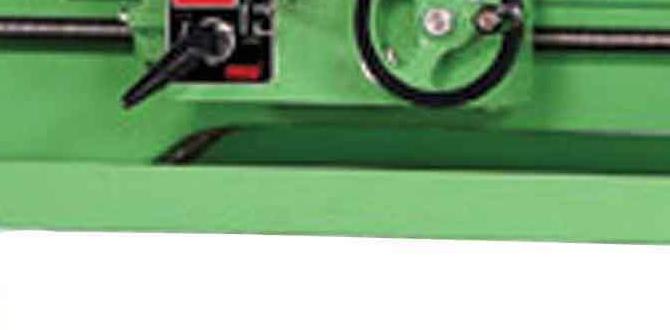

Have you ever watched a lathe machine spin? It’s fascinating! These machines can turn raw metal into something useful. But to keep them running smoothly, they need the right oil. That’s where lathe machine oil comes in.

Imagine trying to use a bicycle without oil on the wheels. It would be tough to ride, right? The same goes for lathe machines. Without proper lubrication, they can wear out quickly. Metal lathe machines need oil to help with movement and prevent damage.

Some people might wonder how to make their lathe even better. That’s where a CNC retrofit comes into play. This upgrade can turn a basic lathe into a high-tech machine that makes precise cuts. Sounds cool, right? With the right oil and a retrofit, you can transform your work.

So, why is choosing the right lathe machine oil so important? The answer lies in performance and longevity. A good oil helps the machine run efficiently, saving you time and money. Plus, who wouldn’t want a smooth, quiet operation? Let’s dive deeper into these fascinating machines and discover how the right tools can make a big difference.

Essential Lathe Machine Oil For Metal Lathe Cnc Retrofit

Lathe Machine Oil and CNC Retrofit

Lathe machine oil keeps metal lathe parts working smoothly. It reduces friction and prevents rust, ensuring better performance. When considering a CNC retrofit, think about using high-quality oil. This change can enhance the efficiency of older machines. Did you know that proper lubrication can extend the life of your lathe? Many small business owners overlook this crucial aspect. A little oil can go a long way in keeping your tools in top shape!Understanding Lathe Machine Oils

Types of lathe machine oils: mineral, synthetic, and biodegradable options. Importance of viscosity and temperature resistance in oil selection.Choosing the right lathe machine oil is like picking the best ice cream flavor—it’s all about the options! You have three main types of oils: mineral, synthetic, and biodegradable. Mineral oils are traditional and popular, while synthetics offer better performance. Biodegradable oils are friendly for the planet, just like a sunny day! But it’s not just about the type; viscosity and temperature resistance matter too! It determines how well the oil protects your machine. Remember, thin oils flow easily but may not handle heat well. Thick oils can take the heat but may struggle to flow. So, choose wisely!

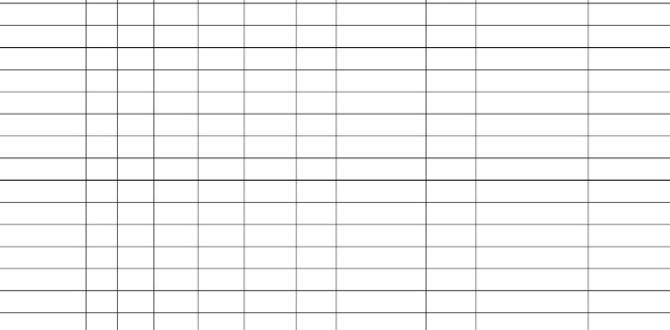

| Type of Oil | Advantages | Disadvantages |

|---|---|---|

| Mineral | Traditional, easily available | May not perform well at high temps |

| Synthetic | Better performance, resistant to heat | Can be more expensive |

| Biodegradable | Environmentally friendly | May not be as effective in all conditions |

Key Benefits of Using Proper Lathe Machine Oil

Enhanced machine performance and longevity. Improved surface finish and precision in machining.Using the right lathe machine oil can make a world of difference. First, it boosts your machine’s performance and makes it last longer. A well-oiled lathe runs smoother and requires less maintenance. Second, it helps achieve a better surface finish and accuracy in machining. A little oil goes a long way—like a magic potion for metal! Who knew being a machinist could be so fun?

| Benefit | Description |

|---|---|

| Enhanced Performance | Improves how well your machine works and extends its life. |

| Better Precision | Gives you smoother finishes and more accurate cuts. |

In short, using proper oil isn’t just smart; it’s essential for getting the best out of your lathe!

Choosing the Right Oil for Your Metal Lathe CNC Retrofit

Factors to consider: material compatibility and machine specifications. Recommendations for top brands and formulations for CNC lathes.Choosing oil for your CNC lathe is key to great results. First, consider material compatibility. Check if the oil matches the materials you work with. Next, look at machine specifications. Every lathe has unique needs.

Top brands provide reliable options:

- Mobil – Known for excellent lubrication.

- Shell – Offers a variety of specialized oils.

- Castrol – Great for high-performance needs.

Using the right oil can extend tool life and improve performance. Don’t overlook this important choice! When in doubt, consult your machine’s manual to find recommended oils.

What should I look for in CNC lathe oil?

Look for compatibility with materials and specific requirements for your lathe model. It’s vital for optimal performance.

Application Techniques for Lathe Machine Oil

How and when to apply oil for optimal results. Tips on oil maintenance and management during CNC operations.Applying lathe machine oil correctly is key for smooth operations. Start by applying oil before using the machine. This ensures everything runs well from the start. During use, keep an eye on the oil level. Reapply oil as needed, especially after long sessions.

For best results, follow these tips:

- Oil moving parts frequently.

- Check oil purity regularly.

- Store oil in a cool, dry place.

- Clean the machine before oiling.

How often should you oil a lathe?

You should oil your lathe after every few hours of use or when it feels dry. Always refer to the machine’s manual for specific guidelines.

Proper oil management can make a big difference in machine life and performance. Keep your lathe happy with regular care!

Common Mistakes to Avoid with Lathe Machine Oil

Overoiling vs. underoiling: finding the right balance. Ignoring manufacturer’s guidelines and oil change frequency.Using the right amount of oil is important for your lathe machine. Overoiling can lead to messy workspaces, while not enough oil can cause damage. Finding the right balance is key. Always check the manufacturer’s guidelines for oil type and change frequency. Not following these can shorten the life of your machine.

- Too much oil creates buildup.

- Too little oil leads to wear and tear.

- Regular oil changes keep machines running smoothly.

How often should lathe oil be changed?

Change lathe oil regularly, about every 100 hours of use, or as suggested by the manufacturer.

Environmental Considerations and Oil Disposal

Understanding the environmental impact of lathe oils. Best practices for oil disposal and recycling options.Using lathe machine oil can be a slippery situation if not handled right. It’s important to know that these oils can harm our environment if we don’t dispose of them properly. So, what can you do? First, never pour oil down the drain. That makes fish sad and the Earth grumpy! Instead, you can recycle your lathe oil. Many recycling centers accept it. Check your local rules. Plus, there are special containers for oil disposal. Use them like a pro!

| Best Practices for Oil Disposal | Recycling Options |

|---|---|

| Never dump oil in the sink. | Find a local recycling center. |

| Use proper disposal containers. | Check community programs for safe disposal. |

Future Trends in Lathe Machine Oils and CNC Technology

Innovations in oil formulations and ecofriendly alternatives. The role of advanced CNC technologies in oil usage optimization.New oils for lathe machines are becoming more advanced. Many companies are looking for eco-friendly solutions. These new oil formulations are safer for the planet and just as effective. Also, advanced CNC technologies help use less oil. They allow machines to run more smoothly. This means less waste is produced. Here are some trends to watch:

- Innovative oil blends reduce environmental impact.

- Smart tools monitor oil usage in real-time.

- Automatic systems adjust oil delivery for specific tasks.

These changes provide better performance and are good for our Earth.

What are the latest trends in lathe machine oil?

New eco-friendly oils and smart CNC technology lead the way. They help machines work more efficiently while protecting the environment.

Conclusion

In conclusion, using the right lathe machine oil is crucial for keeping your metal lathe running smoothly. If you’re considering a CNC retrofit, it can enhance precision and efficiency. To maintain your tools, always lubricate properly. If you want to learn more, explore guides on lathe maintenance and CNC upgrades. Happy machining, and don’t forget to keep practicing!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathes, And Cnc Retrofitting:Lathe machine oil helps keep metal lathes running smoothly. It reduces friction and makes parts last longer. CNC stands for Computer Numerical Control. It helps machines follow precise instructions for making things. Retrofitting means adding new parts to old machines to make them better.

Sure! Please tell me what question you would like me to answer.

What Type Of Oil Is Commonly Recommended For Lubricating A Metal Lathe, And How Does It Differ From Oil Used In Cnc Machines?For a metal lathe, we often use oil called way oil. It is thick and sticks to the metal parts, helping them move smoothly. In CNC machines, we usually use lighter oils or coolants. These help keep things cool and clean while the machine works quickly.

What Are The Key Considerations When Retrofitting A Traditional Metal Lathe To Cnc Operation, Specifically Regarding Lubrication Systems?When changing a metal lathe to CNC (Computer Numerical Control), you need to think about how to keep it lubricated. Good lubrication helps the parts move smoothly and prevents damage. You should decide if you want a manual system or an automatic one. An automatic system saves time and ensures even oil spreading. Finally, think about the right type of oil for the job, so everything works well.

How Can The Choice Of Lathe Machine Oil Affect The Precision And Longevity Of A Retrofitted Cnc Lathe?Choosing the right lathe machine oil is very important for your CNC lathe. Good oil helps the machine run smoothly. When the lathe runs well, it makes better cuts and shapes. This means you get more precise results. Also, using the right oil helps the lathe last longer, saving you money in the end.

What Maintenance Practices Should Be Implemented To Ensure Optimal Performance Of Both The Lathe Machine Oil And The Machine Itself During Cnc Retrofitting?To keep your lathe machine running well, check the oil levels often. You should clean the machine regularly to remove dirt. Change the oil as needed so it stays fresh. Make sure all parts move smoothly and are not rusty. By doing this, your machine will work better during CNC retrofitting.

Are There Any Specific Brands Or Formulations Of Lathe Oil That Are Favored By Professionals For Cnc Retrofitted Machines, And What Are Their Advantages?Yes, some brands are popular for lathe oil in CNC retrofitted machines. For example, Mobil Vactra and CRC 3-36 are often used. These oils help keep machines running smoothly and protect them from rust. They also reduce friction, which makes the machines last longer. Choosing good oil helps you work better and saves money over time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathes, And Cnc Retrofitting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe machine oil helps keep metal lathes running smoothly. It reduces friction and makes parts last longer. CNC stands for Computer Numerical Control. It helps machines follow precise instructions for making things. Retrofitting means adding new parts to old machines to make them better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Commonly Recommended For Lubricating A Metal Lathe, And How Does It Differ From Oil Used In Cnc Machines?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, we often use oil called way oil. It is thick and sticks to the metal parts, helping them move smoothly. In CNC machines, we usually use lighter oils or coolants. These help keep things cool and clean while the machine works quickly.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations When Retrofitting A Traditional Metal Lathe To Cnc Operation, Specifically Regarding Lubrication Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When changing a metal lathe to CNC (Computer Numerical Control), you need to think about how to keep it lubricated. Good lubrication helps the parts move smoothly and prevents damage. You should decide if you want a manual system or an automatic one. An automatic system saves time and ensures even oil spreading. Finally, think about the right type of oil for the job, so everything works well.”}},{“@type”: “Question”,”name”: “How Can The Choice Of Lathe Machine Oil Affect The Precision And Longevity Of A Retrofitted Cnc Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right lathe machine oil is very important for your CNC lathe. Good oil helps the machine run smoothly. When the lathe runs well, it makes better cuts and shapes. This means you get more precise results. Also, using the right oil helps the lathe last longer, saving you money in the end.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented To Ensure Optimal Performance Of Both The Lathe Machine Oil And The Machine Itself During Cnc Retrofitting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe machine running well, check the oil levels often. You should clean the machine regularly to remove dirt. Change the oil as needed so it stays fresh. Make sure all parts move smoothly and are not rusty. By doing this, your machine will work better during CNC retrofitting.”}},{“@type”: “Question”,”name”: “Are There Any Specific Brands Or Formulations Of Lathe Oil That Are Favored By Professionals For Cnc Retrofitted Machines, And What Are Their Advantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some brands are popular for lathe oil in CNC retrofitted machines. For example, Mobil Vactra and CRC 3-36 are often used. These oils help keep machines running smoothly and protect them from rust. They also reduce friction, which makes the machines last longer. Choosing good oil helps you work better and saves money over time.”}}]}