Have you ever wondered how a simple piece of metal can transform into something incredible? Lathe machining makes this magic happen. With a metal lathe, you can carve, shape, and design various metal parts.

But what if your lathe could do even more? Many hobbyists and professionals look for ways to upgrade their metal lathe. An upgrade can unlock new features and capabilities. Imagine being able to create precision parts with ease!

Upgrading your lathe might seem complicated. However, the benefits are worth it. Did you know that a modern lathe can help cut production time by half? That’s right! With the right upgrade, you can work smarter, not harder.

In this article, we will dive into the exciting world of lathe machining. We will explore practical upgrades and their advantages. You don’t want to miss the chance to boost your skills and enjoy new projects!

Lathe Machining: Essential Metal Lathe Upgrade Tips

Lathe Machining Metal Lathe Upgrade

Lathe machining can take your metalworking skills to new heights. Upgrading your metal lathe offers better precision and speed. Imagine crafting intricate parts with ease! Investing in a quality lathe not only boosts your projects but also saves time. You’ll discover tips for choosing the right upgrades and maintaining your lathe for optimal performance. Did you know a simple upgrade can significantly change your machining experience? Embrace the world of lathe machining and unlock new possibilities!Signs You Need to Upgrade Your Metal Lathe

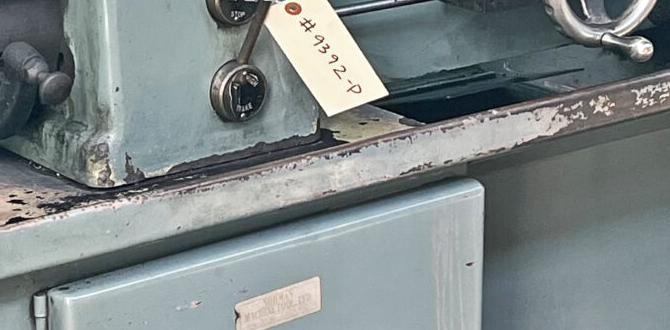

Common performance issues with older machines.. Benefits of upgrading, including efficiency and precision improvements..Old metal lathes often show signs of wear. You may notice poor finishes and vibrations. These are some common issues that can limit your work. Upgrading can bring many benefits. With a new lathe, you will experience improved efficiency and precision.

- Greater accuracy: New models cut better.

- Faster production: Work gets done quickly.

- Less maintenance: Save time and money.

Investing in a metal lathe upgrade means better results and happier workdays!

Why consider an upgrade?

Upgrading enhances your lathe’s performance. Better machines mean smoother operations and sharper cuts. This helps you produce high-quality parts every time!

Assessing Your Lathe’s Compatibility

How to evaluate your current lathe model for upgrades.. The importance of understanding specifications and limitations..Upgrading your lathe can be exciting! First, check your current model’s specifications. Look for the horsepower, speed ranges, and size limits. Knowing these can help you find the right upgrades. Remember, each lathe has strengths and weaknesses. Understanding them is key for improvement. Consider these points:

- What materials can your lathe handle?

- Is the size suitable for your projects?

- What accessories can improve its function?

Keeping these in mind will make your upgrade successful and enhance your work!

How do I know if my lathe can be upgraded?

Check the model number and specifications. Look for reviews online about similar upgrades. Asking experienced users helps too!

Choosing High-Quality Parts for Upgrades

Recommendations for reputable manufacturers and suppliers.. Factors to consider when selecting parts for durability and performance..Upgrading your lathe requires choosing the right parts. Look for parts from well-known manufacturers. Brands that are trusted often lead to better performance. Here are some key points to guide you:

- Check for customer reviews.

- Choose materials known for strength.

- Look for warranties on parts.

Good parts last longer and work better. This affects your lathe’s efficiency. Aim for quality, and your projects will be smoother!

What should I consider when upgrading parts?

Be sure to look at durability and performance. Quality parts keep your lathe running well. They also help make precise cuts on your projects.

DIY Upgrade vs. Professional Services

Pros and cons of upgrading your lathe yourself.. When to hire a professional and how to find the right service..Upgrading your lathe can be exciting! Doing it yourself can save money and teach you new skills. However, it may take time and effort. Here are some pros and cons:

- Pros: Save money, learn new skills, and customize your machine.

- Cons: Risk of mistakes and no expert advice.

Sometimes, hiring a professional makes sense. If the job seems too tricky, it’s better to seek help. You can find the right service by reading reviews and asking friends for recommendations.

What are the benefits of upgrading your lathe?

The main benefits are efficiency and improved accuracy. Upgraded lathes can help you create better projects faster.

How do I find a good professional for lathe upgrades?

Look for experts with positive reviews and clear experience. Ask questions to ensure they can meet your needs.

Costs Involved in Metal Lathe Upgrades

Breakdown of potential costs for various upgrade options.. Budgeting tips for planning your upgrade project..Upgrading your metal lathe can bring better performance. However, costs can add up quickly. Here’s a breakdown of potential costs for different upgrades:

- New tooling: $100 – $500

- Upgraded motors: $200 – $800

- Control systems: $300 – $1000

- New bed or frame: $500 – $2000

To plan your budget wisely:

- Set a clear budget before starting.

- Prioritize upgrades that really improve your work.

- Look for second-hand parts to save money.

Remember, quality upgrades can make a big difference in your projects!

What are some ways to save on upgrade costs?

Consider shopping for used tools, comparing prices online, and doing some work yourself.

Maintaining Your Upgraded Lathe

Best practices for routine maintenance after upgrades.. Tips for ensuring longterm reliability and performance..To keep your upgraded lathe running smoothly, regular maintenance is important. Cleaning and lubricating parts helps them last longer. Use good practices to check for any strange sounds or vibrations. Schedule maintenance often for best results. Here are some helpful tips:

- Clean the machine after each use to avoid dust buildup.

- Check the oil levels regularly to ensure smooth operation.

- Inspect belts and bearings for wear and replace if needed.

- Keep the workspace clean and organized.

These steps can help ensure that your lathe stays reliable for years to come.

How often should you maintain your lathe?

You should check it after every use and do a thorough maintenance every month.

User Experiences and Case Studies

Success stories from machinists who upgraded their lathes.. Lessons learned and the impact of upgrades on their work..Many machinists have exciting success stories after upgrading their lathes. One machinist, Sam, shared that his new lathe cut production time in half. He said, “I went from running laps around my old lathe to sipping coffee and watching it work!” These upgrades often mean smoother finishes and better accuracy, making projects more enjoyable. They also teach valuable lessons about the importance of investing in quality tools. Here’s a quick look at some key outcomes from these upgrades:

| Machinist | Upgrade | Impact |

|---|---|---|

| Sam | New Digital Lathe | Reduced time by 50%! |

| Lara | Variable Speed Control | Smoother finishes |

| Jim | Tooling Upgrade | More accuracy |

These stories remind us that a lathe isn’t just a machine; it’s a ticket to happier and more efficient work days!

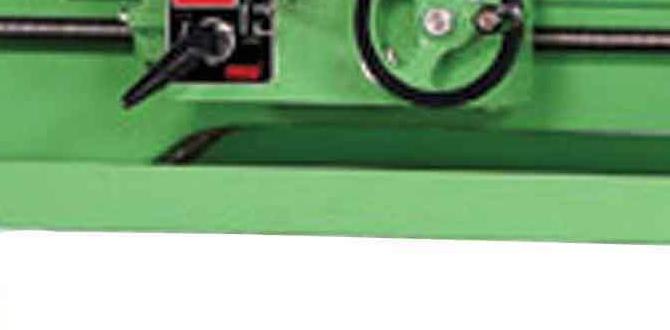

Future of Lathe Machining Technology

Trends in lathe machining and what to expect in future upgrades.. The impact of automation and smart technology on traditional lathes..New technology is shaking up lathe machining. Trends show that machines are becoming smarter and faster. Many machines now include automation. This means less manual work and more time for coffee breaks! Smart technology helps in precision and cuts down on mistakes. Expect upgrades to focus on user-friendliness and efficiency. Imagine a lathe that tells you it needs a coffee refill before it gets too tired! The future looks bright, or should we say shiny?

| Trend | Description |

|---|---|

| Automation | Less manual labor and more time for fun! |

| Smart Technology | Increased precision and fewer errors. |

| User-friendly Designs | Easy to learn and operate – even for beginners! |

Conclusion

In summary, upgrading your lathe machine can boost accuracy and efficiency in metalworking. You’ll enjoy better performance and longer tool life. Consider your needs carefully before choosing upgrades. Research different options to find what works best for you. Explore online resources and guides to deepen your understanding of lathe machining. Start planning your upgrade today for a better future in metalworking!FAQs

What Are The Key Features To Look For When Upgrading A Metal Lathe For Enhanced Precision And Performance?When upgrading a metal lathe, you should look for a few important features. First, check for better bearings. Good bearings help the machine run smoothly. Next, consider a stronger motor for more power. You also want a high-quality bed that keeps everything steady. Lastly, look for a digital readout. It shows measurements so you can work more accurately.

How Does The Size And Capacity Of A New Lathe Compare To My Existing Equipment For Better Machining Flexibility?A new lathe is usually bigger and can handle more types of jobs than your old one. This means you can make different parts more easily. If your new lathe has a bigger size, it can work on larger pieces. This gives you more choices when making things, so you can be more creative!

What Are The Advantages Of Adding Cnc Capabilities To A Traditional Metal Lathe During An Upgrade?Adding CNC (Computer Numerical Control) capabilities to a traditional metal lathe gives you more options. You can make complex shapes easily and accurately. The machine works faster, saving you time. You also get better precision, which means your pieces fit perfectly. Overall, it makes your work easier and more fun!

How Can Tooling And Accessories Impact The Efficiency Of A Lathe Upgrade, And What Should I Prioritize?Tooling and accessories can make your lathe work better and faster. Good tools help you cut materials smoothly. You should focus on getting sharp cutting tools first. Then, think about adding clamps and jigs to hold your work in place. This will help you finish projects easier and more accurately.

What Are The Best Practices For Integrating New Technology With Existing Machinery While Upgrading A Metal Lathe?To upgrade a metal lathe, you should first check how the new technology works with your old machine. It’s smart to clear any clutter around the lathe to make space. We should also ask for help from experts if we’re unsure. Finally, be sure to test everything before starting regular work. This way, you keep everything safe and working well together.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Upgrading A Metal Lathe For Enhanced Precision And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading a metal lathe, you should look for a few important features. First, check for better bearings. Good bearings help the machine run smoothly. Next, consider a stronger motor for more power. You also want a high-quality bed that keeps everything steady. Lastly, look for a digital readout. It shows measurements so you can work more accurately.”}},{“@type”: “Question”,”name”: “How Does The Size And Capacity Of A New Lathe Compare To My Existing Equipment For Better Machining Flexibility? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A new lathe is usually bigger and can handle more types of jobs than your old one. This means you can make different parts more easily. If your new lathe has a bigger size, it can work on larger pieces. This gives you more choices when making things, so you can be more creative!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Adding Cnc Capabilities To A Traditional Metal Lathe During An Upgrade? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adding CNC (Computer Numerical Control) capabilities to a traditional metal lathe gives you more options. You can make complex shapes easily and accurately. The machine works faster, saving you time. You also get better precision, which means your pieces fit perfectly. Overall, it makes your work easier and more fun!”}},{“@type”: “Question”,”name”: “How Can Tooling And Accessories Impact The Efficiency Of A Lathe Upgrade, And What Should I Prioritize? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tooling and accessories can make your lathe work better and faster. Good tools help you cut materials smoothly. You should focus on getting sharp cutting tools first. Then, think about adding clamps and jigs to hold your work in place. This will help you finish projects easier and more accurately.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Integrating New Technology With Existing Machinery While Upgrading A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To upgrade a metal lathe, you should first check how the new technology works with your old machine. It’s smart to clear any clutter around the lathe to make space. We should also ask for help from experts if we’re unsure. Finally, be sure to test everything before starting regular work. This way, you keep everything safe and working well together.”}}]}