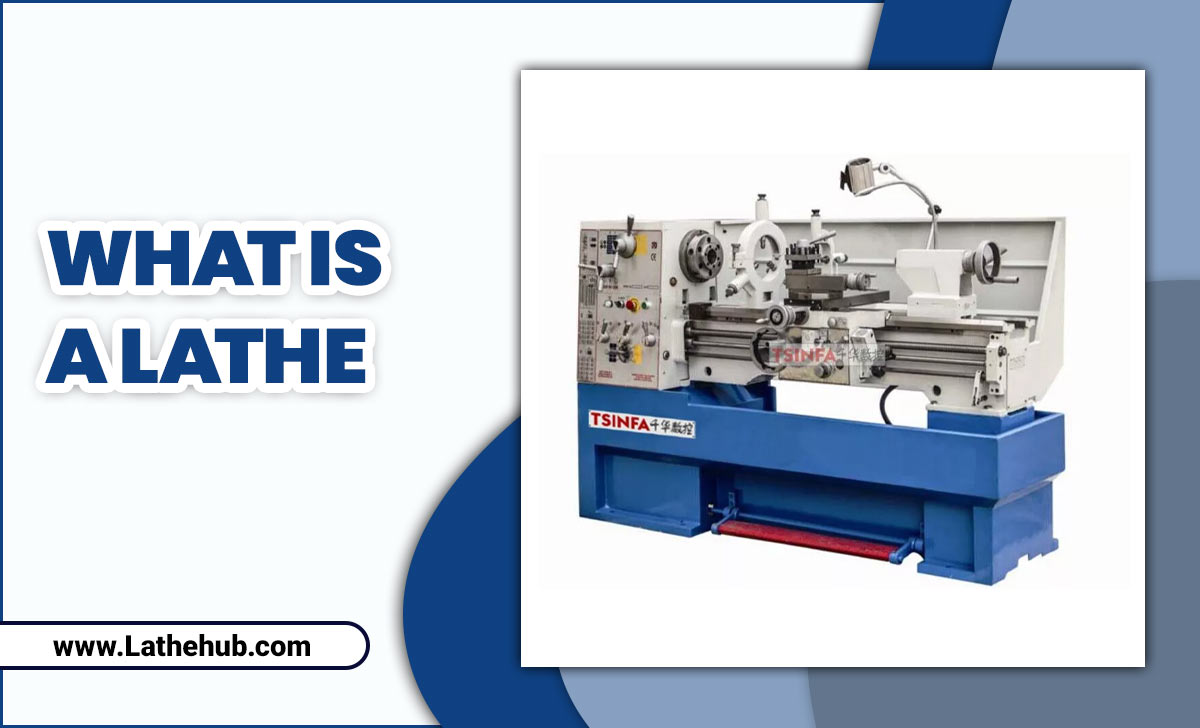

Have you ever wondered how metal parts are shaped and crafted? The secret often lies in a machine called a lathe. This clever tool spins metal pieces and carves them into useful shapes. But did you know that one of the most important aspects of a lathe is its drive system? It controls how smoothly the lathe spins. Just as a car needs oil for a smooth ride, a lathe machine needs the right oil too.

Lathe machine oil plays a vital role in keeping everything running well. Without the right oil, parts can wear down quickly. Imagine trying to ride a bike with rusty wheels. It wouldn’t go far, right? The same goes for a lathe. If you want your metal projects to turn out perfectly, you need to understand how to choose the proper oil and drive system. In this article, we will explore these essentials to help you get started on your metalworking journey.

Lathe Machine Oil For Metal Lathe Drive System Performance

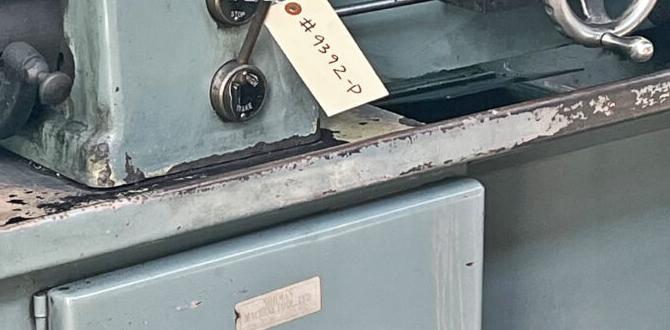

Understanding Lathe Machine Oil in Metal Lathe Drive Systems

Lathe machine oil is essential for keeping your metal lathe running smoothly. It reduces friction, which helps the machine work better and last longer. Did you know that just like oil in a car, this oil helps all the parts move easily? When you apply the right oil, you can make your lathe more efficient. Regular maintenance with quality oil can also help prevent costly repairs down the line. Keeping your lathe in top shape allows for high-quality work and great results.What is Lathe Machine Oil?

Definition and purpose of lathe machine oil. Types of oils commonly used in lathe machines.Lathe machine oil is vital for a machine’s smooth operation. It helps reduce friction and wear, making parts last longer. Different types of oils keep lathe machines running well. Common ones include:

- Mineral oil – good for general use.

- Synthetic oil – lasts longer and protects better.

- Cutting oil – helps with cutting metal efficiently.

What is the purpose of lathe machine oil?

Lathe machine oil keeps the machine running smoothly by reducing friction and heat. It also prevents rust and makes cleaning easier.

The Importance of Proper Lubrication in Metal Lathes

Effects of lubrication on machine performance and longevity. Consequences of using the wrong type of oil.Lubrication makes a big difference in how metal lathes work. It helps machine parts move smoothly, which means less wear and tear. Good oil can make a metal lathe last longer. But using the wrong oil can cause problems. It may not protect gears and could even damage parts. It’s like putting juice in a car instead of gas!

- Good lubrication: Enhances performance.

- Improper oil: Causes damage.

- Correct oil: Increases lifespan.

What happens if I use the wrong oil?

Using the wrong oil can lead to malfunctions and expensive repairs. The machine may not operate well, and parts can break down faster. Always choose the right oil for your lathe!

Factors to Consider When Choosing Lathe Machine Oil

Operating temperature and environmental conditions. Material compatibility and specific lathe requirements.Choosing the right oil for your lathe machine is important. First, think about the operating temperature. If it’s too hot or too cold, the oil can break down. Next, consider the environment. Dusty or wet areas need special oil. Also, check material compatibility. Some oils may not work well with metals in your lathe. Finally, know the specific needs of your machine. Picking the right oil keeps everything running smoothly.

What factors should I consider when selecting lathe machine oil?

Consider these key factors:

- Operating Temperature: Ensure it works in your machine’s temperature range.

- Environment: Match the oil to conditions like humidity or dust.

- Material Compatibility: Ensure it is safe for all metals.

- Specific Requirements: Each lathe may need different types of oil.

How to Properly Apply Lathe Machine Oil

Stepbystep guide on oil application techniques. Maintenance tips for ensuring effective lubrication.First, gather your lathe machine oil. Using a clean cloth, wipe the oil port. This gives the oil a fresh place to go! Next, gently squeeze the oil bottle. Apply a few drops into the oil port. You don’t want to drown the machine, just a drizzle will do! Check the level regularly and refill as needed. Remember, too much oil can create a slippery mess, and nobody wants that! Routine maintenance keeps your machine happy and working smoothly.

| Tip | Description |

|---|---|

| Clean Regularly | Wipe down surfaces to avoid dirt buildup. |

| Check Levels | Keep an eye on oil levels to ensure proper lubrication. |

| Use Quality Oil | Choose the right type of lathe oil for superior performance. |

| Avoid Over-oiling | Less is more; too much oil can lead to mess and slippage! |

Common Mistakes in Using Lathe Machine Oil

Misconceptions about oil types and usage frequency. Signs of oil degradation and when to change oil.Many people think any oil will work in a lathe machine. This is not true. Using the wrong type can damage your machine. It’s important to choose the right lathe machine oil. Also, some believe they only need to oil their machine once in a while. Regular checks are key. Watch for signs of oil degradation, like a dark color or thick texture. Change the oil when you notice these signs to keep your machine running smoothly.

How often should I change lathe machine oil?

You should check and change your machine’s oil regularly. Every 50 hours of use is a good rule of thumb.

Signs of needed oil change:

- Dark or dirty oil

- Thick or sticky texture

- Unusual noises from the machine

Enhancing Efficiency with Advanced Lubrication Solutions

Innovations in lathe machine lubrication technology. Benefits of using automated lubrication systems.New lubrication technology makes using lathe machines smarter. Advanced oils reduce friction and wear. Automatic systems deliver oil directly where it’s needed. This saves time and helps machines run better. Benefits include:

- Less downtime due to fewer breakdowns.

- Longer machine life with proper lubrication.

- Improved efficiency and accuracy in operations.

All these factors mean better results for users. It’s like giving your machine a special boost!

How does automated lubrication help machines?

Automated systems provide consistent lubrication. This leads to better performance and fewer repairs.

Conclusion

In summary, lathe machine oil is essential for keeping metal lathe drive systems running smoothly. It reduces friction and prevents wear. Regularly checking and changing this oil can help your machine last longer. If you’re interested in maintaining a lathe, consider reading more about different types of oils and their benefits. Taking care of your tools pays off!FAQs

What Type Of Oil Is Recommended For Lubricating The Drive System Of A Metal Lathe Machine?You should use a good quality machine oil for the drive system of a metal lathe. This oil helps keep the parts moving smoothly. It reduces friction and prevents rust. Always check the owner’s manual for the right type of oil for your lathe.

How Frequently Should The Oil In A Lathe Machine’S Drive System Be Changed To Ensure Optimal Performance?You should change the oil in a lathe machine’s drive system every six months or after about 500 operating hours. This helps keep the machine running smoothly. Always check the oil level regularly, too. If it looks dirty or smells bad, change it sooner. Taking care of the oil helps the lathe work well for a long time.

What Are The Potential Consequences Of Using The Wrong Type Of Oil In A Lathe Machine’S Drive System?Using the wrong type of oil in a lathe machine can cause problems. The machine may not work well and could break down. It can also make parts wear out faster. You could end up spending a lot of money to fix it. Always use the right oil to keep everything running smoothly!

How Does Proper Lubrication Of A Lathe’S Drive System Affect The Lifespan And Accuracy Of The Machine?Proper lubrication keeps the lathe’s drive system working smoothly. When we oil the parts, they move easily and don’t wear out as fast. This helps the lathe last longer and stay accurate when making things. If we forget to lubricate, parts can get rusty or damaged, making the machine less reliable. So, by keeping it oiled, we help it run well for more years!

What Maintenance Practices Should Be Followed In Addition To Oiling To Keep A Metal Lathe’S Drive System In Good Working Condition?To keep a metal lathe’s drive system working well, we should do a few things. First, check the belts for wear and tear. If they look frayed, replace them. Next, clean the lathe regularly to remove dust and metal shavings. We should also tighten loose screws or bolts. Finally, make sure to check the motors for any strange noises or issues.