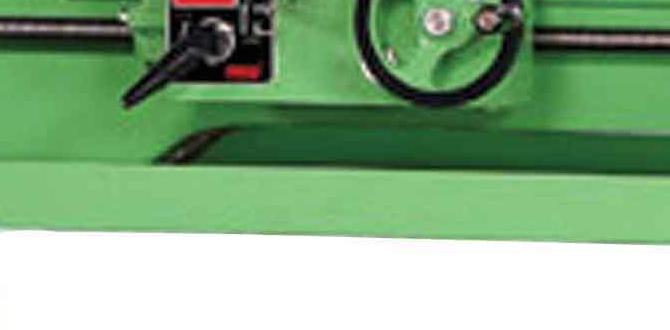

Have you ever watched a metal lathe spin? It’s pretty fascinating! These machines shape metal into perfect forms. Imagine turning a piece of metal into something useful, like a part for a car or a tool for a workshop. With a lathe, you can create amazing things.

One cool feature of lathes is the quick change tool post. This tool holder makes it easy to switch between different tools. Instead of wasting time, you can keep working smoothly. Ever felt frustrated by slow changes while working? The quick change tool post solves that problem.

In this article, we will explore lathe machining, focusing on the benefits of the quick change tool post. You’ll discover how it can improve your projects and save you time. Whether you’re a hobbyist or a professional, this knowledge can help you work smarter. Are you ready to learn more about this handy tool?

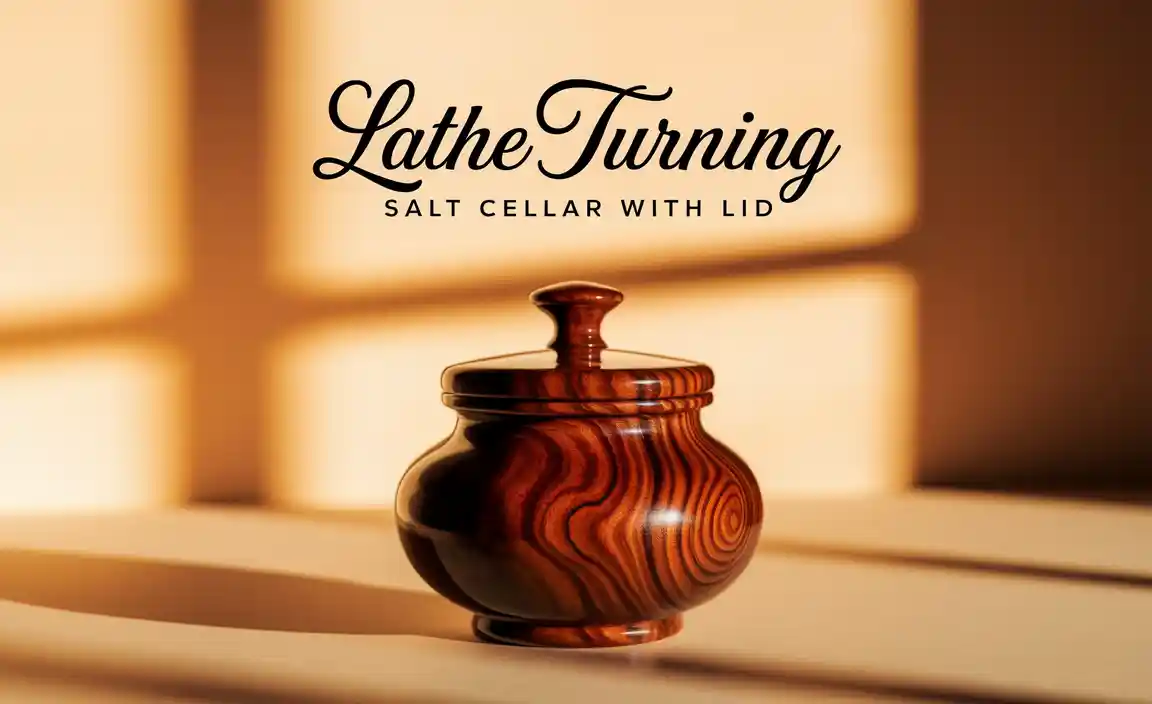

Lathe Machining: Metal Lathe Quick Change Tool Post Benefits

Lathe Machining: Metal Lathe Quick Change Tool Post

Lathe machining is essential for shaping metal. A quick change tool post makes this process easier. It allows you to swap tools without wasting time. Imagine working on a project, and needing a different tool in seconds! This tool post improves efficiency and precision. With it, you can create intricate designs faster. Whether you’re a hobbyist or a professional, investing in a quick change tool post can enhance your lathe experience significantly!The Basics of Metal Lathes

Components and functions of a metal lathe. Key features to consider when selecting a metal lathe.A metal lathe is a tool that shapes metal. It has several important parts. These include the headstock, tailstock, and carriage. The headstock holds the machine’s motor. The tailstock can support long pieces of metal. The carriage moves the cutting tool along the metal.

When choosing a metal lathe, consider:

- Size: Make sure it fits your workspace.

- Power: Higher power can handle tougher jobs.

- Speed: Different materials need different speeds.

- Tool posts: A quick change tool post saves time.

Choose wisely to get the best results.

What are the main parts of a metal lathe?

The main parts are the headstock, tailstock, and carriage. Each part plays a big role in how the lathe works. Understanding these parts helps with better use.

What is a Quick Change Tool Post?

Explanation of the quick change tool post and its purpose. Comparison between quick change tool posts and traditional tool holders.A quick change tool post makes swapping tools on a lathe super easy. Instead of fumbling like a toddler trying to tie shoes, you slide tools in and out quickly. This speeds up work, getting you back to shaping metal faster than you can say “lathe!”

In contrast to traditional tool holders, which can waste time, the quick change tool post is like a superhero for machinists. It grabs tools quickly, making projects smoother and often more fun. Here’s a quick side-by-side:

| Feature | Quick Change Tool Post | Traditional Tool Holder |

|---|---|---|

| Speed | Fast! | Slow |

| Ease of Use | Super easy! | Complicated |

| Efficiency | High! | Low |

Benefits of Using a Quick Change Tool Post

Timesaving advantages in setup and tool changes. Improved accuracy and repeatability in machining.Using a quick change tool post is like having a magic wand in your workshop! It saves time by letting you swap tools fast, so you can spend less time fiddling and more time creating. Also, it boosts accuracy and makes repeat cuts consistently. That means your projects come out looking sharp without a dozen do-overs. Remember, less time messing around means more time to impress your buddies with your latest masterpiece!

| Benefit | Why It Matters |

|---|---|

| Time-Saving | Quick tool changes speed up projects! |

| Improved Accuracy | Repeat cuts with confidence! |

Choosing the Right Quick Change Tool Post for Your Lathe

Factors to consider: compatibility, size, weight capacity. Popular brands and models in the market.Picking out a quick change tool post for your lathe can be a fun adventure! First, think about compatibility. Not all tool posts fit every lathe like a glove. Next is size—ensure it matches your machine. Weight capacity is crucial too. You want your tools to be strong enough to handle your projects without going on strike! Popular brands include Aloris, Dorian, and Phase II. They’re known for making quality tool posts. Check out the table below for some impressive models!

| Brand | Model | Weight Capacity |

|---|---|---|

| Aloris | AXA | 150 lbs |

| Dorian | DA Series | 200 lbs |

| Phase II | TP-250 | 250 lbs |

Installation Guide for Quick Change Tool Posts

Stepbystep installation process. Common mistakes to avoid during installation.Installing a quick change tool post can be fun, but it’s easy to mess up. First, secure the tool post firmly onto the lathe. Make sure to tighten those screws like you’re trying to impress a bolt. Next, check the alignment. You want your tools straight, not doing the cha-cha. Avoid over-tightening; it can break stuff! Here’s a quick table to guide you:

| Step | Action | Common Mistake |

|---|---|---|

| 1 | Attach tool post | Not tightening enough |

| 2 | Align the tool | Misalignment |

| 3 | Tighten screws | Over-tightening |

Remember, measure twice, screw once! Following these steps will help you avoid out-of-alignment tools. Plus, you’ll look like a pro!

Tips for Optimizing Tool Change Efficiency

Best practices for organizing tools and accessories. Techniques to streamline the workflow.Keeping your tools organized can save you time and frustration. Use labeled containers for your accessories—think of it as a treasure hunt where every tool is a shiny prize waiting to be found! Create a routine that makes grabbing tools as easy as pie. Want to speed things up? Consider using a quick change tool post. This nifty gadget can cut your tool-changing time in half. And don’t forget a checklist; it’s the secret sauce to a smooth workflow!

| Best Practices | Tips for Streamlining |

|---|---|

| Labeled storage | Routine for tool use |

| Regular cleaning | Quick change tool post |

| Tool checklists | Clear workspace |

So next time you’re wrestling with a tool change, remember these tips. It’s not just work, it’s an adventure in efficiency!

Maintenance and Care for Quick Change Tool Posts

Routine maintenance tasks to ensure longevity. Troubleshooting common issues and solutions.Keeping your quick change tool post in good shape is essential. Regular care helps it last longer and work better. Here are some simple tasks to do:

- Check for dirt and clean it regularly.

- Lubricate moving parts to reduce wear.

- Look for loose screws and tighten as needed.

- Inspect for rust or damage.

If you face issues, here are some quick fixes:

- If the tool post won’t lock, clean the locking mechanism.

- If it’s hard to move, add some lubricant.

- For uneven cuts, adjust the tool height.

By doing these tasks, your tool post will stay reliable!

How often should you maintain your tool post?

Cleaning and inspecting your tool post every month is a good practice. Regular maintenance keeps it working well.

What to do if there’s a problem?

Assess the issue, and refer to the troubleshooting list above for quick fixes. This can save time and effort!

Innovations in Lathe Machining Technologies

Recent advancements in lathe machining and tool post technologies. Future trends in the lathe machining industry.Lathe machining has seen exciting new changes. Tool post technology is now faster and easier to use. Recent upgrades allow quick tool changes, saving time in workshops. This boosts productivity. The future looks bright. Experts predict even smarter machines with better automation. They may allow for remote operation, making work simpler. These trends will help shape the industry’s growth and efficiency.

What are the latest advancements in lathe machining?

Recent advancements in lathe machining focus on speed and efficiency. Many machines now have automatic features. This allows operators to change tools quickly. This saves time and effort.

Key Advancements Include:

- Faster tool changes

- Smart technology integration

- Improved design for accuracy

Real-World Applications of Quick Change Tool Posts

Case studies from various industries using quick change tool posts. Testimonials and success stories from machinists.Many industries use quick change tool posts to make work easier. In manufacturing, companies have seen big improvements. For example, a car factory reduced tool change time by 30%. This saved money and time! Machinists share similar success stories.

- One machinist said, “These tool posts change my workflow!”

- Another noted, “I cut my setup time in half!”

Using quick change tool posts boosts efficiency. It helps workers finish jobs faster and creates high-quality products. These tools are changing the game in machining!

What is a quick change tool post and why is it important?

A quick change tool post is a device that allows machinists to change tools quickly and easily. This tool saves time during the machining process and improves productivity.

Conclusion

In conclusion, a lathe machining metal lathe with a quick change tool post saves time and boosts efficiency. You can easily switch tools, making your projects smoother. Whether you’re a beginner or an expert, this tool can enhance your work. Explore more about lathes and tool posts online. Start experimenting today, and enjoy the creativity of machining!FAQs

What Are The Advantages Of Using A Quick Change Tool Post On A Metal Lathe Compared To A Standard Tool Post System?Using a quick change tool post on a metal lathe is faster and easier than a standard tool post. You can switch tools quickly, which saves time. It also helps you set the tools at the right height easily. This lets you work better and finish projects faster. Overall, it makes your job simpler and more fun!

How Do You Properly Install And Align A Quick Change Tool Post On A Lathe Machine?To install a quick change tool post on a lathe, first, clean the top of the lathe’s bed. Then, place the tool post on top and use a wrench to tighten it. Next, you need to align it. Look at the tool’s position and adjust it until it’s straight and easy to use. Finally, check that everything is tight and secure before starting to work.

What Types Of Tooling Options Are Typically Compatible With Quick Change Tool Posts For Metal Lathes?Quick change tool posts for metal lathes work well with different tools. You can use turning tools, which shape the metal. Boring bars help make holes bigger. You can also attach parting tools to cut the metal. Each tool switches easily and saves time while you work.

Can A Quick Change Tool Post Improve Machining Efficiency And Accuracy, And If So, How?Yes, a quick change tool post can help you work faster and more accurately. You can switch tools easily without wasting time. This means you can finish your projects quicker. It also helps make better cuts, so your work looks nice. Overall, it’s a great way to improve your machine work!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Performance Of A Quick Change Tool Post?To keep a quick change tool post working well, you should clean it regularly. Dust and dirt can make it stick. You can also oil the moving parts to help them move smoothly. Always check for any worn-out parts and replace them if needed. Finally, store it in a safe place to avoid damage.