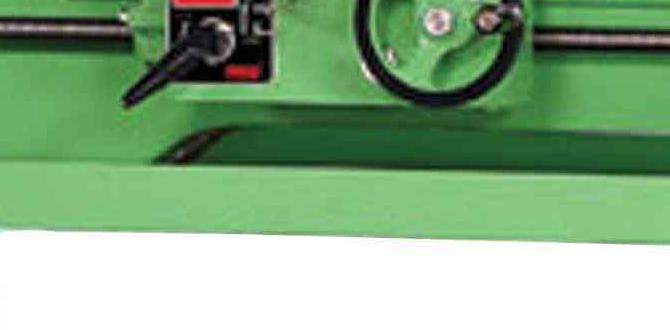

Have you ever watched a metal lathe in action? It’s like magic when metal is shaped into perfect forms. A metal lathe is a powerful tool that helps turn raw metal into useful parts. However, to make the best shapes, the lathe needs proper alignment.

Picture this: you have a project due tomorrow, and you need that exact piece. Suddenly, your lathe isn’t cutting straight! Frustrating, right? This is why understanding lathe metal shaping and alignment is so important.

Did you know? A well-aligned lathe can create smoother cuts and save time. When everything lines up, it makes your work easier and more fun.

In this article, we will explore the importance of lathe metal shaping and how to align your metal lathe properly. Get ready to dive in and discover tips that can improve your metalworking skills!

Lathe Metal Shaping: Essential Metal Lathe Alignment Tips Lathe Metal Shaping Is A Crucial Process In Various Manufacturing Industries, Primarily Due To Its Ability To Create Precise And Intricate Metal Components. A Metal Lathe Functions By Rotating A Workpiece Against A Cutting Tool, Allowing For The Shaping Of Metal Into Desired Forms. However, Achieving Optimal Results In Lathe Metal Shaping Heavily Relies On The Correct Alignment Of The Metal Lathe. Proper Alignment Not Only Improves The Accuracy Of Cuts But Also Enhances The Overall Quality And Finish Of The Machined Parts. Understanding Metal Lathe Alignment Metal Lathe Alignment Involves The Precise Positioning Of The Lathe’S Components To Ensure That The Cutting Tool And Workpiece Are In The Correct Orientation During Operation. Misalignment Can Lead To Issues Such As Uneven Cuts, Increased Wear On Tools, And Even Damage To The Machinery. Therefore, Ensuring That Your Lathe Is Properly Aligned Is A Fundamental Step In The Metal Shaping Process. Key Steps For Metal Lathe Alignment 1. **Check Leveling**: Before You Begin Aligning Your Metal Lathe, Ensure That It Is Level. Use A Machinist’S Level To Check For Evenness Across The Bed Of The Lathe. Adjust The Leveling Feet Accordingly. 2. **Spindle Alignment**: The Spindle Must Be Perpendicular To The Ways Of The Lathe. You Can Check This Using A Dial Indicator Mounted On The Carriage. Rotate The Spindle And Observe Any Variations In Measurement; Adjustments May Be Necessary. 3. **Tailstock Alignment**: The Tailstock Should Align With The Spindle For Accurate Cutting. Use A Test Bar Or A Similar Tool To Verify Alignment; You May Need To Adjust The Tailstock Position To Rectify Any Discrepancies. 4. **Checking For Taper**: A Test Cut Can Help Identify Any Taper Issues In Your Setup. After Making Adjustments, Perform A Cut And Measure The Workpiece To Ensure Consistency Along Its Length. 5. **Regular Maintenance**: Regularly Check And Recalibrate Your Lathe Settings As Part Of Your Maintenance Routine. This Practice Helps To Sustain Precision In Metal Shaping And Extend The Life Of Your Equipment. Conclusion By Prioritizing Metal Lathe Alignment In Your Lathe Metal Shaping Processes, You Can Enhance The Quality Of Your Machined Parts And Ensure A Smoother Operational Flow. Consistently Performing Alignments And General Maintenance Not Only Optimizes Performance But Also Prevents Potential Mechanical Failures, Setting A Solid Foundation For Achieving Exceptional Results In Your Metal Working Projects.

Lathe Metal Shaping and Alignment

Lathe metal shaping is essential for creating precise parts. Proper metal lathe alignment ensures accuracy and quality. Did you know that misalignment can lead to poor cuts and wasted material? That’s why checking your lathe’s setup regularly is so important. A well-aligned lathe can make the difference between a smooth finish and a rough one. With just a few tips, you can master the art of lathe alignment and enhance your metalworking skills!Understanding Metal Lathe Basics

Definition and components of a metal lathe. Different types of metal lathes and their applications.A metal lathe is a machine that shapes metal into different forms. It works like a giant pencil sharpener, spinning metal around while tools cut away parts of it. Key parts include the spindle, carriage, and tailstock. There are various types of lathes, like CNC lathes for precision and engine lathes for general work. Each type has its uses, from creating tiny bolts to crafting big gears – talk about versatility!

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General metal shaping |

| CNC Lathe | High precision tasks |

| Turret Lathe | Production of smaller parts |

Importance of Lathe Alignment

How alignment affects precision in shaping. Common issues caused by poor alignment.Aligning a lathe is like tuning a guitar. If strings are off, it sounds bad. Similarly, poor alignment can ruin precision in metal shaping. Parts may end up uneven, leading to mistakes and frustration. Common issues include wobbly cuts, uneven surfaces, and a whole lot of do-overs. It’s like trying to bake a cake with the oven set to “broil”—chaos awaits! Check out the table below for a quick look at alignment problems:

| Alignment Issue | Effect |

|---|---|

| Wobbly Spindle | Uneven cuts |

| Misaligned Bed | Surface irregularities |

| Poor Chuck Grip | Slipping workpieces |

A little effort in alignment goes a long way, making your shaping journey smoother. So, make sure your lathe is in tip-top shape!

Tools Required for Lathe Alignment

Essential tools for checking alignment. Advanced tools for precision measurements.To align a lathe properly, you need several tools. First, basic tools are essential for checking alignment. These include:

- Precision Level

- Calipers

- Dial Indicator

For more accuracy, advanced tools help a lot. These can include:

- Laser Alignment Systems

- Alignment Bars

- Optical Alignment Tools

Using the right tools ensures your lathe runs smoothly and saves time. Remember, accuracy is key in metal shaping!

What tools do I need for lathe alignment?

To check lathe alignment, you need precision levels, calipers, and a dial indicator. Advanced options like laser systems can help too!

Step-by-Step Guide to Aligning a Metal Lathe

Preparing your workspace and tools. Checking and adjusting the tailstock alignment.Before you start aligning your metal lathe, get your workspace ready. A clean and organized area helps avoid accidents. Gather your tools like wrenches and measuring devices. You don’t want to be searching for a tool while working with metal—it’s like looking for a needle in a haystack! Next, check the tailstock alignment. If it’s off, your projects will look like they were made by a kid with a crayon. Use a dial indicator to measure it precisely. Adjust until it’s just right!

| Tool | Purpose |

|---|---|

| Wrenches | For tightening bolts |

| Dial Indicator | To check alignment |

| Measuring Tape | For accurate measurements |

Checking Chuck Alignment

Methods for verifying chuck accuracy. Correcting chuck misalignment.To ensure your lathe works like a charm, checking the chuck alignment is key. There are a few simple methods to verify accuracy. One is the dial indicator method, where you mount a dial indicator to test runout. A misalignment? Don’t worry! You can correct it by adjusting the chuck screws. Remember, a well-aligned chuck means smoother cuts and happier metal! If only cats were as easy to align…

| Method | Description |

|---|---|

| Dial Indicator | Mount to test runout for accuracy. |

| Visual Inspection | Check if the chuck is parallel to the bed. |

Best Practices for Maintaining Lathe Alignment

Regular maintenance routines. Tips for preventing alignment issues over time.Taking care of your lathe machine is important. Regular maintenance can keep it aligned and running smoothly. Here are some best practices:

- Check the machine often for loose parts.

- Clean the lathe after each use to remove dust and chips.

- Lubricate moving parts as needed.

- Inspect the alignment regularly to catch problems early.

By following these simple tips, you can prevent alignment issues. This will help keep your metal shaping work precise and efficient.

How often should you check lathe alignment?

You should check alignment monthly or whenever you notice changes in performance. Regular checks can save time and materials in the long run.

Quick Tips for Alignment Maintenance

- Stay aware of unusual sounds or vibrations.

- Remember to adjust the bed and tailstock regularly.

Troubleshooting Common Alignment Problems

Identifying symptoms of misalignment. Solutions to fix common lathe alignment issues.Misalignment in lathe machines can cause big problems. You might notice rough finishes or uneven cuts. These issues appear because parts are not lined up correctly. If your projects are not turning out right, it might be time to check. Here are some signs of misalignment:

- Uneven cuts or finishes

- Increased vibration during operation

- Unusual noise while cutting

To fix these issues, you can:

- Check and adjust the tailstock alignment

- Use a dial indicator to measure accuracy

- Tighten loose bolts and screws

Taking these steps can help your lathe work smoothly again.

What are the common signs of lathe misalignment?

Misalignment often shows as rough finishes and uneven cuts. It may cause vibrations or strange noises, too.

Impact of Alignment on Workpiece Quality

How alignment influences surface finish. The relationship between alignment and tool wear.Alignment is key for creating smooth surfaces. If the lathe isn’t properly aligned, the surface finish of the workpiece can suffer. This means rough edges and a poor look. Good alignment also reduces tool wear. Misalignment can cause tools to work harder, leading them to break down faster. When tools wear out quicker, production costs increase.

How does alignment affect the quality of workpieces?

Proper alignment enhances surface quality and tool life. It can lead to:

- Smoother finishes on the workpieces.

- Longer tool life, saving time and money.

- Better precision in shaping metal.

Case Studies of Successful Lathe Alignment

Realworld examples of alignment improvements. Lessons learned from misalignment scenarios.Imagine a factory where machines are more like temperamental cats than reliable workers. One company faced a huge challenge with their machining due to misaligned lathes. They quickly learned that precision is key. By adjusting the alignment, they improved production efficiency by 30%! Another team faced similar problems and found that misalignment led to wasted materials and time. Their lesson? Regular checks make a big difference. Here’s a snapshot of their findings:

| Scenario | Alignment Change | Result |

|---|---|---|

| Manufacturer A | Fixed misaligned lathe | 30% more efficiency! |

| Manufacturer B | Regular alignment checks | Less waste, more smiles! |

In the end, proper lathe alignment isn’t just smart; it’s necessary! Remember, a well-aligned lathe makes a happy factory.

Conclusion

In summary, aligning a metal lathe is crucial for precise shaping. You ensure accuracy by checking levels and tightness. Proper alignment helps you create better parts and saves time. If you’re interested in improving your skills, consider reading more about lathe setups. Experimenting with alignment will make your projects more successful. Happy machining!FAQs

Here Are Five Questions Related To Lathe Metal Shaping And Metal Lathe Alignment:Sure! Here’s a short answer about lathe metal shaping and alignment. A lathe is a machine that helps shape metal. You put metal on it and it spins around. While it spins, you can cut it to make different shapes. It’s important to align the lathe correctly so everything works well and is safe. Would you like to know more about how to use one?

Sure! Please tell me the question you want me to answer.

What Are The Key Steps Involved In Aligning A Metal Lathe To Ensure Accurate Machining?To align a metal lathe, you first need to check the bed. Make sure it’s level using a bubble level. Next, check the tailstock and the headstock are straight and even. You can adjust them if they’re not. Finally, run a test piece to ensure everything is working correctly. This helps you make precise cuts!

How Can Misalignment In A Metal Lathe Affect The Precision And Quality Of The Finished Workpiece?If a metal lathe is not lined up properly, it can make mistakes in shaping the metal. You might see bumps or uneven parts on the finished piece. This happens because the tool doesn’t cut straight. We want our work to be smooth and fit well, so alignment is very important. If things aren’t aligned, we could waste materials and time.

What Tools And Techniques Are Commonly Used To Check The Alignment Of A Metal Lathe?To check the alignment of a metal lathe, we often use a few important tools. A dial indicator helps us see if the metal is straight. A level makes sure the lathe sits on a flat surface. We can also use a straight edge to check if everything lines up correctly. These tools help us make sure the lathe works well.

How Does The Alignment Of A Lathe’S Tailstock And Headstock Impact The Overall Machining Process?If the tailstock and headstock of a lathe are not lined up, it can cause problems. First, you might make uneven cuts. This means the item you’re working on may not be the correct shape. It can also cause extra wear on the tools. By keeping them aligned, you help make smoother and better parts.

What Are The Signs Of Improper Alignment In A Metal Lathe, And How Can They Be Corrected?If a metal lathe is not aligned properly, you might see the workpiece wobble or shake. The cuts may not look smooth, and you could hear loud noises. To fix this, you can adjust the lathe’s parts to make them straight and even. We should check the bed and tailstock to ensure they are lined up correctly. If you are unsure, ask a teacher or an expert for help!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Lathe Metal Shaping And Metal Lathe Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a short answer about lathe metal shaping and alignment. A lathe is a machine that helps shape metal. You put metal on it and it spins around. While it spins, you can cut it to make different shapes. It’s important to align the lathe correctly so everything works well and is safe. Would you like to know more about how to use one?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Aligning A Metal Lathe To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, you first need to check the bed. Make sure it’s level using a bubble level. Next, check the tailstock and the headstock are straight and even. You can adjust them if they’re not. Finally, run a test piece to ensure everything is working correctly. This helps you make precise cuts!”}},{“@type”: “Question”,”name”: “How Can Misalignment In A Metal Lathe Affect The Precision And Quality Of The Finished Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is not lined up properly, it can make mistakes in shaping the metal. You might see bumps or uneven parts on the finished piece. This happens because the tool doesn’t cut straight. We want our work to be smooth and fit well, so alignment is very important. If things aren’t aligned, we could waste materials and time.”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Commonly Used To Check The Alignment Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the alignment of a metal lathe, we often use a few important tools. A dial indicator helps us see if the metal is straight. A level makes sure the lathe sits on a flat surface. We can also use a straight edge to check if everything lines up correctly. These tools help us make sure the lathe works well.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of A Lathe’S Tailstock And Headstock Impact The Overall Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock and headstock of a lathe are not lined up, it can cause problems. First, you might make uneven cuts. This means the item you’re working on may not be the correct shape. It can also cause extra wear on the tools. By keeping them aligned, you help make smoother and better parts.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Improper Alignment In A Metal Lathe, And How Can They Be Corrected?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is not aligned properly, you might see the workpiece wobble or shake. The cuts may not look smooth, and you could hear loud noises. To fix this, you can adjust the lathe’s parts to make them straight and even. We should check the bed and tailstock to ensure they are lined up correctly. If you are unsure, ask a teacher or an expert for help!”}}]}