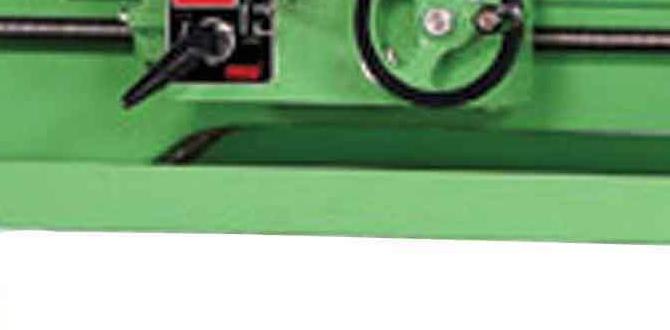

Have you ever watched a metal lathe spinning as it shapes metal? It’s fascinating! The lathe machine is a powerful tool that helps create precise parts. A critical component to keep it running smoothly is lathe machine oil. This oil helps reduce friction and wear while protecting the machine.

Imagine trying to thread a piece of metal without a threading dial. It would be tough, right? The threading dial helps users make perfect cuts each time. Knowing how to use it properly can make all the difference in your project.

Fun fact: The right lathe machine oil can boost the lifespan of your equipment. Taking care of your tools means less time fixing and more time creating. In this article, we will explore how to choose the best lathe machine oil and make threading a breeze.

Lathe Machine Oil: Essential For Metal Lathe Threading Dial

Understanding Lathe Machine Oil for Metal Lathes

Using the right lathe machine oil is crucial for smooth metal lathe operations. It prevents friction and wear, ensuring longevity. Did you know that proper lubrication can improve threading accuracy? The threading dial, an important tool in lathing, helps users know when to engage the lead screw for perfect threads. Regular oiling of the lathe not only enhances performance but also makes your projects easier and more enjoyable. Don’t overlook this simple step in your metalworking routine!Understanding Lathe Machines

Definition and types of lathe machines. Importance of maintenance for longevity and performance.Lathe machines are tools that shape materials like metal or wood. They spin the material while cutting it into the desired shape. There are different types, such as metal lathes and wood lathes. Regular maintenance is key. It keeps the machine running well and increases its life. This includes cleaning and using the right lathe machine oil. Proper care helps workers create better projects with ease.

What are the benefits of maintaining a lathe machine?

Maintaining a lathe machine improves performance and extends its lifespan. Regular maintenance prevents breakdowns and ensures accuracy while working.

Here are some maintenance tips:

- Clean the machine after use.

- Check for worn-out parts regularly.

- Use proper lathe machine oil for smooth operation.

The Role of Lubrication in Metal Lathing

How oil affects the precision and accuracy of threading. Benefits of using the right lubricant.Lubrication is key in metal lathing. It helps machines run smoothly. When cutting threads, oil ensures accuracy. Without proper oil, threads may be uneven. This could lead to errors and scrap parts. Using the right lubricant offers many benefits:

- Improved precision

- Less friction

- Longer tool life

- Better surface finish

Selecting the right lathe oil makes all the difference. It ensures quality and prevents damage. Good lubrication creates a clean workspace too!

How does proper lubrication improve threading accuracy?

Proper lubrication reduces friction and heat. This improves the cutting process, resulting in cleaner and more accurate threads.

Choosing the Right Lathe Machine Oil

Factors to consider when selecting oil. Recommended oil types for specific tasks.Picking the right oil for your lathe machine is important. You want it to work smoothly without any hiccups—like a dance party where everyone has the right moves! Start by considering the viscosity and temperature range of the oil. Your lathe’s manual is a great place to check for recommendations. For threading tasks, a heavier oil may be your best friend. Here’s a quick overview of recommended oils:

| Task | Recommended Oil Type |

|---|---|

| General Use | Non-detergent oil |

| Threading | Cutting oil |

| High Temp | High viscosity oil |

Remember, the right oil can save you time and keep your lathe happy! It’s like giving it a spa day—everyone deserves one, right?

Application Techniques for Lathe Oil

Proper methods for applying oil to ensure optimal performance. Frequency and timing of oil application during lathing.Keeping your lathe machine running smoothly is like giving it a spa day with oil! Apply oil to the moving parts to keep them happy and shiny. You’ll want to do this often, especially right before you start working. It’s like feeding your pet before a big race. Try checking every hour or so during use. Too much oil? That’s like soaking a pizza in sauce—just a bit will do!

| Application Timing | Frequency |

|---|---|

| Before starting work | Every hour |

| During long tasks | As needed |

Remember, more isn’t always better. Just keep those gears gliding, and your lathe will thank you!

Maintaining Your Lathe’s Threading Dial

Importance of keeping the threading dial lubricated. Techniques for cleaning and maintaining threading components.Keeping your threading dial happy is key to smooth operations! A well-lubricated dial helps you avoid messy threads—trust me, no one wants spaghetti instead of bolts. Regularly applying lathe machine oil keeps the parts fresh and prevents wear and tear.

To maintain those threading components, clean them using a soft cloth to remove dirt. A gentle brush works wonders in tight spots. Remember, if it’s sticky, it’s not your snack; it’s time for some elbow grease!

| Maintenance Task | How Often | Tip |

|---|---|---|

| Lubricate the dial | Every use | Use just a drop! |

| Clean threading components | Weekly | Soft cloth or brush! |

Always ensure your lathe is in tip-top shape. Remember, a happy lathe means happy projects!

Common Problems Due to Improper Lubrication

Signs of inadequate oiling on lathe productivity. Effects of old or unsuitable oil on machine performance.Using too little oil on your lathe machine can lead to big problems. You might notice increased noise and a reduced speed of the machine. These signs usually scream, “Hey, I need some oil!” Old or wrong oil can make things worse. It can turn sticky, like a forgotten gum under a school desk. This sticky situation can cause wear and tear on the parts, slowing down your work and costing you time and money. Remember, a well-lubricated lathe is a happy lathe!

| Signs of Inadequate Oiling | Effects of Old or Unsuitable Oil |

|---|---|

| Noisy operation | Sticky performance |

| Slow machine speed | Increased wear on parts |

| Poor cut quality | Shorter machine lifespan |

Tips for Storing Lathe Machine Oil

Best practices for oil storage to prevent contamination. Shelf life and indicators of degraded oil.Storing lathe machine oil is like keeping cookies in a jar—if done right, they’ll last longer! First, use tight, clean containers to prevent contamination. Dirty containers are like inviting dust bunnies to party! Always keep oil in a cool, dry place, away from sunlight. Light can spoil the fun quickly. Remember, oil doesn’t last forever. Its shelf life is usually around a year. Check for changes in color or smell; that’s oil waving a little white flag! If it’s time, throw it out and get a fresh batch.

| Indicator | What It Means |

|---|---|

| Dark Color | Oil is degraded. |

| Foul Smell | Oil has gone bad. |

Frequently Asked Questions about Lathe Machine Oil

Common queries regarding oil types and usage. Expert answers to alleviate common concerns.People often wonder about lathe machine oil. Many ask which oil is best for their metal lathe. The right oil helps keep machines running smoothly. Here are common questions:

- What type of oil should I use? It’s best to use high-quality, machine-specific oil for lubrication.

- How often should I oil my lathe? Regular oiling, especially before heavy jobs, keeps the machine in good shape.

- Can I use motor oil? While some do, it’s safer to use oil made for lathes for better performance.

Conclusion

In summary, using the right lathe machine oil is crucial for smooth metal lathe operation. It keeps parts running well and extends the machine’s life. The threading dial helps you make precise cuts for better results. If you’re interested in machining, consider reading more about lathe maintenance and oil types. It’s a great way to improve your skills and knowledge!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathe, And Threading Dial:Sure! A metal lathe is a machine that helps us shape metal into different shapes. We use lathe machine oil to keep it running smoothly. The oil makes sure the parts don’t get stuck or wear out. A threading dial helps us make neat and even threads on metal. It makes our work easier and more accurate!

Sure! I can help with that. Just let me know what question you want me to answer.

What Type Of Oil Is Best Suited For Lubrication Of A Metal Lathe To Ensure Optimal Performance And Longevity?For a metal lathe, you should use machine oil or cutting oil. These oils help keep the machine running smoothly. They also prevent rust and reduce wear on parts. Always remember to check the oil level and change it when needed. This way, your lathe will last longer and work better!

How Frequently Should A Lathe Machine Be Oiled To Maintain The Threading Dial’S Precision And Accuracy During Operations?You should oil the lathe machine regularly, at least once a week. This helps keep the threading dial working well. If you use the machine a lot, consider oiling it every day. Always check the oil level to make sure it has enough. This way, your machine stays precise and accurate!

What Are The Common Signs That Indicate A Lathe Machine Requires Lubrication Or Maintenance?You might notice some signs when a lathe machine needs oil or care. If it makes strange noises, like squeaks or grinding, it’s time for help. You might see rust or sticky spots on it, too. If the machine works slowly or stops, it definitely needs maintenance. Keeping it clean and well-oiled helps it work better!

How Does The Threading Dial On A Metal Lathe Function, And Why Is Proper Lubrication Essential For Its Operation?The threading dial on a metal lathe helps you cut threads neatly. You turn the dial to match the right numbers while working. This helps you make perfect threads on metal. Proper lubrication is important because it keeps the machine running smoothly. It helps prevent parts from wearing out and makes your work easier.

Can Improper Oiling Of A Lathe Machine Cause Threading Errors, And If So, What Steps Can Be Taken To Prevent This Issue?Yes, not oiling a lathe machine properly can cause threading mistakes. If the machine is too dry, parts can stick and move oddly. To prevent this, always check and add oil where needed. You can also read the manual to know how much oil to use. Keeping your lathe well-oiled helps it work better and makes threading easier.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Oil, Metal Lathe, And Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that helps us shape metal into different shapes. We use lathe machine oil to keep it running smoothly. The oil makes sure the parts don’t get stuck or wear out. A threading dial helps us make neat and even threads on metal. It makes our work easier and more accurate!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Best Suited For Lubrication Of A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you should use machine oil or cutting oil. These oils help keep the machine running smoothly. They also prevent rust and reduce wear on parts. Always remember to check the oil level and change it when needed. This way, your lathe will last longer and work better!”}},{“@type”: “Question”,”name”: “How Frequently Should A Lathe Machine Be Oiled To Maintain The Threading Dial’S Precision And Accuracy During Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should oil the lathe machine regularly, at least once a week. This helps keep the threading dial working well. If you use the machine a lot, consider oiling it every day. Always check the oil level to make sure it has enough. This way, your machine stays precise and accurate!”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Lathe Machine Requires Lubrication Or Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice some signs when a lathe machine needs oil or care. If it makes strange noises, like squeaks or grinding, it’s time for help. You might see rust or sticky spots on it, too. If the machine works slowly or stops, it definitely needs maintenance. Keeping it clean and well-oiled helps it work better!”}},{“@type”: “Question”,”name”: “How Does The Threading Dial On A Metal Lathe Function, And Why Is Proper Lubrication Essential For Its Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial on a metal lathe helps you cut threads neatly. You turn the dial to match the right numbers while working. This helps you make perfect threads on metal. Proper lubrication is important because it keeps the machine running smoothly. It helps prevent parts from wearing out and makes your work easier.”}},{“@type”: “Question”,”name”: “Can Improper Oiling Of A Lathe Machine Cause Threading Errors, And If So, What Steps Can Be Taken To Prevent This Issue?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, not oiling a lathe machine properly can cause threading mistakes. If the machine is too dry, parts can stick and move oddly. To prevent this, always check and add oil where needed. You can also read the manual to know how much oil to use. Keeping your lathe well-oiled helps it work better and makes threading easier.”}}]}