Have you ever wondered how metal parts are made? Lathe machining is a fascinating process that shapes metal into useful items. With a metal lathe, you can turn raw metal into precise shapes and sizes. But there’s an important feature that often gets overlooked: the foot brake.

Imagine you’re working on a project, and you need to stop the machine quickly. That’s where the lathe foot brake comes in. It helps you stop the lathe safely and swiftly. This simple tool can make a big difference when you’re working on something intricate.

Did you know that the foot brake has been around for many years? It has evolved with the technology of metal lathes. Understanding how it works can help you improve your projects. So, let’s dive deeper into the world of lathe machining and discover why the foot brake is so essential!

Lathe Machining: Enhancing Metal Lathe Foot Brake Safety

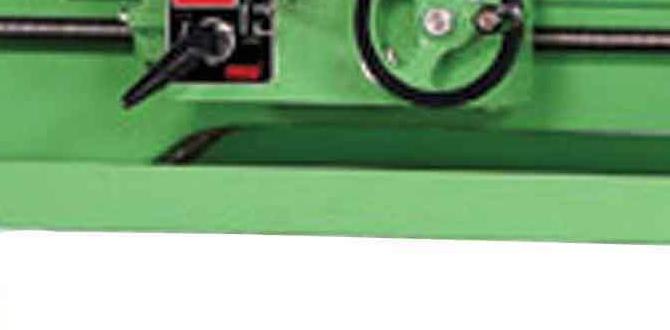

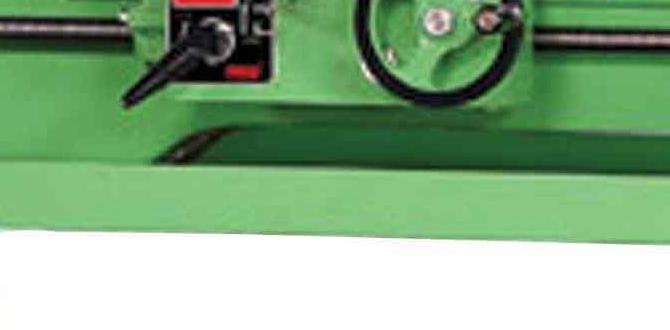

Lathe Machining Metal Lathe Foot Brake

Lathe machining is vital in shaping metal parts. One key feature is the foot brake. It helps operators quickly stop the lathe, enhancing safety and control. Imagine working with sharp tools and spinning metal! A responsive brake prevents accidents. Understanding how the foot brake works can elevate your machining skills. Did you know that even small adjustments can impact the lathe’s performance? Discovering these elements can turn a beginner into an expert.What is Lathe Machining?

Definition and types of lathe machines. Applications of lathe machining in various industries.Lathe machining is a process that shapes materials like metal and wood. It uses a tool called a lathe, which spins the material while cutting it. There are different types of lathes, such as metal lathes, which focus on metal work, and wood lathes, ideal for shaping wood. This method is used in many industries, including:

- Automotive

- Aerospace

- Construction

Lathe machining is essential for creating parts like gears and shafts. It helps in making precise items that are important in everyday life.

What is a metal lathe used for?

These lathes are for shaping metal. They create parts for machines, tools, and other items that need strong materials.

The Role of the Foot Brake in Metal Lathes

Explanation of how foot brakes function in metal lathes. Importance of foot brakes for safety and efficiency.The foot brake on a metal lathe is like a superhero’s sidekick—it helps keep things running smoothly! It works by pressing down with your foot, which activates the brake to stop the lathe quickly. This feature is super important for safety. Picture this: you’re working on a project, and suddenly, something goes wrong. With a quick tap of the foot, the lathe stops, saving you from potential mishaps. It also boosts efficiency. That means more time creating and less time worrying!

| Benefit | Description |

|---|---|

| Safety | Helps stop the lathe quickly to prevent accidents. |

| Efficiency | Allows for quicker stops, boosting productivity. |

Benefits of Using a Foot Brake

Enhanced control during machining operations. Reduction in accidents and injuries.Using a foot brake on a lathe machine improves safety and control. This feature helps workers manage the machine better. Enhanced control means smoother operations, leading to better results. It also lowers the risk of accidents. With a foot brake, users can stop quickly. This quick reaction can prevent injuries. Operators feel more secure while working, knowing they can act fast.

What are the main benefits of a foot brake?

- Better control: Operators can stop the machine easily.

- Fewer accidents: Quick stopping reduces injury risks.

Types of Foot Brakes Used in Lathe Machining

Mechanical vs. electrical foot brakes. Comparison of performance and reliability.Foot brakes play a key role in lathe machines. They can be mechanical or electrical. Each type has its strengths. Mechanical foot brakes are simple and reliable. They often last long and are easy to fix. Electrical foot brakes, on the other hand, offer quick stops. They may need more care since they use electronics. Both types can be effective, but which one is best for you? Here’s a quick comparison:

- Mechanical: Easy to repair, very durable.

- Electrical: Fast stopping, may require maintenance.

What are the benefits of mechanical and electrical brakes?

Mechanical brakes are tough and last a long time, while electrical brakes stop quickly and can be very precise. Each has unique benefits based on the job at hand. Always choose what fits your needs best.

Installation and Maintenance of Foot Brakes

Steps for installing foot brakes on metal lathes. Regular maintenance practices to ensure longevity.Installing foot brakes on metal lathes involves a few simple steps. First, gather your tools and find a flat surface. Next, attach the brake assembly to the lathe base. Align the components carefully. Secure the parts tightly with screws. Finally, connect the brake pedal wiring. To keep your lathe running well, perform regular maintenance tasks:

- Check for loose screws.

- Clean the brake area regularly.

- Lubricate moving parts once a month.

- Inspect the brake function weekly.

These steps help your lathe last longer and work better.

What tools do I need to install a foot brake?

You will need basic tools like a screwdriver, wrench, and pliers for the installation. These simple tools will help you set up the foot brake without any fuss.

Common Issues with Foot Brakes and Troubleshooting

Identifying common problems with foot brakes. Solutions and tips for effective troubleshooting.Foot brakes are essential for safe lathe operation. However, they can have issues. Here are some common problems to watch for:

- Brake sticks or doesn’t release.

- Unusual noises when used.

- Weak braking strength.

To troubleshoot effectively, consider these tips:

- Check for dirt or debris around the brake.

- Inspect cables for wear or damage.

- Lubricate moving parts regularly.

Prompt attention can prevent bigger issues later. Keep your lathe safe and working well!

What are the signs of a faulty foot brake?

Look for sticky brakes or weird noises when using them. Weak braking power is also a sign that something is wrong.

How can I fix foot brake issues?

Check for dirt, inspect cables, and make sure to lubricate parts. These steps help keep everything running smoothly!

Comparative Analysis: Foot Brake vs. Hand Control

Pros and cons of foot brakes compared to handoperated controls. Situations where foot brakes are more advantageous.Foot brakes and hand controls serve different purposes in lathe machining. Each has unique benefits and drawbacks.

- Foot Brake Pros: Hands stay free for work. Also allows for quick stopping, which can be safe.

- Hand Control Pros: Easier for precise adjustment. Users can control the machine for steady operations.

- Foot Brake Cons: May need practice to use well. Some users take time to adjust.

- Hand Control Cons: Can be tiring during long use. Might slow down work for some tasks.

In situations where speed is key, like cutting multiple pieces quickly, foot brakes are ideal. They allow smoother and faster transitions. Users can keep their focus on the project, leading to better results.

Why choose foot brakes?

Foot brakes are often best for heavy work. They let you focus on your hands and tools. Users enjoy the freedom and safety they provide.

Real-World Case Studies of Foot Brake Impact

Examples from manufacturing and fabrication sectors. Testimonials from machinists on the benefits of foot brakes.Foot brakes play a vital role in machining. Many factories and shops use them. For instance, machinists often highlight their importance in smooth operation. These brakes help workers quickly stop machines when needed. This keeps them safe and reduces accidents. Testimonies from machinists show they feel more confident using machines with foot brakes. Here are some benefits:

- Faster response time during operations.

- Increased safety for operators.

- Improved focus on tasks without distractions.

How do foot brakes enhance safety in machining?

Foot brakes ensure quick stopping, allowing machinists to avoid accidents and injuries.

Future Innovations in Foot Brake Technology for Lathes

Emerging trends and technologies in lathe foot brakes. Predictions for advancements in safety features and functionalities.New ideas are brewing in foot brake technology for lathes. Imagine foot brakes that not only stop the machine but also keep you safe! Emerging features now include smart brakes that sense the user’s reaction. If you sneak up too close, they might just stop the machine before you have a chance to trip! It sounds like science fiction, but it’s closer than you think.

Experts predict that these advanced brakes will include automatic locking and enhanced grip. So say goodbye to slipping feet and hello to smoother operations! With these innovations, working on lathes will be safer and more fun. Check out the table below for some super cool upcoming features:

| Feature | Description |

|---|---|

| Smart Sensors | Senses user’s closeness; activates brakes. |

| Automatic Locking | Locks on sudden stops to prevent accidents. |

| Enhanced Grip | Prevents slipping for better control. |

Conclusion

In summary, a metal lathe foot brake is essential for safety while machining. It helps you stop the lathe quickly when needed. Understanding how to use this feature can improve your skills and keep you safe. We encourage you to explore more about lathe machining. Check out tutorials or guides that explain these tools in detail. Your learning journey can be exciting!FAQs

Here Are Five Questions Related To Lathe Machining And Metal Lathe Foot Brakes:Sure! A lathe is a machine that helps us shape metal. We use it to make things like tools or parts for machines. A foot brake on a lathe is a special pedal you press. It stops the lathe quickly for safety. Always remember to use it when you finish working!

Sure! Just send me the question you want me to answer, and I’ll help you out.

What Are The Advantages Of Using A Foot Brake On A Metal Lathe Compared To Other Braking Systems?A foot brake on a metal lathe lets you stop the machine quickly with your foot. This keeps your hands free to keep working. It is easy to use and helps you control what you’re doing. Using a foot brake can also make it safer because you can stop faster if there’s a problem. Overall, it makes operating the lathe simpler and more efficient.

How Does The Design Of A Foot Brake Contribute To Operator Safety And Machine Control During Lathe Operations?The design of a foot brake helps keep you safe when using a lathe. When you press the brake, it quickly stops the machine. This helps you avoid accidents and gives you better control. You can use both hands for work, keeping your focus on the job. A good foot brake makes lathe operations easier and safer for everyone.

What Maintenance Practices Are Essential For Ensuring The Proper Functionality Of A Foot Brake On A Metal Lathe?To keep the foot brake on a metal lathe working well, you should check it often. Make sure it is clean and free of dust or dirt. You can also make sure that all parts move smoothly and nothing is stuck. If you notice any problems, fix them right away. This will help the brake work safely every time you use it.

How Can Improper Use Of A Foot Brake Affect The Quality Of The Finished Workpiece In Lathe Machining?Using the foot brake incorrectly on a lathe can mess up the workpiece. If you stop the machine too quickly, it can cause extra bumps or scratches on the surface. This means the finished piece won’t be smooth or look nice. It’s important to use the brake gently to keep everything neat. A good finish makes your work better!

What Are The Common Issues That May Arise With A Foot Brake Mechanism On A Metal Lathe, And How Can They Be Resolved?Common issues with a foot brake on a metal lathe are squeaking sounds, brakes not stopping, or sticking. If the brake squeaks, you can check if it needs oil. If it doesn’t stop well, something might be loose, so tighten the parts. If it sticks, cleaning the brake helps it move freely. Always ask for help from an adult when working on machines!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Lathe Machining And Metal Lathe Foot Brakes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. We use it to make things like tools or parts for machines. A foot brake on a lathe is a special pedal you press. It stops the lathe quickly for safety. Always remember to use it when you finish working!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just send me the question you want me to answer, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Foot Brake On A Metal Lathe Compared To Other Braking Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A foot brake on a metal lathe lets you stop the machine quickly with your foot. This keeps your hands free to keep working. It is easy to use and helps you control what you’re doing. Using a foot brake can also make it safer because you can stop faster if there’s a problem. Overall, it makes operating the lathe simpler and more efficient.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Foot Brake Contribute To Operator Safety And Machine Control During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a foot brake helps keep you safe when using a lathe. When you press the brake, it quickly stops the machine. This helps you avoid accidents and gives you better control. You can use both hands for work, keeping your focus on the job. A good foot brake makes lathe operations easier and safer for everyone.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Proper Functionality Of A Foot Brake On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake on a metal lathe working well, you should check it often. Make sure it is clean and free of dust or dirt. You can also make sure that all parts move smoothly and nothing is stuck. If you notice any problems, fix them right away. This will help the brake work safely every time you use it.”}},{“@type”: “Question”,”name”: “How Can Improper Use Of A Foot Brake Affect The Quality Of The Finished Workpiece In Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the foot brake incorrectly on a lathe can mess up the workpiece. If you stop the machine too quickly, it can cause extra bumps or scratches on the surface. This means the finished piece won’t be smooth or look nice. It’s important to use the brake gently to keep everything neat. A good finish makes your work better!”}},{“@type”: “Question”,”name”: “What Are The Common Issues That May Arise With A Foot Brake Mechanism On A Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common issues with a foot brake on a metal lathe are squeaking sounds, brakes not stopping, or sticking. If the brake squeaks, you can check if it needs oil. If it doesn’t stop well, something might be loose, so tighten the parts. If it sticks, cleaning the brake helps it move freely. Always ask for help from an adult when working on machines!”}}]}