Have you ever wondered how metal objects are shaped and cut with such precision? Lathe machining is a fascinating process that does just that. Imagine a machine that spins a metal piece while a cutting tool shapes it. This is the magic of a metal lathe!

Torque plays a big role in how well this machine works. It’s like when you twist a bottle cap. The more force you use, the easier it comes off. Similarly, a lathe needs the right amount of torque to shape metal smoothly. Too much or too little can make a mess.

Here’s a fun fact: the oldest known lathes date back to ancient Egypt! They show how important this tool has always been. Today, lathe machining has advanced but still relies on those same basic principles. Curious to learn more about how this incredible machine operates? Let’s dive into the world of lathe machining and discover its secrets!

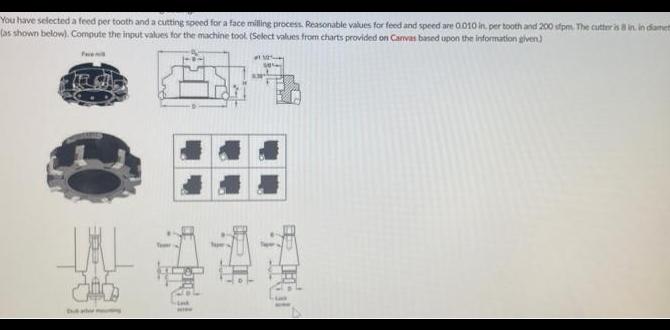

Lathe Machining: Understanding Metal Lathe Torque Essentials

Lathe Machining Metal Lathe Torque

Lathe machining uses metal lathes to shape materials precisely. But what about torque? Torque is the force that helps the lathe turn the material effectively. Proper torque leads to smooth cuts and better finishes. Have you ever tried cutting through tough metal? Without the right torque, it becomes very difficult! Understanding torque not only improves your skills but also makes the whole process smoother and more enjoyable. Discovering this can make anyone’s metalworking experience a lot better!The Importance of Torque in Metal Lathes

Explanation of torque and its role in machining processes. How torque affects cutting performance and material removal rates.Torque is the turning force that helps machines work. In metal lathes, torque is very important for cutting metal shapes. It determines how well the machine cuts through materials. Higher torque means better cutting performance. This helps to remove metal faster and more smoothly.

- Higher torque improves cutting speed.

- Torque affects how clean cuts are.

- More torque can handle tougher materials.

Understanding torque means better machining. It helps workers choose the right settings for their projects.

Why is torque vital for metal lathes?

Torque is crucial for effective metal machining. It ensures better performance and efficiency in the cutting process, leading to faster material removal rates.

Factors Influencing Torque in Metal Lathes

Machine design characteristics affecting torque output. Tooling and material considerations that impact torque.Several machine design features can impact the torque of a metal lathe. Factors like the motor size and the gear ratio play a huge role. Bigger motors pack more punch, while the right gear ratio can make any lathe feel like it’s on turbo mode. Tooling choices also matter. Stronger materials help the cutting tools maintain their shape and bite, leading to better torque. So, if you want your lathe to work like a superhero, pick your machine and tools wisely!

| Factor | Influence on Torque |

|---|---|

| Motor Size | More power equals more torque |

| Gear Ratio | Affects speed and torque delivery |

| Tool Material | Stronger materials reduce wear |

Measuring Torque in Lathe Operations

Techniques for measuring torque during machining. Tools and equipment used for torque measurement.Measuring torque helps us understand how much force is used during lathe operations. Several effective techniques exist for this purpose. You can use a torque wrench or a digital torque meter as tools for accurate readings. These devices ensure the correct amount of torque is applied to the workpiece, improving safety and efficiency.

- Torque Wrench

- Digital Torque Meter

- Torque Sensors

These tools provide reliable measurements, making machining smoother and more precise.

What are effective techniques for measuring torque?

Torque wrenches and digital torque meters are popular options. They help check the right amount of torque needed.

Optimal Settings for Torque in Lathe Machining

Recommended speeds and feeds for maximizing torque. Tips for adjusting machine settings for optimal performance.Getting the torque settings just right on a lathe is like finding the perfect recipe for cookies! You want to balance speed and feed to get the best results. A slow speed often equals more torque. For metals, aim for speeds around 600 to 1,200 RPM and adjust the feed rate accordingly. Remember, it’s all about trial and error—don’t be afraid to play with those dials! And if the machine isn’t performing well, just think of it as a cranky kid needing a nap!

| Material | Speed (RPM) | Feed Rate (inches/rev) |

|---|---|---|

| Aluminum | 1,200 | 0.05 |

| Steel | 600 | 0.03 |

| Brass | 1,000 | 0.04 |

Don’t forget to regularly check your settings! A well-tuned machine is like a happy dog—it performs better and with more energy. Keep adjusting until you find that sweet spot of torque for your project!

Common Problems Related to Insufficient Torque

Identifying symptoms of low torque in lathe operations. Solutions to overcome torquerelated issues.Low torque in lathe operations can cause headaches, and sometimes, your project may just shout, “Help!” Common signs include difficulty in cutting metal and uneven finishes. You might feel like you’re trying to slice bread with a dull butter knife—no fun!

To tackle these torque troubles, start by checking your lathe’s settings and ensuring everything is tight. If that doesn’t work, consider upgrading your motor or adding more weight to keep things steady. Think of it as giving your lathe a superhero cape!

| Symptoms of Low Torque | Solutions |

|---|---|

| Poor cutting accuracy | Adjust settings |

| Uneven surface finish | Upgrade motor |

| Slow feed rate | Add weight |

Remember, even lathes need a little love and care to keep spinning smoothly! Don’t let low torque ruin your metal masterpieces.

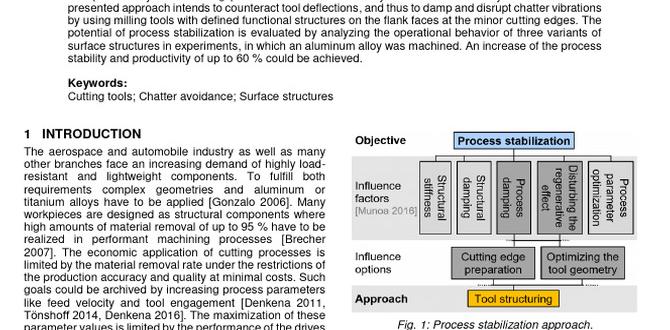

Advanced Techniques to Enhance Torque Output

Innovations in lathe technology for increased torque. Strategies for effective torque management during machining.New tools and features can give lathe machines a turbo boost in torque! Recent innovations focus on improving motor efficiency and gear designs. This helps keep the power flowing smoothly. Also, using the right cutting tools is key. They should match the material for less resistance. Isn’t that cool? Properly planning your machining process, like adjusting speed and feed rates, also helps manage torque better. Remember, Torque is your friend… unless you have a bad pun!

| Innovations | Benefits |

|---|---|

| Upgraded motors | Higher efficiency |

| Smart sensors | Real-time torque feedback |

| Customized tooling | Less resistance |

So, use these advanced techniques to enhance your lathe machining skills. The right mix can make all the difference in your torque output!

Case Studies: Successful Torque Optimization

Examples of industries benefiting from optimized torque in machining. Lessons learned from case studies on torque enhancement.Many industries have improved by using optimized torque in machining. For example, the automotive sector saw parts fitting better and lasting longer. The aerospace industry increased safety with sharper tools. Lessons from these successes include:

- Regular torque checks improve product consistency.

- Adjusting settings can enhance machine performance.

- Training workers increases efficiency and accuracy.

These case studies show that small changes can make a big difference in production.

What industries benefit from optimized torque in machining?

Industries like automotive, aerospace, and manufacturing see big gains from optimized torque. These fields improve tool life and product quality, leading to happier customers.

Future Trends in Lathe Machining and Torque Management

Anticipated advancements in lathe technology and torque applications. The role of automation and smart technology in enhancing torque efficiency.Exciting changes are on the horizon for lathe machining! As technology advances, metal lathes will become smarter and faster. Automation will play a huge role. Imagine machines that can think, making sure torque is just right—no more guesswork! This will help create better products with less waste. Plus, a future with torque management systems could save time and energy. Now that’s a win-win!

| Advancements | Benefits |

|---|---|

| Smart technology | Better efficiency |

| Automation | Less manpower needed |

| Advanced torque control | Fewer errors |

Conclusion

In conclusion, understanding lathe machining and the role of torque is essential. It helps you shape metal accurately. You can control the speed and power of your lathe for better results. Explore more about lathe techniques and practice on your own to gain hands-on experience. Remember, learning about lathe machining opens new possibilities for your projects!FAQs

Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Torque:Sure! A lathe is a machine that helps us shape metal. It spins the metal while we carefully cut it to make it smooth and round. Torque is the strength that helps turn the metal. The more torque, the easier it is to cut tough materials. So, with the right torque, we can create cool shapes from metal!

Sure! Please provide the question you would like me to answer.

What Factors Influence The Torque Requirements When Machining Different Metals On A Lathe?When you use a lathe to shape metal, the type of metal affects how much twisting force, or torque, you need. Softer metals, like aluminum, need less torque than harder metals, like steel. The speed at which you cut also matters; faster speeds require different torque. Finally, the thickness of the metal piece you’re working on can change the amount of torque needed.

How Can The Laws Of Physics, Such As Torque And Leverage, Be Applied To Optimize The Performance Of A Metal Lathe?To make a metal lathe work better, we can use physics ideas like torque and leverage. Torque helps us understand how much twisting force we need to turn the metal. Leverage helps us use longer handles to make it easier to push or pull. By using both, we can cut metal smoothly and save energy. This makes our work faster and more fun!

What Are The Common Methods For Calculating The Required Torque For Specific Lathe Operations, Such As Turning Or Facing?To find the required torque for lathe work, like turning or facing, you can use a simple formula. First, you need to know the power needed for the job. Then, you can use the formula: Torque = Power divided by Speed. Power is measured in watts, and speed is measured in RPM (revolutions per minute). By changing the power or speed, you can find the right torque for different tasks.

How Does Tool Geometry And Material Affect The Torque Needed During Metal Lathe Machining?The shape of the tool and what it’s made of can change how hard you need to twist the machine. If the tool has sharp edges and is made from a strong material, it cuts better. This means you won’t have to use as much force or torque. But if the tool is dull or made from weak material, it’s tougher to cut, and you need to push harder. So, good tool design and material help us work more easily.

What Safety Precautions Should Be Taken When Working With High-Torque Lathe Operations To Prevent Accidents And Ensure Quality Machining?When using a high-torque lathe, you should always wear safety goggles to protect your eyes. Keep your hands away from the spinning parts. Make sure to tie back long hair and remove loose clothing. Check that all tools are in good shape before starting. Finally, follow the machine’s instructions carefully to stay safe and create good work.