Have you ever wondered how metal parts are shaped with precision? A lathe machine is often the answer. Imagine a piece of metal spinning as sharp tools shape it into perfect forms. That’s the magic of a lathe machine!

With advancements in technology, lathe machine learning is changing the game. It can help predict how much torque is needed for different shapes. This means faster work and better results! Can you see how helpful that could be?

Here’s a fun fact: Did you know that lathes have been used for over 2,000 years? They’ve come a long way since then! Today, by combining traditional methods with machine learning, we unleash new possibilities in metalwork.

This article will explore how lathe machine learning can make metal lathes smarter. Get ready to dive into a world where machines learn and improve. Are you excited to find out how this all works?

Lathe Machine Learning: Enhancing Metal Lathe Torque Efficiency

Understanding Metal Lathe Torque through Machine Learning

Did you know that machine learning can help improve metal lathe performance? By analyzing torque data, engineers can optimize cutting processes. This technology allows for more precise machining, leading to better quality parts and less waste. Imagine a lathe that learns as it works, making adjustments in real-time! With advancements in machine learning, the future of metal lathes looks promising. Explore how this blend of engineering and technology can revolutionize manufacturing.What is a Lathe Machine?

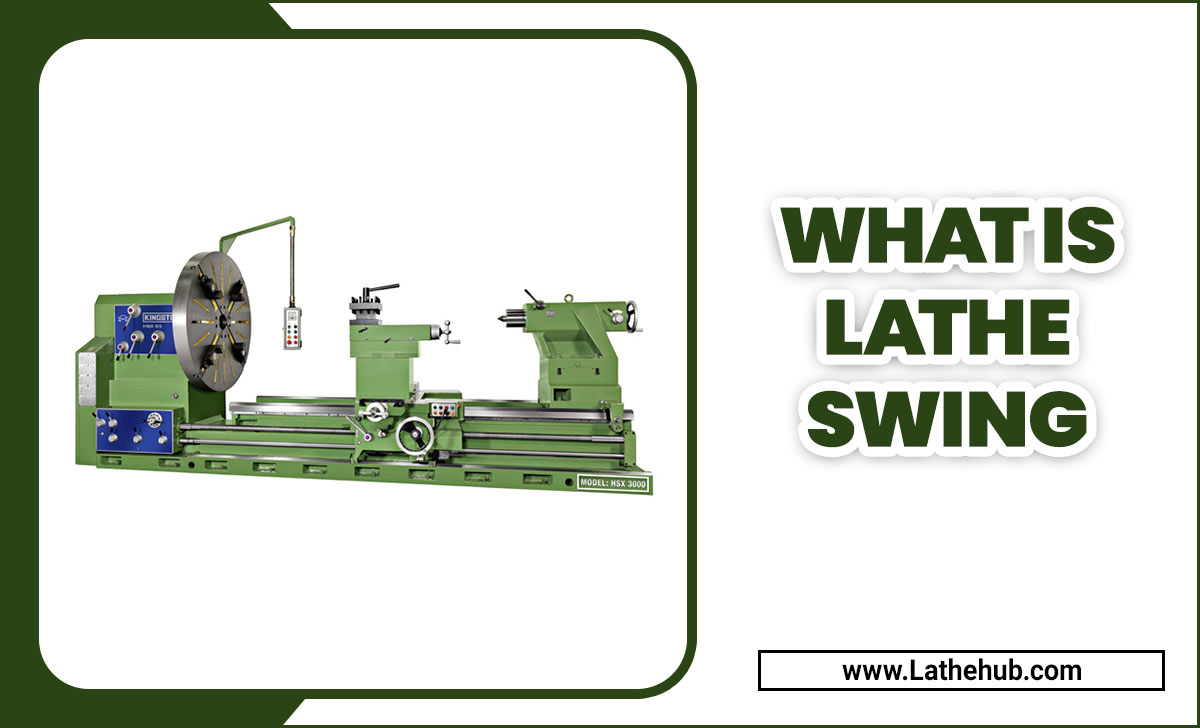

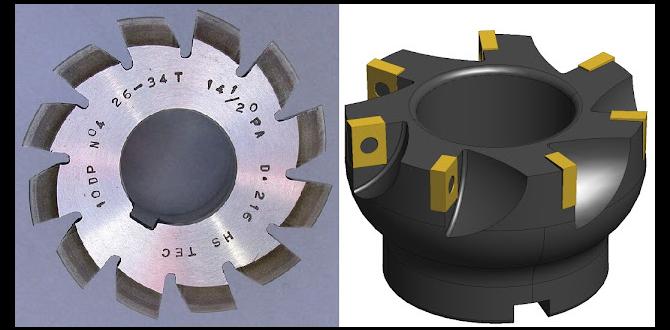

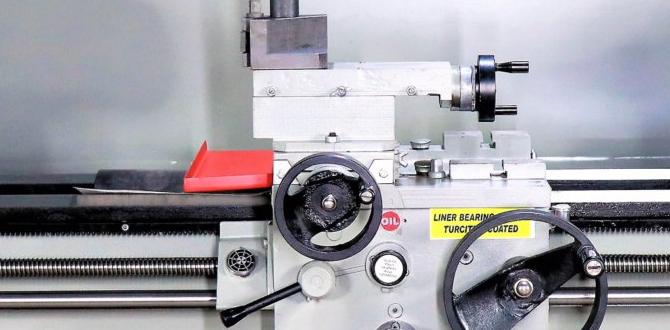

Definition and purpose of a lathe machine.. Types of lathe machines: Metal, wood, CNC, etc..A lathe machine is a tool used to shape materials, like metal and wood. It spins the material while a cutting tool removes unwanted sections. This helps create smooth and precise shapes. Some common types of lathes include:

- Metal Lathe: Used mainly for shaping metal.

- Wood Lathe: Perfect for crafting wooden items.

- CNC Lathe: A computer-controlled lathe for complex designs.

Each type serves a specific purpose, making lathes essential in workshops and factories.

What are the benefits of using a lathe machine?

Using a lathe machine can enhance creativity and efficiency in producing items. It ensures precision in shapes, leading to high-quality products. Making items on a lathe can be both fun and educational!

The Role of Machine Learning in Manufacturing

Explanation of machine learning concepts relevant to manufacturing.. Benefits of integrating machine learning into production processes..Manufacturing gets smarter with machine learning. This technology helps machines learn from data and improve over time. It can predict problems and enhance quality. Here are some key benefits:

- Reduces waste

- Increases efficiency

- Improves decision-making

These advantages lead to faster production and happier customers. Machine learning transforms how factories operate and succeed.

How does machine learning help in manufacturing?

Machine learning helps manufacturers become more efficient and accurate. It uses data to predict needs, optimize processes, and reduce errors, creating a better production flow.

Torque in Metal Lathes: Importance and Measurement

Definition and significance of torque in metal lathes.. Methods for measuring torque in machining operations..Torque is the force that helps metal lathes spin the material. It is very important because it determines how well the lathe performs. High torque means better cutting power and smoother operations. Measuring torque ensures the lathe works correctly and safely. Without proper torque, machines can break or produce bad parts. Here are ways to measure torque:

- Using a torque wrench to get exact measurements.

- Using sensors that detect the force while the lathe is working.

- Checking the lathe’s motor power for indirect torque readings.

Understanding torque helps metalworkers create high-quality parts with ease.

Why is torque important in metal lathes?

Torque is vital because it affects the cutting ability of the lathe and ensures precision.

How is torque measured in machining operations?

- Torque wrenches measure direct force applied.

- Load sensors track forces during cutting tasks.

- Motor outputs give indirect torque readings.

Challenges in Implementing Machine Learning in Lathe Operations

Technical barriers and data requirements.. Potential issues with accuracy and realtime processing..Many people face issues when trying to use machine learning in lathe operations. Technical barriers can slow things down. For example, the machines need accurate data to learn. If the data isn’t good, the results won’t be good either. Accuracy is also a problem. Sometimes, machines can make mistakes. If a machine makes a wrong move, it could damage both the part and the machine. Real-time processing can be tricky too, as it requires fast decisions. Balancing these challenges is key to success.

What are the main issues with machine learning in lathe operations?

The main issues include technical barriers, data accuracy, and real-time processing challenges. These areas need careful planning to ensure the machine operates well.

Common Challenges:

- Need for clear data

- Risk of inaccuracies

- Fast decision-making required

Future Trends: Smart Lathes and AI Integration

Predictions for the future of lathe machines with AI capabilities.. Potential advancements in torque control through smart technology..The future of lathe machines looks bright with smart technology and AI. These advanced tools will have better torque control. This means they can work faster and more accurately. Imagine a lathe that learns how to cut better every time! This could save time and materials.

- Smart lathes will adjust settings automatically.

- AI will help plan the best cutting paths.

- These machines will be safer and easier to use.

As technology grows, so will the potential for lathe machines. They will become essential in workshops everywhere, making work easier for everyone.

What advancements can we expect in lathe machines?

Future lathe machines may feature smart sensors, automatic adjustments, and AI-driven calculations. This means less manual work and more precision. Expect sharper tools and better efficiency!

Real-World Applications of Lathe Machine Learning

Industries benefiting from lathe machine learning applications.. Success stories of companies utilizing machine learning for torque management..Many industries are reaping the rewards of lathe machine learning. From automotive to aerospace, companies are improving their production lines. They’re cutting down errors and saving money, all thanks to smart technology. One prime example is a car manufacturer that used machine learning for torque management. They found a way to increase efficiency by 30%! That’s like finding an extra cookie in the jar! Below is a summary of industries benefiting from this technology:

| Industry | Benefit |

|---|---|

| Automotive | Improved assembly accuracy |

| Aerospace | Enhanced safety standards |

| Manufacturing | Reduced material waste |

These success stories show how machine learning can help companies play it smart and work a lot better. And you thought calculators were impressive!

Conclusion

In conclusion, understanding how a lathe machine works with metal and torque is important. You can create precise parts easily. Learning about machine learning can help improve the efficiency of lathes. We encourage you to explore more about these machines and their technologies. Try simple projects or read books to deepen your knowledge. Keep experimenting and learning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically Focusing On Metal Lathe Torque:Metal lathe machines shape metal by turning it against a tool. Torque is how much power the machine uses to do this. If the torque is too low, the machine can’t cut well. If it’s too high, it can break the metal or the tool. By learning about torque, we can make the machine work better and safer.

Sure! Please provide the question you would like answered.

How Can Machine Learning Algorithms Be Used To Predict Torque Requirements For Different Materials Being Machined On A Metal Lathe?We can use machine learning algorithms to predict torque needs when making parts with a metal lathe. First, we collect data about different materials, like steel or aluminum. Then, the computer learns from this data to understand how much force is needed for each material. When we give it a new material, it can guess the torque needed quickly. This helps us work better and save time!

What Factors Influence Torque Variation During The Turning Process On A Metal Lathe, And How Can Machine Learning Models Account For These Factors?Torque can change during turning because of cutting speed, tool sharpness, and the metal type. If you push too hard with a dull tool, it takes more effort. Also, the machine’s settings can affect how smooth or rough the cutting is. Machine learning can help by using data from past cuts to predict and adjust for these changes. It learns from mistakes to make the process better each time.

How Can Real-Time Torque Data Be Collected And Analyzed Using Machine Learning To Improve The Precision And Efficiency Of Lathe Operations?We can collect real-time torque data by using special sensors on the lathe machine. These sensors measure how hard the machine works while cutting metal. Then, we can use computer programs, called machine learning, to look at this data. The programs help us find patterns which show how to make the machine work better. This makes our lathe operations faster and more accurate!

In What Ways Can Machine Learning Enhance The Monitoring And Detection Of Anomalies In Torque During Metal Lathe Machining Processes?Machine learning helps us watch machines closely. It can learn what normal torque looks like during metal lathe machining. If something goes wrong, it can tell us right away. This way, we catch problems early and fix them before they get worse. We become better at making things safely and correctly.

What Are The Potential Benefits And Limitations Of Integrating Machine Learning Technologies In Optimizing Torque Parameters For Various Lathe Machining Applications?Using machine learning can help us find the best settings for torque on lathes, which is a tool that spins things to shape them. The benefits include faster production and better quality of the items we make. However, one limitation is that we need good data for the machine learning to work well. If the data is wrong or missing, it might not help us at all.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically Focusing On Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe machines shape metal by turning it against a tool. Torque is how much power the machine uses to do this. If the torque is too low, the machine can’t cut well. If it’s too high, it can break the metal or the tool. By learning about torque, we can make the machine work better and safer.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like answered.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Used To Predict Torque Requirements For Different Materials Being Machined On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning algorithms to predict torque needs when making parts with a metal lathe. First, we collect data about different materials, like steel or aluminum. Then, the computer learns from this data to understand how much force is needed for each material. When we give it a new material, it can guess the torque needed quickly. This helps us work better and save time!”}},{“@type”: “Question”,”name”: “What Factors Influence Torque Variation During The Turning Process On A Metal Lathe, And How Can Machine Learning Models Account For These Factors?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Torque can change during turning because of cutting speed, tool sharpness, and the metal type. If you push too hard with a dull tool, it takes more effort. Also, the machine’s settings can affect how smooth or rough the cutting is. Machine learning can help by using data from past cuts to predict and adjust for these changes. It learns from mistakes to make the process better each time.”}},{“@type”: “Question”,”name”: “How Can Real-Time Torque Data Be Collected And Analyzed Using Machine Learning To Improve The Precision And Efficiency Of Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can collect real-time torque data by using special sensors on the lathe machine. These sensors measure how hard the machine works while cutting metal. Then, we can use computer programs, called machine learning, to look at this data. The programs help us find patterns which show how to make the machine work better. This makes our lathe operations faster and more accurate!”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Enhance The Monitoring And Detection Of Anomalies In Torque During Metal Lathe Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning helps us watch machines closely. It can learn what normal torque looks like during metal lathe machining. If something goes wrong, it can tell us right away. This way, we catch problems early and fix them before they get worse. We become better at making things safely and correctly.”}},{“@type”: “Question”,”name”: “What Are The Potential Benefits And Limitations Of Integrating Machine Learning Technologies In Optimizing Torque Parameters For Various Lathe Machining Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using machine learning can help us find the best settings for torque on lathes, which is a tool that spins things to shape them. The benefits include faster production and better quality of the items we make. However, one limitation is that we need good data for the machine learning to work well. If the data is wrong or missing, it might not help us at all.”}}]}