Have you ever seen a lathe in action? It’s fascinating to watch! A lathe is a special machine that shapes metal and creates cool things like gears. Imagine turning a block of metal into a perfectly shaped gear. It’s like magic, but it’s science and skill.

Lathe machining isn’t just for professionals. Many hobbyists love to use metal lathes. They create everything from art pieces to practical tools. But why do they love working with gear on a lathe? It’s because they can make parts that fit together perfectly.

But here’s a fun fact: did you know that the basic principles of lathe machining have been around for thousands of years? The lathe has evolved, but the process remains the same. It still takes creativity and practice to master this craft.

So, whether you’re a curious beginner or a seasoned expert, lathe machining has something for everyone. Are you ready to dive into the world of metal lathes and gears? Let’s explore the exciting possibilities together!

Lathe Machining: Exploring Metal Lathe Gear Techniques

Lathe Machining: Metal Lathe Gear Explained

Lathe machining is a fascinating process used in crafting metal parts. A metal lathe gear plays a crucial role in this technique, allowing precise shapes. Picture a clock’s gear; it helps keep everything running smoothly. Understanding how lathe machines work opens doors to creativity in metalwork. Did you know that a lathe can turn a block of metal into art? It’s like magic, but it’s all about skill and gears! Discover the wonders of lathe machining today!What is Lathe Machining?

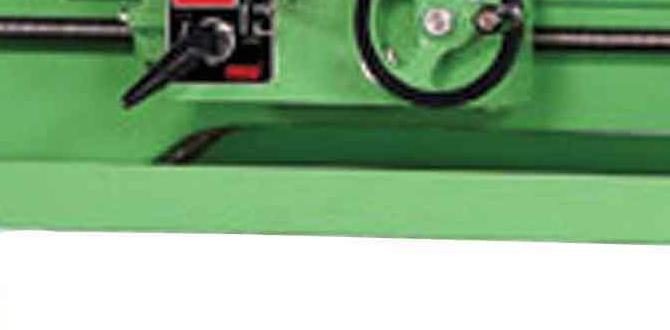

Definition and basic principles of lathe machining. Types of lathe machines and their applications.Lathe machining is like the hairdresser for metal. It shapes and cuts materials into precise forms. Imagine spinning a piece of metal while carving it—voilà, that’s what happens! There are different types of lathes, each with their own special jobs. For example, a wood lathe is great for making furniture legs, while a metal lathe handles tougher tasks. Check out the table below for some fun facts about each type:

| Type of Lathe | Application |

|---|---|

| Wood Lathe | Shaping wood items like bowls and furniture parts. |

| Metal Lathe | Machining metal for gears, shafts, and more. |

| CNC Lathe | Automated precision work for complex designs. |

In short, lathe machining is essential for crafting all sorts of items. Next time you see something nicely shaped, remember: it might just be a lathe’s magic at work!

The Importance of Metal Lathes

Advantages of using metal lathes in machining processes. Industries that rely heavily on metal lathes.Metal lathes play a crucial role in shaping metal parts. They allow workers to create precise parts quickly and efficiently. This is why many industries depend on them. The advantages of using metal lathes include:

- High accuracy in shaping materials

- Ability to produce complex shapes

- Increased production speed

Industries like automotive, aerospace, and manufacturing rely heavily on metal lathes. They help create everything from car engines to airplane parts.

What industries use metal lathes?

Common industries include automotive, aerospace, and machinery manufacturing. These fields need precision and speed, and metal lathes provide that.

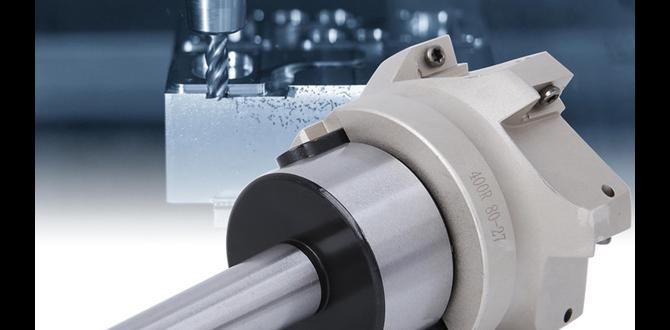

Understanding Gears in Lathe Machining

Types of gears used in metal lathes. The role of gears in the lathe machining process.Gears are the unsung heroes of lathe machining. They help control speed and movement, making cutting smooth like butter. Common types include spur gears, bevel gears, and worm gears. Each has a special job, kind of like a superhero team. Spur gears move in a straight line, while bevel gears can twist like a pretzel!

| Type of Gear | Purpose |

|---|---|

| Spur Gears | Transfer power directly |

| Bevel Gears | Change direction of motion |

| Worm Gears | Provide high torque |

These gears ensure everything runs smoothly. Without them, machining could turn into a chaotic circus act! So, next time you see a lathe, remember its gears are like a well-rehearsed dance troupe, keeping everything in rhythm.

Choosing the Right Lathe for Your Needs

Factors to consider when selecting a metal lathe. Comparison of different models based on features and performance.Selecting the perfect lathe requires some thought. First, consider your needs. Are you making tiny toys, or are you crafting big pieces? Then, check out different models and their features. Some lathes are like sports cars—fast and flashy—while others are like trusty school buses. They get the job done but aren’t winning any races! Here’s a quick comparison to help you choose:

| Model | Max Speed | Weight | Price |

|---|---|---|---|

| Lathe A | 2000 RPM | 150 lbs | $500 |

| Lathe B | 1500 RPM | 200 lbs | $700 |

| Lathe C | 2500 RPM | 100 lbs | $900 |

Based on your projects, choose wisely! A good lathe will help turn your ideas into shiny metal wonders.

Lathe Machining Techniques

Common machining techniques (turning, facing, boring, etc.). Best practices for optimizing machining outcomes.Lathe machining uses various techniques to shape metal. Common methods include turning, facing, and boring. Each method has a unique purpose. Turning shapes the outer side of the metal. Facing smooths flat surfaces. Boring enlarges holes accurately. Using the right speed and feed rate leads to better results.

- Keep tools sharp for clean cuts.

- Always check measurements for accuracy.

- Use proper coolant to reduce heat.

What is turning in lathe machining?

Turning is a technique that shapes the outer surfaces of a workpiece. It spins the material against a cutting tool for precise shaping. This method is widely used in creating cylindrical parts.

Maintenance of Metal Lathes

Routine maintenance tasks to ensure longevity. Troubleshooting common issues with lathe machines.Keeping your metal lathe in tip-top shape is like giving it a spa day. Regular checks and clean-ups can prevent major headaches later. Wipe off dust and oil, and always check for loose screws. If it starts making weird noises, don’t ignore it! That squeak could mean trouble. For common hiccups, like sticky gears or shaky parts, refer to this table for quick fixes:

| Problem | Solution |

|---|---|

| Squeaky noise | Lubricate the gears |

| Uneven cuts | Check tool alignment |

| Stuck parts | Clean and oil regularly |

With a little care, your lathe will be the happiest tool in the shop! Think of it as giving your lathe a donut – it’ll run smoother and longer!

Future Trends in Lathe Machining

Innovations impacting metal lathe technology. The role of automation and CNC in lathe machining advancements.Exciting changes are coming to lathe machining! New technologies are making metal lathes smarter and faster. Innovations like CNC technology allow machines to work with less human help. This saves time and money. Automation is changing how we make things. It can complete complex tasks easily and quickly. This means better products for everyone.

- Smarter controls for precision.

- Less manual effort needed.

- Faster production times.

- More opportunities for creativity in design.

What are some important innovations in lathe machining?

Important innovations in lathe machining include CNC technology and automation. These advancements help machines work better and faster.

Conclusion

In conclusion, lathe machining involves shaping metal using a machine called a lathe. You can create gears and other parts easily. Understanding how to use a metal lathe boosts your skills. We encourage you to explore hands-on projects and tutorials online. Practice is key to mastering lathe machining. Grab some materials and start creating your own designs today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathes And Gears:Sure! Here are five questions about metal lathes and gears: 1. **What is a metal lathe?** A metal lathe is a machine that shapes metal. It spins the metal while tools cut it into the right shape. 2. **How do we use a lathe to make gears?** We place a metal piece on the lathe, then use special tools to cut out the gear shape. 3. **What materials can we use in a lathe?** You can use different metals like aluminum or steel. They help us make strong parts. 4. **Why is safety important when using a lathe?** It’s important to stay safe because the lathe can be dangerous. Always wear safety goggles and follow rules. 5. **Can we make other things with a lathe?** Yes! You can make many things like tools, parts for machines, or even small toys.

Sure! Please give me the question you’d like me to answer.

What Are The Key Differences Between A Metal Lathe And A Wood Lathe In Terms Of Design And Functionality?A metal lathe is built to shape hard materials like metal. It has stronger parts to handle tough jobs. A wood lathe is lighter and made for softer materials like wood. It can turn shapes quickly and easily. You can use each lathe for different projects!

How Do You Determine The Appropriate Cutting Speed And Feed Rate When Machining Gears On A Metal Lathe?To find the right cutting speed and feed rate for making gears, you start with the type of metal. Each metal needs a different speed. You can use a chart or calculator to find these numbers. Then, you set your metal lathe to those speeds and rates. It’s like following a recipe for the best results!

What Are The Common Materials Used For Manufacturing Gears On A Metal Lathe, And How Do Their Properties Affect The Machining Process?We often use steel, aluminum, and brass to make gears on a metal lathe. Steel is super strong but can be tough to cut. Aluminum is easier to shape but isn’t as strong. Brass is nice because it doesn’t rust easily, making it good for some projects. The choice of material affects how quickly and easily we can make the gears.

What Tooling And Setup Are Required For Turning And Shaping Gear Teeth Accurately On A Metal Lathe?To make gear teeth on a metal lathe, you need a few important tools. First, you’ll use a tool called a gear cutting tool. This helps shape the teeth. Next, you need a way to hold your metal piece, like a chuck. Finally, you must set the lathe’s speed and angle just right. Together, these tools help you create accurate gear teeth.

What Are The Advantages Of Using A Cnc Metal Lathe For Gear Machining Compared To A Manual Lathe?Using a CNC (Computer Numerical Control) metal lathe makes gear machining easier and more precise. You can create complex shapes that a manual lathe might struggle with. CNC lathes also work faster, so you can make more gears in less time. Plus, they repeat the same cuts perfectly every time, which helps keep everything uniform. Overall, CNC lathes help you make better gears with less effort.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathes And Gears:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about metal lathes and gears: 1. **What is a metal lathe?** A metal lathe is a machine that shapes metal. It spins the metal while tools cut it into the right shape. 2. **How do we use a lathe to make gears?** We place a metal piece on the lathe, then use special tools to cut out the gear shape. 3. **What materials can we use in a lathe?** You can use different metals like aluminum or steel. They help us make strong parts. 4. **Why is safety important when using a lathe?** It’s important to stay safe because the lathe can be dangerous. Always wear safety goggles and follow rules. 5. **Can we make other things with a lathe?** Yes! You can make many things like tools, parts for machines, or even small toys.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Metal Lathe And A Wood Lathe In Terms Of Design And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe is built to shape hard materials like metal. It has stronger parts to handle tough jobs. A wood lathe is lighter and made for softer materials like wood. It can turn shapes quickly and easily. You can use each lathe for different projects!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Cutting Speed And Feed Rate When Machining Gears On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right cutting speed and feed rate for making gears, you start with the type of metal. Each metal needs a different speed. You can use a chart or calculator to find these numbers. Then, you set your metal lathe to those speeds and rates. It’s like following a recipe for the best results!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Manufacturing Gears On A Metal Lathe, And How Do Their Properties Affect The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We often use steel, aluminum, and brass to make gears on a metal lathe. Steel is super strong but can be tough to cut. Aluminum is easier to shape but isn’t as strong. Brass is nice because it doesn’t rust easily, making it good for some projects. The choice of material affects how quickly and easily we can make the gears.”}},{“@type”: “Question”,”name”: “What Tooling And Setup Are Required For Turning And Shaping Gear Teeth Accurately On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make gear teeth on a metal lathe, you need a few important tools. First, you’ll use a tool called a gear cutting tool. This helps shape the teeth. Next, you need a way to hold your metal piece, like a chuck. Finally, you must set the lathe’s speed and angle just right. Together, these tools help you create accurate gear teeth.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Cnc Metal Lathe For Gear Machining Compared To A Manual Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a CNC (Computer Numerical Control) metal lathe makes gear machining easier and more precise. You can create complex shapes that a manual lathe might struggle with. CNC lathes also work faster, so you can make more gears in less time. Plus, they repeat the same cuts perfectly every time, which helps keep everything uniform. Overall, CNC lathes help you make better gears with less effort.”}}]}