Have you ever wondered how everyday metal parts are made? Imagine a perfectly shaped piece of metal, spinning smoothly as it gets cut and shaped. This is where lathe machining comes in. It uses a special tool called a metal lathe to create amazing items, from car parts to jewelry.

But what powers this incredible machine? That’s right! The lathe motor drives the whole process. Without it, the lathe wouldn’t spin, and shaping metal would be impossible.

Many people think that machining is complicated. But in reality, it’s a blend of art and science. When you use a lathe, you can watch metal change right before your eyes. Have you ever seen metal shavings fly while a lathe works? It’s fascinating!

In this article, we will explore how lathe machining works. We’ll discuss the different types of lathes and the motors that make them run smoothly. Get ready to dive into the world of metal shaping!

Lathe Machining: Exploring The Metal Lathe Motor Benefits

Understanding Lathe Machining and Motor Basics

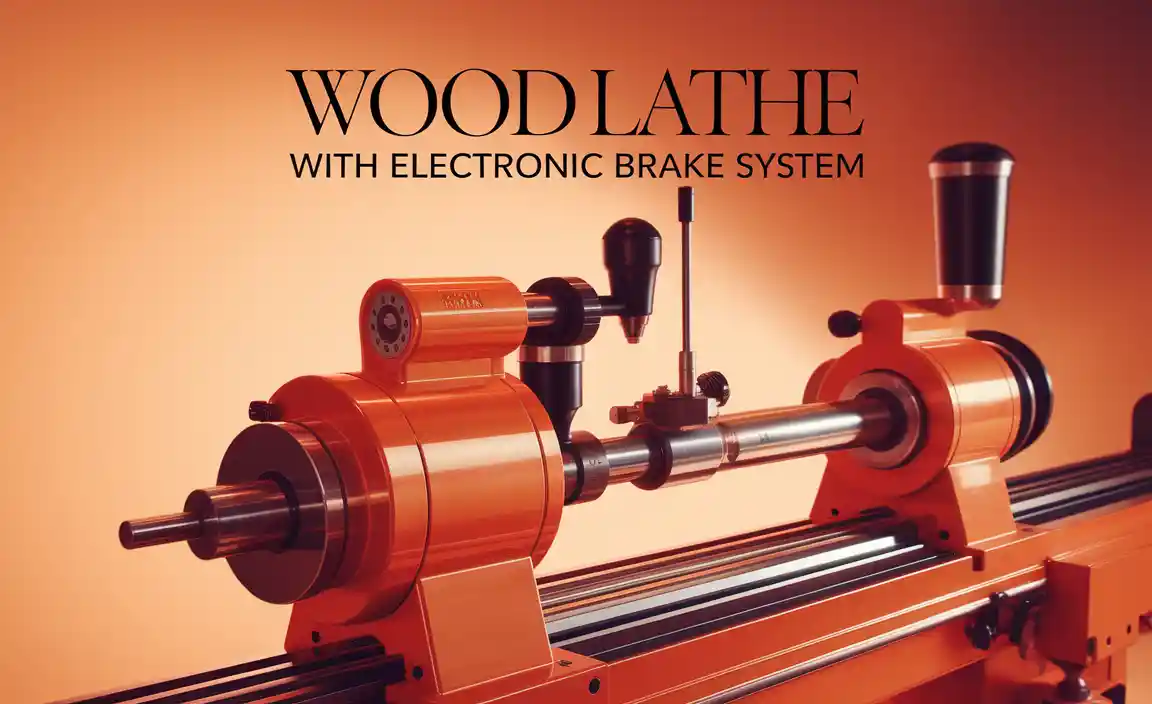

Lathe machining uses a metal lathe motor to shape materials into precise forms. Ever wonder how metal parts get their smooth edges? The lathe machine spins metal while cutting tools carve it into the desired shape. Whether you’re making complex designs or simple pieces, every project benefits from this technology. With a good motor, the lathe can operate smoothly and efficiently, making it a go-to for hobbyists and professionals alike. Using a lathe can turn your creative ideas into reality!What is a Metal Lathe?

Definition and purpose of metal lathes.. Types of metal lathes and their applications..A metal lathe is a machine that spins metal to shape it. It can make cool stuff like car parts or even tools. Imagine a giant pencil sharpener, but instead of wood, it works with metal. There are different types of metal lathes, each with its own special jobs. Some are small and perfect for home projects, while others are huge and found in factories. These machines help create precise items that make our lives easier.

| Type of Metal Lathe | Application |

|---|---|

| Engine Lathe | Making precise parts and tools |

| Turret Lathe | High volume production of identical items |

| CNC Lathe | Automatic machining with computer control |

Understanding Lathe Motors

Explanation of what a lathe motor is and its role in lathe operation.. Different types of motors used in metal lathes (AC, DC, stepper, and servo motors)..A lathe motor is the heart of a lathe machine. It powers the cutting tools that shape metal into desired forms. Without it, a lathe would just be a fancy paperweight! There are different types of motors that can be used in metal lathes. They include AC, DC, stepper, and servo motors. Each type has unique strengths, like speed or control.

| Motor Type | Key Feature |

|---|---|

| AC Motor | Reliable and efficient for steady operations. |

| DC Motor | Great for speed control and variable operations. |

| Stepper Motor | Moves in precise steps, perfect for detailed work. |

| Servo Motor | Offers high performance and accuracy in control. |

Choosing the right motor can be like picking a favorite ice cream flavor. Each has its own taste! So, understanding lathe motors is essential for creating beautiful metalwork.

How to Choose the Right Lathe Motor

Factors to consider: horsepower, speed, and torque.. Recommendations based on specific applications and user experience..Choosing the right motor for your lathe is important. Focus on three main factors: horsepower, speed, and torque. Horsepower affects the power the motor can deliver. More power is great for tougher materials. Speed lets you work quickly. Match it to your projects. Lastly, consider torque. High torque is best for heavy cutting tasks. Always read user reviews too. They help you see how motors perform in real life. Here are some tips:

- For small tasks, 1-2 HP is enough.

- For heavy jobs, look for 3-5 HP.

- Higher speeds are better for lighter materials.

What factors should I consider when choosing a lathe motor?

You should consider horsepower, speed, and torque. These factors are key to matching the motor with your lathe’s tasks and your needs.

Maintenance Tips for Lathe Motors

Importance of regular maintenance to ensure optimal performance.. Stepbystep maintenance practices for longevity of the motor..Taking care of your lathe motor is like giving it a good hug! Regular maintenance keeps it happy and working well. Think of it as a spa day for machines!

To keep your motor in tip-top shape, follow these simple steps:

| Maintenance Task | Frequency | Why It’s Important |

|---|---|---|

| Clean the motor | Weekly | Prevents dust buildup and overheating |

| Check for loose parts | Monthly | Keeps everything secure and safe |

| Lubricate moving parts | Every 6 months | Ensures smooth operation |

| Inspect electrical connections | Annually | Prevents electrical issues |

These tips can make your lathe motor last longer and perform better. Remember, a happy motor means fewer headaches for you! Who knew maintenance could be this fun?

Upgrading Your Lathe Motor

Signs that it may be time to upgrade your motor.. Benefits of upgrading and how to choose a suitable replacement..Noticing your lathe motor slowing down? It might be time for an upgrade! Signs include strange noises, overheating, or jerky movements. A new motor can boost performance and save you from machine tantrums. Choosing the right replacement is key. Match your motor’s power to your projects. Remember, a happy machine makes for happy machining! Here’s a handy table to help you decide:

| Signs It’s Time | Benefits of Upgrading | Choosing a Replacement |

|---|---|---|

| 1. Strange noises | Increased efficiency | Match power ratings |

| 2. Overheating | Longer lifespan | Consider brand compatibility |

| 3. Jerky operations | Smoother operations | Check features needed |

Safety Considerations When Using Metal Lathes

Essential safety precautions while operating lathes.. Recommendations for protective gear and best practices..Using a metal lathe can be exciting, but safety comes first! Always wear protective gear, like goggles and gloves, to shield yourself from flying metal chips. Don’t forget to keep loose clothing and long hair away from the machine; you wouldn’t want to become a “tangled tool!” Follow these essential precautions to stay safe while having fun in the shop.

| Protective Gear | Best Practices |

|---|---|

| Safety goggles | Keep the workspace tidy |

| Gloves | Check tools are secure |

| Dust mask | Avoid distractions |

Psst! Remember: even a well-oiled machine can cause trouble if not handled correctly. Keep an eye on your work and always be aware of your surroundings!

Conclusion

In conclusion, lathe machining with a metal lathe motor is an exciting skill. It helps you shape metal into useful parts. You can create everything from simple tools to complex designs. Remember to practice safely and regularly. If you want to learn more, check out tutorials or classes. Discover the amazing projects you can create with your new skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathe Motors:Sure! Here are five questions about lathe machining and metal lathe motors: 1. What is a lathe? A lathe is a machine that spins metal. It helps us shape the metal into different forms. 2. How does a metal lathe motor work? The metal lathe motor makes the lathe spin. This helps cut and shape the metal pieces. 3. Why are motors important for lathes? Motors provide the power needed for spinning. Without them, lathes can’t shape metal at all. 4. What can you make with a lathe? You can make things like table legs, knobs, and parts for machines. It helps in creating many items! 5. How do you take care of a lathe motor? You should keep it clean and check for problems. It helps the motor work better and last longer.

Sure! Please give me the question you’d like me to answer.

What Are The Different Types Of Motors Used In Metal Lathes And How Do They Affect Machining Performance?Metal lathes use different types of motors to help shape and cut metal. The common types are AC (Alternating Current) and DC (Direct Current) motors. AC motors are good for steady work, while DC motors can change speed easily. The right motor helps you work faster and make better cuts. So, the type of motor can really affect how well you can machine your metal pieces!

How Can The Speed And Torque Of A Metal Lathe Motor Influence The Types Of Materials That Can Be Effectively Machined?The speed and torque of a metal lathe motor help us decide what materials we can cut. High speed is good for soft materials like plastic and aluminum. If the motor has high torque, it can handle tougher materials like steel. So, if we know our motor’s speed and torque, we can pick the right materials to work with.

What Are The Common Maintenance Practices For Ensuring The Longevity And Efficiency Of A Metal Lathe Motor?To keep your metal lathe motor working well, you should follow some easy steps. First, always keep it clean by wiping off dust and debris. Next, check and tighten any loose screws or parts regularly. Lubricate moving parts with oil to help them move smoothly. Lastly, make sure the motor is not overheating by checking it often. These simple tasks will help your motor last longer!

How Do Variable Speed Motors In Metal Lathes Enhance The Versatility Of Machining Operations?Variable speed motors in metal lathes let you change how fast the machine works. You can go slow or fast, depending on what you are making. This means you can cut different types of materials easily. With more speed options, you can do many different tasks and make your projects better. It helps you create a variety of shapes and sizes!

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Powerful Motor To Prevent Accidents And Injuries?When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothing to prevent them from getting caught. Keep your hands clear of the spinning parts. Make sure to use the machine in a clean area to avoid trips and falls. Finally, read the instructions before starting and ask for help if you’re unsure.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathe Motors:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe machining and metal lathe motors: 1. What is a lathe? A lathe is a machine that spins metal. It helps us shape the metal into different forms. 2. How does a metal lathe motor work? The metal lathe motor makes the lathe spin. This helps cut and shape the metal pieces. 3. Why are motors important for lathes? Motors provide the power needed for spinning. Without them, lathes can’t shape metal at all. 4. What can you make with a lathe? You can make things like table legs, knobs, and parts for machines. It helps in creating many items! 5. How do you take care of a lathe motor? You should keep it clean and check for problems. It helps the motor work better and last longer.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Motors Used In Metal Lathes And How Do They Affect Machining Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different types of motors to help shape and cut metal. The common types are AC (Alternating Current) and DC (Direct Current) motors. AC motors are good for steady work, while DC motors can change speed easily. The right motor helps you work faster and make better cuts. So, the type of motor can really affect how well you can machine your metal pieces!”}},{“@type”: “Question”,”name”: “How Can The Speed And Torque Of A Metal Lathe Motor Influence The Types Of Materials That Can Be Effectively Machined?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The speed and torque of a metal lathe motor help us decide what materials we can cut. High speed is good for soft materials like plastic and aluminum. If the motor has high torque, it can handle tougher materials like steel. So, if we know our motor’s speed and torque, we can pick the right materials to work with.”}},{“@type”: “Question”,”name”: “What Are The Common Maintenance Practices For Ensuring The Longevity And Efficiency Of A Metal Lathe Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe motor working well, you should follow some easy steps. First, always keep it clean by wiping off dust and debris. Next, check and tighten any loose screws or parts regularly. Lubricate moving parts with oil to help them move smoothly. Lastly, make sure the motor is not overheating by checking it often. These simple tasks will help your motor last longer!”}},{“@type”: “Question”,”name”: “How Do Variable Speed Motors In Metal Lathes Enhance The Versatility Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed motors in metal lathes let you change how fast the machine works. You can go slow or fast, depending on what you are making. This means you can cut different types of materials easily. With more speed options, you can do many different tasks and make your projects better. It helps you create a variety of shapes and sizes!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Powerful Motor To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothing to prevent them from getting caught. Keep your hands clear of the spinning parts. Make sure to use the machine in a clean area to avoid trips and falls. Finally, read the instructions before starting and ask for help if you’re unsure.”}}]}