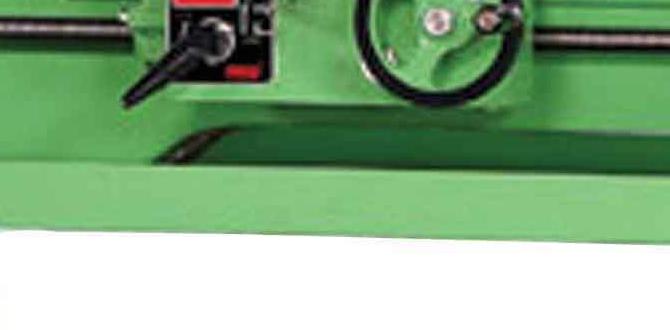

Have you ever wondered how metal shapes into usable tools or parts? Enter the world of lathe metal shaping. A lathe is a magical machine. It spins metal and carves it into different shapes. From shiny knobs to complex gears, metal lathes play a big role in our lives.

But there’s more! To make the most out of a metal lathe, you need the right accessories. These tools can help you work faster and create better shapes. They can turn a simple project into something amazing!

Imagine your dad or an older friend in a garage, making cool metal projects. They use a lathe with special tools, turning a block of metal into a masterpiece. Accessories like chisels and tool holders make everything easier. Interested in learning how these accessories can help you? Let’s dive in!

Essential Metal Lathe Accessories For Lathe Metal Shaping

Lathe Metal Shaping and Accessories

Lathe metal shaping is a vital process in manufacturing. It allows you to create precise shapes from metal. Have you ever wondered how creations like gears and shafts are made? Metal lathe accessories enhance this process. They include tool holders, cutting tools, and chucks. Each accessory plays a unique role, making tasks easier and more efficient. Using the right accessories improves the quality of your work. Discover how these tools can elevate your projects today!Key Accessories for Metal Lathes

Detailed description of essential accessories (chucks, tailstocks, tool posts).. Importance of each accessory in enhancing machining capabilities..Using the right tools can make your work with a lathe much easier. Here are some must-have accessories:

- Chucks: These hold the metal securely during shaping. They help you create precise cuts.

- Tailstocks: These support the other end of the workpiece. They improve stability and accuracy.

- Tool posts: They hold the cutting tools in place. With proper tool posts, you can switch tools quickly.

Each accessory plays a key role in boosting your machining capabilities. Without them, crafting a perfect metal shape can be tough!

Why are accessories important for metal lathes?

Accessories enhance efficiency and accuracy in machining. They help achieve cleaner, more precise cuts, making your projects turn out better.

Upgrading Your Metal Lathe

Benefits of upgrading accessories for improved efficiency.. Examples of highquality upgrades available on the market..Upgrading accessories for your metal lathe can change everything. Better tools make your work easier and faster. For example, using a high-quality chuck can improve grip and accuracy. A better tailstock helps with precise drilling. This upgrade leads to smoother cuts and less waste. Here are some great upgrades:

- Quick-change tool post

- Digital readouts

- Heavy-duty steel stands

These upgrades can boost efficiency by up to 40%! So, why wait? Enjoy better results today.

What are the benefits of upgrading metal lathe accessories?

Upgrading metal lathe accessories increases precision and saves time. New tools can reduce errors and improve quality. This means you finish your projects faster and better!

Examples of high-quality upgrades:

- High-speed tooling

- Improved coolant systems

- Enhanced safety guards

Safety Features and Best Practices

Essential safety accessories for metal lathes.. Best practices for safe operation of metal lathes..Using a metal lathe can be fun and useful. But safety is important too. Essential accessories help keep you safe. Always wear safety goggles to protect your eyes. Use ear protection to guard against loud noises. Don’t forget a dust mask to avoid breathing in harmful particles.

Follow these best practices:

- Keep your hands clear of moving parts.

- Never wear loose clothing.

- Always keep tools organized and close at hand.

Respect your tools, and they will keep you safe!

What accessories do I need for safety?

You need safety goggles, ear protection, and dust masks for safe operation of a metal lathe.

Maintenance of Metal Lathe Accessories

Routine maintenance tips to ensure longevity of accessories.. Common issues and troubleshooting for metal lathe attachments..Keeping metal lathe accessories in good shape really matters. Routine maintenance can help them last longer. Here are some helpful tips:

- Regularly clean the parts to remove dust and chips.

- Check for wear on belts and gears. Replace them if they’re worn.

- Oil moving parts to ensure smooth operation.

- Inspect the alignment for better accuracy.

Common issues might include noisy operation or misalignment. If you hear strange sounds, check for loose parts. Misalignment can be fixed by adjusting the tool holders. Fixing these problems early keeps everything working right.

What are common problems with metal lathe accessories?

Some common problems include: rust build-up, imbalance in rotating parts, and lack of lubrication. Regular checks can help catch these issues before they become serious.

Choosing the Right Accessories for Your Project

Criteria for selecting accessories based on project requirements.. Importance of compatibility with specific lathe models..Picking the right accessories makes your project easier and more fun. First, think about what you need for your project. Choose tools that fit your type of work, like cutting or shaping. Each lathe model has specific needs. Using accessories that match helps them work better together. Here are some questions to consider:

- What type of project are you doing?

- Will the accessory fit your lathe model?

- Do you need extra tools for special tasks?

Using tools that fit well can save time and prevent mistakes. A good fit means smooth performance and better results!

What should you consider when choosing lathe accessories?

When selecting lathe accessories, consider project needs, compatibility with lathe models, and additional tools for specific tasks. This guarantees smooth operation and successful results.

Cost Considerations and Budgeting

Average price ranges for various metal lathe accessories.. Tips for budgeting and finding quality accessories at a good price..Buying metal lathe accessories can feel like a treasure hunt. Prices can vary a lot, so it’s smart to do some digging before spending your coins. On average, you might pay between $20 and $300 for accessories. To find the best deals, check reviews and compare prices. Sometimes, quality comes at a price, but you can still snag a good deal. Remember, a wise shopper is a happy shopper!

| Accessory Type | Average Price Range |

|---|---|

| Cutting Tools | $20 – $100 |

| Chucks | $50 – $150 |

| Tool Holders | $30 – $200 |

| Face Plates | $40 – $250 |

Case Studies: Successful Projects with Add-on Accessories

Examples of projects that benefited from specific accessories.. Lessons learned and tips derived from practical applications..Many projects have achieved great success by using specific metal lathe accessories. For example, a hobbyist created intricate clock gears with a precision chuck. This tool allowed for smooth and accurate shaping. Another case involved a workshop that used a steady rest. They crafted long shafts without wobbling—definitely a ‘stay steady’ strategy! Always remember to choose the right accessory for your project. It saves time and makes shaping metal much easier.

| Project | Accessory Used | Benefit |

|---|---|---|

| Clock Gears | Precision Chuck | Smooth shaping |

| Long Shafts | Steady Rest | Reduced wobbling |

From these examples, the lesson is clear: the right accessories can make all the difference. Who knew adding a simple tool could create masterpieces?

Conclusion

In summary, lathe metal shaping is essential for creating precise metal parts. Using metal lathe accessories can enhance your projects and improve accuracy. You can experiment with different tools for better results. Remember, practice makes perfect! Try exploring more about lathe techniques and accessories to boost your skills. Happy crafting, and enjoy your metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Accessories:Lathes are tools that help us shape metal into different forms. You can use various accessories to make the lathes work better. Some accessories include cutting tools that help cut the metal nicely. You can also use a chuck, which holds the metal tightly in place. This way, we can create different shapes and sizes easily!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Accessories Needed For A Metal Lathe To Enhance Its Functionality And Precision?To make a metal lathe work better, you need a few important accessories. First, a good set of cutting tools will help you shape the metal. A chuck holds the metal tight, so it doesn’t move. A tailstock supports longer pieces, keeping them steady. Finally, a measuring tool, like a caliper, helps you check sizes accurately.

How Do Different Types Of Cutting Tools Impact The Performance And Finish Of Metal Workpieces On A Lathe?Different cutting tools can change how well we shape metal on a lathe. Some tools are sharp, so they make clean cuts and smooth surfaces. Other tools might be dull, making rougher surfaces that need more work. The right tool helps us finish our projects faster and look better. Choosing the best tool is important for great results!

What Safety Precautions Should Be Taken When Operating A Metal Lathe, And How Can Accessories Contribute To Safety?When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep long hair tied back and wear fitted clothes to avoid getting caught in the machine. Make sure to use the correct tools and keep your hands away from moving parts. Accessories like guards can help keep you safe by blocking parts of the machine. Using a tool rest can also help you work more safely and easily.

How Can Chucks And Collets Improve Workpiece Holding And Accuracy While Machining On A Lathe?Chucks and collets help hold workpieces tight while we machine them on a lathe. They keep the piece from moving around. This means we can cut and shape it more accurately. When the workpiece is steady, our finished product is better. Using these tools makes our work easier and more precise.

What Is The Role Of A Tailstock In A Metal Lathe, And How Can Accessories Like Dead Centers And Drill Chucks Expand Its Capabilities?The tailstock on a metal lathe holds tools and helps support the piece we’re working on. It keeps everything steady while we cut or shape metal. Accessories like dead centers can help us make precise holes. Drill chucks let us use different drills for making holes in our metal pieces. Together, they make the tailstock even more useful!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathes are tools that help us shape metal into different forms. You can use various accessories to make the lathes work better. Some accessories include cutting tools that help cut the metal nicely. You can also use a chuck, which holds the metal tightly in place. This way, we can create different shapes and sizes easily!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Accessories Needed For A Metal Lathe To Enhance Its Functionality And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe work better, you need a few important accessories. First, a good set of cutting tools will help you shape the metal. A chuck holds the metal tight, so it doesn’t move. A tailstock supports longer pieces, keeping them steady. Finally, a measuring tool, like a caliper, helps you check sizes accurately.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Cutting Tools Impact The Performance And Finish Of Metal Workpieces On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools can change how well we shape metal on a lathe. Some tools are sharp, so they make clean cuts and smooth surfaces. Other tools might be dull, making rougher surfaces that need more work. The right tool helps us finish our projects faster and look better. Choosing the best tool is important for great results!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe, And How Can Accessories Contribute To Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep long hair tied back and wear fitted clothes to avoid getting caught in the machine. Make sure to use the correct tools and keep your hands away from moving parts. Accessories like guards can help keep you safe by blocking parts of the machine. Using a tool rest can also help you work more safely and easily.”}},{“@type”: “Question”,”name”: “How Can Chucks And Collets Improve Workpiece Holding And Accuracy While Machining On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chucks and collets help hold workpieces tight while we machine them on a lathe. They keep the piece from moving around. This means we can cut and shape it more accurately. When the workpiece is steady, our finished product is better. Using these tools makes our work easier and more precise.”}},{“@type”: “Question”,”name”: “What Is The Role Of A Tailstock In A Metal Lathe, And How Can Accessories Like Dead Centers And Drill Chucks Expand Its Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tailstock on a metal lathe holds tools and helps support the piece we’re working on. It keeps everything steady while we cut or shape metal. Accessories like dead centers can help us make precise holes. Drill chucks let us use different drills for making holes in our metal pieces. Together, they make the tailstock even more useful!”}}]}