Have you ever watched a machine spin metal like magic? That’s the incredible world of lathe machining. It’s a process where a lathe takes a block of metal and cuts it into amazing shapes. But have you ever wondered how lathe machines get the job done?

Lathe machining involves special tools called cutting tools. These tools help shape the metal smoothly and accurately. Imagine a sculptor using a chisel to create a statue; lathe cutting tools do something very similar, but with metal!

One fun fact is that the lathe is one of the oldest machines, dating back thousands of years. Back then, craftspeople used simple hand-powered lathes. Today, we have high-tech versions that make our work faster and easier.

In this article, we will dive deeper into lathe machining and explore how cutting tools work. Get ready to uncover the fascinating techniques behind creating metal masterpieces with a lathe!

Essential Lathe Machining: Metal Lathe Cutting Tools Guide

Lathe Machining: Key Insights on Metal Lathe Cutting Tools

Lathe machining shapes metal into desired forms using precise tools. These tools, like turning tools, parting tools, and boring bars, play vital roles in achieving accurate cuts. Ever wonder how a simple block of metal turns into intricate designs? The right cutting tools make this possible. Understanding their types and uses helps hobbyists and professionals alike. With the right tools, you can create anything from small parts to large components with ease.Key Components of a Metal Lathe

Description of essential parts (e.g., headstock, tailstock, carriage). Importance of each component in the machining process.A metal lathe has many important parts that work together. Each piece plays a key role in shaping metal. Here are the main components:

- Headstock: This is where the motor powers the lathe. It holds the main part, called the spindle.

- Tailstock: This piece supports the other end of the metal. It helps keep everything in place.

- Carriage: It moves the cutting tool. This allows for precise shaping of the metal.

Understanding these parts helps you see how they contribute to the machining process. Each component works together to create smooth and accurate cuts.

What is the importance of the headstock in a metal lathe?

The headstock provides power and support. It holds the spindle, ensuring the metal spins correctly. This spinning is vital for shaping the metal properly, leading to better results.

Choosing the Right Cutting Tool for Your Project

Factors to consider when selecting cutting tools (material, shape, size). Comparison of cutting tools based on specific applications.Picking the perfect cutting tool feels like choosing a superhero for your project! You need to think about materials, shapes, and sizes to make the right call. Stainless steel tools might be your trusty sidekick for harder metals. Meanwhile, carbide tools are like that friend who can’t stop talking but gets the job done quickly. Check this handy table for some quick comparisons!

| Material | Shape | Size | Best For |

|---|---|---|---|

| High-Speed Steel | Flat | Large | Wood and soft metals |

| Carbide | Pointed | Medium | Harder alloys and faster cuts |

| Cobalt | Curved | Small | Precision work |

Remember, choosing wisely can turn your project from drab to fab! Happy machining!

Techniques for Effective Lathe Machining

Best practices for setup and alignment. Tips for achieving precision and optimizing tool life.Good lathe machining starts with proper setup and alignment. Make sure your machine is level. Use precision tools for accuracy. Check the distance between your cutting tool and the workpiece. This can greatly improve quality. Here are some best practices:

- Align your workpiece correctly.

- Tighten all parts securely.

- Use proper cutting speeds.

To achieve high precision and extend tool life, consider these tips:

- Maintain steady pressure while cutting.

- Regularly inspect tools for wear.

- Use lubrication to reduce friction.

Following these methods can make your lathe work smoother and last longer.

Why is tool alignment important?

Tool alignment ensures accurate cuts and reduces damage. A well-aligned tool means better quality and fewer mistakes while machining.

Common Challenges in Lathe Machining

Identification of frequent issues (vibration, tool wear, inaccuracies). Solutions and preventive measures for overcoming these challenges.Lathe machining can be tough sometimes. Common issues like vibration, tool wear, and inaccuracies can happen. These problems can affect the final product. To fix them, try these tips:

- Check your machine for stability to reduce vibration.

- Use high-quality tools to prevent wear.

- Regularly calibrate your lathe to avoid inaccuracies.

Taking these steps can help you achieve better results and make machining easier!

What are common issues in lathe machining?

Common issues include vibration, tool wear, and inaccuracies in measurements. These can lead to poor-quality work and wasted materials.

Safety Considerations in Lathe Operations

Essential safety gear and equipment. Important safety practices to follow during lathe machining.Working with a lathe can be exciting, but safety is very important. Always wear essential safety gear like goggles, gloves, and a face shield. This helps protect you from flying metal shavings. Keep the work area clean and organized to avoid accidents. Here are some important safety practices to follow during lathe machining:

- Always turn off the machine before making adjustments.

- Use the right cutting tools for the job.

- Do not wear loose clothing; it can get caught in the machine.

- Stay focused and avoid distractions while working.

Remember, safety keeps you sharp and helps you enjoy your work!

What safety gear should I use while working on a lathe?

Use goggles, gloves, and a face shield to protect yourself from metal shavings.

Why is it important to keep the area clean?

A clean area helps prevent accidents and keeps you safe while you work.

Future Trends in Lathe Machining Technology

Innovations in lathe design and cutting tool materials. Impact of automation and CNC technology on traditional lathe machining.Many exciting changes are coming in lathe machining. New designs make machines faster and easier to use. Modern cutting tools use better materials, lasting longer than before. Automation changes the game, too. With CNC technology, lathes can work on their own. This means higher precision and fewer mistakes. Makers can produce more parts quickly and efficiently. The future looks bright for lathe machining!

What new materials are being used in lathe cutting tools?

Engineers are using carbide, ceramics, and cubic boron nitride in cutting tools. These materials are strong and last much longer.

Key Innovations:

- Stronger materials for cutting tools

- Faster machinery designs

- Rise of automation and CNC technology

Conclusion

In conclusion, lathe machining is essential for shaping metal. Understanding metal lathe cutting tools helps you create precise designs. You can explore different tools like chisels and drills for better results. I encourage you to practice using a lathe and learn more about techniques. This hands-on experience will make you more skilled and confident in metalworking. Keep reading and experimenting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Cutting Tools:Lathes are machines that help us shape metal. We use special tools called cutting tools to do this. Cutting tools are like big fancy knives for metal. They help us make parts that fit together nicely. With lathes, we can create many shapes, like cylinders or cones!

Sure! Please provide the question you’d like me to answer.

What Are The Different Types Of Cutting Tools Commonly Used In Metal Lathe Machining, And How Do They Differ In Application?In metal lathe machining, we use several types of cutting tools. One common tool is the roughing tool, which shapes metal quickly and removes lots of material. The finishing tool makes the metal smooth and adds a nice look. There’s also the parting tool, which cuts pieces off the metal. Each tool has a special job to help us create different shapes and finishes.

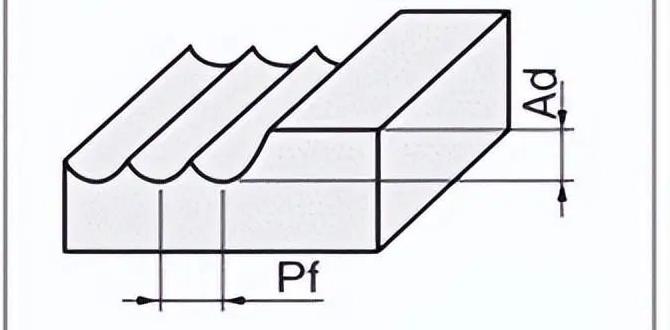

How Do You Determine The Appropriate Cutting Speed And Feed Rate When Using A Lathe For Metalworking?To find the right cutting speed, we look at the type of metal we’re using. Each metal has a different speed that works best for cutting. We can check a chart or guide to find these numbers. For the feed rate, we think about how fast we want to move the tool. A slower feed rate gives a smoother finish, while a faster one cuts quicker but might be rough. Always start with the recommended speeds and adjust if needed.

What Factors Should Be Considered When Selecting Materials For Lathe Cutting Tools To Optimize Performance And Durability?When choosing materials for lathe cutting tools, you should think about strength, hardness, and heat resistance. Strong materials help the tool last longer. Hard materials cut better and stay sharp. Heat resistance prevents the tool from wearing out too quickly. All these factors help make the tools work well and last longer.

How Do Tool Geometry And Coatings Affect The Efficiency And Life Span Of Lathe Cutting Tools?The shape of cutting tools, called tool geometry, helps them cut better. If the tool is shaped right, it can slice through materials easier and last longer. Coatings, or special surfaces on tools, protect them from wear and heat. This means they stay sharp and work well for a long time. Together, good shapes and coatings make tools more efficient and help them last longer.

What Maintenance Practices Are Essential For Ensuring The Longevity And Effectiveness Of Cutting Tools Used In Metal Lathe Operations?To keep cutting tools on a metal lathe working well, you should do a few important things. First, always clean your tools after each use to remove dirt and metal pieces. Second, check for any damage, like chips or bends, and fix them right away. You should also sharpen the tools regularly so they cut smoothly. Finally, store the tools in a dry place to prevent rust. This way, your tools will last longer and work better!