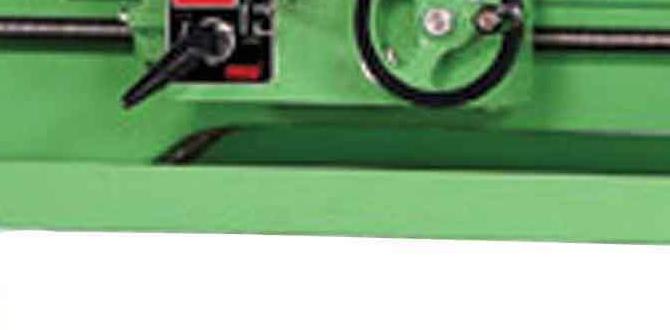

If you’ve ever worked in a workshop, you know how important tools can be. Among them, the lathe machine stands out. It helps create beautiful shapes from metal. But have you ever thought about the oil that keeps it running smoothly? That’s right! Lathe machine oil plays a key role in keeping your tools in top shape.

Imagine you’re at your workspace. The metal lathe is humming smoothly, making perfect cuts. Suddenly, you notice a strange sound. Uh-oh! That’s a sign your lathe might need some oil. Wouldn’t it be nice to avoid those problems?

This is where the quick change tool post comes in handy. It makes switching tools quick and easy. You can save time and focus on creating amazing projects. Have you ever wished for faster setups when working on metal? With a quick change tool post, you can have that luxury!

Let’s dive deeper into how lathe machine oil and tool posts can help you. You might be surprised at what you learn!

Lathe Machine Oil For Metal Lathe Quick Change Tool Post

Lathe Machine Oil and Quick Change Tool Post

Lathe machine oil keeps metal lathes running smoothly. Using the right oil ensures better performance and longer tool life. Ever wondered how quick change tool posts work? They allow quick swaps of tools, saving time during projects. Picture speeding through tasks without delays! Keeping your lathe and tools in top shape makes your work easier. Regular maintenance with quality oil is a simple way to enhance your lathe’s efficiency. What will you create next with your upgraded setup?Understanding Lathe Machine Oil

Importance of lubrication in metalworking. Types of oils for lathe machines.Lubrication is super important in metalworking. It helps parts move smoothly and reduces wear and tear. Think of lathe machine oil as the superhero of your metal lathe! It keeps everything running like a well-oiled machine—literally! There are different types of oils you can use, each with its own superpower.

| Type of Oil | Benefit |

|---|---|

| Mineral Oil | Good for general use and budget-friendly! |

| Synthetic Oil | High performance and lasts longer. |

| Cutting Oil | Great for tough cutting tasks. |

Choosing the right oil can keep your tools happy and your projects smooth. So don’t forget: a little lubrication goes a long way!

Key Features of Lathe Machine Oil

Viscosity rating and its significance. Additives used for enhanced performance.Lathe machine oil plays a vital role in keeping machines running smoothly. One key feature is its viscosity rating. This rating shows how thick or thin the oil is. Thicker oils work well for heavy machining, while thinner oils suit lighter tasks. Additives in the oil boost its performance. These additives can reduce wear, prevent rust, and enhance lubrication. This makes the oil more efficient for your metal lathe use.

What are the key benefits of viscosity and additives in lathe oil?

Viscosity ensures the oil protects the machine while additives improve performance and lifespan.

Key benefits include:

- Better protection against wear

- Reduced friction for smooth operation

- Longer tool life

- Prevention of rust and corrosion

Benefits of Using the Right Lathe Machine Oil

Reduction of wear and tear on components. Improved surface finish of workpieces.Using the right lathe machine oil is like giving your tools a cozy blanket. It helps to reduce wear and tear on parts, making your metal lathe last longer. A well-oiled lathe also gives a smoother finish to your workpieces. Think of it as a spa day for your machine – no one wants rough edges! Remember, happy tools mean happy projects!

| Benefit | Explanation |

|---|---|

| Reduced Wear | Less friction means less damage. |

| Smoother Finish | Good oil makes your workpieces shine! |

Factors to Consider When Choosing Lathe Oil

Compatibility with machine materials. Operating temperature and conditions.Choosing the right lathe oil is important for your machine’s health. First, ensure the oil matches the materials of your lathe. Using improper oil can cause damage. Next, think about the machine’s operating temperature. High heat can break down oil quickly. Here are some factors to remember:

- Compatibility: Check oil labels for material match.

- Temperature: Pick oil for your machine’s heat level.

What Should You Look For in Lathe Oil?

Look for compatibility with your machine’s parts. This helps prevent wear and tear. Also, choose oil that works well with the temperatures your lathe reaches. This keeps it running smoothly and protects your tools.

How to Properly Maintain Your Lathe with Oil

Regular oil change intervals. Techniques for effective oil application.To keep your lathe running smoothly, regular oil changes are essential. Check your lathe oil every month. If it’s dirty, it’s time for a change. Use fresh oil to protect the machine’s parts. Apply oil evenly. A little goes a long way. Follow these steps for best results:

- Clean the area before applying oil.

- Use a funnel for precise pouring.

- Wipe off any excess oil.

How often should you change lathe oil?

Change lathe oil at least every month or when it appears dirty. This keeps your machine in top shape. Regular maintenance can help you avoid costly repairs.

Common Mistakes When Using Lathe Machine Oil

Overoiling vs. underoiling. Ignoring oil contamination.Many people make mistakes with lathe machine oil. One common error is overoiling. Too much oil can cause buildup, making it hard for parts to move. Under-oiling is another mistake. It leads to friction and wear. Both problems can damage your machine.

Another big mistake is ignoring oil contamination. Dirty oil can harm tools and parts. Always check the oil for dirt or debris. Keeping oil clean helps the machine work better.

What happens if you use too much or too little oil?

Using too much oil can create a mess and lead to overheating. Too little oil makes parts rub together and wear out quickly.

Common issues:

- Overoiling slows machines down

- Underoiling increases heat

- Contaminated oil breaks tools

Recommended Lathe Machine Oils for Quick Change Tool Posts

Top products in the market. Comparing user reviews and ratings.Choosing the right oil for your lathe machine can be tricky, but it’s important! Different products have various features that help keep your metal lathe quickly changing those tool posts without a hitch. User reviews say that Brand A stands out for its smooth performance, while Brand B boasts an impressive shelf life. Let’s take a look at how they stack up:

| Product | User Rating | Comments |

|---|---|---|

| Brand A Lathe Oil | 4.8/5 | “Like butter for my lathe!” |

| Brand B Precision Oil | 4.5/5 | “Lasts longer than my last relationship!” |

| Brand C Heavy-Duty Oil | 4.3/5 | “Works hard, just like me!” |

Getting the right lathe machine oil helps keep everything running smoothly. Pick wisely, and your tools will thank you—probably with fewer squeaks and more cheers!

DIY Tips for Lathe Oil Application

Homemade oil mixtures. Tools and techniques for application.Keeping your lathe happy is easier than you think! First, consider making homemade oil mixtures. A simple mix of motor oil and a bit of kerosene works wonders. It’s like giving your machine a spa day! To apply the oil, grab a brush or an old rag. Just make sure to cover all moving parts. But watch your fingers; they might get a bit slippery!

| Tools | Techniques |

|---|---|

| Brush | Apply with a steady hand. |

| Rag | Wipe down surfaces lightly. |

Regular oiling keeps your lathe working smoothly and lasts longer. Remember, a happy lathe makes for a happy crafter!

Troubleshooting Common Issues with Lathe Machine Oil

Identifying oilrelated problems. Solutions and adjustments to improve performance.Oil problems in a lathe machine can ruin your day. Common issues include poor lubrication and strange noises. First, check the oil level. If it’s low, top it up! Always use the right oil; funky oil can spoil your fun. Got a leak? Grab a rag before your workshop looks like a slip-and-slide. Adjusting the tool post can also help. Here’s a quick table for easy fixes:

| Problem | Solution |

|---|---|

| Low oil level | Top it up with the correct oil |

| Strange noises | Check lubrication and tighten loose parts |

| Leak | Find and seal the source |

Remember, a well-cared lathe is a happy lathe!

Conclusion

In summary, using the right lathe machine oil keeps your metal lathe running smoothly. A quick change tool post makes switching tools easy and efficient. Remember, proper maintenance extends your machine’s life. So, check your oil regularly and experiment with tool posts. For more tips, keep reading or visit your local workshop for hands-on advice!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathes, And Quick Change Tool Posts:Sure! Lathe machine oil helps keep metal lathes running smoothly. It stops parts from sticking and helps them move freely. Quick change tool posts let us swap tools quickly. This saves time when we’re working on projects. Using the right oil makes our work better and easier!

Sure! Please give me the question you want me to answer.

What Type Of Oil Is Recommended For Maintaining A Metal Lathe To Ensure Optimal Performance And Longevity?To keep a metal lathe running well, we should use machine oil or motor oil. This oil helps the parts move smoothly. It also keeps the metal from rusting. You should check and add oil often to keep everything in good shape.

How Does A Quick Change Tool Post Enhance Productivity And Efficiency When Using A Metal Lathe?A quick change tool post lets you swap out tools fast on a metal lathe. This means you don’t waste time changing tools by hand. You can work on different parts without stopping much. Because of this, you finish your projects quicker and stay focused. Overall, it helps you get more done in less time!

What Are The Key Features To Look For When Selecting A Quick Change Tool Post For A Lathe Machine?When choosing a quick change tool post for a lathe machine, you should look for a few important things. First, check if it fits your lathe properly. Next, see how easy it is to attach and remove tools. Also, look for a sturdy design so it lasts a long time. Finally, check how much tools can move around, as this helps with different jobs.

How Frequently Should Lathe Machine Oil Be Changed Or Replenished To Maintain The Machine’S Operating Conditions?You should check the lathe machine oil regularly. It’s a good idea to change it every month or after some heavy use. Always keep an eye on the oil level, too. If it looks dirty or low, it’s time to refill it. Clean oil helps your machine work better and last longer!

What Are The Common Issues That Can Occur With A Metal Lathe If The Oil Is Inadequate Or Improperly Applied?If the oil on a metal lathe is low or put on the wrong way, problems can happen. The lathe can get too hot and hurt itself. Parts might stick together and even break. We might see rough marks on our finished work, too. Taking care of the oil helps everything run smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathes, And Quick Change Tool Posts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe machine oil helps keep metal lathes running smoothly. It stops parts from sticking and helps them move freely. Quick change tool posts let us swap tools quickly. This saves time when we’re working on projects. Using the right oil makes our work better and easier!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Maintaining A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe running well, we should use machine oil or motor oil. This oil helps the parts move smoothly. It also keeps the metal from rusting. You should check and add oil often to keep everything in good shape.”}},{“@type”: “Question”,”name”: “How Does A Quick Change Tool Post Enhance Productivity And Efficiency When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick change tool post lets you swap out tools fast on a metal lathe. This means you don’t waste time changing tools by hand. You can work on different parts without stopping much. Because of this, you finish your projects quicker and stay focused. Overall, it helps you get more done in less time!”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Selecting A Quick Change Tool Post For A Lathe Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a quick change tool post for a lathe machine, you should look for a few important things. First, check if it fits your lathe properly. Next, see how easy it is to attach and remove tools. Also, look for a sturdy design so it lasts a long time. Finally, check how much tools can move around, as this helps with different jobs.”}},{“@type”: “Question”,”name”: “How Frequently Should Lathe Machine Oil Be Changed Or Replenished To Maintain The Machine’S Operating Conditions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the lathe machine oil regularly. It’s a good idea to change it every month or after some heavy use. Always keep an eye on the oil level, too. If it looks dirty or low, it’s time to refill it. Clean oil helps your machine work better and last longer!”}},{“@type”: “Question”,”name”: “What Are The Common Issues That Can Occur With A Metal Lathe If The Oil Is Inadequate Or Improperly Applied?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the oil on a metal lathe is low or put on the wrong way, problems can happen. The lathe can get too hot and hurt itself. Parts might stick together and even break. We might see rough marks on our finished work, too. Taking care of the oil helps everything run smoothly!”}}]}