Have you ever wondered how metal objects are shaped and formed? Imagine a magic machine that can sculpt metal into beautiful parts. This is what lathe machining does. A metal lathe is the key tool that makes it happen.

Picture a pencil. Have you seen how its shape tapers to a point? A metal lathe can create similar designs but with metals. It spins the metal piece while tools cut away material. This makes smooth and precise shapes.

Did you know that lathe machining has been used for thousands of years? Ancient craftsmen used simple lathes to make wooden items. Today, technology has advanced, letting us create metal parts for cars, machines, and even toys.

In this article, we’ll explore the fascinating world of lathe machining. You’ll learn how metal lathes work and why they are important in many industries. Get ready to dive into the world of precision and creativity!

Exploring Lathe Machining: The Essential Metal Lathe Guide

Understanding Lathe Machining: Metal Lathes Explained

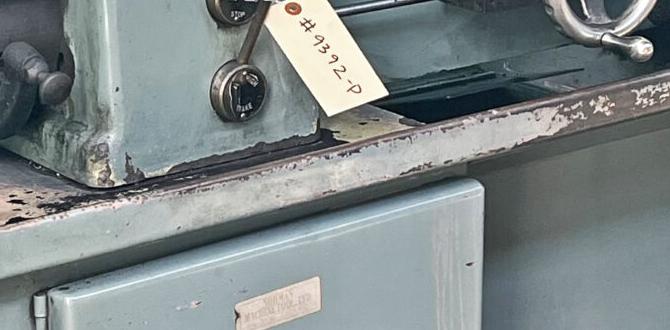

Lathe machining is a key process in shaping metal. A metal lathe allows you to rotate the material while cutting it. This creates smooth, precise shapes. Did you know that ancient craftsmen used lathes as far back as 1300 BC? Modern lathes can create anything from tiny gears to large axles. They are essential in many industries. Lathe machining not only makes tasks easier but also boosts production speed. Isn’t it fascinating how technology shapes our world?Components of a Metal Lathe

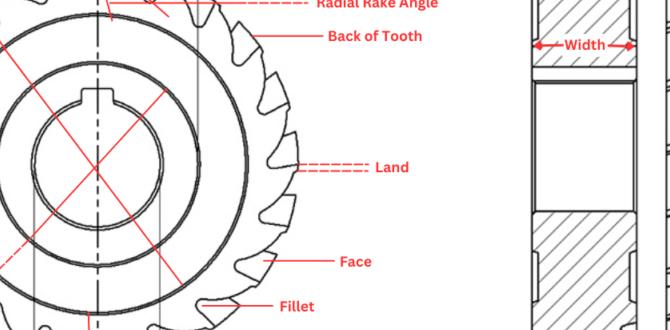

Detailed description of essential parts such as the bed, spindle, and tailstock.. Functionality of various components in achieving precision machining..Every metal lathe has important parts. The bed holds everything steady. It supports the other parts and keeps them aligned. The spindle spins the material, helping to shape it. The tailstock supports tools and adds stability for precise cuts. Each part works together to make sure everything is done right. With all these parts working together, you get smooth and accurate results.

What are the main parts of a metal lathe?

The main parts of a metal lathe include the bed, spindle, and tailstock. These components are essential for the lathe’s function and precision.

Key Components:

- Bed: Base that supports all other parts.

- Spindle: Rotates the workpiece for shaping.

- Tailstock: Provides support and stability for tools.

Types of Metal Lathes

Comparison of engine lathes, turret lathes, and CNC lathes.. Advantages and applications of each type in different industries..There are different types of metal lathes. Engine lathes are great for basic tasks. They are versatile and easy to use. Turret lathes can handle larger jobs. They allow for quick tool changes, which saves time. CNC lathes offer the most precision. They can repeat patterns flawlessly. Each lathe has specific advantages and uses in industries like manufacturing and automotive.

- Engine Lathes: Good for general work.

- Turret Lathes: Fast tool changes for bigger jobs.

- CNC Lathes: High precision for detailed work.

What advantages do different lathes have?

Engine lathes are simple and flexible, turret lathes are efficient for larger tasks, and CNC lathes excel in accuracy and repeating designs.

Lathe Machining Processes

Explanation of common machining processes: turning, facing, and boring.. Stepbystep breakdown of each process and its applications..Lathe machining involves key processes that shape metal smoothly. Let’s explore three main techniques: turning, facing, and boring.

- Turning: A rotating workpiece gets shaped by a cutting tool. This method creates outside or inside surfaces.

- Facing: The tool moves across the end of a workpiece. It creates a flat surface and improves the look.

- Boring: This enlarges existing holes. It perfects sizes for better fits.

These processes help create parts for machines, tools, and more. Each method serves specific tasks. Knowing them makes metal machining easier!

What are lathe machining processes used for?

Lathe machining processes are used for shaping, resizing, or finishing metal parts. They ensure pieces fit together correctly. This is important in many industries, like automotive and aerospace.

Setting Up Your Metal Lathe

Instructions on how to properly level and align the lathe.. Safety measures and best practices for setting up a workspace..Before you start your lathe adventures, ensure it’s level! Use a bubble level to check that it sits flat. A tipped lathe can lead to wonky cuts—like wearing shoes on the wrong feet! Make sure the headstock and tailstock are in line, or you might find out turning is not as fun as it sounds. For safety, keep your workspace tidy. A clean area helps you focus and keeps your toes safe from accidental ‘lathe hugs.’

| Setting Up Checklist |

|---|

| Level the Lathe |

| Check Alignment |

| Keep Area Clean |

| Wear Safety Gear |

Remember, being safe means being smart. Following these tips can save you from becoming a lathe’s new favorite snack!

Choosing the Right Materials for Lathe Machining

Characteristics of various metals suitable for lathe machining.. Tips on material selection based on project requirements..Picking the right metal for lathe machining can feel like choosing toppings for a pizza—everyone has their favorites! Different metals come with unique traits. For instance, aluminum is lightweight and easy to cut, while steel is super strong but a bit hard to work with. When selecting materials, think about your project’s needs. Is it for something light? Go with aluminum. Need durability? Steel is your guy! Remember, a little humor helps too; even metal has its moods!

| Metal Type | Characteristics | Best Uses |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Aircraft parts, car frames |

| Steel | Strong, durable but hard to cut | Construction, machinery |

| Brass | Easy to machine, good corrosion resistance | Plumbing, decorative items |

Common Challenges in Lathe Machining

Identification of frequent issues like tool wear and vibration.. Solutions and best practices to overcome machining challenges..Machining can be a bit tricky, like balancing on a seesaw while juggling! One big issue is tool wear. If your tools are dull, they can ruin your work. Another challenge is vibration, which happens when the machine shakes more than a excited puppy. To tackle these problems, swap your tools regularly and keep everything tightened up. These simple practices can help you avoid many headaches! Plus, who wants to waste time fixing mistakes, right?

| Common Challenges | Solutions |

|---|---|

| Tool Wear | Regular Tool Changes |

| Vibration | Secure All Parts |

Maintenance and Care for Metal Lathes

Importance of regular maintenance to ensure precision and longevity.. Checklist of maintenance tasks for optimal lathe performance..Regular maintenance of a metal lathe is key for precision and long-lasting performance. Keeping your lathe in top shape helps it run smoothly, making your projects better. When you take care of your tools, they last longer and do more work for you. Here are some important tasks to keep in mind:

- Clean the machine after each use.

- Check for wear and tear on parts.

- Oil moving parts regularly.

- Inspect belts and gears for damage.

- Calibrate settings for accuracy.

Following this checklist keeps your lathe powerful and effective. A well-maintained lathe not only works better but remains your reliable partner in crafting! Remember, taking care of your tools saves time and money in the long run.

Why is maintenance important for metal lathes?

Regular maintenance ensures your lathe runs accurately and lasts longer. It prevents problems that could slow down your work or cause damages. Investing time in care is smart, and it pays off in great results!

Quick Maintenance Tips:

- Schedule a cleaning day each week.

- Keep a log of repairs and checks.

- Learn manufacturer guidelines.

Conclusion

In conclusion, lathe machining with a metal lathe is essential for shaping materials precisely. We learned how it works and its importance in various industries. You can explore more by visiting local workshops or watching videos online. Practicing with a metal lathe can improve your skills. Dive deeper into this exciting field and see what you can create!FAQs

Sure! Here Are Five Questions Related To Lathe Machining, Specifically Focusing On Metal Lathes:Sure! Here are five questions related to lathe machining, especially about metal lathes: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins the metal while cutting tools shape it. 2. What do we use a metal lathe for? We use it to make things like parts for cars and tools. It helps create round shapes. 3. How do you turn on a metal lathe? You press a button or turn a switch. Always make sure it’s safe first! 4. How do you keep safe when using a metal lathe? You should wear goggles and keep hair and clothes away from the machine. Safety is important! 5. Can kids use a metal lathe? No, kids shouldn’t use it alone. It’s for adults, and they need to be very careful.

Sure! Please ask your question, and I will provide a short answer just for you!

What Are The Primary Components Of A Metal Lathe And Their Functions In The Machining Process?A metal lathe has several important parts. First, there’s the bed, which is the strong base that holds everything together. Then, we have the headstock, where the motor spins the metal. Next, the tailstock holds the other end of the metal piece. Finally, there are cutting tools that shape the metal as it spins. Together, these parts help make metal pieces into different shapes!

How Do You Determine The Optimal Feed Rate And Spindle Speed For Different Types Of Metals When Using A Lathe?To find the best feed rate and spindle speed for metals on a lathe, you need to consider a few things. First, look at the type of metal you’re working with. Softer metals spin faster, while harder metals need slower speeds. You can use a simple chart or calculator to help you find the right numbers. Always start slow, then adjust as you see how the metal cuts.

What Are The Safety Precautions That Should Be Taken When Operating A Metal Lathe?When using a metal lathe, always wear safety glasses to protect your eyes. Tie back long hair so it doesn’t get caught. Keep your hands and clothing away from the moving parts. Make sure the area around the lathe is clean and free of clutter. Finally, always follow the instructions that come with the machine.

How Does Cnc Lathe Machining Differ From Traditional Manual Lathe Machining In Terms Of Production Efficiency And Precision?CNC lathe machining uses a computer to control the machine. This makes it faster and more accurate than manual lathe machining. When we use CNC, we can create many pieces quickly and with the same shape every time. Manual lathes need more human effort and time. So, CNC machines help us work better and make fewer mistakes!

What Are Some Common Types Of Machining Operations That Can Be Performed On A Metal Lathe, And What Tools Are Typically Used For Each Operation?You can do several things with a metal lathe. First, you can turn parts to make them round. You use a sharp cutting tool for this. Second, you can drill holes, using a drill bit. Third, you can shape parts by using different tools like chisels. Each tool helps you create different shapes and sizes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Machining, Specifically Focusing On Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions related to lathe machining, especially about metal lathes: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins the metal while cutting tools shape it. 2. What do we use a metal lathe for? We use it to make things like parts for cars and tools. It helps create round shapes. 3. How do you turn on a metal lathe? You press a button or turn a switch. Always make sure it’s safe first! 4. How do you keep safe when using a metal lathe? You should wear goggles and keep hair and clothes away from the machine. Safety is important! 5. Can kids use a metal lathe? No, kids shouldn’t use it alone. It’s for adults, and they need to be very careful.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I will provide a short answer just for you!”}},{“@type”: “Question”,”name”: “What Are The Primary Components Of A Metal Lathe And Their Functions In The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has several important parts. First, there’s the bed, which is the strong base that holds everything together. Then, we have the headstock, where the motor spins the metal. Next, the tailstock holds the other end of the metal piece. Finally, there are cutting tools that shape the metal as it spins. Together, these parts help make metal pieces into different shapes!”}},{“@type”: “Question”,”name”: “How Do You Determine The Optimal Feed Rate And Spindle Speed For Different Types Of Metals When Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best feed rate and spindle speed for metals on a lathe, you need to consider a few things. First, look at the type of metal you’re working with. Softer metals spin faster, while harder metals need slower speeds. You can use a simple chart or calculator to help you find the right numbers. Always start slow, then adjust as you see how the metal cuts.”}},{“@type”: “Question”,”name”: “What Are The Safety Precautions That Should Be Taken When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety glasses to protect your eyes. Tie back long hair so it doesn’t get caught. Keep your hands and clothing away from the moving parts. Make sure the area around the lathe is clean and free of clutter. Finally, always follow the instructions that come with the machine.”}},{“@type”: “Question”,”name”: “How Does Cnc Lathe Machining Differ From Traditional Manual Lathe Machining In Terms Of Production Efficiency And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathe machining uses a computer to control the machine. This makes it faster and more accurate than manual lathe machining. When we use CNC, we can create many pieces quickly and with the same shape every time. Manual lathes need more human effort and time. So, CNC machines help us work better and make fewer mistakes!”}},{“@type”: “Question”,”name”: “What Are Some Common Types Of Machining Operations That Can Be Performed On A Metal Lathe, And What Tools Are Typically Used For Each Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can do several things with a metal lathe. First, you can turn parts to make them round. You use a sharp cutting tool for this. Second, you can drill holes, using a drill bit. Third, you can shape parts by using different tools like chisels. Each tool helps you create different shapes and sizes.”}}]}