Have you ever seen a lathe machine in action? It’s fascinating how these machines shape metal with precision. But did you know that one important part is often overlooked? It’s the lathe machine oil.

Lathe machine oil keeps everything running smoothly. Without it, the machine might struggle or break. Think of it like how oil helps an engine run well. So, what’s the role of the oil when using a metal lathe?

Imagine you are using a metal lathe. You are shaping a piece of steel. As you work, the lathe control panel guides you. But if the oil is old or dirty, the machine can act up. It might slow down or even stop.

Did you know that using the right lathe machine oil can extend the life of your equipment? It’s true! This little detail can save you time and money. Now, let’s dive into the world of lathe machine oil and discover why it matters.

Lathe Machine Oil: Essential For Metal Lathe Control Panel

Understanding Lathe Machine Oil and Control Panels

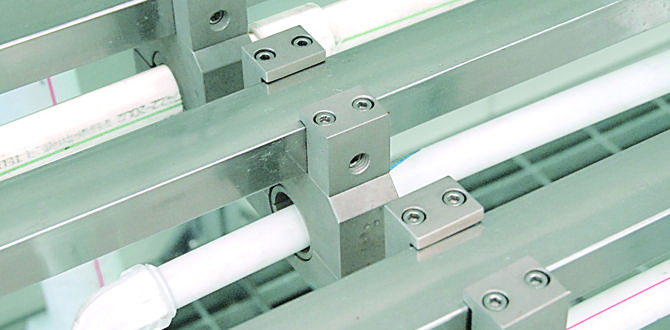

Lathe machines need proper oil for smooth operation. Using the right lathe machine oil keeps the metal lathe in good condition. It helps reduce friction and wear on parts. The control panel of a lathe is important too. It allows you to adjust the machine settings easily. Did you know that regular maintenance can extend the life of your machine? Keeping it clean and well-oiled is vital! Curious to learn more about lathe care?Understanding Lathe Machines

Definition and purpose of lathe machines. Common applications and industries using lathe machines.Imagine a machine that can turn metal into beautifully crafted shapes. That’s a lathe! These machines spin materials to carve out parts used in many things, from tiny screws to big airplane components. The fun doesn’t stop there! Lathe machines work wonders in industries like automotive, aerospace, and even art. You might think of them like a magician’s wand—transforming raw metal into useful products.

| Application | Industry |

|---|---|

| Creating gears | Automotive |

| Crafting sculptures | Art |

| Making parts for planes | Aerospace |

Importance of Lathe Machine Oil

Role of oil in lathe machine performance. Types of lathe machine oils and their characteristics.Lathe machine oil is vital for keeping machines running smoothly. It helps reduce friction, which keeps parts from wearing out quickly. With the right oil, you can improve the machine’s performance and lifespan. Here are some types of lathe machine oils:

- Mineral Oils: Basic, effective, and great for most tasks.

- Synthetic Oils: These oils last longer and resist heat better.

- Biodegradable Oils: Eco-friendly options that are safe for the environment.

Choosing the right oil helps ensure your lathe machine works well. It can save time and money in the long run.

Why is lathe machine oil important?

Lathe machine oil is important because it cools and lubricates the moving parts, preventing damage and improving efficiency.

Types of lathe machine oils and their benefits:

- Mineral Oil: Affordable and effective.

- Synthetic Oil: Better heat resistance and longer life.

- Biodegradable Oil: Environmentally friendly choice.

Choosing the Right Lathe Machine Oil

Factors to consider when selecting oil. Recommended oil brands and products for metal lathes.Choosing the right oil for your lathe machine is important. Factors to consider include viscosity, temperature range, and compatibility with your machine. Use oils that protect against wear and offer good lubrication. Some recommended brands for metal lathes are:

- Mobil Velocite 3 – Great for high-speed lathes.

- Shell Tellus S2 M – Ideal for various conditions.

- Castrol Hysol – Perfect for metalworking.

Using the right oil helps your lathe run smoothly and lasts longer.

What should I look for in lathe machine oil?

Look for good viscosity, temperature stability, and anti-wear properties. These factors keep your lathe safe and functioning well.

Maintenance of Lathe Machine Oil

Signs that oil needs changing. Steps for properly maintaining lathe machine oil levels.Oil in a lathe machine is crucial for smooth operation. Knowing when to change it is important. Look for these signs: 1) Dark color, 2) Unusual noises, 3) Slower movement.

Maintaining oil levels is easy. Check the oil level regularly using the control panel. Refill if it’s low. Keep the machine clean to avoid dirt in the oil. This helps in better performance.

How do I know if the oil needs changing?

Check for signs like dark color or strange noises. These can mean it’s time to change the oil.

Steps to maintain oil levels:

- Check the level frequently.

- Refill when low.

- Keep the area clean.

How to Operate a Metal Lathe Control Panel

Basic controls and settings explained. Safety precautions when using a control panel.Operating a metal lathe control panel is like driving a car; it has key buttons and settings! Start with the power switch, and don’t forget to adjust the speed. A feed control lets you choose how fast the tool moves. Now, here’s a safety tip: always wear goggles and keep hands clear. Remember, a lathe doesn’t like uninvited guests! Check the oil levels too, as dry lathes are cranky. They can throw a tantrum faster than a kid on a sugar rush!

| Control | Function |

|---|---|

| Power Switch | Toggles the machine on/off |

| Speed Control | Adjusts the rotation speed |

| Feed Control | Sets how fast the tool moves |

Common Issues with Lathe Control Panels

Troubleshooting common control panel problems. Preventative measures to avoid issues.Lathe control panels can sometimes act up. Many users face issues like unresponsive buttons or blinking lights. These problems can be frustrating. But don’t worry! Here are some common problems and smart ways to fix them:

- Check the power supply.

- Inspect for loose wires.

- Look for blown fuses.

To keep everything running smoothly, take some preventative measures:

- Clean the control panel regularly.

- Use the right lathe machine oil.

- Schedule routine checks.

Staying proactive can save time and money!

How can I fix my lathe control panel if it malfunctions?

Check the power connections and replace any blown fuses. Ensure all wires are tightly connected for a smooth operation.

Integrating Technology with Lathe Operations

Modern advancements in lathe control panels. Benefits of digital controls over traditional systems.Recent advancements have transformed lathe control panels. Today’s digital controls offer precision that traditional systems can only dream about. Imagine having a panel that talks back—now that’s smart! These new controls help reduce human error and increase production speed. With features like touchscreen navigation, it’s like upgrading from a flip phone to the latest smartphone. Plus, they often come with built-in safety features. It’s like having a trusted buddy watching your back while you work.

| Feature | Digital Controls | Traditional Systems |

|---|---|---|

| Precision | High | Moderate |

| Speed | Fast | Slower |

| Ease of Use | User-Friendly | Complex |

| Safety Features | Advanced | Basic |

Best Practices for Lathe Machine Operations

Recommended practices for maximizing efficiency. Importance of regular maintenance and inspections.Using a lathe machine well can improve your work. Here are some tips for better operation:

- Always keep the lathe machine oil topped up. This helps it run smoothly.

- Check the control panel regularly for any warnings or issues.

- Clean the machine after each use to avoid build-up.

- Schedule regular maintenance and inspections. This helps catch problems early.

Regular maintenance can boost efficiency by 25%. It also helps tools last longer. So, take time to inspect your machine often!

What should I check for in lathe machine maintenance?

Check the oil level and listen for unusual sounds. Make sure all parts are functioning well. Regularly inspect the control panel for alerts. This keeps your lathe running at its best!

Conclusion

In summary, lathe machine oil keeps your metal lathe running smoothly. It reduces friction and prevents wear. The control panel helps you manage the lathe’s functions easily. To maintain your lathe, always check oil levels regularly. You can learn more by reading guides on lathe maintenance or watching tutorial videos. Get hands-on experience to become a pro!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil And Metal Lathe Control Panels:Sure! Here are some answers about lathe machines. 1. What is lathe machine oil used for? Lathe machine oil keeps the machine parts lubricated. It helps them move smoothly and not get too hot. 2. How do you know when to change the oil? You should change the oil when it looks dirty or when the machine sounds louder than usual. 3. What is a metal lathe control panel? A metal lathe control panel has buttons and switches. You use it to start or stop the machine and adjust settings. 4. Why is it important to maintain a lathe machine? Maintaining a lathe machine helps it work better. It can last longer and make better parts. 5. Can kids use a metal lathe? Kids should only use a metal lathe if an adult teaches them. It is important to be safe around machines.

Sure! Please provide the question you would like me to answer.

What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Does It Differ From Other Machine Oils?For lubricating a metal lathe, you should use a light machine oil or special lathe oil. This oil helps the machine parts move smoothly. It is thinner than some other oils, which makes it better for fine parts. Other oils might be too thick and could slow things down. Always check the user manual to make sure you use the right oil!

How Do You Properly Maintain The Control Panel Of A Metal Lathe To Ensure Accurate Operation And Longevity?To keep the control panel of a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe away dust and dirt. Check for any loose buttons or switches and fix them if needed. Avoid spilling liquids on it to prevent damage. Lastly, always follow the manufacturer’s instructions for care.

What Are The Signs That A Lathe Machine Requires Oiling, And How Often Should Oil Be Applied?You can tell a lathe machine needs oil when it makes loud noises, moves slowly, or shows rust. If you see these signs, it’s time to add oil. You should oil the machine every month or more often if you use it a lot. Regular oiling helps keep it running smoothly. Always check the machine to see if it needs oil.

Can Using The Wrong Type Of Oil Affect The Performance Of A Metal Lathe, And If So, What Are The Potential Consequences?Yes, using the wrong type of oil can hurt the metal lathe’s performance. Oil helps the lathe move smoothly. If you use the wrong oil, it might not protect the machine well. This can cause parts to wear out faster and even break. You want to use the right oil to keep everything running well.

How Do You Troubleshoot Common Issues With A Metal Lathe’S Control Panel, Such As Unresponsive Buttons Or Incorrect Display Readings?To fix problems with a metal lathe’s control panel, start by checking the power. Make sure the machine is plugged in and turned on. If buttons don’t work, clean them gently with a cloth. For wrong display readings, restart the machine to reset it. If the issue keeps happening, ask a grown-up for help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil And Metal Lathe Control Panels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about lathe machines. 1. What is lathe machine oil used for? Lathe machine oil keeps the machine parts lubricated. It helps them move smoothly and not get too hot. 2. How do you know when to change the oil? You should change the oil when it looks dirty or when the machine sounds louder than usual. 3. What is a metal lathe control panel? A metal lathe control panel has buttons and switches. You use it to start or stop the machine and adjust settings. 4. Why is it important to maintain a lathe machine? Maintaining a lathe machine helps it work better. It can last longer and make better parts. 5. Can kids use a metal lathe? Kids should only use a metal lathe if an adult teaches them. It is important to be safe around machines.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Does It Differ From Other Machine Oils?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For lubricating a metal lathe, you should use a light machine oil or special lathe oil. This oil helps the machine parts move smoothly. It is thinner than some other oils, which makes it better for fine parts. Other oils might be too thick and could slow things down. Always check the user manual to make sure you use the right oil!”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain The Control Panel Of A Metal Lathe To Ensure Accurate Operation And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the control panel of a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe away dust and dirt. Check for any loose buttons or switches and fix them if needed. Avoid spilling liquids on it to prevent damage. Lastly, always follow the manufacturer’s instructions for care.”}},{“@type”: “Question”,”name”: “What Are The Signs That A Lathe Machine Requires Oiling, And How Often Should Oil Be Applied?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a lathe machine needs oil when it makes loud noises, moves slowly, or shows rust. If you see these signs, it’s time to add oil. You should oil the machine every month or more often if you use it a lot. Regular oiling helps keep it running smoothly. Always check the machine to see if it needs oil.”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Oil Affect The Performance Of A Metal Lathe, And If So, What Are The Potential Consequences?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong type of oil can hurt the metal lathe’s performance. Oil helps the lathe move smoothly. If you use the wrong oil, it might not protect the machine well. This can cause parts to wear out faster and even break. You want to use the right oil to keep everything running well.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues With A Metal Lathe’S Control Panel, Such As Unresponsive Buttons Or Incorrect Display Readings?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a metal lathe’s control panel, start by checking the power. Make sure the machine is plugged in and turned on. If buttons don’t work, clean them gently with a cloth. For wrong display readings, restart the machine to reset it. If the issue keeps happening, ask a grown-up for help.”}}]}