Have you ever wondered how metal parts are shaped in factories? One important tool used in this process is the lathe machine. It helps carve and mold metal with precision. But did you know that the kind of oil used in these machines plays a vital role? That’s right! Lathe machine oil is crucial for keeping the gear running smoothly.

Imagine a craftsman carefully designing a part on a computer. They use CAD design to create exact shapes and sizes. The design comes to life when it reaches the lathe machine. Proper oil makes sure everything works perfectly.

Here’s a fun fact: The first lathe machine dates back to ancient Egypt! Just think how much it has evolved! In this article, we will explore why lathe machine oil is important. We’ll also look at how CAD design helps in creating amazing metal parts. Get ready to dive into the world of lathes and see how they work!

Lathe Machine Oil For Metal Lathe Cad Design Applications

Lathe Machine Oil and Metal Lathe CAD Design

Lathe machine oil is crucial for keeping metal lathes running smoothly. It reduces friction and prevents rust. Imagine trying to ride a bike with no oil on the chain—it just wouldn’t work well! CAD design helps create precise parts for these machines. It allows engineers to visualize and plan every detail. Did you know that using the right oil can extend the life of your lathe? Understanding these tools can make your projects smoother and more efficient.Understanding Lathe Machines

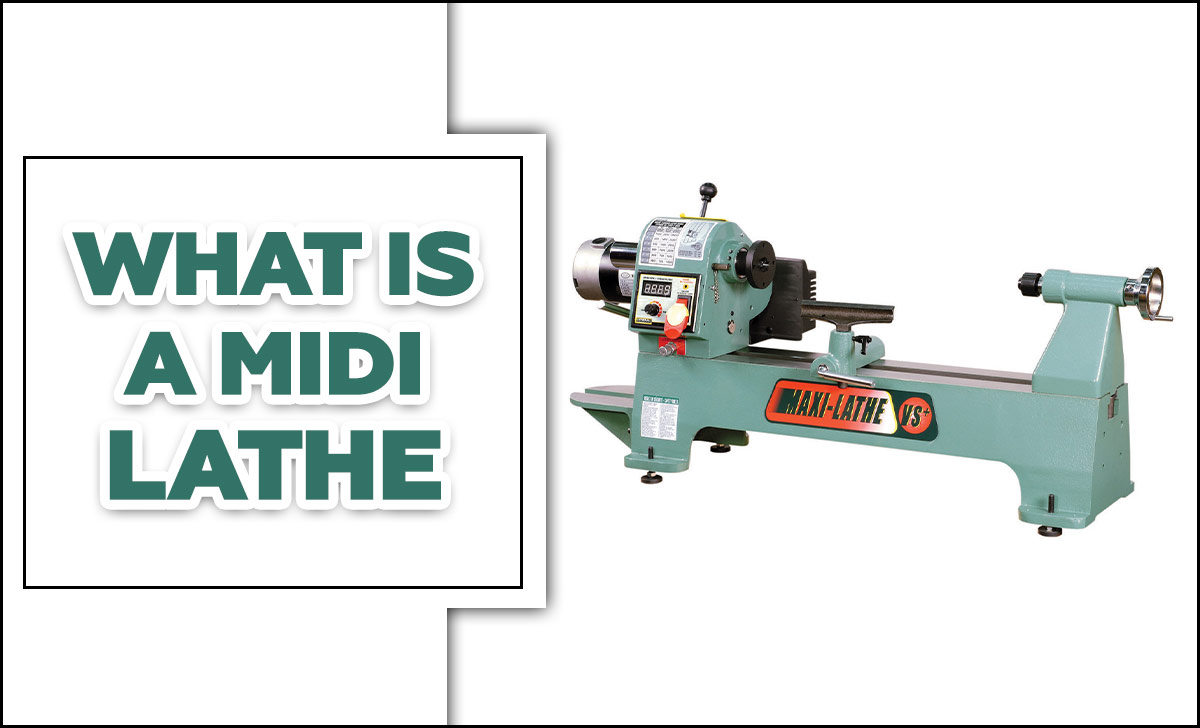

Definition and components of a lathe machine. Different types of lathe machines used in metalworking.A lathe machine is like a magic tool in a metalworker’s shop! It helps shape materials into cute and useful objects. A lathe spins the material while a cutter removes bits to create the final shape. Key parts include the headstock, tailstock, and tool rest. There are several types of lathes, each with its own job. Some are meant for big projects while others work on tiny details. Here’s a quick look:

| Type of Lathe | Use |

|---|---|

| Engine Lathe | General Purpose |

| Turret Lathe | Production Work |

| CNC Lathe | Automated Precision |

Whether you’re making a doorknob or a spaceship part, a lathe machine is your best buddy in the metalworking world!

The Importance of Lathe Machine Oil

Role of lubrication in lathe machine operation. Effects of proper lubrication on machining precision and tool life.Lubrication is like giving a lathe machine a nice massage. It helps the machine run smoothly and efficiently. Without proper oil, parts may grind together, causing problems. Good lubrication keeps your tools sharp and makes precise cuts. Think of it as a superhero cape for your lathe—protecting it from wear and tear! A well-oiled lathe can last up to 50% longer than a dry one. So, keep that oil flowing!

| Benefit | Result |

|---|---|

| Reduces Friction | Less wear on parts |

| Improves Precision | Accurate measurements |

| Extends Tool Life | Longer lasting tools |

Choosing the Right Oil for Your Metal Lathe

Factors to consider (e.g., machine type, material being machined). Recommended oil brands and products for different lathe applications.Choosing the right oil for your lathe is like picking the right cereal—get it wrong, and you’ll have a messy day! First, consider your machine type and the material you’re working with. Some oils suit metals, while others work better with plastics. It’s all about finding that perfect match!

Check out this handy table for oil brand recommendations:

| Application | Recommended Oil |

|---|---|

| General Lubrication | Mobil Vactra |

| CNC Machining | Valvoline Cutting Oil |

| High-Temperature Work | WD-40 Specialist |

Remember, the right oil helps your lathe shine like a star, avoiding unnecessary squeaks and creaks. So, keep your metal lathe happy, and it’ll work wonders for you!

Best Practices for Lubrication in CAD Design

Integration of lubrication considerations in the CAD design process. How oil selection impacts design efficiency and functionality.Lubrication plays a key role in CAD design. It helps machines run smoothly. Choosing the right oil can make a big difference in design efficiency. Properly lubricated parts work better and last longer. Poor oil choices may lead to increased wear and failures. So, think about oil selection throughout the design process. Here are some points to consider:

- Select oils based on machine needs.

- Consider temperature effects on oil performance.

- Understand how oil viscosity impacts machinery function.

- Design for easy access to lubrication points.

Why is oil choice important in CAD design?

Oil choice affects machine performance and longevity. The right lubricant ensures smooth operation and reduces costs over time.

Application Techniques for Lathe Machine Oil

Methods for applying oil during operation and maintenance. Tips for ensuring uniform lubrication across machine components.Using the right oil application techniques for your lathe machine is very important. Proper oil keeps everything running smoothly. Here are some methods to help:

- Use an oil can for quick spots where grease is necessary.

- Install an automatic lubricator for consistent oil flow.

- Regularly check oil levels to avoid dry parts.

For uniform lubrication, follow these tips:

- Oil all moving parts evenly.

- Watch out for dirt; it can block the oil.

- Clean parts before applying new oil.

Keeping your lathe oiled improves its life and keeps work appealing.

How do I maintain my lathe machine oil?

To maintain lathe machine oil, regularly check oil levels and replace old oil. Use the right type of oil for your machine’s needs.

Maintenance and Storage of Lathe Machine Oil

Optimal storage conditions for prolonging oil shelf life. Regular maintenance protocols to ensure oil effectiveness.To keep your lathe machine oil fresh, store it in a cool, dark place. Avoid keeping it near heat sources; oil doesn’t like it hot! Regularly check for any changes in color or smell. If it smells funky, it may be time to say goodbye. Using the right oil can also prevent disasters. Here’s a handy table to remember maintenance tips:

| Tip | Frequency |

|---|---|

| Check for leaks | Monthly |

| Inspect oil quality | Every three months |

| Change oil | Every six months |

Keeping up with these simple steps can help your oil last longer and work better. Remember, a happy lathe machine makes for a happy workshop!

Environmental Considerations and Safety

Understanding environmental impact and disposal of lathe oils. Safety measures to adopt when handling lathe machine oil.Using lathe machine oil is important, but we must care for the environment. These oils can harm nature if not disposed of correctly. Here’s how to keep both people and the planet safe:

- Dispose of used oil at a recycling center.

- Wear gloves to protect your skin.

- Use goggles to shield your eyes.

Keeping these points in mind can help us handle lathe oils safely and keep our surroundings clean.

What should you do with used lathe machine oil?

Recycle it at a proper disposal facility to protect the environment.

Why is safety important when handling lathe oils?

Safety ensures your well-being and prevents harmful spills.

Future Trends in Lathe Machine Oils and CAD Technology

Innovations in lubrication technology for enhanced performance. The role of CAD advancements in optimizing oil use in lathe machines.Technology is changing how we use lathe machines. New lubrication innovations make machines run smoother and last longer—like giving them a spa day! Advanced CAD designs help to use oil more wisely, cutting waste like a ninja. CAD can calculate the perfect amount of oil needed so you don’t end up with a slippery mess. It’s like finding the perfect pizza slice; nobody likes a soggy crust!

| Trend | Description |

|---|---|

| Smart Oils | Oils that adapt to heat and pressure changes. |

| Eco-Friendly Options | Biodegradable oils that are kind to the planet. |

| Precision CAD Tools | New software that helps optimize oil usage. |

Conclusion

In summary, using the right lathe machine oil keeps your metal lathe running smoothly. CAD design helps you create better projects. You can improve your skills with hands-on practice and research. Explore more about lathe oil and CAD design online. This knowledge will help you make amazing creations with your lathe!FAQs

What Types Of Oil Are Most Commonly Used For Lubricating Metal Lathe Machines, And What Are Their Specific Benefits?We commonly use two types of oil for metal lathe machines: machine oil and cutting oil. Machine oil helps keep parts moving smoothly. It prevents rust and makes the machine last longer. Cutting oil cools the metal and helps cut better. This means your machine works faster and lasts longer!

How Can Cad Software Be Utilized To Design Custom Components For A Metal Lathe To Ensure Optimal Lubrication And Maintenance?You can use CAD software to make special parts for a metal lathe. First, you can design shapes that help oil flow easily. This way, the lathe stays well-lubricated and runs smoothly. You can also make components that are easy to clean. This helps keep everything in good shape for a long time.

What Are The Key Factors To Consider When Selecting Lathe Machine Oil For High-Speed Machining Operations?When choosing lathe machine oil for high-speed work, you should think about a few important things. First, look for oil that cools well and keeps things from getting too hot. Second, pick oil that makes it easy for the machine parts to move smoothly. You also want oil that protects against rust and wear over time. Lastly, check if it works well with the materials you’re using in your project.

How Does The Viscosity Of Lathe Machine Oil Impact The Performance And Longevity Of A Metal Lathe?The viscosity of lathe machine oil helps it flow easily in the machine. If the oil is too thick, it can’t reach all parts. This means some parts might not get enough lubrication. When all parts are well-oiled, they last longer and work better. Using the right oil keeps your lathe in great shape!

What Are Some Cad Design Techniques To Enhance The Accessibility And Efficiency Of Oil Application Points On A Metal Lathe?To make oil application points easier on a metal lathe, we can use several CAD design techniques. First, place oil points where you can easily reach them. Next, create clear paths for your hands and tools to get there. We can also show these points in bright colors on the design. Finally, adding labels helps everyone know where to apply oil.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Oil Are Most Commonly Used For Lubricating Metal Lathe Machines, And What Are Their Specific Benefits? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We commonly use two types of oil for metal lathe machines: machine oil and cutting oil. Machine oil helps keep parts moving smoothly. It prevents rust and makes the machine last longer. Cutting oil cools the metal and helps cut better. This means your machine works faster and lasts longer!”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design Custom Components For A Metal Lathe To Ensure Optimal Lubrication And Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to make special parts for a metal lathe. First, you can design shapes that help oil flow easily. This way, the lathe stays well-lubricated and runs smoothly. You can also make components that are easy to clean. This helps keep everything in good shape for a long time.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting Lathe Machine Oil For High-Speed Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing lathe machine oil for high-speed work, you should think about a few important things. First, look for oil that cools well and keeps things from getting too hot. Second, pick oil that makes it easy for the machine parts to move smoothly. You also want oil that protects against rust and wear over time. Lastly, check if it works well with the materials you’re using in your project.”}},{“@type”: “Question”,”name”: “How Does The Viscosity Of Lathe Machine Oil Impact The Performance And Longevity Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The viscosity of lathe machine oil helps it flow easily in the machine. If the oil is too thick, it can’t reach all parts. This means some parts might not get enough lubrication. When all parts are well-oiled, they last longer and work better. Using the right oil keeps your lathe in great shape!”}},{“@type”: “Question”,”name”: “What Are Some Cad Design Techniques To Enhance The Accessibility And Efficiency Of Oil Application Points On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make oil application points easier on a metal lathe, we can use several CAD design techniques. First, place oil points where you can easily reach them. Next, create clear paths for your hands and tools to get there. We can also show these points in bright colors on the design. Finally, adding labels helps everyone know where to apply oil.”}}]}