Have you ever wondered how metal parts are made? Let’s dive into the fascinating world of lathe machining! Lathe machining is a popular way to shape metal parts. It uses a machine called a lathe. This tool spins the metal while a sharp blade cuts it into the desired shape.

Picture this: a small piece of metal that slowly transforms into a smooth cylinder. That’s lathe machining in action! It’s amazing how simple movements can create intricate designs. Whether it’s for car parts or tools, lathe machining plays a vital role in our everyday lives.

Fun fact: the lathe is one of the oldest machines used by humans! Invented thousands of years ago, it has evolved but remains essential. In this article, we will explore various aspects of lathe machining and its importance in creating metal lathe parts. Get ready to discover how this incredible process works!

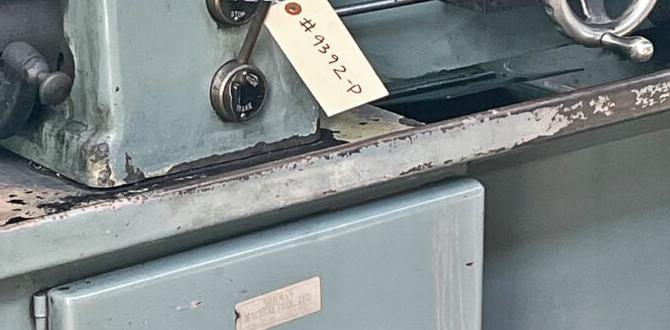

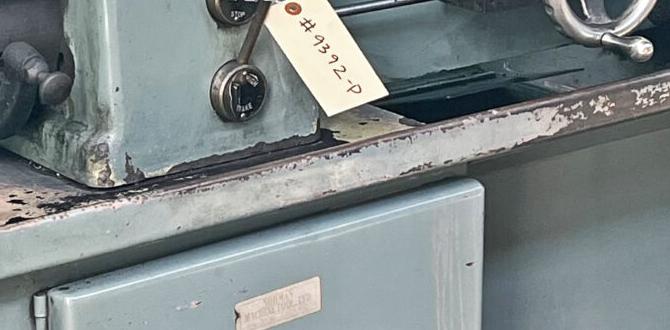

Lathe Machining: Essential Metal Lathe Parts Explained Lathe Machining Is A Vital Process In Manufacturing, Allowing For The Precision Shaping And Cutting Of Various Materials, Primarily Metals. It Involves The Use Of A Lathe Machine, Which Rotates The Workpiece Against Cutting Tools To Produce Desired Shapes And Dimensions. Understanding The Essential Components Of A Lathe Can Help Optimize Your Machining Operations. Key Components Of Metal Lathe Parts 1. **Bed**: The Foundation Of The Machine, Supporting All Other Parts And Providing Stability During Operation. 2. **Headstock**: This Is Where The Motor And Spindle Are Housed. It Drives The Workpiece And Allows For Speed Adjustments. 3. **Tailstock**: Located Opposite The Headstock, It’S Used For Supporting The Other End Of The Workpiece And Can Hold Drill Bits And Other Tools. 4. **Carriage**: This Assembly Moves The Cutting Tool Along The Workpiece. It Includes The Cross-Slide And The Saddle. 5. **Cross-Slide**: Part Of The Carriage, It Allows The Cutting Tool To Move Side To Side, Providing Depth Control. 6. **Apron**: Attached To The Front Of The Carriage, It Houses Controls For Engaging The Feeds And Back Gears. 7. **Tool Post**: A Holder For The Cutting Tools, Allowing For Easy Switching And Securing Of Tools. 8. **Chuck**: The Component That Holds The Workpiece In Place, Crucial For Stability During Machining. Benefits Of Using A Lathe For Machining Metal – **Precision**: Lathes Can Create Highly Accurate And Repeatable Shapes. – **Versatility**: Suitable For Various Materials, Making Them Ideal For Different Projects. – **Efficiency**: Capable Of Producing Complex Parts In A Relatively Short Time. Conclusion Understanding The Different Metal Lathe Parts And How They Work Together Can Greatly Enhance Your Lathe Machining Experience. Proper Maintenance And Familiarity With Each Component Can Lead To Improved Efficiency And Quality In Your Machining Projects.

Lathe Machining: Metal Lathe Parts Explained

Lathe machining shapes metal parts with precision. A metal lathe uses tools to cut, sand, or drill materials. It spins the metal while tools carve into it, creating detailed shapes. Did you know that lathes have been around for thousands of years? They revolutionized metalworking! Understanding which parts make up a lathe can help you use this machine better. Key components include the bed, tailstock, and carriage. Each part plays a vital role in creating perfect metal pieces.Types of Lathes

Description of different types: Engine lathe, Turret lathe, CNC lathe. Pros and cons of each type.When it comes to turning metal into art, lathes are your trusty sidekicks! There are three main types: the Engine lathe, Turret lathe, and CNC lathe. Each has its own tricks. The Engine lathe is like a classic rock band—great for many tasks but requires a skilled operator. The Turret lathe is faster, like a speeding car, good for repeated jobs, but it might be a bit bulky. Finally, the CNC lathe is the tech whiz, precise and automated, but can be costly. Choose wisely!

| Type of Lathe | Pros | Cons |

|---|---|---|

| Engine Lathe | Versatile and simple to use! | Requires skilled operators. |

| Turret Lathe | Fast for repetitive work! | Can occupy more space. |

| CNC Lathe | Super precise and automated. | Expensive to maintain. |

Key Components of Metal Lathe Parts

Detailed description of essential lathe parts such as bed, headstock, tailstock. Functionality of each component in machining processes.Metal lathes have several key components that work together like a perfect team. The bed is the sturdy foundation where everything rests, making sure your work doesn’t wobble during machining. Next is the headstock, which holds the main spindle and motor, ready to spin your metal like a DJ at a dance party! Then we have the tailstock, which supports the other end of your workpiece. It moves easily to help with drilling and other tasks. These parts are essential for creating precise shapes and sizes, ensuring your project turns out just right!

| Component | Function |

|---|---|

| Bed | Provides stability for the lathe |

| Headstock | Holds the spindle and drives the workpiece |

| Tailstock | Supports the workpiece and allows for drilling |

Choosing the Right Metal Lathe

Factors to consider: Size, Capacity, Type of materials. Recommendations for different user needs (hobbyists vs. professionals).Picking the right metal lathe is important. You need to think about three main factors:

- Size: Larger lathes handle bigger projects, while smaller ones are good for quick tasks.

- Capacity: Consider how much material you will work with. More capacity means more versatility.

- Type of materials: Some lathes work better with hard metals, while others are great for softer ones.

Hobbyists may prefer smaller, simpler machines. Professionals often choose larger models for complex jobs. Make your choice based on your needs!

What should I consider when choosing a lathe?

Understand your needs before selecting. Size, capacity, and material type are crucial. A good fit makes work easier and more enjoyable.

Maintenance of Lathe Machines

Importance of regular maintenance for longevity and performance. Common maintenance tips and practices.Taking care of lathe machines is very important for them to last. Regular maintenance helps these machines work better and longer. Here are some simple tips:

- Clean the machine often to remove dust and chips.

- Check the oil levels regularly.

- Tighten loose parts to avoid extra wear.

- Sharpen or replace dull cutting tools.

By following these steps, you can ensure your lathe continues to run well! Remember, a well-maintained machine works more efficiently.

What happens if lathe machines are not maintained?

If lathe machines are not regularly maintained, they can break down easily and have shorter lifespans. This can cause delays and extra costs for repairs.

Common Issues and Troubleshooting

Typical problems encountered during lathe machining. Solutions and troubleshooting techniques for common issues.Lathe machining can have some common problems. These issues might make your work tricky. Here are typical problems and solutions:

- Chatter: This causes a noisy vibration. To fix it, adjust the speed and feed rate.

- Tool wear: Dull tools can ruin parts. Regularly check your tools and replace them as needed.

- Misalignment: If the piece is off-center, it won’t cut properly. Always ensure your workpiece is well-placed.

- Surface finish issues: A rough surface isn’t nice. Use the correct speed and the right cutting tool for a smoother finish.

By knowing these problems, you can make better metal lathe parts easily!

What are common issues in lathe machining?

Common issues in lathe machining include vibration, dull tools, misalignment, and rough surfaces. These problems can affect the quality of your work badly.

Future Trends in Lathe Machining

Innovations in lathe technology and their impact on the industry. Predictions for the future of lathe machining practices.Exciting changes are on the horizon for lathe machining! New innovations are helping machines become faster and smarter. For example, many lathe machines now use advanced software to plan cuts more precisely. This means parts come out better and more quickly. In the near future, we might see machines that can learn on their own, like having a robot apprentice. Who wouldn’t want a metal-working buddy that doesn’t ask for breaks? It’s safe to say that lathe machining will become more efficient and maybe even a bit more fun!

| Innovation | Impact |

|---|---|

| Smart Software | Improved precision |

| AI Integration | Self-learning capabilities |

| Automation | Increased speed and efficiency |

Resources for Further Learning

Recommended books, online courses, and workshops for mastering lathe machining. Links to relevant organizations and communities for metalworking enthusiasts.If you want to learn more about lathe machining, there are some great resources available. Books can give you detailed knowledge. Online courses offer hands-on practice. Workshops help you meet experts and fellow learners. Here are some helpful resources:

- Books: “Machining Fundamentals” introduces essential concepts.

- Online Courses: Websites like Coursera and Udemy have great courses for beginners.

- Workshops: Check local community colleges for practical classes.

- Organizations: Join groups like the American Machinists’ Institute for tips and support.

By exploring these options, you can boost your skills in lathe machining metal lathe parts.

What books help with lathe machining?

Books like “Machining Fundamentals” provide a solid foundation for beginners and experts alike.

Where to find online classes?

Platforms like Coursera and Udemy offer many courses on lathe machining.

Conclusion

In conclusion, lathe machining is essential for shaping metal parts accurately. You can create strong, precise components for various projects. Understanding how to operate a metal lathe can be rewarding. We encourage you to explore hands-on practice or read more about lathe techniques. By improving your skills, you can enhance your metalworking abilities and tackle new challenges confidently.FAQs

Sure! Here Are Five Questions Related To Lathe Machining Metal Lathe Parts:Sure! Here are five questions about lathe machining for metal parts: 1. What is a lathe? A lathe is a machine that spins metal to shape it into different parts. 2. How does a lathe work? We put a piece of metal on the lathe, and it spins while tools cut it to make the shape we want. 3. What materials can we use on a lathe? We can use different types of metal like steel, aluminum, or brass for lathe work. 4. Why do we use lathes? We use lathes to make parts that fit together in machines, toys, and many other things. 5. Is it safe to use a lathe? Using a lathe can be safe if you follow instructions and wear protective gear like glasses.

Sure! Please provide the question you’d like me to answer.

What Are The Key Components Of A Metal Lathe, And How Do They Contribute To The Machining Process?A metal lathe has a few important parts. First, there’s the bed, which holds everything steady. The headstock holds the spinning piece of metal. The tailstock helps to keep the metal straight. Lastly, the tool rest holds the cutting tools in place. All these parts work together to shape metal into different objects.

What Types Of Materials Are Commonly Machined Using A Metal Lathe, And How Do Their Properties Affect The Machining Process?We commonly machine materials like steel, aluminum, and brass with a metal lathe. Steel is strong but can be hard to cut. Aluminum is lighter and easier to shape. Brass is shiny and soft, which makes it fun to work with. Each material’s toughness and softness change how we use the lathe.

How Do You Select The Appropriate Cutting Tools For Different Lathe Operations, Such As Turning, Facing, And Threading?To choose the right cutting tools for a lathe, you first look at the work you’re doing. For turning, you need a sharp tool that shapes the piece evenly. When facing, use a flat tool to make the end smooth. For threading, pick a tool designed to create grooves. Always make sure your tools are sharp and correct for the job!

What Are The Safety Precautions One Should Take While Operating A Metal Lathe To Prevent Accidents And Injuries?When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothing so nothing gets caught. Keep your hands away from moving parts to stay safe. Make sure the machine is turned off before you change tools or materials. Finally, always follow the rules and listen to your teacher or supervisor.

What Are The Common Defects Or Challenges Encountered During Lathe Machining, And How Can They Be Minimized Or Resolved?When we use a lathe to make parts, we can face some problems. One common issue is rough surfaces, which can happen if the tool is dull. To fix this, you should keep your tools sharp. Another challenge is getting the size wrong, which can be fixed by measuring carefully before cutting. Lastly, the machine might shake, causing mistakes. We can stop this by securing the parts and using the right speed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Machining Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe machining for metal parts: 1. What is a lathe? A lathe is a machine that spins metal to shape it into different parts. 2. How does a lathe work? We put a piece of metal on the lathe, and it spins while tools cut it to make the shape we want. 3. What materials can we use on a lathe? We can use different types of metal like steel, aluminum, or brass for lathe work. 4. Why do we use lathes? We use lathes to make parts that fit together in machines, toys, and many other things. 5. Is it safe to use a lathe? Using a lathe can be safe if you follow instructions and wear protective gear like glasses.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe, And How Do They Contribute To The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has a few important parts. First, there’s the bed, which holds everything steady. The headstock holds the spinning piece of metal. The tailstock helps to keep the metal straight. Lastly, the tool rest holds the cutting tools in place. All these parts work together to shape metal into different objects.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Commonly Machined Using A Metal Lathe, And How Do Their Properties Affect The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We commonly machine materials like steel, aluminum, and brass with a metal lathe. Steel is strong but can be hard to cut. Aluminum is lighter and easier to shape. Brass is shiny and soft, which makes it fun to work with. Each material’s toughness and softness change how we use the lathe.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Cutting Tools For Different Lathe Operations, Such As Turning, Facing, And Threading?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right cutting tools for a lathe, you first look at the work you’re doing. For turning, you need a sharp tool that shapes the piece evenly. When facing, use a flat tool to make the end smooth. For threading, pick a tool designed to create grooves. Always make sure your tools are sharp and correct for the job!”}},{“@type”: “Question”,”name”: “What Are The Safety Precautions One Should Take While Operating A Metal Lathe To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothing so nothing gets caught. Keep your hands away from moving parts to stay safe. Make sure the machine is turned off before you change tools or materials. Finally, always follow the rules and listen to your teacher or supervisor.”}},{“@type”: “Question”,”name”: “What Are The Common Defects Or Challenges Encountered During Lathe Machining, And How Can They Be Minimized Or Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a lathe to make parts, we can face some problems. One common issue is rough surfaces, which can happen if the tool is dull. To fix this, you should keep your tools sharp. Another challenge is getting the size wrong, which can be fixed by measuring carefully before cutting. Lastly, the machine might shake, causing mistakes. We can stop this by securing the parts and using the right speed.”}}]}