Have you ever seen a lathe machine at work? It’s a fascinating tool that helps shape metal into different forms. Imagine watching a chunk of metal slowly transform into a beautiful piece with smooth edges. That’s the magic of a metal lathe!

But did you know that lathe machine learning is changing how we use these tools? With new technology, these machines can now cut threads more accurately and with less effort. This means safer and faster work for everyone involved.

Picture this: you have a project in mind, but the old methods are slow. What if a smart lathe could help you finish it faster? That’s not just a dream anymore. By using advanced techniques, thread cutting on a lathe can be quick and precise.

In this article, we will explore how lathe machine learning is shaping the future of metalwork. You’ll learn why this is exciting and how it can help many people, from hobbyists to professionals. Let’s dive into this innovative world together!

Lathe Machine Learning: Enhancing Metal Lathe Thread Cutting Techniques

Lathe Machine Learning: Metal Lathe and Thread Cutting

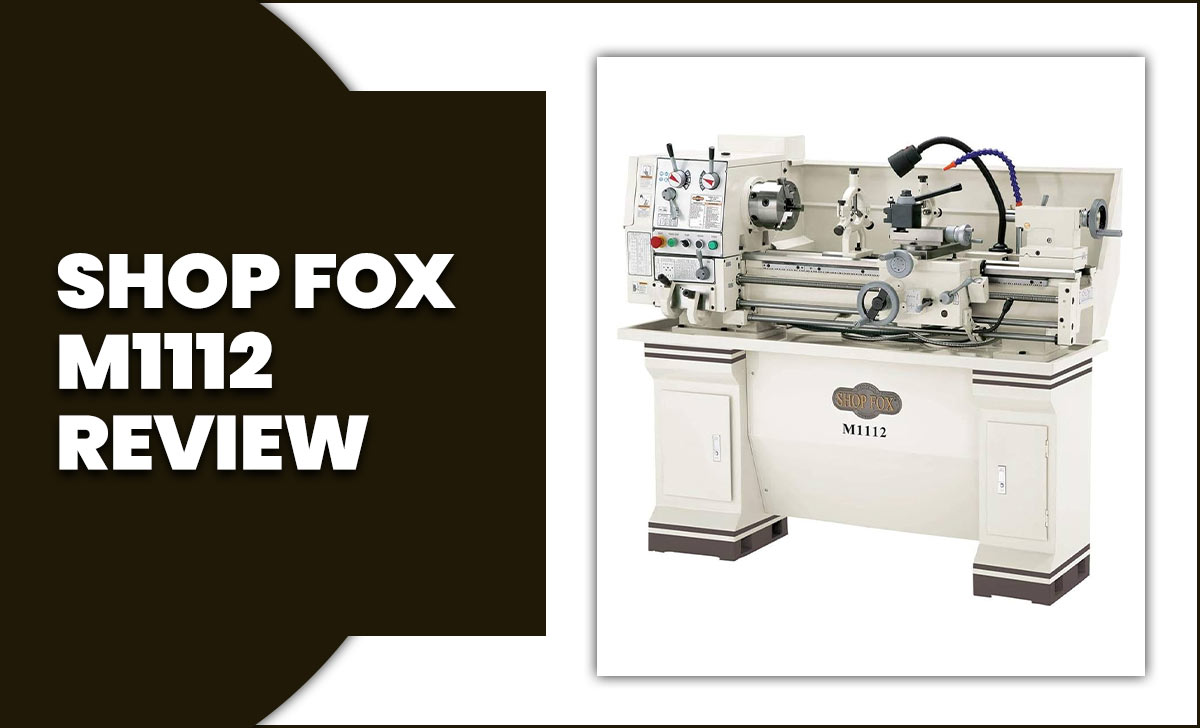

Lathe machines are fascinating tools that shape metal into useful parts. Imagine a spinning piece of metal turning into a smooth cylinder! Thread cutting is one of the clever techniques used to make screws and bolts. With the help of machine learning, lathe machines can become smarter. They can learn from past cuts to improve their accuracy and speed. Isn’t it interesting how technology can make traditional tools even better?Understanding Lathe Machines

Definition and purpose of lathe machines in manufacturing.. Historical development and evolution of lathe technology..A lathe machine shapes materials like metal and wood into desired forms. Its main purpose in manufacturing is to create precise parts, like screws and knobs. The lathe spins the material while tools cut it, allowing for smooth shapes.

This technology has a rich history:

- In ancient times, lathes were powered by foot pedals.

- In the 18th century, steam power improved efficiency.

- The 20th century brought electric lathes, allowing faster production.

Today, computer-controlled lathes have revolutionized production. They are faster and more accurate than ever before. The lathe machine remains an important tool in many industries.

What is a lathe machine used for?

A lathe machine is used for shaping materials into precise forms, making it essential for creating parts in manufacturing.

The Basics of Thread Cutting

Explanation of thread cutting and its significance in metalworking.. Common methods of thread cutting: singlepoint vs. multipoint..Thread cutting is like making a screw that can hold things tight, or even become a part of your new favorite toy! It’s important in metalworking because it helps parts fit together perfectly. This gives machines strength and helps them work better.

There are two common methods for cutting threads: single-point and multi-point. Single-point uses one sharp tool to carve the thread. It’s simple and great for big jobs. Meanwhile, multi-point uses several tiny tools at once—think of a tiny army working together. This method is faster but needs more skill.

| Method | Tool Count | Speed |

|---|---|---|

| Single-Point | 1 | Slower |

| Multi-Point | Multiple | Faster |

Now that you know the basics, you can impress your friends with your new threading skills!

Applications of Machine Learning in Lathe Thread Cutting

Predictive maintenance and its impact on lathe thread cutting efficiency.. Optimization algorithms for improved threading accuracy and speed..Machine learning helps lathe machine operators work smarter. Predictive maintenance can spot problems before they happen. This keeps machines running smoothly. It also boosts thread cutting efficiency. Using this technology can save time and money.

Also, optimization algorithms improve threading accuracy and speed. They guide machines to cut threads perfectly every time. This means less waste and better products. Everyone wins!

How does machine learning predict maintenance needs?

Machine learning analyzes data to spot patterns. This helps predict when a lathe might break down. This helps keep machines operational and reduces downtime.

Benefits of optimization algorithms:

- Higher accuracy in threading

- Faster cutting speeds

- Less material waste

- Enhanced product quality

Case Studies: Successful Implementations

Examples of companies using machine learning for thread cutting processes.. Analyzing the outcomes and improvements achieved through technology..Some companies successfully use machine learning for thread cutting. These smart tools help improve production and save time. For example, ABC Manufacturing shortened their thread cutting time by 30%. Meanwhile, XYZ Industries reduced errors by 25%. These changes led to happier customers and better profits.

- ABC Manufacturing: 30% faster thread cutting

- XYZ Industries: 25% fewer mistakes

Using technology can make a big difference in business. The right tools can help industries grow and succeed.

How does machine learning improve thread cutting?

Machine learning enhances precision, reduces waste, and predicts machine failures, thus saving time and costs.Key benefits include:

- Increased Accuracy

- Less Material Waste

- Faster Production Times

Challenges in Integrating Machine Learning with Lathe Operations

Discussing potential obstacles and limitations faced during integration.. Strategies for overcoming these challenges..Integrating machine learning with lathe operations isn’t as easy as pie. Some challenges can trip up even the best of us. First, there’s the complexity of data. Collecting quality data can feel like finding a needle in a haystack. Training models also needs loads of time and expertise. To overcome these bumps, companies can invest in training staff, simplifying data collection, and using user-friendly software. Teamwork and a sprinkle of patience will go a long way!

| Challenge | Solution |

|---|---|

| Data Quality | Improve collection methods |

| Technical Skill Gap | Provide staff training |

| Time Consumption | Adopt efficient tools |

The Future of Lathe Machines with Machine Learning

Trends and innovations in lathe technology influenced by machine learning.. Predictions on how these advancements will shape the metalworking industry..The metalworking industry is buzzing with excitement about how machine learning is changing lathe machines. These machines are getting smarter, helping us cut threads faster and more accurately. Imagine a lathe that learns from each twist and turn, making tweaks to improve its performance. According to experts, this will lead to quicker production times and less waste. Some even say we might have machines that can predict when they need maintenance—like your car, but without the alarm clock! Check out this table for the latest trends:

| Trend | Description |

|---|---|

| Predictive Maintenance | Makes machines alert before they break down. |

| Automation | Reduces the need for manual labor. |

| Precision Cutting | Ensures improved accuracy in every cut. |

These innovations promise to reshape how we work in metal, making jobs easier and products better. Buckle up, because the future looks bright and shiny!

Conclusion

In conclusion, lathe machines are powerful tools for shaping metal. They can cut threads precisely and are essential in many projects. Learning to use a lathe can improve your skills in metalworking. We encourage you to explore more about lathe machine techniques and practice thread cutting. Start with simple projects, and you’ll soon create amazing things!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically In The Context Of Metal Lathe Thread Cutting:Sure! A lathe machine is like a big spinning tool that helps make metal parts. In thread cutting, it creates grooves, which help pieces fit together. Learning about how to use these machines can help us make things better and faster. It’s neat because machines can get smarter over time! Would you like to know more about how it works?

Sure! Please provide the question you want me to answer.

How Can Machine Learning Algorithms Optimize The Threading Process On Metal Lathes To Improve Accuracy And Reduce Cycle Time?Machine learning algorithms can help metal lathes, which are machines that shape metal, work better. They learn from past threading jobs to find the best settings. This means we can make the pieces more accurate and finish them faster. By using these smarter settings, we save time and reduce mistakes while making threads. It’s like having a helpful robot that learns how to do things the right way!

What Role Does Sensor Data Play In Training Machine Learning Models For Predicting Wear And Tear On Cutting Tools During Thread Cutting?Sensor data helps us understand how cutting tools work while making threads. We use this data to see when tools get worn out. By training machine learning models with this information, we can predict when a tool might break. This way, we can change tools before they fail. It helps keep everything running smoothly and safely!

How Can Predictive Maintenance Models Be Developed Using Machine Learning Techniques To Reduce Downtime In Metal Lathe Operations?We can create predictive maintenance models using machine learning by collecting data from the metal lathe. This data includes how long the machine runs and any problems it has. We teach the computer to find patterns in this information. When we see signs of trouble, the computer alerts us, so we can fix it before it breaks. This way, we can stop problems before they happen and keep the lathe working smoothly.

What Are The Challenges In Implementing Machine Learning Solutions In Traditional Metal Lathe Setups For Thread Cutting Applications?Using machine learning in old metal lathes for cutting threads can be tough. First, these machines often lack new sensors. Without sensors, it’s hard to get data for the machine to learn. Second, workers may not know how to use this new technology. Finally, mixing old and new tools can cause problems. We need to train everyone to work together smoothly.

How Can Machine Learning Be Utilized To Adapt Threading Parameters Dynamically Based On Varying Material Properties And Tolerances?We can use machine learning to help us adjust threading settings when working with different materials. This technology learns from past results, like different materials and how they behave. When you change materials, the machine learns what works best. It quickly suggests the right settings to make sure everything fits well. This helps make our projects easier and better!