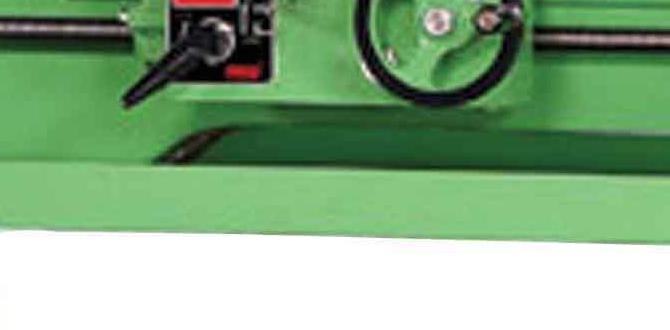

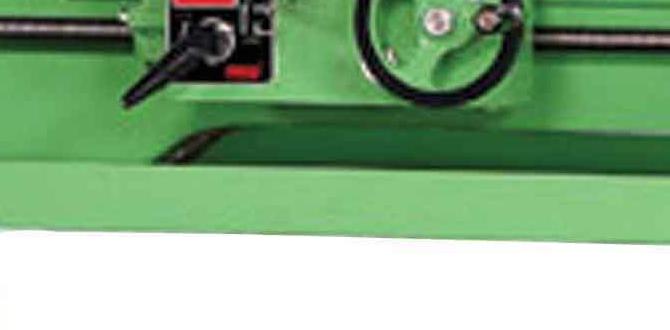

Have you ever wondered how machines make tough metal parts? One key player in this process is the lathe machine. This amazing tool spins metal to shape it into useful items. But did you know that choosing the right lathe machine oil can make a big difference? It keeps the machine running smoothly and helps it last longer.

Imagine using a metal lathe to create beautiful projects. You design a chair, a small table, or even parts for a robot. But wait! You notice your lathe’s chuck key is missing. Without it, you can’t tighten or loosen your materials. What should you do then?

In this article, we’ll explore how lathe machine oil and the lathe chuck key work together. We’ll share tips to keep your lathe in top shape. You might learn something new that could help with your next project! Let’s dive in and discover more about this fascinating world of metalworking.

Essential Lathe Machine Oil For Metal Lathe Chuck Key Care

Lathe Machine Oil and Chuck Keys

Lathe machine oil is essential for keeping your metal lathe running smoothly. It reduces friction and helps prevent rust, which can harm the machine. The lathe chuck key is a small yet vital part. It helps you tighten and loosen the chuck, ensuring secure workpieces. Did you know that proper lubrication can extend the life of your lathe? Without the right oil and tools, you can face big problems while working on your projects.What is Lathe Machine Oil?

Definition and purpose of lathe machine oil. Types of lathe machine oils available in the market.Lathe machine oil is like the superhero of the workshop. It keeps your lathe running smoothly and prevents wear and tear. Imagine if your favorite toy could only work with a special kind of juice—it’s pretty much the same here! There are different types of lathe oils available, each serving a unique purpose.

| Type | Purpose |

|---|---|

| Mineral Oil | Great for general use |

| Synthetic Oil | Durable and high performance |

| Cutting Oil | Best for metal cutting tasks |

Choosing the right oil can make your lathe feel like it’s dancing in delight, instead of grinding its gears! Trust me; a well-oiled machine is a happy machine.

Importance of Choosing the Right Lathe Machine Oil

Effects of different oils on machine performance. Factors to consider when selecting lathe oil.Choosing the right lathe machine oil is like picking the best sauce for your pasta. The type of oil affects how your machine runs. Think of it as giving your lathe a nice, smooth massage. Using the wrong oil can lead to a slippery situation, resulting in poor performance.

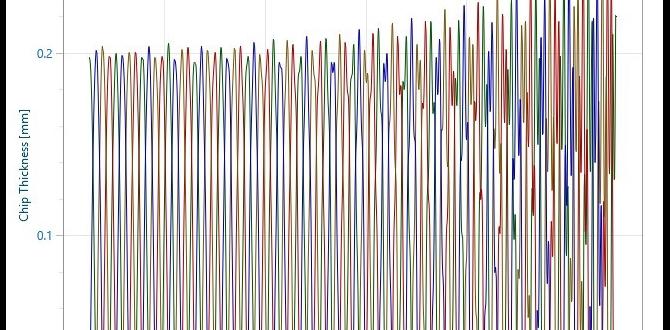

When selecting lathe oil, consider factors like viscosity and temperature range. Always check if it’s suitable for metalworking. Remember, the right oil keeps things spinning smoothly and makes those metal chips dance!

| Factor | Description |

|---|---|

| Viscosity | Thickness or flow rate of the oil. Too thick or too thin can harm performance. |

| Temperature Range | How well the oil performs in different temperatures. Keep your lathe from overheating! |

| Metal Compatibility | Ensure the oil is safe for the metal types used in your lathe. |

In the end, the right oil can brighten your day and keep your lathe happy! Every drop counts!

How to Properly Lubricate a Lathe Machine

Stepbystep guide for oil application. Common mistakes to avoid during lubrication.To keep your lathe machine running smoothly, lubrication is key. Follow these simple steps for proper oil application:

- Clean the machine before you start.

- Apply oil to moving parts, like bearings and gears.

- Use the right type of oil to avoid damage.

- Wipe off excess oil to prevent buildup.

Avoid these common mistakes:

- Don’t skip cleaning before oiling.

- Don’t overapply oil; it can attract dirt.

- Don’t use the wrong type of oil.

Regularly lubricating your machine helps it last longer. A well-oiled lathe works better and is safer to use.

What oil should I use for my lathe machine?

Use a light machine oil specifically made for lathe machines. This ensures smooth operation and protects the metal parts.

Understanding Metal Lathe Chuck Keys

Definition and role of chuck keys in lathe operations. Types of chuck keys and their functionalities.Chuck keys are small but mighty tools. They help secure the workpiece on metal lathes, ensuring everything spins smoothly. Without them, your project could go off the rails—literally! There are different types of chuck keys, like the T-handle key and the pin key, each serving its own purpose. These little heroes make sure your metal lathe runs without a hitch, keeping your fingers safe from spinning metal. Remember, a chuck key is not just a tool; it’s the master of rotating metal!

| Type of Chuck Key | Functionality |

|---|---|

| T-handle Key | Offers better grip and torque for tightening. |

| Pin Key | Great for small shafts and lighter workpieces. |

Maintenance of Metal Lathe Chuck Keys

Cleaning and care tips for extending chuck key lifespan. Troubleshooting common issues with chuck keys.To keep your metal lathe chuck key in great shape, clean it often. Use a soft cloth to wipe off dirt and oil. This simple step can help extend its lifespan. Be sure to check for any rust or damage and fix it right away. If your chuck key gets stuck, try to clean the area around it first. You can also apply a bit of lathe machine oil to help it move smoothly.

Common Issues and Solutions

If you’re facing trouble with your chuck key, here are helpful tips:

- Check for dirt buildup.

- Look for rust and remove it carefully.

- Apply oil regularly.

These steps can help your chuck key work better and last longer!

How to Clean a Chuck Key?

To clean a chuck key, use soap and water, then dry it thoroughly.

Best Practices for Lathe Operation and Maintenance

Daily operational checks for lathe machines. Scheduled maintenance routines for optimal performance.To keep your lathe machine running smoothly, daily checks are key. Start by ensuring the lathe machine oil is filled and clean. Don’t forget to inspect the chuck key; a loose key can lead to mistakes and accidents. Set aside time for regular maintenance too. This includes cleaning dust, checking alignment, and lubricating moving parts. Following these tips helps avoid surprises and keeps the lathe in great shape. Remember, a well-cared lathe is a happy lathe!

| Daily Checks | Scheduled Maintenance |

|---|---|

| Check oil levels | Inspect for wear and tear |

| Clean chuck key | Lubricate moving parts |

| Listen for strange noises | Tighten loose components |

Frequently Asked Questions about Lathe Oil and Chuck Keys

Common concerns and misconceptions. Suggested solutions and expert advice.Many people worry about how to use lathe oil and chuck keys. Some think any oil works. This isn’t true. Using the wrong oil can harm your equipment. It’s important to use the correct lathe machine oil for your lathe. Here are some common concerns:

- What oil should I use? Always choose oil recommended for your machine.

- How often should I oil? Regularly check and oil your lathe to keep it running smoothly.

- Can I use water? No, water can rust your metal parts.

For expert advice, always read your lathe’s manual. Following these tips will help you maintain your machine and keep it in great shape!

Conclusion

In summary, lathe machine oil keeps your metal lathe running smoothly. Using the right oil helps prevent wear and tear. Don’t forget to use a chuck key to hold your work in place securely. You can enhance your skills by practicing with these tools. Explore more about lathe maintenance to keep your projects successful and efficient!FAQs

What Type Of Oil Is Recommended For Lubricating A Metal Lathe Machine, And How Often Should It Be Applied?For a metal lathe machine, you should use a light machine oil or a specific lathe oil. This oil helps all the moving parts work smoothly. You should apply the oil every few hours while you use the machine. Always check the owner’s manual for the best advice.

How Do You Properly Use A Chuck Key With A Metal Lathe, And Why Is It Important For Maintaining Safety?To use a chuck key with a metal lathe, first, make sure the lathe is turned off. Then, insert the chuck key into the holes on the chuck. Turn the key to tighten or loosen the chuck. Always remove the chuck key after use to avoid accidents. This keeps everyone safe because a key left in can get caught in the spinning parts.

What Are The Key Considerations When Selecting A Lathe Machine Oil For Optimal Performance And Longevity Of The Equipment?When choosing oil for a lathe machine, you should think about a few key things. First, pick oil that is right for the machine’s size and type. Next, look for oil that can handle high temperatures and reduces wear. You also want oil that helps keep dirt and dust away. Finally, check that the oil is easy to find and isn’t too expensive.

Can Using The Wrong Type Of Oil Or Insufficient Lubrication Affect The Performance Of A Metal Lathe And Its Components, Such As The Chuck?Yes, using the wrong oil or not enough oil can hurt a metal lathe. It can make the machine work poorly. The chuck, which holds the metal, might not grip well. This can lead to mistakes and even damage the lathe. So, always use the right oil and enough of it!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Metal Lathe, Including The Care Of The Chuck And Lubrication?To keep a metal lathe working well, you should clean it regularly. Wipe off dust and chips after using it. Take care of the chuck by checking it for dirt or oil. Lubricate moving parts with oil to prevent rust and help it move smoothly. Also, check belts and tools often to make sure everything is in good shape.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe Machine, And How Often Should It Be Applied? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe machine, you should use a light machine oil or a specific lathe oil. This oil helps all the moving parts work smoothly. You should apply the oil every few hours while you use the machine. Always check the owner’s manual for the best advice.”}},{“@type”: “Question”,”name”: “How Do You Properly Use A Chuck Key With A Metal Lathe, And Why Is It Important For Maintaining Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a chuck key with a metal lathe, first, make sure the lathe is turned off. Then, insert the chuck key into the holes on the chuck. Turn the key to tighten or loosen the chuck. Always remove the chuck key after use to avoid accidents. This keeps everyone safe because a key left in can get caught in the spinning parts.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations When Selecting A Lathe Machine Oil For Optimal Performance And Longevity Of The Equipment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing oil for a lathe machine, you should think about a few key things. First, pick oil that is right for the machine’s size and type. Next, look for oil that can handle high temperatures and reduces wear. You also want oil that helps keep dirt and dust away. Finally, check that the oil is easy to find and isn’t too expensive.”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Oil Or Insufficient Lubrication Affect The Performance Of A Metal Lathe And Its Components, Such As The Chuck? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong oil or not enough oil can hurt a metal lathe. It can make the machine work poorly. The chuck, which holds the metal, might not grip well. This can lead to mistakes and even damage the lathe. So, always use the right oil and enough of it!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Metal Lathe, Including The Care Of The Chuck And Lubrication? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you should clean it regularly. Wipe off dust and chips after using it. Take care of the chuck by checking it for dirt or oil. Lubricate moving parts with oil to prevent rust and help it move smoothly. Also, check belts and tools often to make sure everything is in good shape.”}}]}