Have you ever wondered how metal parts are shaped? Imagine a giant machine that spins metal to create beautiful shapes. That’s a lathe! Metal shaping with a lathe is a fascinating process. It turns solid metal into precise pieces for cars, planes, and more.

Now, picture a factory where lathes work on their own. This is metal lathe automation. It helps workers create items faster and with more accuracy. Why is that important? Because it saves time and money!

Here’s a fun fact: the first lathes appeared over 5,000 years ago! They were simple, hand-operated tools. Today’s lathes are much more advanced. They use computers to guide their movements. This change makes metal shaping easier and smarter.

Let’s explore how metal lathes have evolved. We’ll see how automation is changing the game in the world of manufacturing.

Lathe Metal Shaping: Metal Lathe Automation Explained

Lathe Metal Shaping and Automation

Have you ever wondered how metal parts are shaped perfectly? A metal lathe does just that! It spins metal while cutting tools shape it into precise forms. Automation in metal lathes has made this process even faster and more accurate. Imagine machines doing the work for you! This technology saves time and reduces mistakes. With automation, factories can produce more parts with less effort. It’s like having a helpful robot in the shop!The Process of Metal Shaping on Lathes

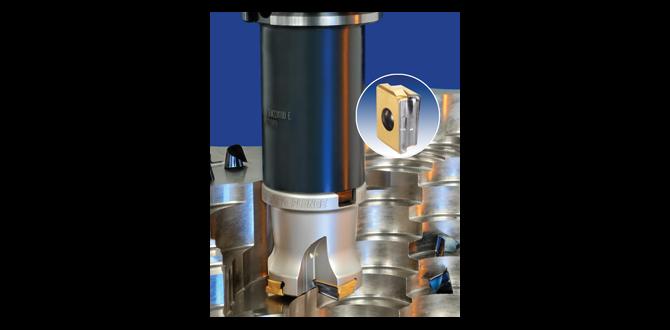

Key techniques in metal shaping. Importance of material selection in shaping processes.Metal shaping on lathes uses key techniques to create different shapes. First, it’s important to choose the right material. Different metals have unique properties that affect how they can be shaped. For example, soft metals are easier to mold than hard ones. Techniques often include turning, boring, and facing.

- Turning involves rotating the material.

- Boring enlarges holes.

- Facing smooths the ends of the material.

Understanding these methods helps produce quality parts quickly and accurately.

Why is material selection important?

Choosing the correct material affects durability, ease of shaping, and overall costs. Different applications require different metals for the best results.

Automation in Metal Lathing

Definition and benefits of automation in lathe operations. Key technologies driving automation: CNC vs. manual lathes.Automation in metal lathing makes machines work better and faster. With automation, tools can create shapes without much help from people. This saves time and reduces mistakes. CNC lathes are popular because they use computers for precision. In contrast, manual lathes need hands-on control. Here are some benefits of automation:

- Increased speed of production

- Higher precision and accuracy

- Less waste of materials

Automation is changing how we shape metal, making it easier and smarter!

What are the benefits of automation in metal lathing?

Automation boosts speed, accuracy, and efficiency in metal lathing, making it a game-changer in manufacturing.

Applications of Automated Metal Lathes

Industries that benefit from automated metal lathes. Case studies of successful automation implementations.Many industries gain a lot from automated metal lathes. These machines help make parts quickly and accurately. Manufacturing, automotive, and aerospace sectors benefit the most. For example, car makers use lathes to create engine components. This saves time and reduces waste. A successful case study in aerospace shows that automation cut production time by 30%. It also improved part quality. These machines are changing the way we work!

What industries benefit from automated metal lathes?

Industries like manufacturing, automotive, and aerospace gain significantly from automated metal lathes.

Successful Case Studies:

- Aerospace reduced production time by 30%.

- Car manufacturers improved part quality.

Choosing the Right Lathe for Your Needs

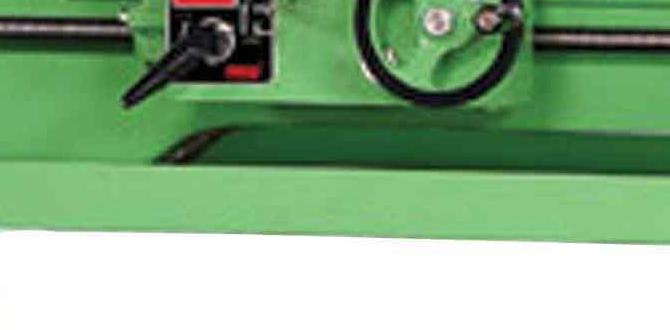

Factors to consider when selecting a metal lathe. Comparison of popular metal lathe models and features.Picking the right lathe can be tricky. There are several things to think about. First, consider your projects. What will you make? Different lathes work better for different jobs. Next, think about space. How much room do you have? You also need to look at power and speed. Will you need a fast machine?

Popular lathes include:

- Mini Lathe: Great for small projects.

- Benchtop Lathe: Good for hobbyists.

- Industrial Lathe: Best for heavy-duty work.

Do some research to find the best one for you!

What should you check when selecting a lathe?

Check the size, type of work, and power options. Look closely at extra features too, like automation choices.

Key Features to Consider:

- Size and weight

- Speed options

- Material capacity

- Extra attachments

Best Practices for Maintaining Metal Lathes

Routine maintenance tasks for longevity. Troubleshooting common issues in lathe operation.Keeping a metal lathe in top shape is easy with some routine care. Regularly clean the machine to prevent dust and shavings from causing trouble. Lubricate moving parts to keep things running smoothly—think of it as giving your lathe a spa day! If something feels off, don’t ignore it; check for loose bolts or unusual noises. Small fixes can save big headaches later. Here’s a quick troubleshooting guide:

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent Cuts | Worn Tool Bit | Replace or sharpen the bit. |

| Loud Noises | Loose Parts | Tighten bolts and check connections. |

| Machine Stalling | Overheating | Allow it to cool down; check coolant levels. |

These simple steps can help your lathe last for years. Remember, a happy lathe makes for happy projects!

Future Trends in Metal Lathe Automation

Innovations in lathe technology and automation. Predictions for the future of metal shaping industries.Exciting changes are on the horizon for metal lathe automation! New technologies are here to make shaping metal quicker and smarter. Imagine machines that think for themselves—yes, we’re talking about robots! These automated lathes will save time and reduce mistakes, like a superhero for manufacturers. Predictions say that by 2030, the metal shaping industry will boom, with automation leading the way. Who knows? Maybe one day, your coffee cup will be shaped by a robot!

| Innovation | Impact |

|---|---|

| Smart Sensors | Reduce errors |

| AI Technology | Enhance efficiency |

| Cloud Automation | Real-time updates |

Resources for Further Learning on Metal Lathes

Recommended books, online courses, and tutorials. Community forums and expert groups for metal lathe enthusiasts.Many resources can help you learn about metal lathes. You can find great books, online courses, and tutorials. Here are some recommendations:

- Books: “Metalworking: A Comprehensive Guide” offers practical tips.

- Online Courses: Check websites like Udemy or Skillshare for easy learning.

- Tutorials: YouTube has many helpful videos demonstrating techniques.

Engage with others by joining community forums and expert groups. Facebook Groups and Reddit have boards where lathe fans share tips and tricks. These connections can deepen your knowledge and skills!

Remember, learning is fun! Are you ready to explore the world of metal lathes?

What are some good resources for learning about metal lathes?

Books, online courses, and community forums are excellent ways to learn.

Conclusion

In summary, lathe metal shaping is crucial for creating precise parts. Metal lathes automate this process, making it faster and easier. You can achieve high-quality results with practice and the right tools. Explore more resources to deepen your understanding. Whether you’re a beginner or experienced, learning about lathe automation can open new doors for your projects!FAQs

What Are The Key Benefits Of Automating Metal Shaping Processes On A Lathe Compared To Traditional Manual Methods?Automating metal shaping on a lathe makes things faster and easier. You can make the same shape many times without mistakes. It saves energy and cuts costs too. We also get safer workspaces since machines can do risky tasks. Plus, it helps us create better products with nice details.

How Does Cnc (Computer Numerical Control) Technology Enhance The Precision And Efficiency Of Metal Lathe Automation?CNC, which stands for Computer Numerical Control, helps metal lathes work better. It uses a computer to guide the machines. This means the cuts are very accurate and happen quickly. You can make the same part over and over without mistakes. Overall, CNC makes things faster and more precise!

What Types Of Automated Attachments Or Accessories Can Be Integrated Into A Traditional Metal Lathe To Improve Productivity?You can add several tools to a metal lathe to make work faster. A digital readout shows measurements clearly, so you cut accurately. Automatic tool changers swap tools quickly without your help. A chip conveyor removes metal shavings, keeping the work area clean. These attachments help you finish tasks quicker and easier!

What Are Some Common Challenges Faced When Implementing Automation In Metal Shaping On Lathes, And How Can They Be Addressed?When using machines to shape metal, you might face some problems. First, machines can break down often. To fix this, you should keep them well-maintained. Second, workers might not know how to use new machines. We can solve this by giving them good training. Lastly, connecting different machines can be tricky. You can address this by hiring experts to help set everything up properly.

How Do Advancements In Robotics And Ai Impact The Future Of Automated Metal Lathe Operations?Advancements in robotics and AI will make metal lathe machines work better and faster. You will see robots do jobs like cutting and shaping metal. These robots can learn and improve, so they make fewer mistakes. This means we can create more things with less time and effort. In the future, metalworking will be easier and more fun for everyone!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Benefits Of Automating Metal Shaping Processes On A Lathe Compared To Traditional Manual Methods? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating metal shaping on a lathe makes things faster and easier. You can make the same shape many times without mistakes. It saves energy and cuts costs too. We also get safer workspaces since machines can do risky tasks. Plus, it helps us create better products with nice details.”}},{“@type”: “Question”,”name”: “How Does Cnc (Computer Numerical Control) Technology Enhance The Precision And Efficiency Of Metal Lathe Automation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC, which stands for Computer Numerical Control, helps metal lathes work better. It uses a computer to guide the machines. This means the cuts are very accurate and happen quickly. You can make the same part over and over without mistakes. Overall, CNC makes things faster and more precise!”}},{“@type”: “Question”,”name”: “What Types Of Automated Attachments Or Accessories Can Be Integrated Into A Traditional Metal Lathe To Improve Productivity? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add several tools to a metal lathe to make work faster. A digital readout shows measurements clearly, so you cut accurately. Automatic tool changers swap tools quickly without your help. A chip conveyor removes metal shavings, keeping the work area clean. These attachments help you finish tasks quicker and easier!”}},{“@type”: “Question”,”name”: “What Are Some Common Challenges Faced When Implementing Automation In Metal Shaping On Lathes, And How Can They Be Addressed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using machines to shape metal, you might face some problems. First, machines can break down often. To fix this, you should keep them well-maintained. Second, workers might not know how to use new machines. We can solve this by giving them good training. Lastly, connecting different machines can be tricky. You can address this by hiring experts to help set everything up properly.”}},{“@type”: “Question”,”name”: “How Do Advancements In Robotics And Ai Impact The Future Of Automated Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements in robotics and AI will make metal lathe machines work better and faster. You will see robots do jobs like cutting and shaping metal. These robots can learn and improve, so they make fewer mistakes. This means we can create more things with less time and effort. In the future, metalworking will be easier and more fun for everyone!”}}]}