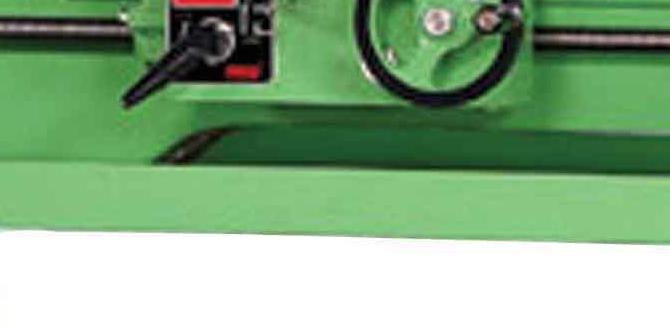

Lathe machines are essential tools in metalworking. They help shape materials into precise parts. A sturdy metal lathe stand is crucial for stability during operation. Users often wonder, how does a strong stand improve performance? A reliable stand absorbs vibrations, ensuring smoother cuts. Did you know that the right adjustments can enhance your lathe’s efficiency? Investing in quality equipment leads to better results and a more enjoyable experience. Embrace the world of lathes to advance your metalworking skills!Understanding Lathe Machines

Definition and function of lathe machines. Types of lathe machines and their uses in metalworking.Lathe machines are like magic wands for metalworkers! They help create round shapes by spinning the material while cutting tools shape it. There are different types too. For example, a bench lathe is small and great for home projects, while a CNC lathe uses a computer to do all the hard work. It’s like giving a robot a birthday present! Let’s look at some common types:

| Type of Lathe | Use |

|---|---|

| Bench Lathe | Small projects and hobby work |

| CNC Lathe | Precise, complex shapes |

| Turret Lathe | Mass production with multiple tools |

Each type brings its own style to metalworking, allowing creativity to shine! So, whether you’re making a tiny toy or a monster truck part, there’s a lathe machine ready to help.

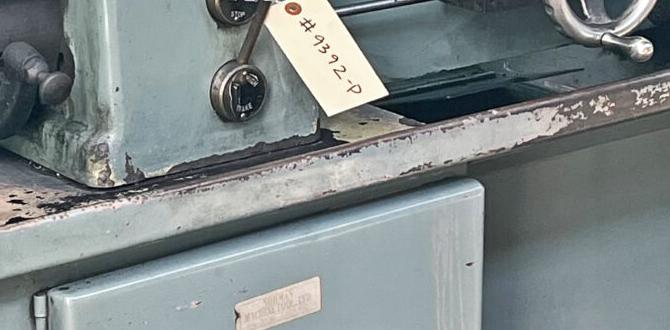

Importance of Metal Lathe Stands

Role of lathe stands in stability and precision. Materials and design considerations for durable stands.Having a strong metal lathe stand is key for anyone who works with lathes. A stable stand supports the lathe, ensuring precision in cuts. With a sturdy base, vibrations are reduced, making your work more accurate. Durability matters too. Choose materials like steel or heavy wood for long-lasting strength. The design should allow for easy adjustments, keeping your lathe in the best position. Remember, the right stand makes all the difference!

What should I consider when choosing a metal lathe stand?

Key factors include size, weight capacity, and material. A good stand needs to hold your lathe securely. Look for features that allow adjustments for height or stability.

Important Factors:

- Size to fit your workspace

- Weight limit based on your lathe

- Material for sturdiness

Integrating Machine Learning with Lathe Operations

Data collection methods for lathe performance. Predictive analytics for maintenance and efficiency improvements.Data collection is crucial for lathe performance. Sensors can track speed, vibration, and temperature. This data helps us understand how well the lathe works. With enough information, we can predict when parts might break down. This is where predictive analytics comes in handy. It tells us when to fix things before they break, saving time and money. After all, nobody wants to find a broken lathe in their shop, right? Or worse, a lathe that is working harder than a dog in a snowstorm!

| Data Collection Method | Example |

|---|---|

| Speed Sensors | Measures the rotation speed of the lathe. |

| Vibration Analysis | Detects unusual movements that could signify wear and tear. |

| Temperature Monitoring | Checks for overheating parts that might need maintenance. |

This approach not only keeps our machines running smoothly but also boosts efficiency. Imagine never having to worry if your metal lathe will suddenly stop working during that big project. That’s the power of combining machine learning with lathe operations!

Benefits of Using Machine Learning in Metal Lathe Stands

Enhanced productivity and operational efficiency. Realtime monitoring and decisionmaking support.Using machine learning in metal lathe stands can be a game changer! First, it boosts productivity and improves operational efficiency. Imagine programming your lathe to run faster while you take a coffee break—sounds like a dream, right? With real-time monitoring, it helps make quick decisions. No more waiting for hours to find out why your lathe is grumbling like a hungry bear! Instead, you get immediate feedback and can fix issues on the spot.

| Benefits | Description |

|---|---|

| Enhanced Productivity | Boosts output while reducing manual work. |

| Real-time Monitoring | Instantly tracks machine performance and alerts you to problems. |

Case Studies: Successful Implementations

Examples of businesses using machine learning in lathe operations. Results and improvements observed from these implementations.Many companies have joined the machine learning party, using it to make their lathe operations super smooth. For example, a popular auto parts manufacturer improved its cutting speed by 20%. Now that’s fast! Another toolmaker saw a 30% reduction in waste by predicting material needs accurately. It’s like having a crystal ball for production! Here’s a quick look at these success stories:

| Business | Improvement | Result |

|---|---|---|

| Auto Parts Manufacturer | Cutting Speed | +20% |

| Toolmaker | Material Waste | -30% |

These stories show how machine learning can help lathe machines work better, faster, and smarter. The future of manufacturing is bright, and a little tech magic goes a long way!

Challenges and Limitations of Lathe Machine Learning

Common barriers to integration in existing setups. Technical and financial challenges faced by manufacturers.Integrating lathe machine learning can be tricky. Many setups face common barriers. Machines don’t always talk well together, like two kids fighting over the last cookie. Technical issues can make things harder. Manufacturers often deal with costly upgrades and fancy software that doesn’t always work. Money can slip away faster than a magician on stage! It’s important to understand these challenges to move forward.

| Challenges | Details |

|---|---|

| Compatibility | Old machines are like grandpas; they don’t always understand new tech. |

| Costs | Upgrading can cost more than your favorite video game! |

In short, facing these challenges is just part of the fun ride in the world of lathe machine learning!

Future Trends in Lathe Machines and Machine Learning

Emerging technologies that may influence lathe manufacturing. Predictions for the evolution of machine learning in machining industries.The future of lathe machines looks bright, with thrilling technologies on the horizon. Imagine lathes that can learn! Machine learning is set to revolutionize how these machines operate. They might soon adjust settings automatically, making fewer mistakes than your clumsy uncle in the workshop. As data becomes smarter, so will our tools. Predictions say we’ll see machines making faster, more precise parts while you sip coffee nearby. Sounds like a win-win!

| Emerging Technologies | Impact on Lathe Manufacturing |

|---|---|

| AI Integration | Improves precision and reduces waste |

| IoT Connectivity | Enables real-time monitoring and control |

| Advanced Materials | Allows for faster and stronger components |

Conclusion

In summary, understanding a lathe machine can boost your metalworking skills. A sturdy lathe stand keeps your machine stable and safe. You can learn a lot by experimenting and practicing with a lathe. Ready to create? Dive deeper by reading more and trying your hand at beginner projects. Your journey in metalworking starts now!FAQs

What Are The Essential Design Considerations For A Metal Lathe Stand To Ensure Stability And Accuracy During Machining Operations?To make a metal lathe stand stable and accurate, you should use sturdy materials. A heavy base helps keep it from wobbling. Make sure the legs are level and sturdy on the ground. You can also add rubber feet to reduce shaking. Lastly, check that the lathe is securely attached to the stand.

How Can Machine Learning Algorithms Be Integrated Into The Operation Of A Lathe Machine To Optimize Cutting Parameters And Improve Efficiency?We can use machine learning to help lathe machines cut better and faster. First, we can collect data about how the machine performs with different materials. Then, the machine learns from this data to find the best cutting speeds and depths. This way, it saves time and uses less energy while making better parts. Finally, we can make changes based on what the machine learns to keep improving its work!

What Materials Are Commonly Used For Constructing Lathe Stands, And How Do These Materials Affect The Performance Of The Lathe Machine?Lathe stands are often made from wood, steel, or cast iron. Wood is light but not very strong. Steel is tough and can hold heavier lathes. Cast iron is really strong and helps keep the lathe steady. A stable stand helps the lathe work better and makes smoother pieces.

How Can Predictive Maintenance, Powered By Machine Learning, Enhance The Reliability And Longevity Of Lathe Machines?Predictive maintenance uses smart computer technology to help us take care of lathe machines. It watches how the machine works and learns from it. If it notices something might go wrong, it tells us to fix it before it breaks. This way, our lathe machines run better and last longer. Taking action early helps us avoid big problems and save money!

What Safety Features Should Be Included In The Design Of A Metal Lathe Stand To Protect Operators During Machining Processes?When designing a metal lathe stand, we should focus on safety features. First, we need to have a sturdy base so it doesn’t tip over. Next, we can add guards to block flying chips and sparks. It’s also smart to include emergency stop buttons that you can reach easily. Finally, using a non-slip surface will help keep your feet safe while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Design Considerations For A Metal Lathe Stand To Ensure Stability And Accuracy During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe stand stable and accurate, you should use sturdy materials. A heavy base helps keep it from wobbling. Make sure the legs are level and sturdy on the ground. You can also add rubber feet to reduce shaking. Lastly, check that the lathe is securely attached to the stand.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Integrated Into The Operation Of A Lathe Machine To Optimize Cutting Parameters And Improve Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to help lathe machines cut better and faster. First, we can collect data about how the machine performs with different materials. Then, the machine learns from this data to find the best cutting speeds and depths. This way, it saves time and uses less energy while making better parts. Finally, we can make changes based on what the machine learns to keep improving its work!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Constructing Lathe Stands, And How Do These Materials Affect The Performance Of The Lathe Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe stands are often made from wood, steel, or cast iron. Wood is light but not very strong. Steel is tough and can hold heavier lathes. Cast iron is really strong and helps keep the lathe steady. A stable stand helps the lathe work better and makes smoother pieces.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance, Powered By Machine Learning, Enhance The Reliability And Longevity Of Lathe Machines? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses smart computer technology to help us take care of lathe machines. It watches how the machine works and learns from it. If it notices something might go wrong, it tells us to fix it before it breaks. This way, our lathe machines run better and last longer. Taking action early helps us avoid big problems and save money!”}},{“@type”: “Question”,”name”: “What Safety Features Should Be Included In The Design Of A Metal Lathe Stand To Protect Operators During Machining Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a metal lathe stand, we should focus on safety features. First, we need to have a sturdy base so it doesn’t tip over. Next, we can add guards to block flying chips and sparks. It’s also smart to include emergency stop buttons that you can reach easily. Finally, using a non-slip surface will help keep your feet safe while you work.”}}]}